Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

287results about "Dividing poultry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for separating meat and bone of fowl and device used by the method

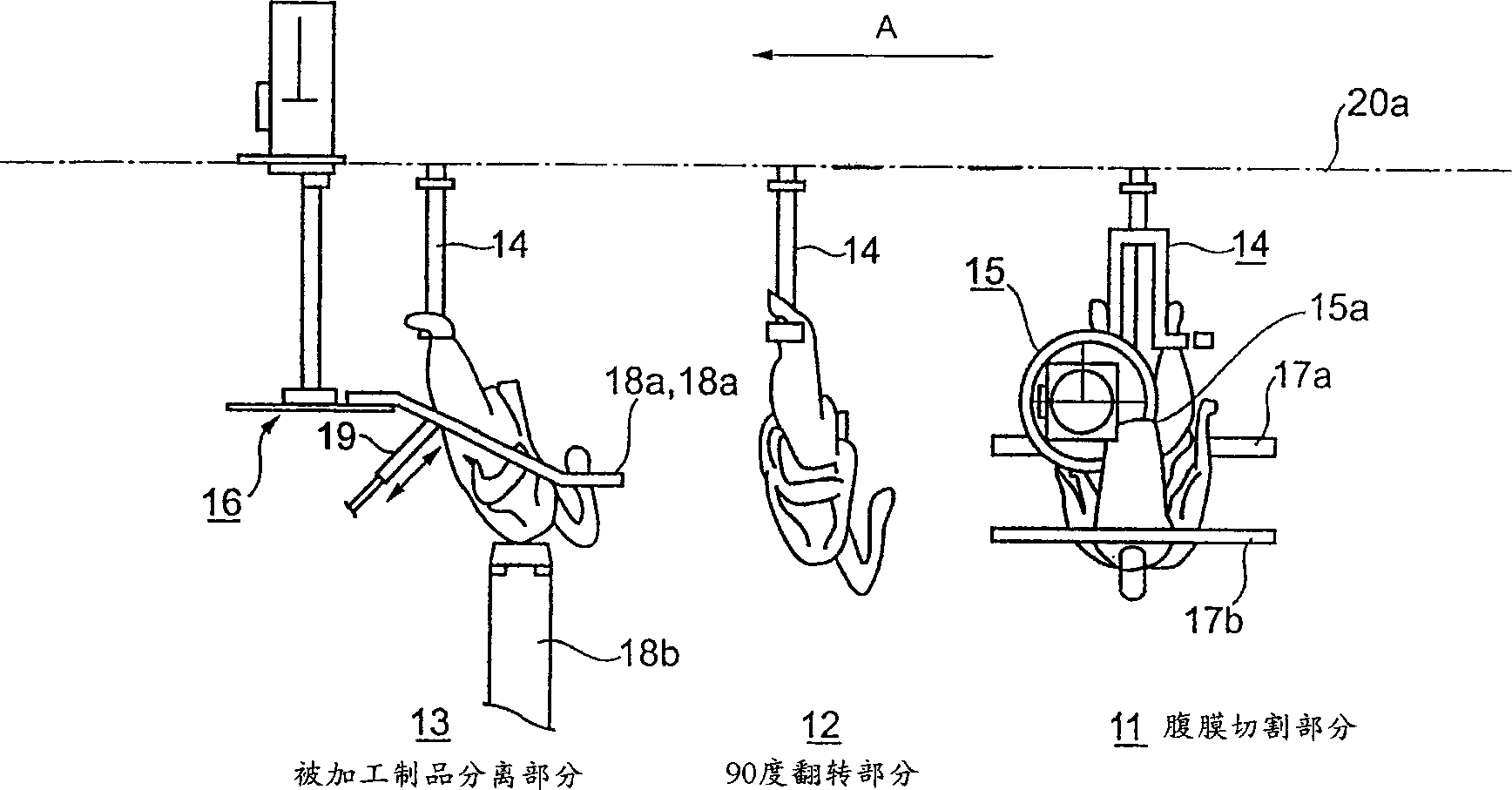

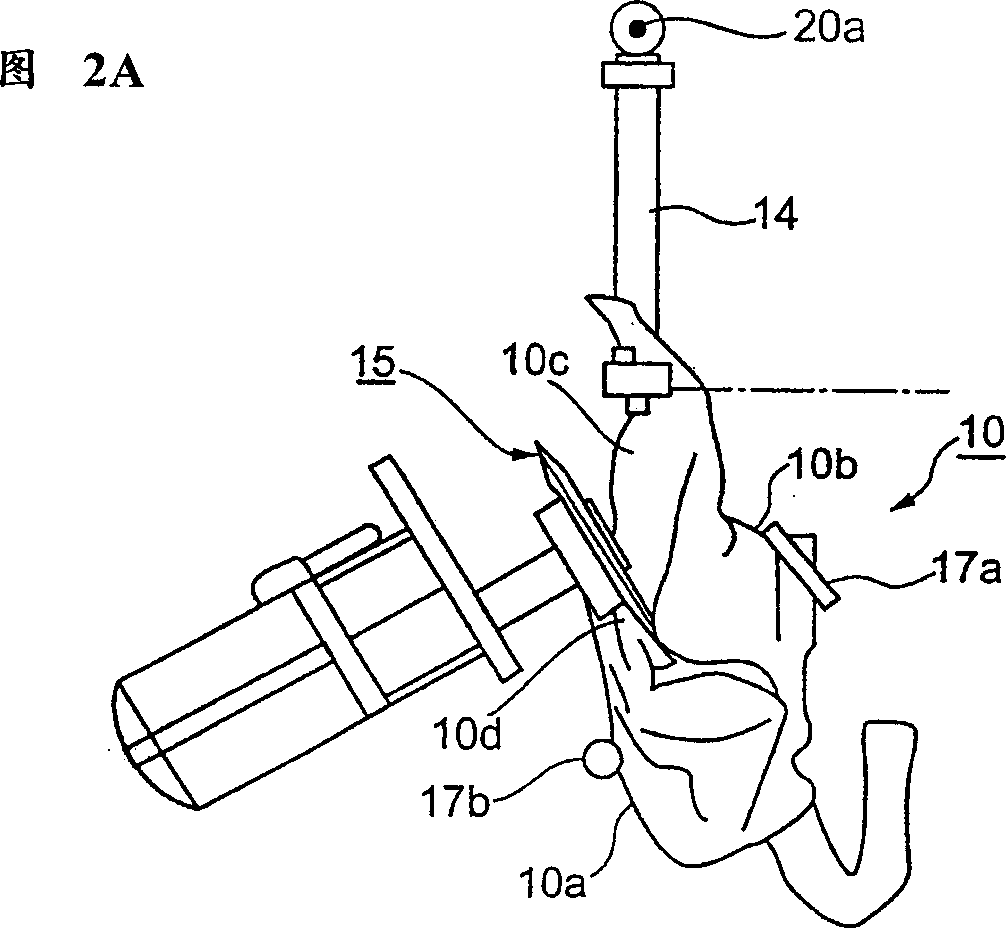

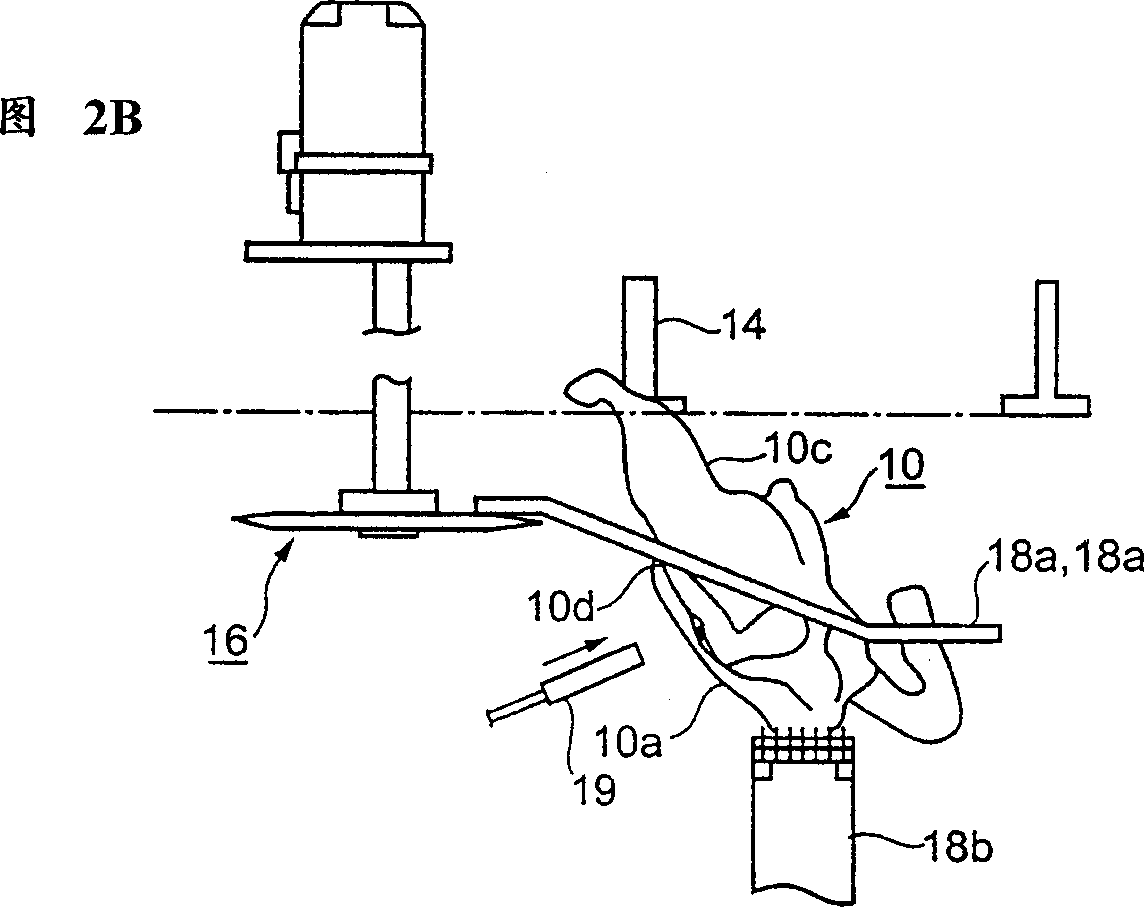

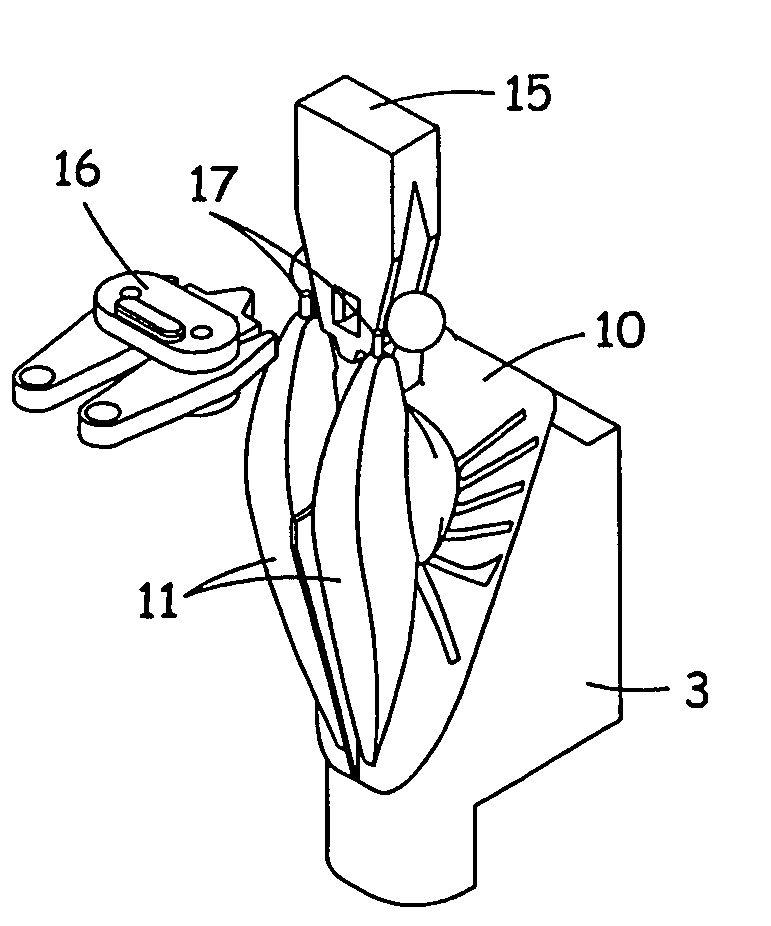

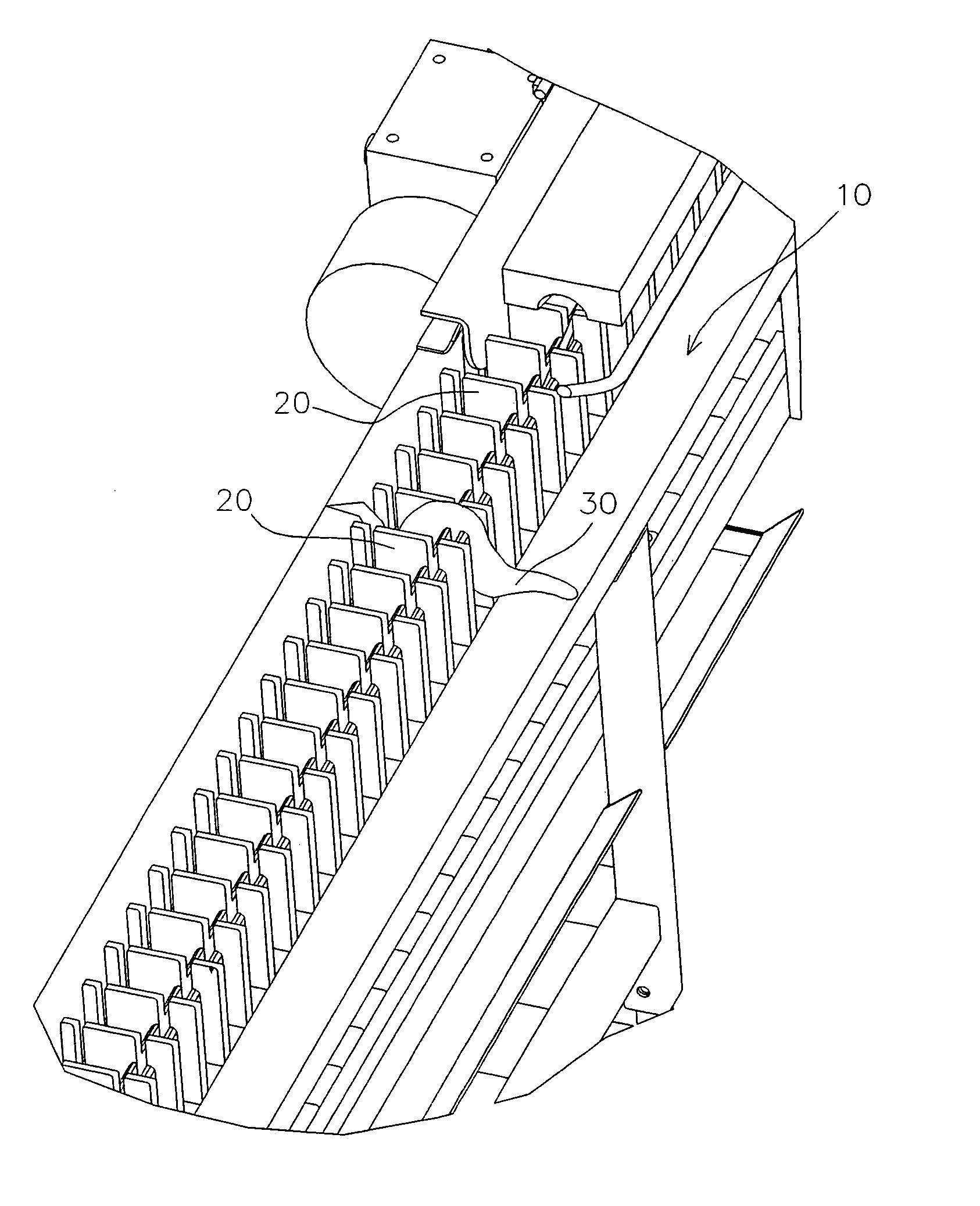

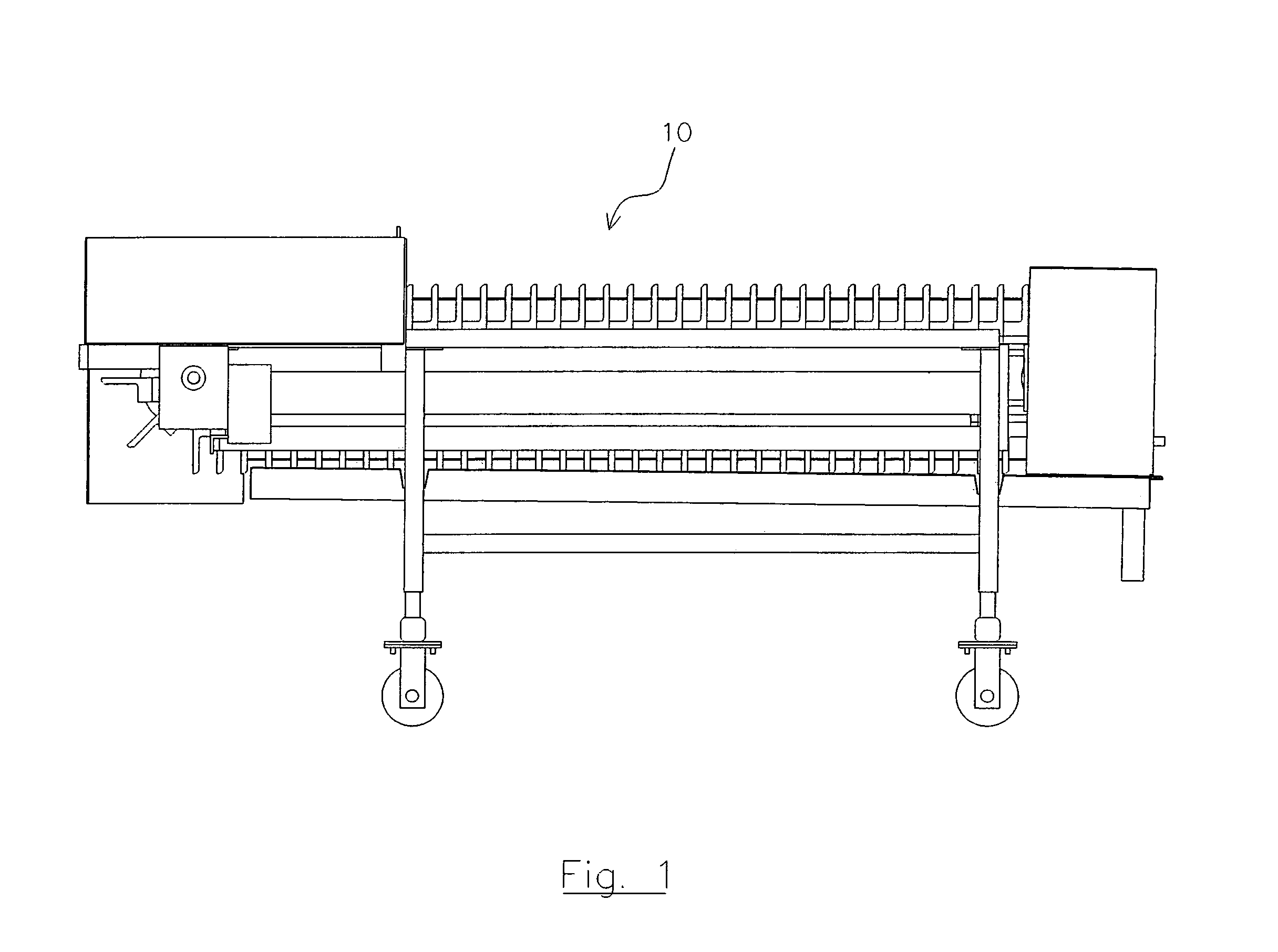

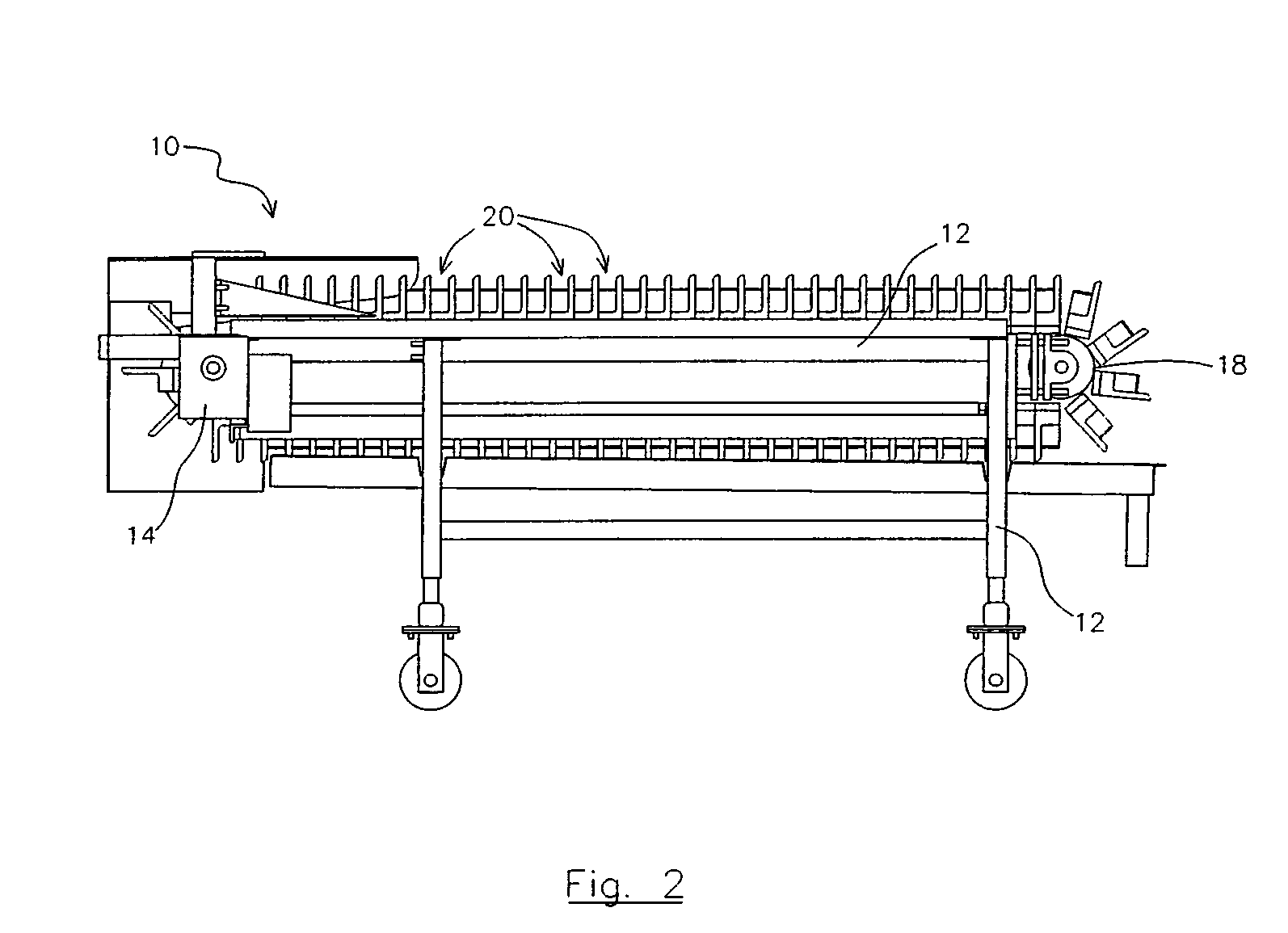

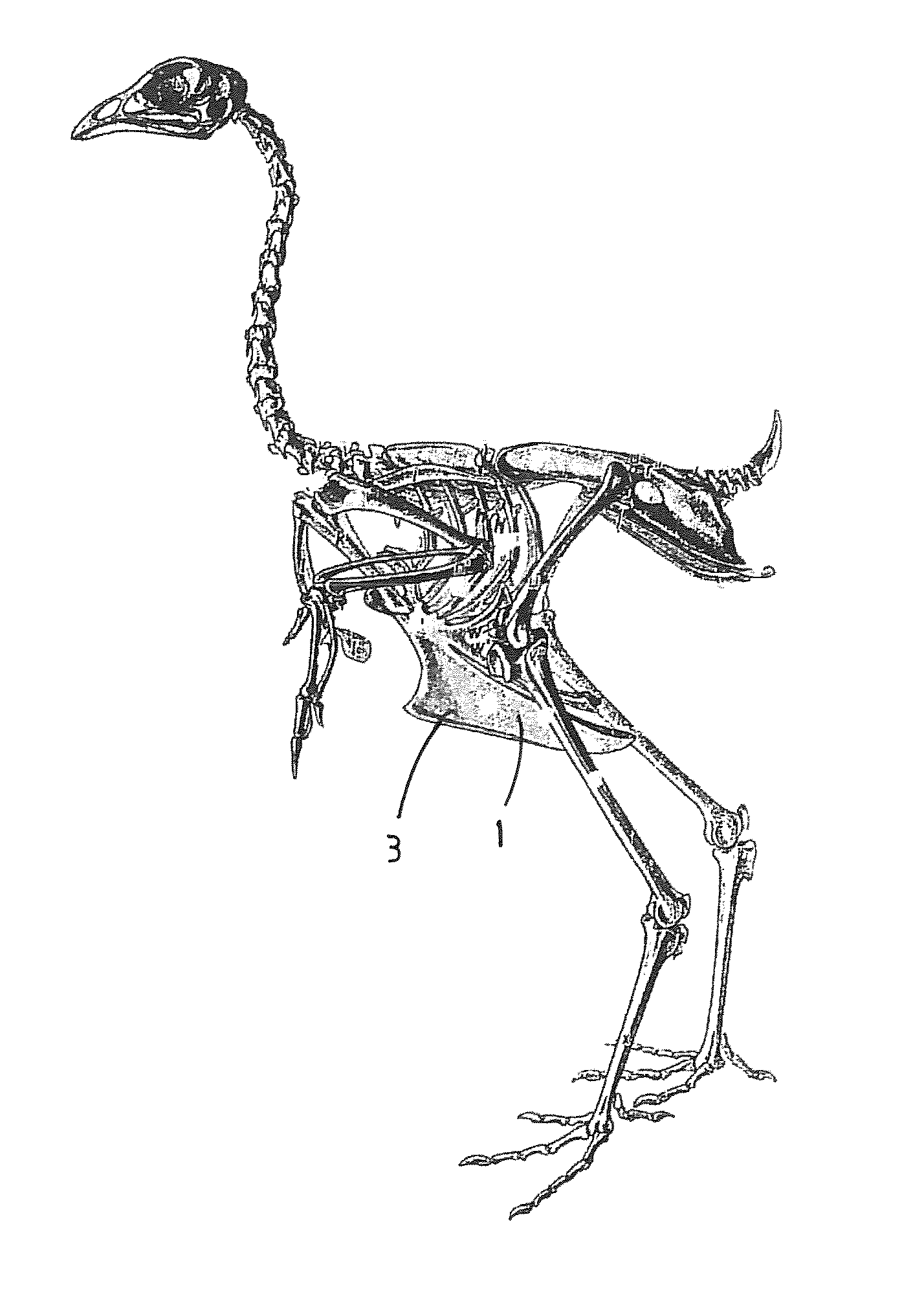

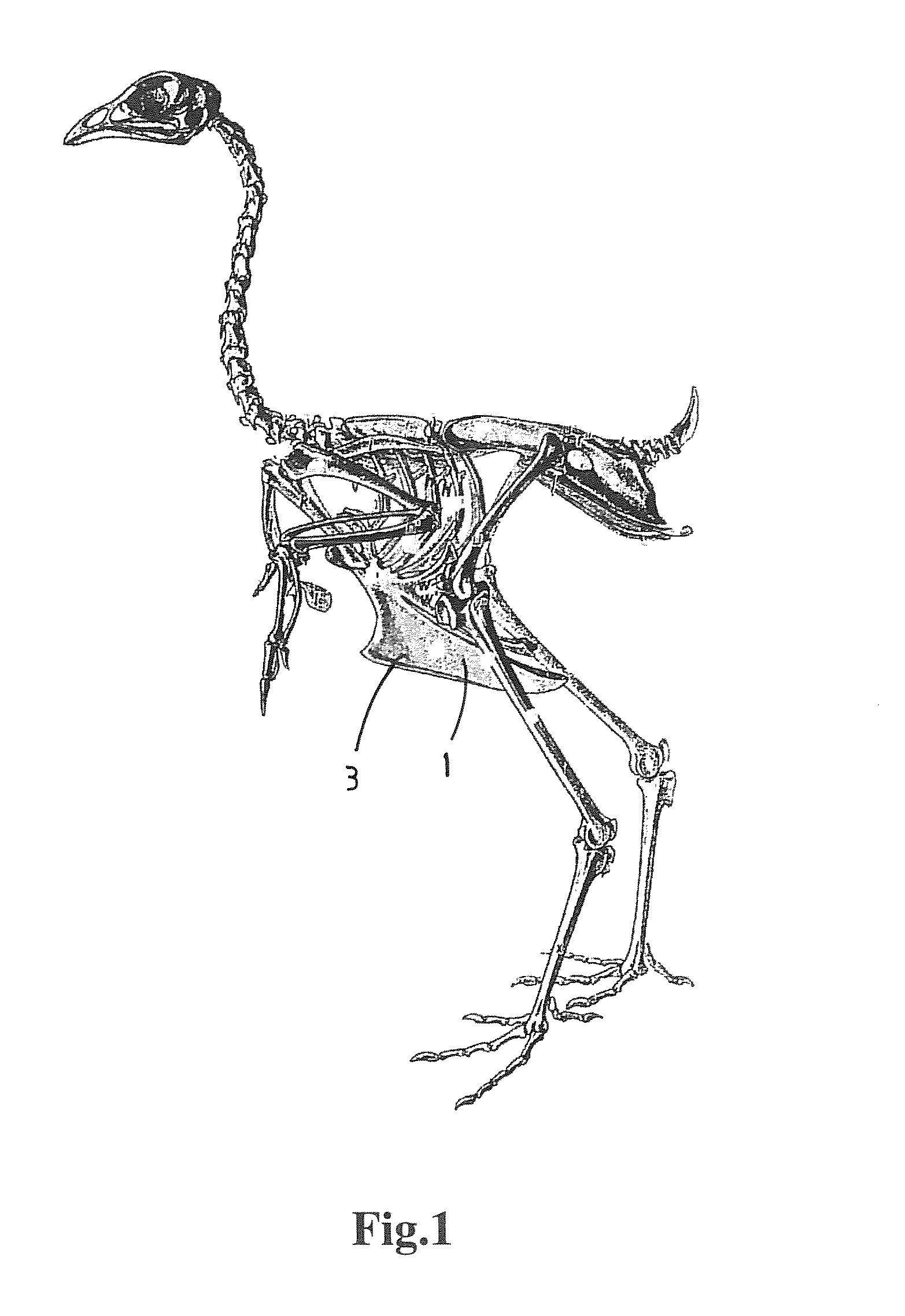

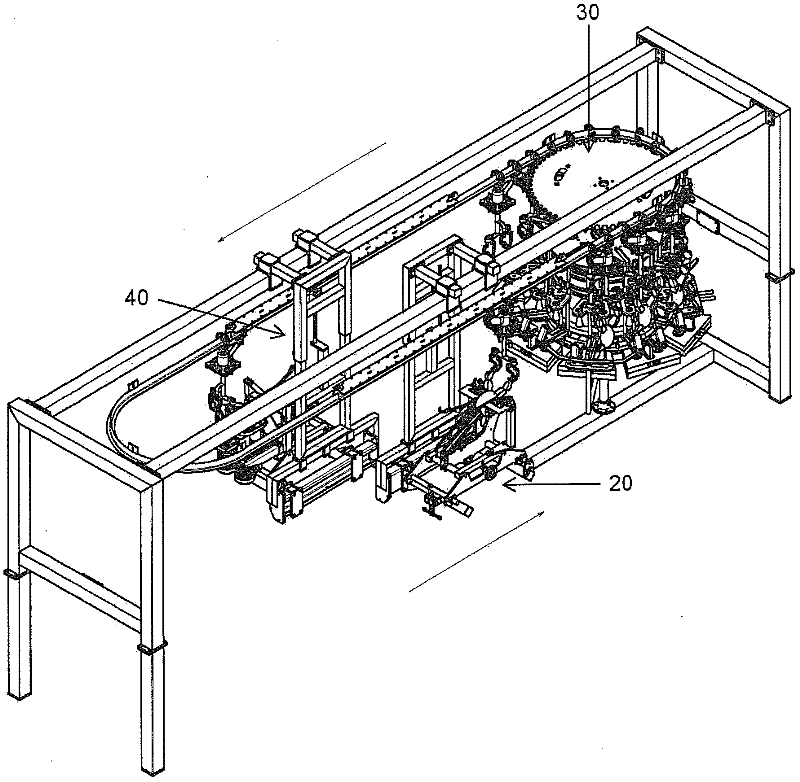

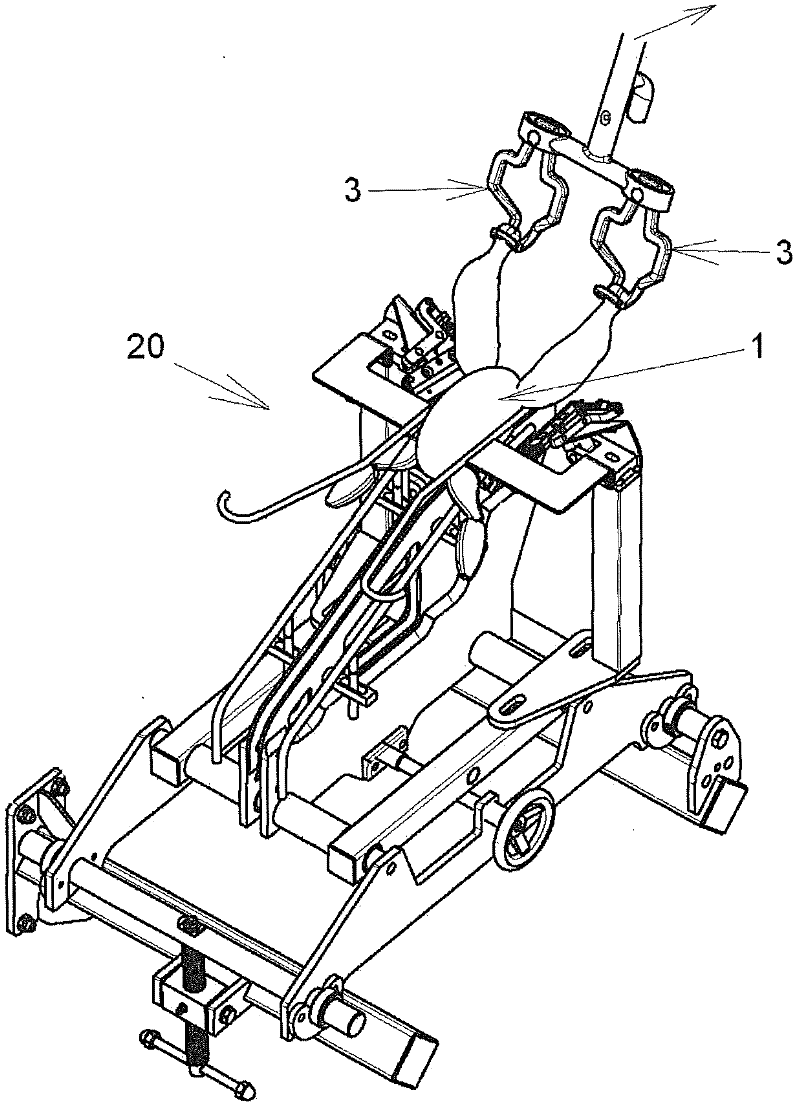

The present invention provides a first processing step and a second processing step in the case where the hollow carcass of the poultry is broken down into a lower carcass including the thighs and the back part, and an upper carcass including the remaining part of the rib-containing breast and back parts. , in the first processing step, when the hollow body is transported in a suspended state, the hollow body is cut from the thigh root through the tail end of the intestinal bone without cutting the spine; in the second processing step, the femoral part is cut The tendon and connective tissue are cut, that is, the thigh is peeled off. The present invention performs the above processing steps with high productivity. The first processing step includes a conveying line, a peritoneal cutting part, a 90-degree turning part and a processed product separation part. The second processing step consists of a conveyor with teeth, which conveys the lower body half hooked at the femur through an underside running belt; a parallel moving conveyor arranged under the conveyor with teeth for peeling off the thighs of the lower body half; A parallel guide plate is arranged under the lower running belt.

Owner:MAYEKAWA MFG CO LTD

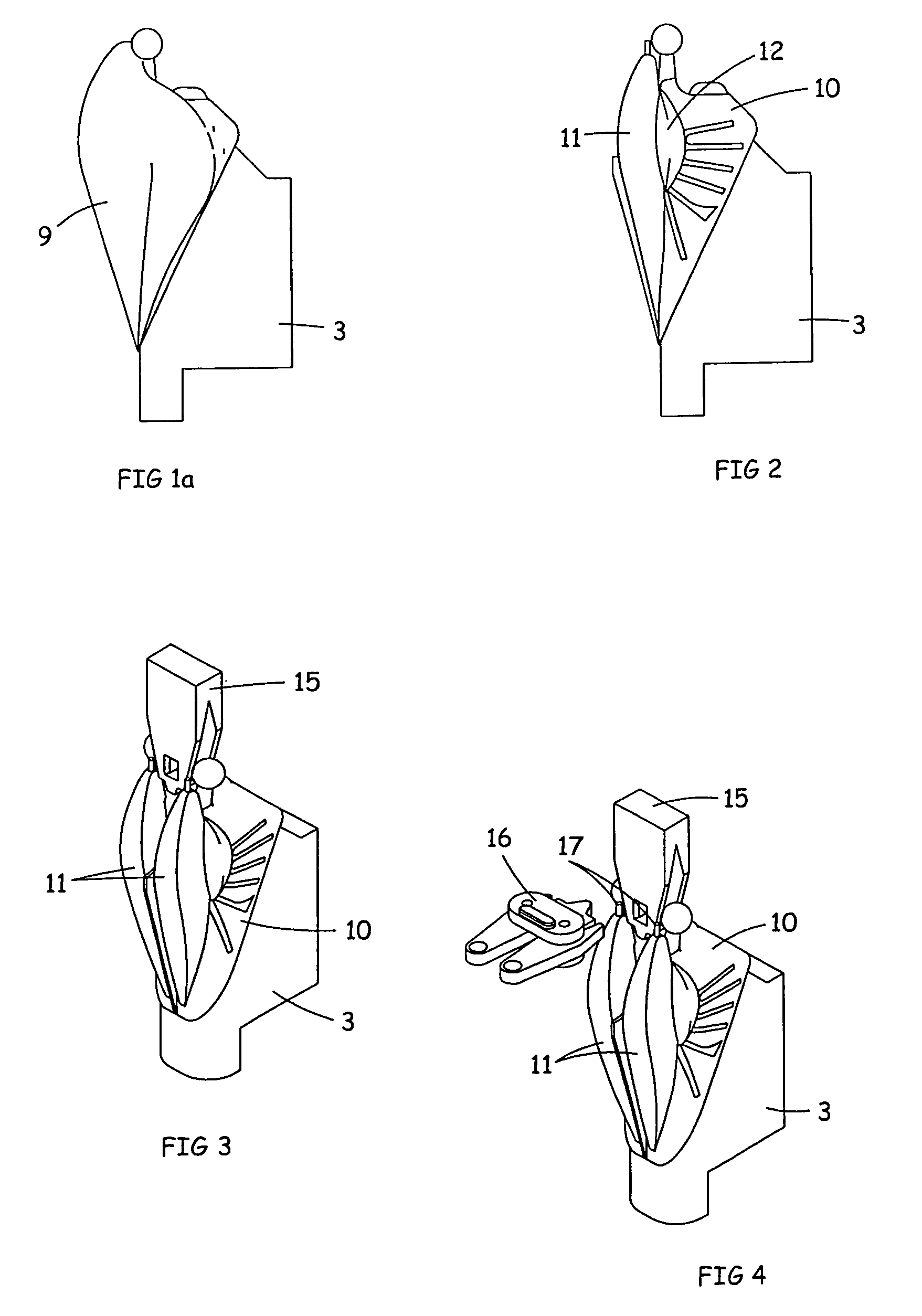

Method and apparatus for harvesting an inner fillet from poultry

A method and apparatus is provided for harvesting an inner fillet from poultry, wherein a tendon with which the inner fillet is or was connected to a wing bone of the poultry projects from the inner fillet. The tendon is gripped, and subsequently the tendon and the inner fillet attached thereto are pulled over a predetermined first distance off the carcass part of the poultry so as to completely or partly detach them from the carcass part.

Owner:MEYN FOOD PROCESSING TECH BV

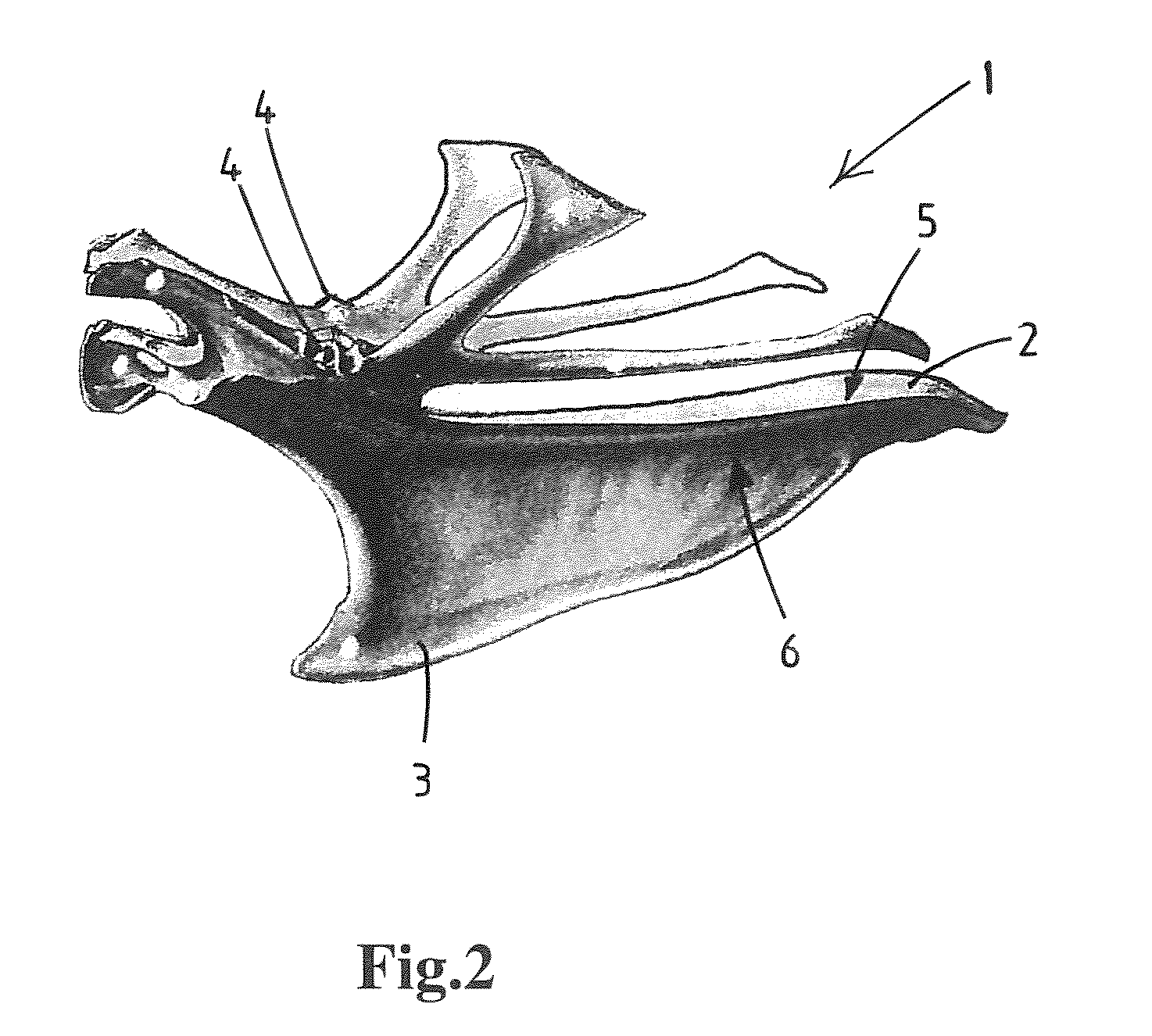

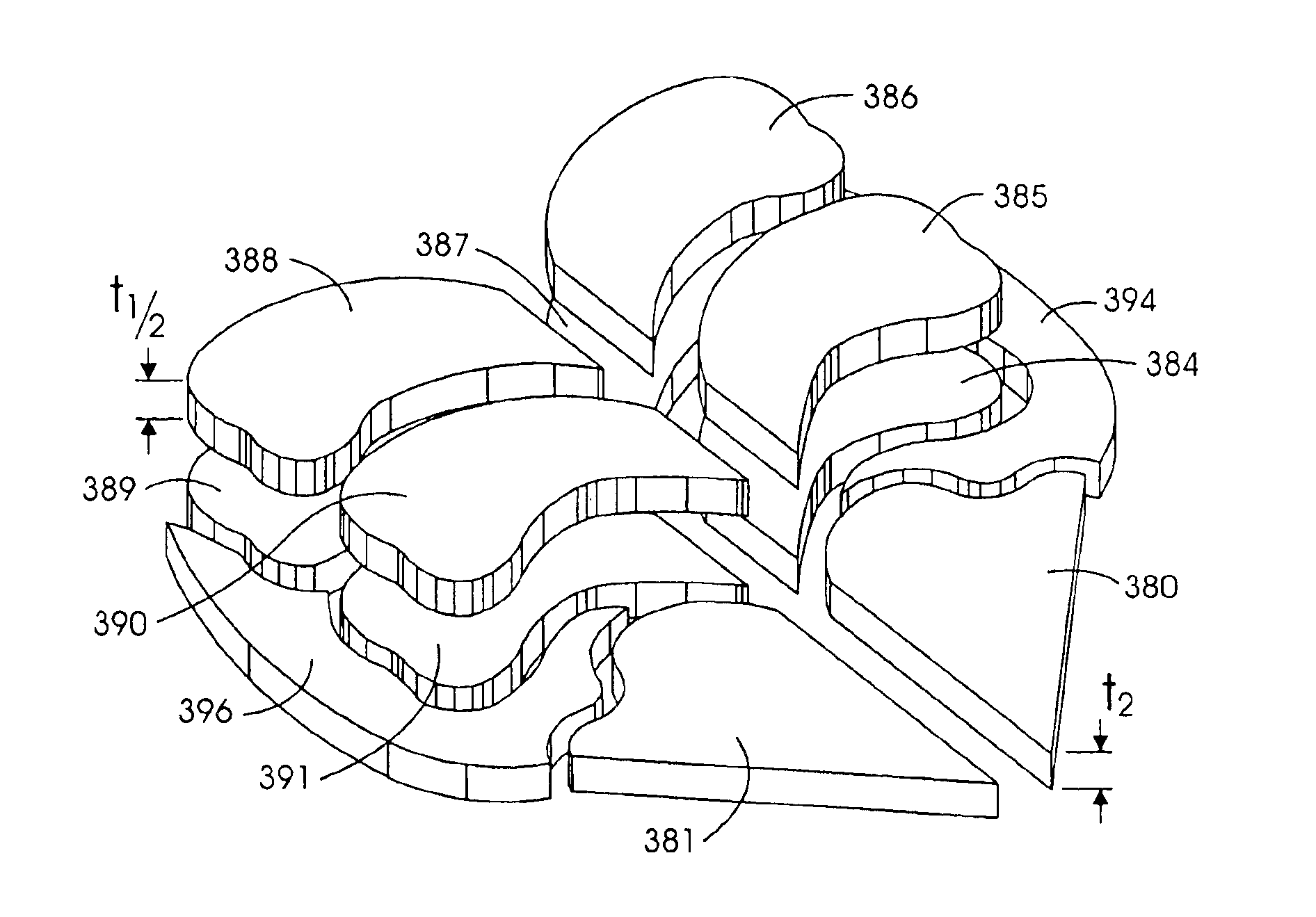

Filleting device

InactiveUS6935942B1Increase productionMeat processing plantsDividing poultrySacroiliac jointEngineering

Poultry carcasses are conveyed on saddles with their breastbone plate facing downwards to a scraping device having left and right scraping elements arranged adjacent to each other to simulate the contour of the approaching poultry carcass. The scraping elements are spaced apart by a signal from the control unit in relation to the individual width of the poultry carcass. Each scraping element has a sinew restraint that finds and restrains the tender sinew located in the region of the body joint, so that the scraping element can pass unhindered into the region between bone and meat and so obtain an optimum yield. A second scraping device, arranged essentially symmetrically to the direction of conveying, has left and right discs that are slidable by pivot levers to move on the corresponding part of the symmetrical wishbone in order to detach the meat connected to the wishbone.

Owner:NORDISCHER MASCHINENBAU RUD BAADER GMBH CO KG

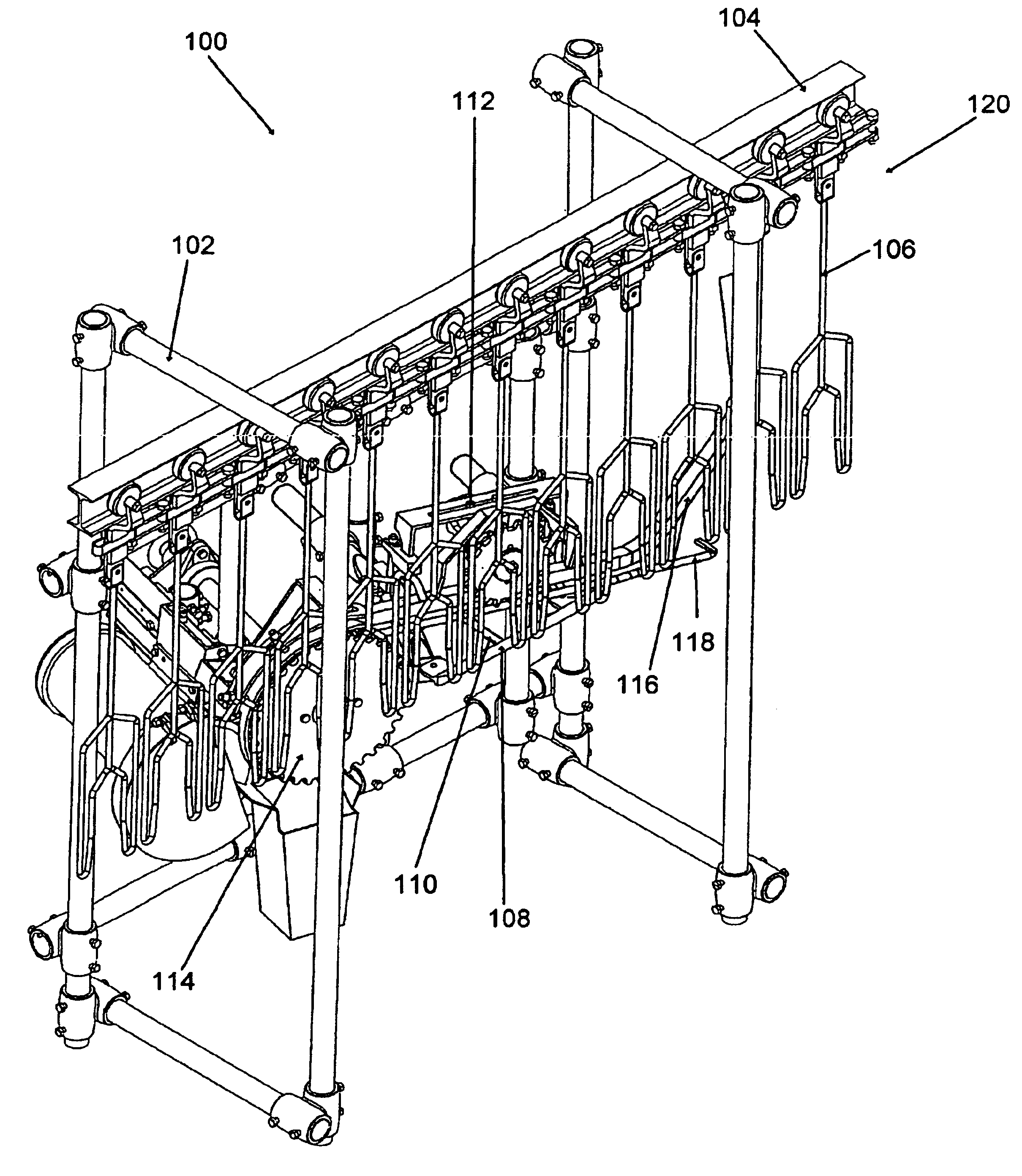

Apparatus for automatically removing a tail from poultry

ActiveUS7115030B2Promote resultsEasy accessMeat processing plantsDividing poultryEngineeringSupport surface

The invention relates to an apparatus for automatically removing a tail from poultry. An overhead conveyor moves the poultry or part of a bird suspended by the legs, and a guiding device is disposed underneath the overhead conveyor for supporting and guiding the poultry. A cutting device is functionally disposed behind a lead element for the poultry and which is part of the guiding device. The overhead conveyor is designed to convey the poultry with the back facing forward while the guiding device supports and guides the poultry substantially at the side of the back. The cutting device is disposed in or under an effective supporting surface of the guiding device.

Owner:MEYN FOOD PROCESSING TECH BV

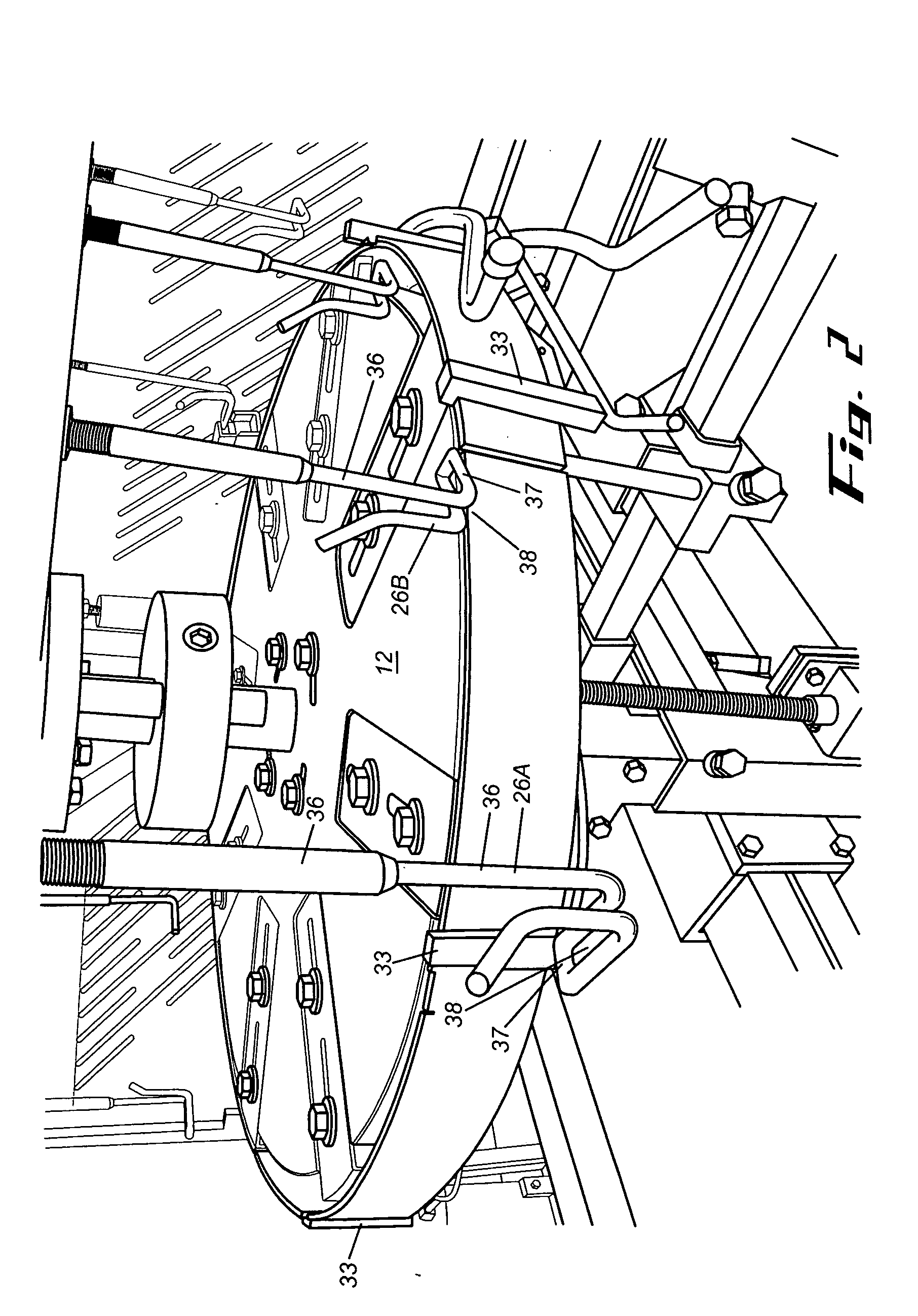

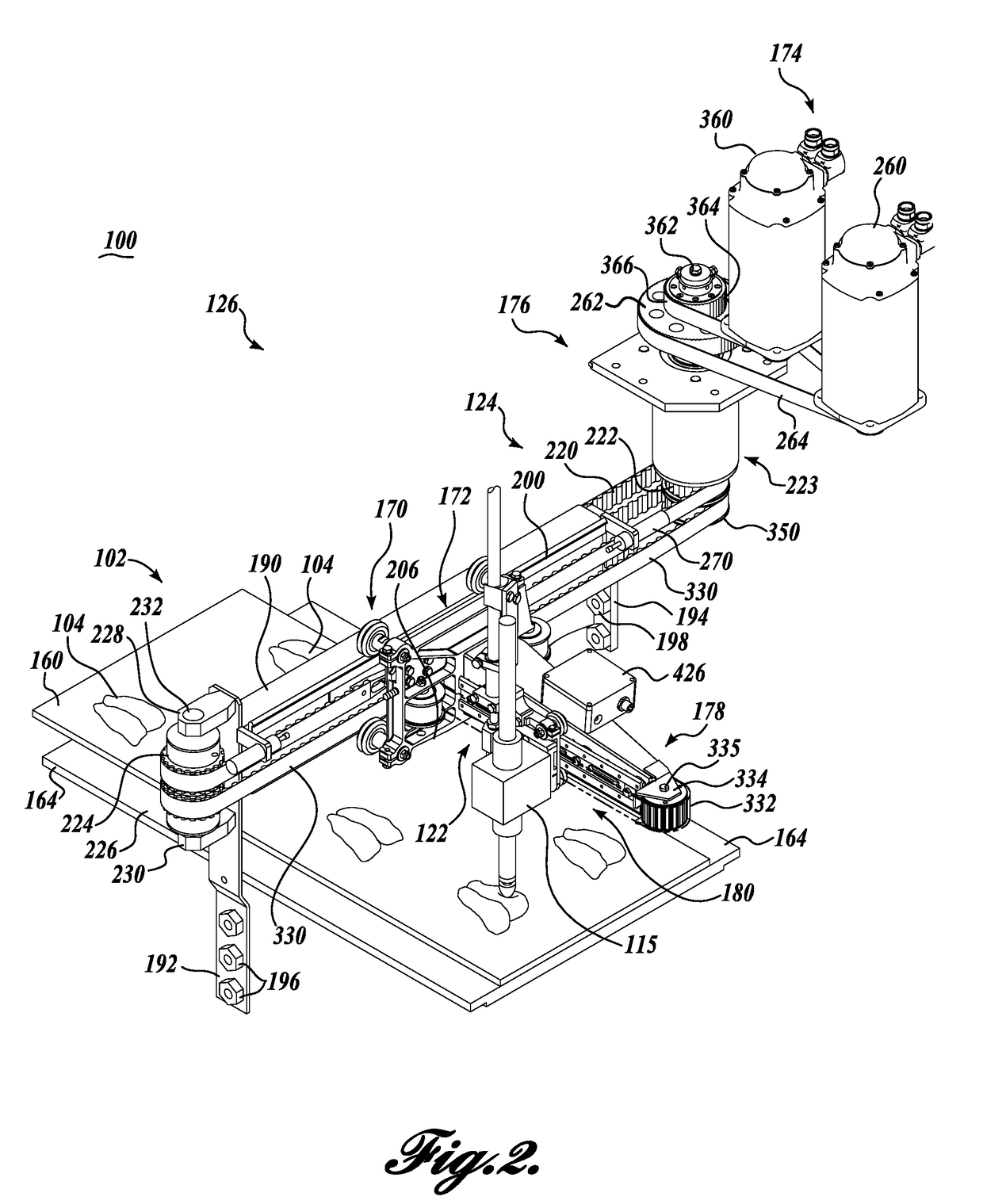

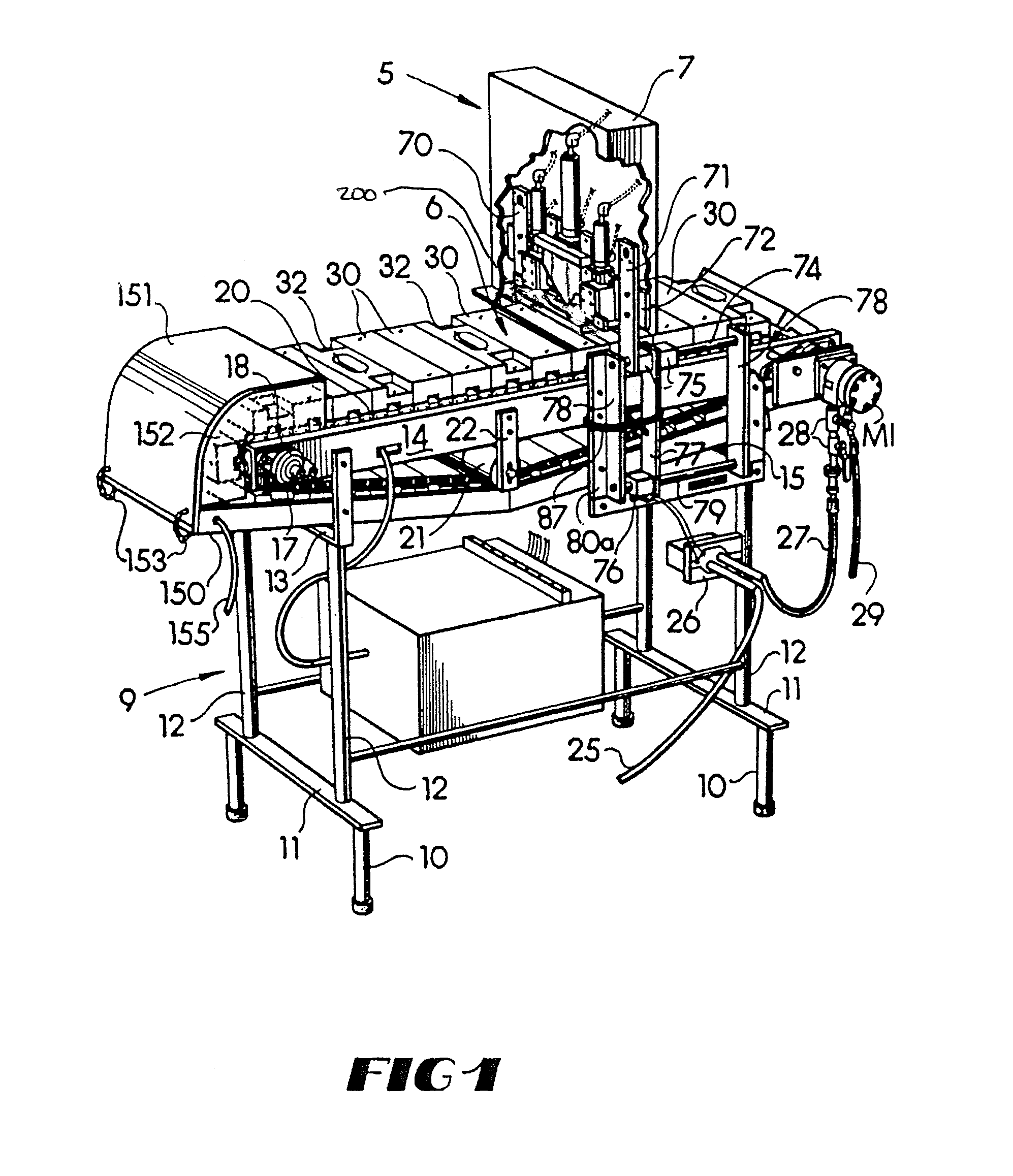

Poultry wing separator and partial deboner

Poultry wings are suspended by their tip segments and oriented so that their outside surfaces face one side of the processing path, with right wings oriented with their elbows leading, and left wings oriented with their elbows trailing. The lower, primary segments are bent at the elbow joints by a bending guide, laterally and upwardly about an elbow guide, opening the elbow joints. The open joints are cut so as to release the primary segments. The mid-wing segments are compressed and the bone ends are moved laterally from the wing tip segments, causing the bone ends of the mid-wing segments to pop out of the tip segments. In both instances, the bones of the segments are exposed in the final products, so when the products are cooked, the exposed bone ends are free of grease, etc. and are suitable for grasping by the fingers of the hand for eating as finger food.

Owner:SYSTATE GROUP

Poultry wing separator and partial deboner

InactiveUS20050186897A1Residue reductionPoultry deboningMeat processing plantsEngineeringRight flank

Poultry wings are suspended by their tip segments and oriented so that their outside surfaces face one side of the processing path, with right wings oriented with their elbows leading, and left wings oriented with their elbows trailing. The lower, primary segments are bent at the elbow joints by a bending guide, laterally and upwardly about an elbow guide, opening the elbow joints. The open joints are cut so as to release the primary segments. The mid-wing segments are compressed and the bone ends are moved laterally from the wing tip segments, causing the bone ends of the mid-wing segments to pop out of the tip segments. In both instances, the bones of the segments are exposed in the final products, so when the products are cooked, the exposed bone ends are free of grease, etc. and are suitable for grasping by the fingers of the hand for eating as finger food.

Owner:SYSTATE GROUP

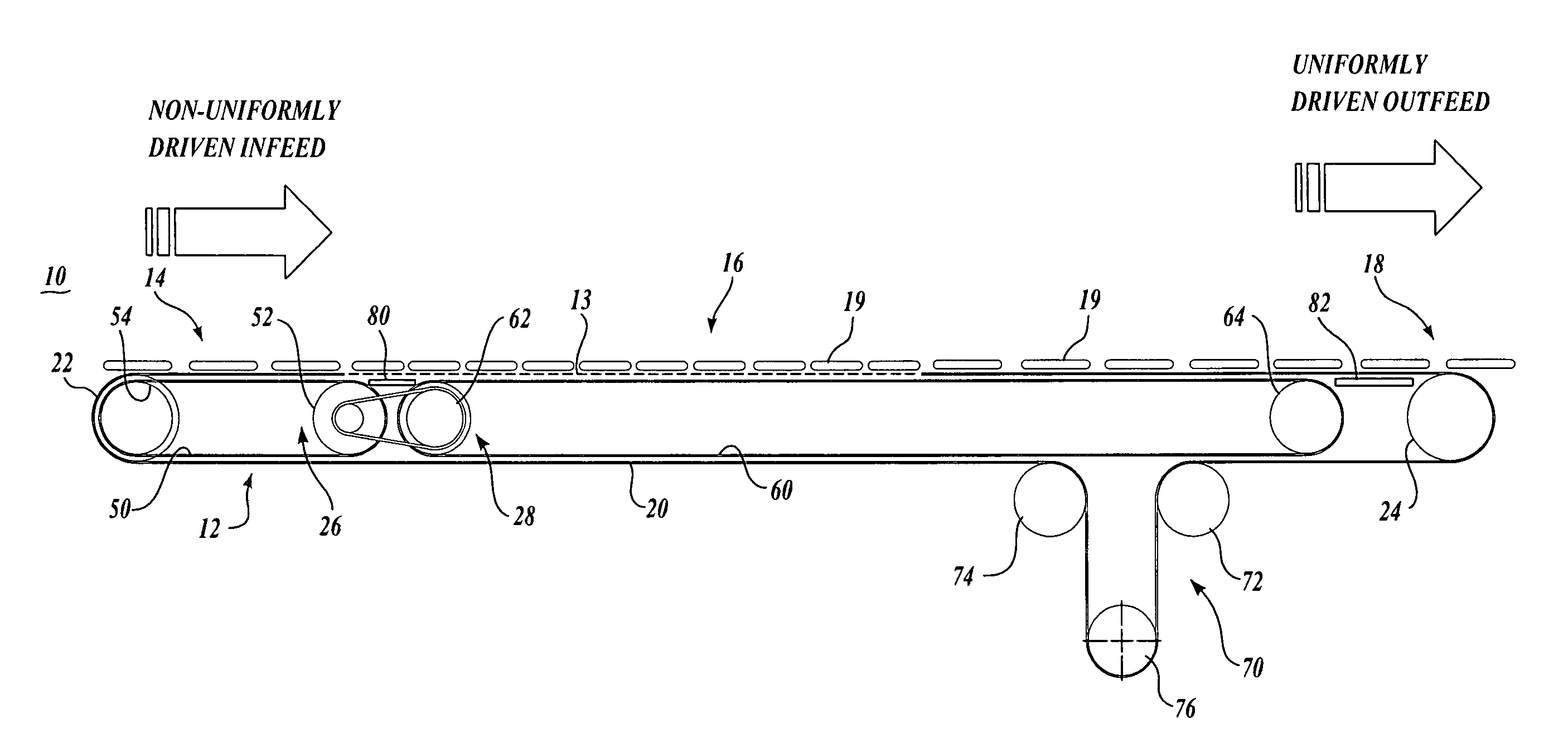

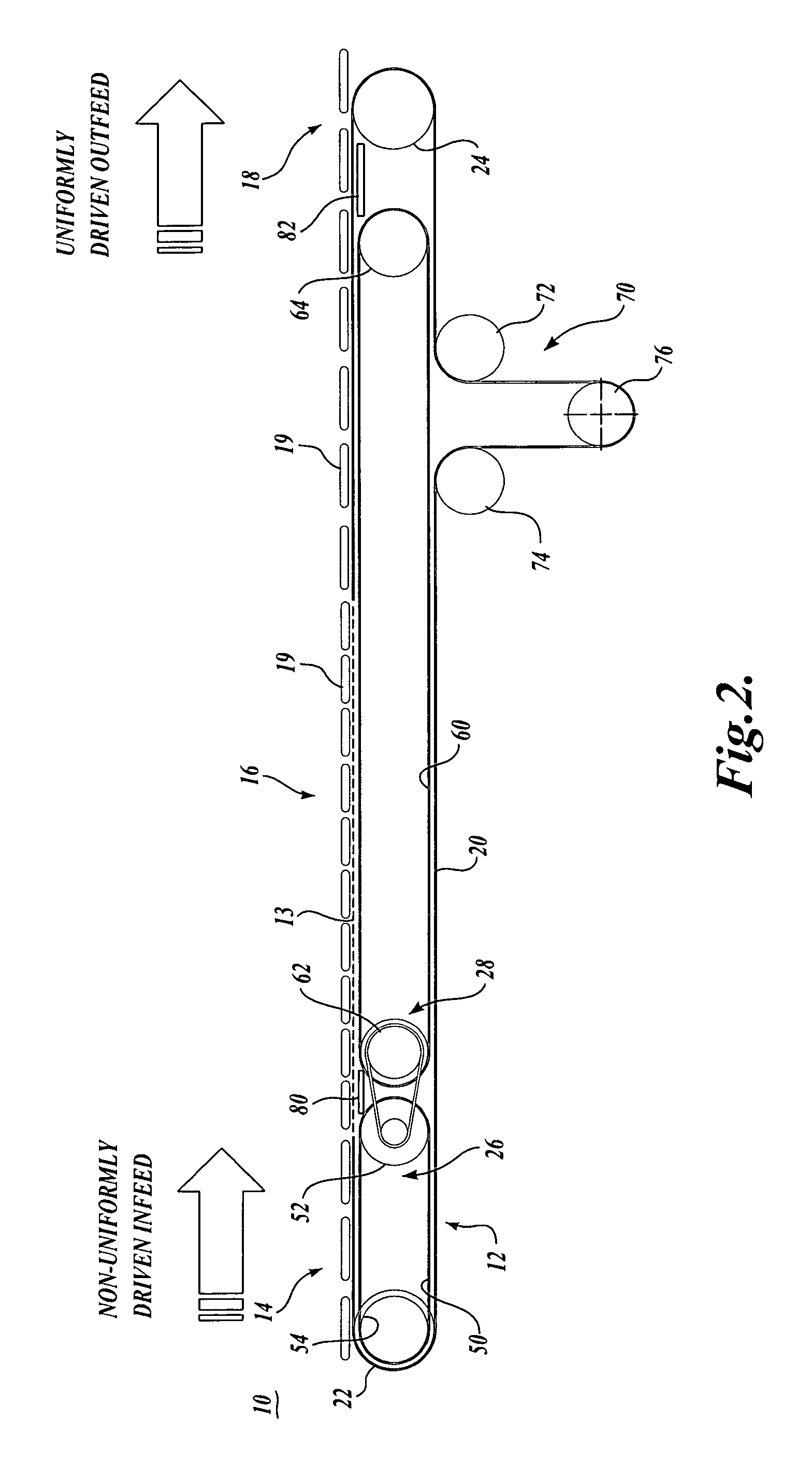

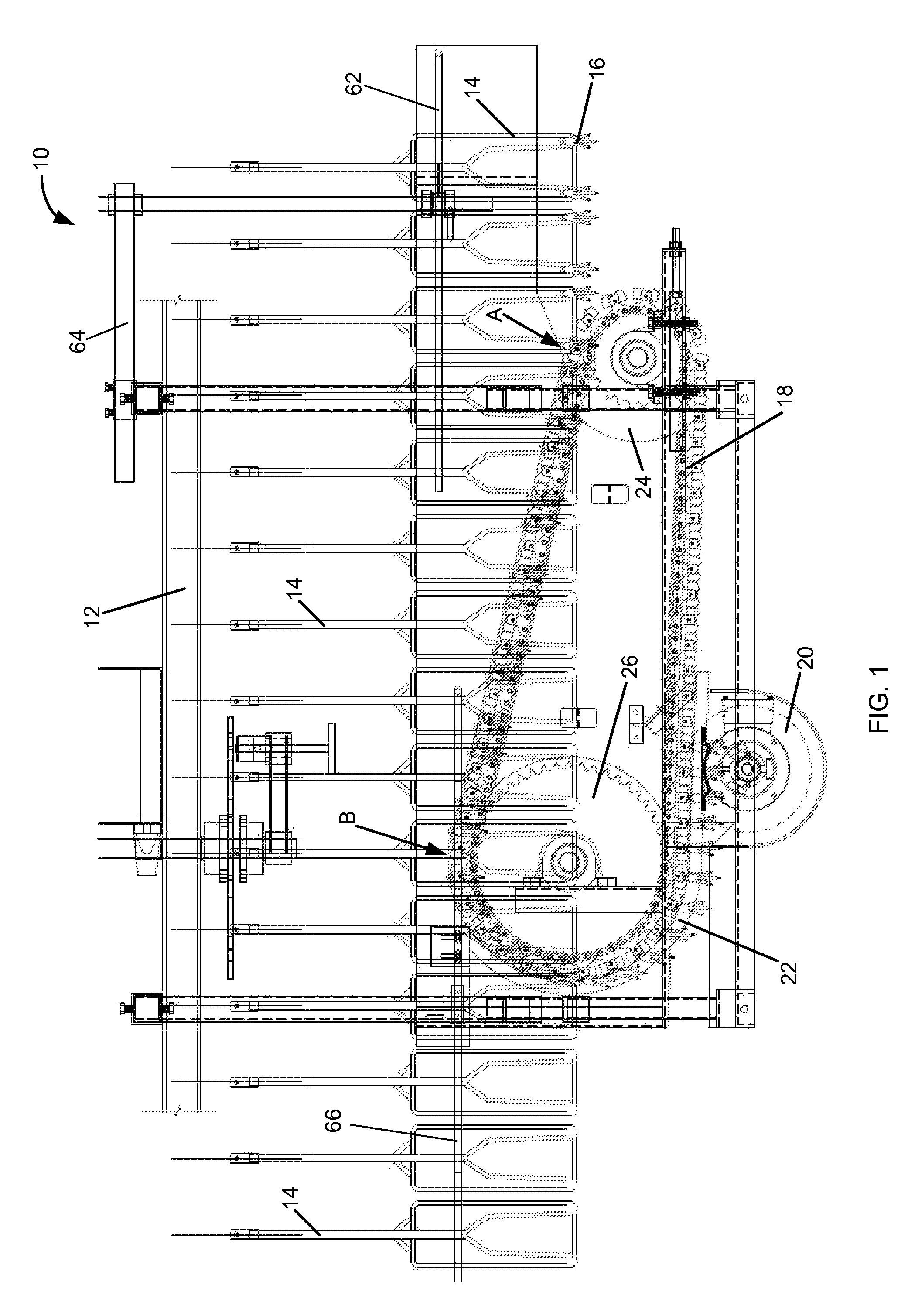

Conveying conformable products

A buffer conveyor (12) for conveying conformable work products (66) includes a collapsible conveyor belt (13) having an infeed section (14), a collapsible intermediate section (16) and an outfeed section (18). The infeed section (14) may be driven at a non-continuous speed, and the outfeed section may also be driven at a uniform, or non-continuous, speed, but the average speed of both the infeed and outfeed sections is the same. The intermediate section of the conveyor is driven at a non-uniform speed that is slower than, but proportional to, the speed of the infeed section.

Owner:JOHN BEAN TECH CORP

Bird wing cutting machine

A machine for cutting poultry wings into segments. Holders convey wings through a guide that positions the first joint between the drumette and midwing. A blade incises the connective tissue after the bones at the joint have been disarticulated by lateral guides that form a tapered corridor. A second joint at the midwing and wingtip is forced into a pocket by one of the lateral guides extending into the second joint. The second joint is severed by a blade extending into the second joint from the side opposite the lateral guide.

Owner:PRIME EQUIP GRP LLC

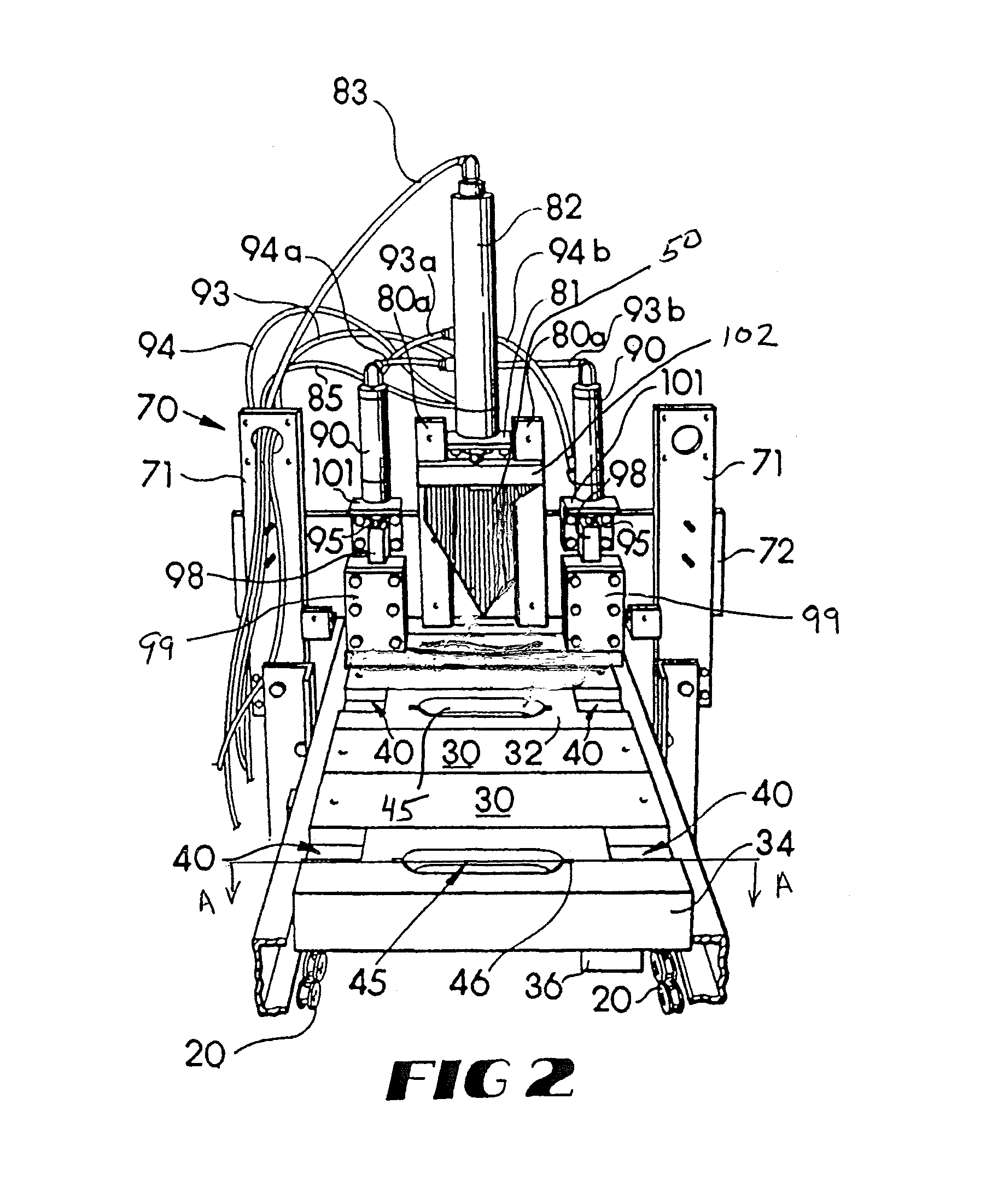

Poultry breast saw apparatus

A breast saw apparatus (10) is used for cutting a poultry breast having a keel bone. A conveyor (30) moves the poultry breast through the apparatus (10). A bottom member (80) is supported above the conveyor (30). The bottom member (80) is configured for the poultry breast moving along the bottom member's length and supporting the poultry breast on its keel bone. An elongate top member (90) is positioned above the bottom member (30). A blade (70) is utilized to cut the poultry breast and the poultry breast is held straight between the top member (90) and the bottom member (80) as the poultry breast is moved by the conveyor (30) to the blade (70) for cutting.

Owner:JENNIE O TURKEY STORE

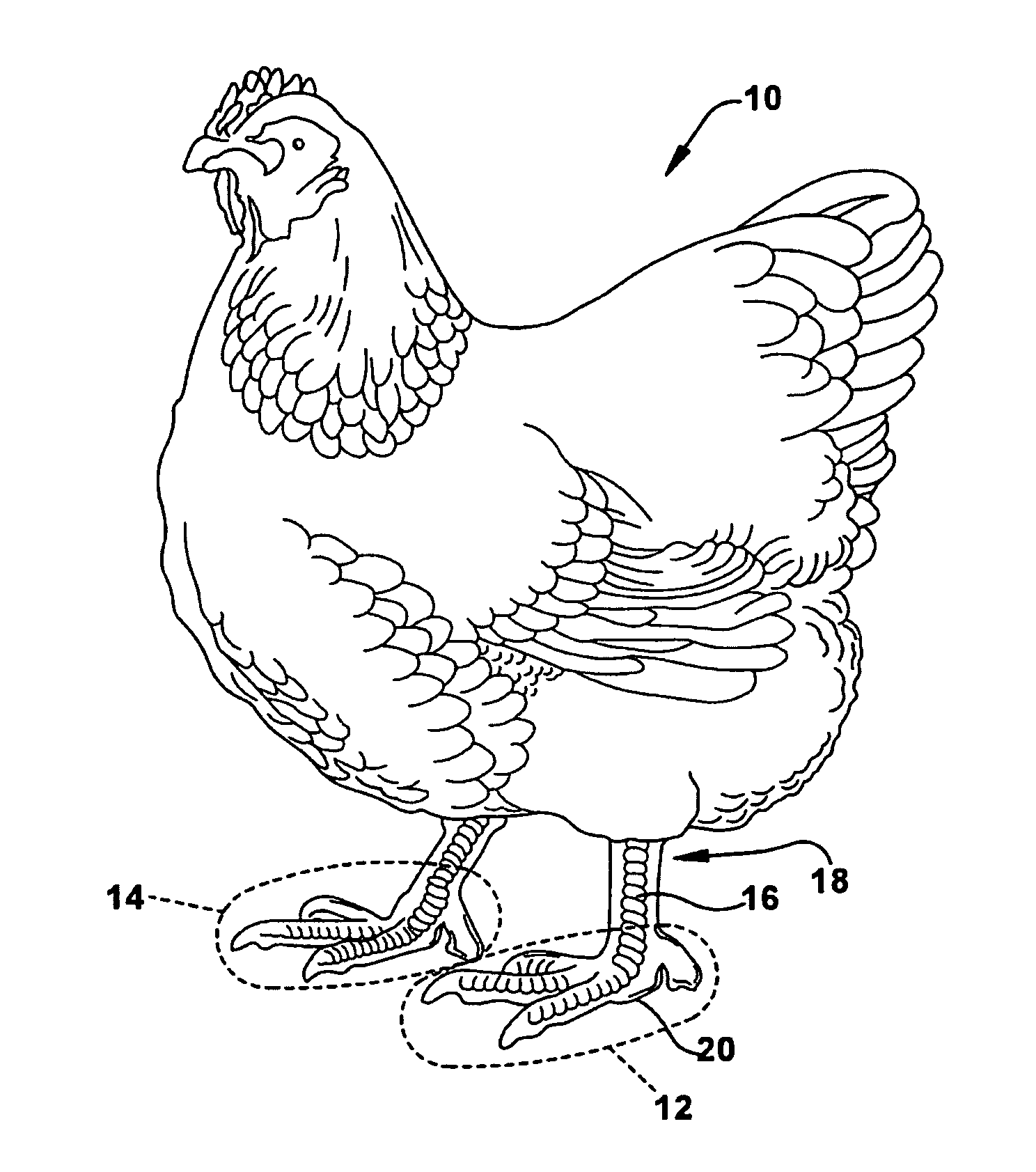

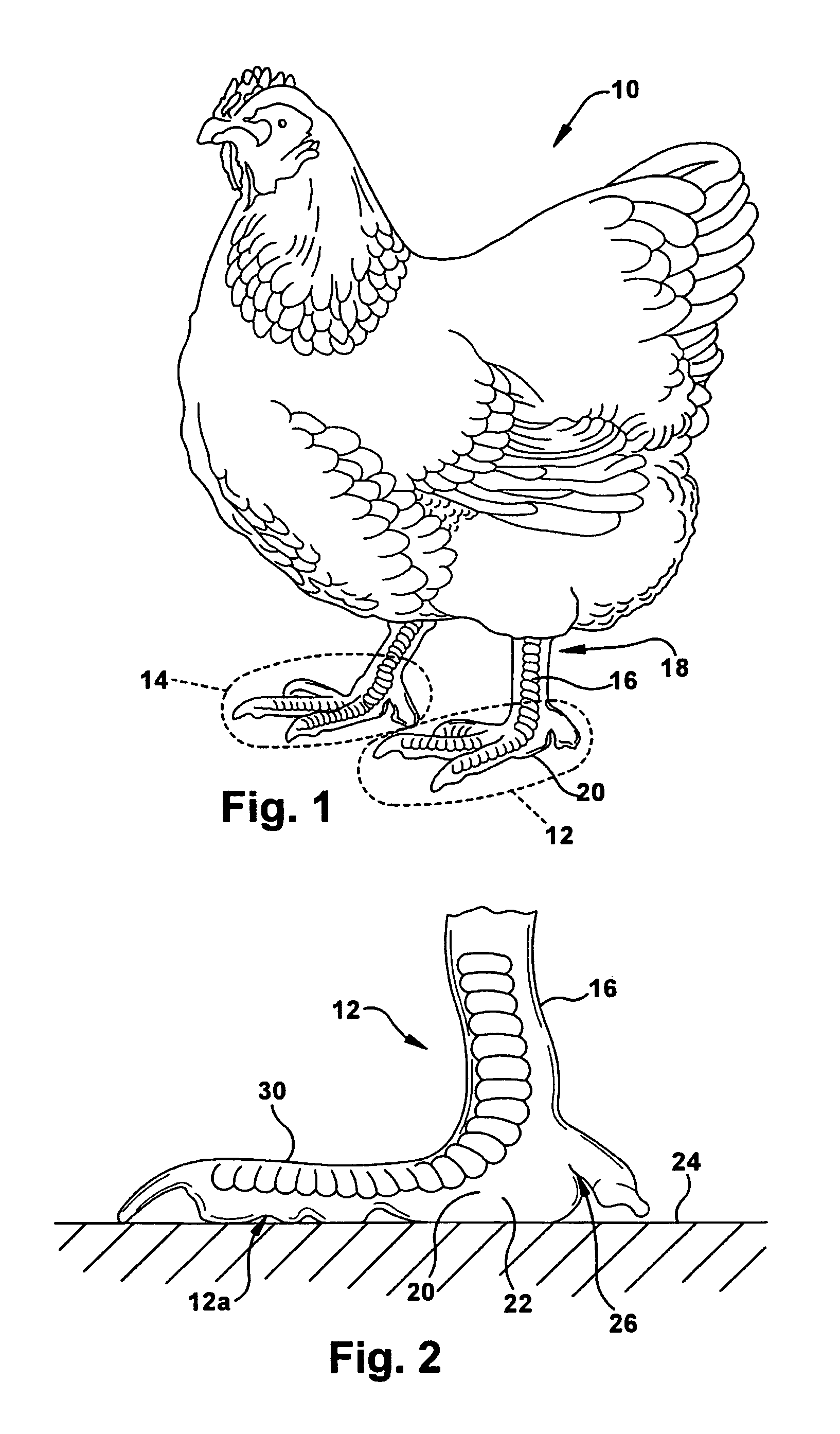

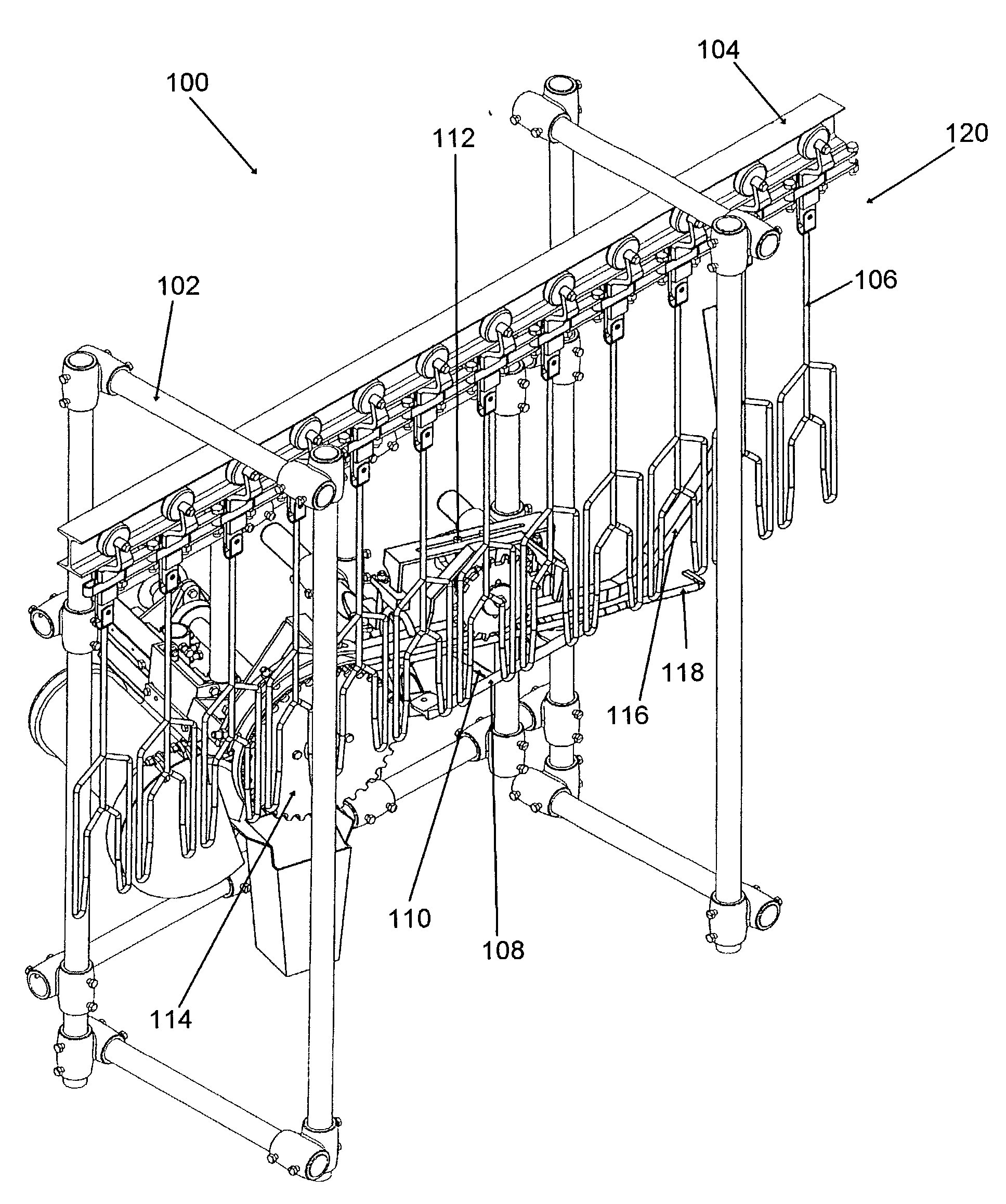

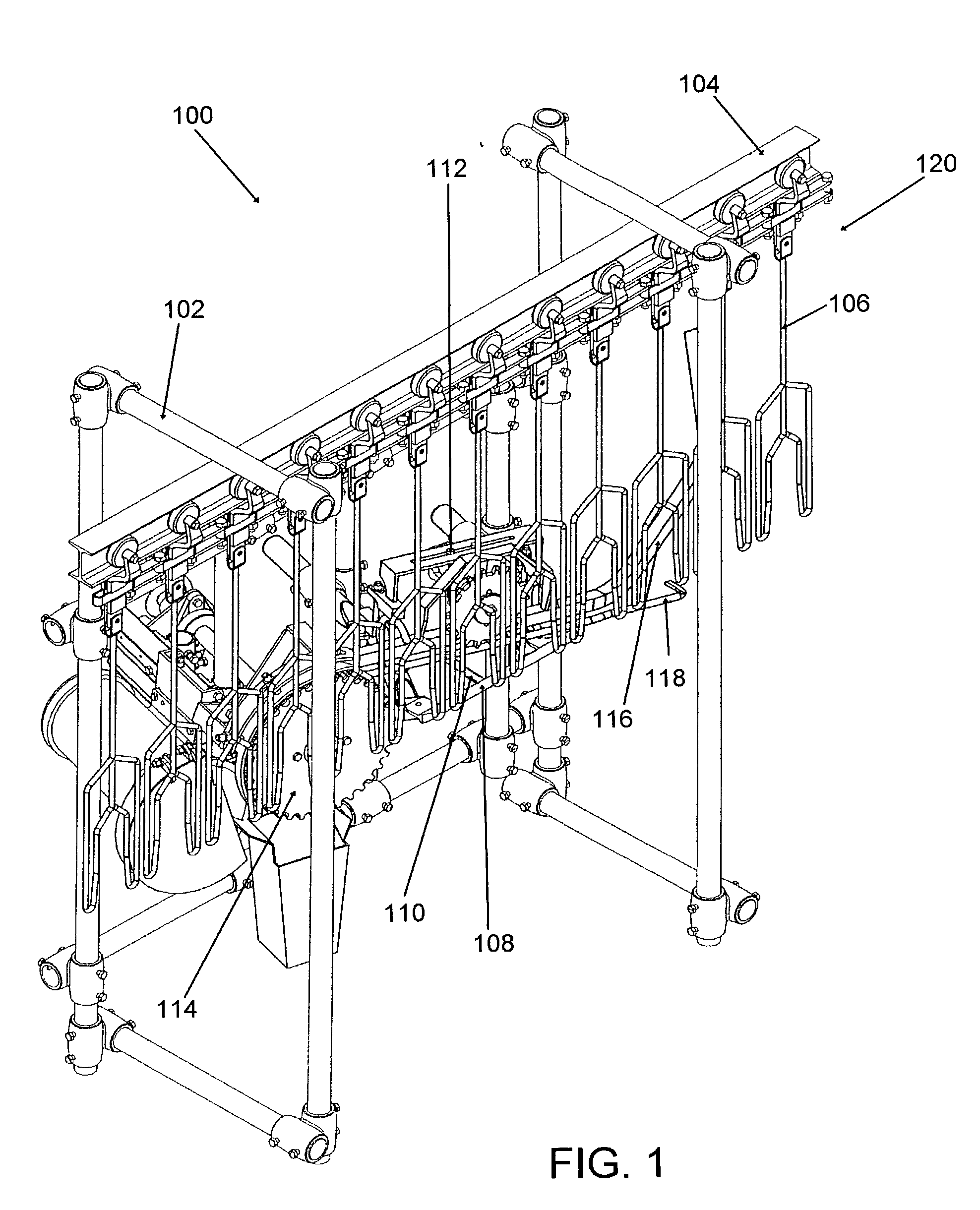

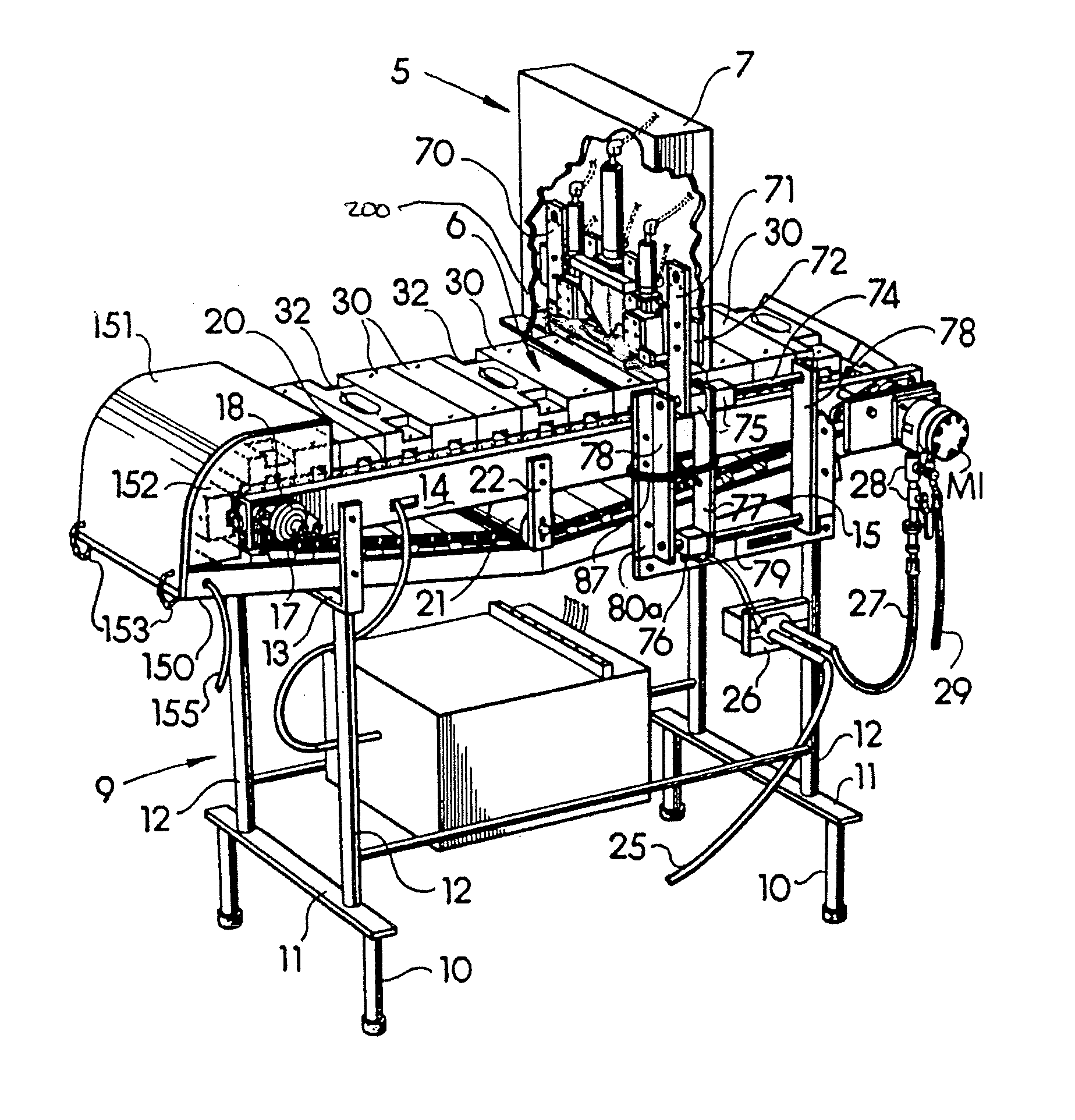

Apparatus and method of edible feet harvest and paw production

InactiveUS6749497B2Rule out the possibilityMeat processing plantsSlaughtering accessoriesAbdominal eviscerationEngineering

A method and apparatus for partially cutting hock joints, and letting feet remain attached to the rest of carcass by skin and one or more tendons, exposing the hock joint by folding feet, and hanging the carcasses in the evisceration shackles by hock joints, the method unambiguously ensures that if a carcass is condemned by an Inspector, the feet belonging to that carcass are condemned as well. Furthermore, this invention solves the even more tractable problem of capturing folded feet, separating feet from the carcass while leaving the carcass still hanging in the shackles, transferring feet into an infeed paw cutter wheel, and cutting knuckle portion to produce chicken paws ready for further processing.

Owner:TYSON FOODS

Method of trimming portion of chicken paw metatarsal pad using power operated rotary knife

A method for trimming an undesirable portion of a metatarsal pad of a chicken paw using a power operated rotary knife. The steps of the method include: a) providing a power operated rotary knife including an annular knife blade rotatable about a central axis and defining a central open area; moving one of the rotary knife and the chicken paw with respect to the other to position the rotary knife with respect to a bottom of the chicken paw such that the undesirable portion of the metatarsal pad is within the central open area of the blade and the cutting edge of the blade is proximate to a periphery of the undesirable portion; and moving one of the rotary knife and the chicken paw such that the cutting edge of the blade slices a layer of the metatarsal pad thereby removing at least part of the undesirable portion.

Owner:BETTCHER INDUSTRIES

Carrier for supporting a carcass part of slaughtered poultry

ActiveUS9173413B2Avoid partialHold positionPoultry processing support devicesPoultry transferring/conveying devicesMedial partEngineering

A carrier for supporting a carcass part of slaughtered poultry includes a carrier body having a support surface for engaging at least a part of the inner face of the carcass part, a hook for holding the carcass part on the carrier body, a positioning element for positioning the carcass part relative to the carrier, which has a dome shaped engagement end for engaging the inner face of the carcass part, and is moveable between a retracted position and an extended position in which the dome shaped engagement end of the positioning element protrudes from the support surface of the carrier body. The positioning element is arranged such relative to the support surface of the carrier body that in its extended position, the dome shaped engagement end of the positioning element engages the inner face of the carcass part at or adjacent to the facies visceralis sterni of the sternum in the region between the left and right margo costalis of the sternum.

Owner:MAREL STORK POULTRY PROCESSING

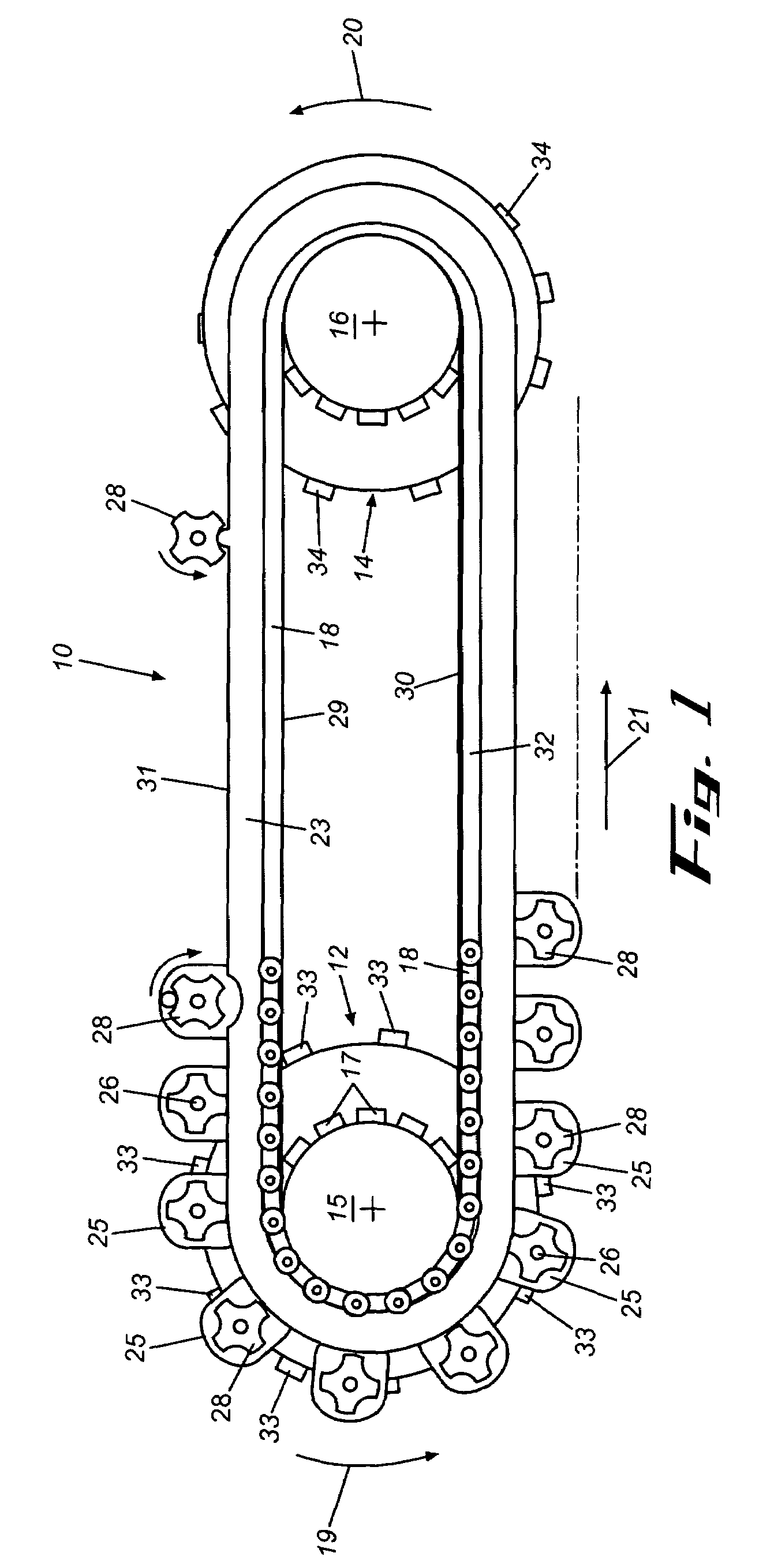

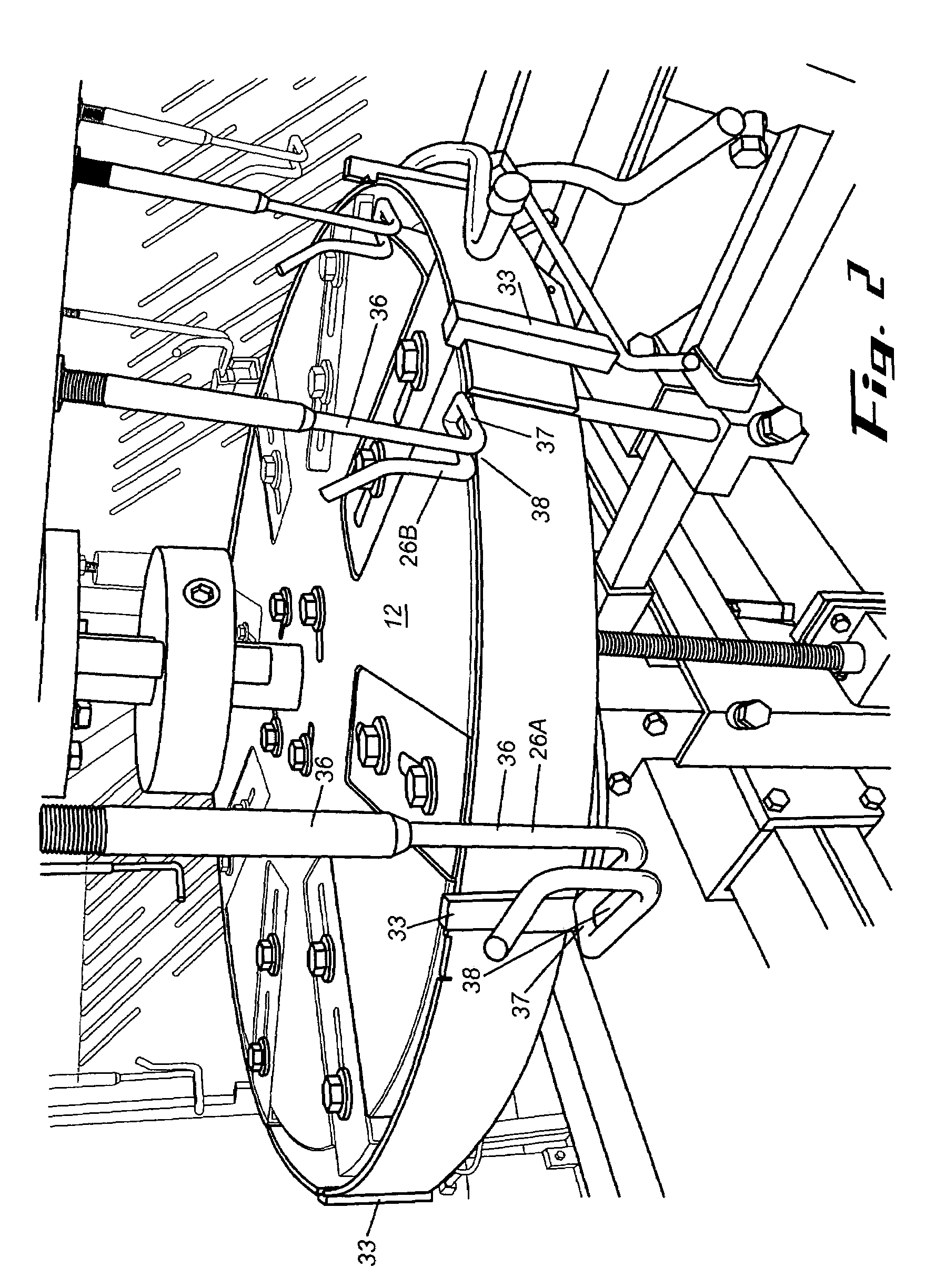

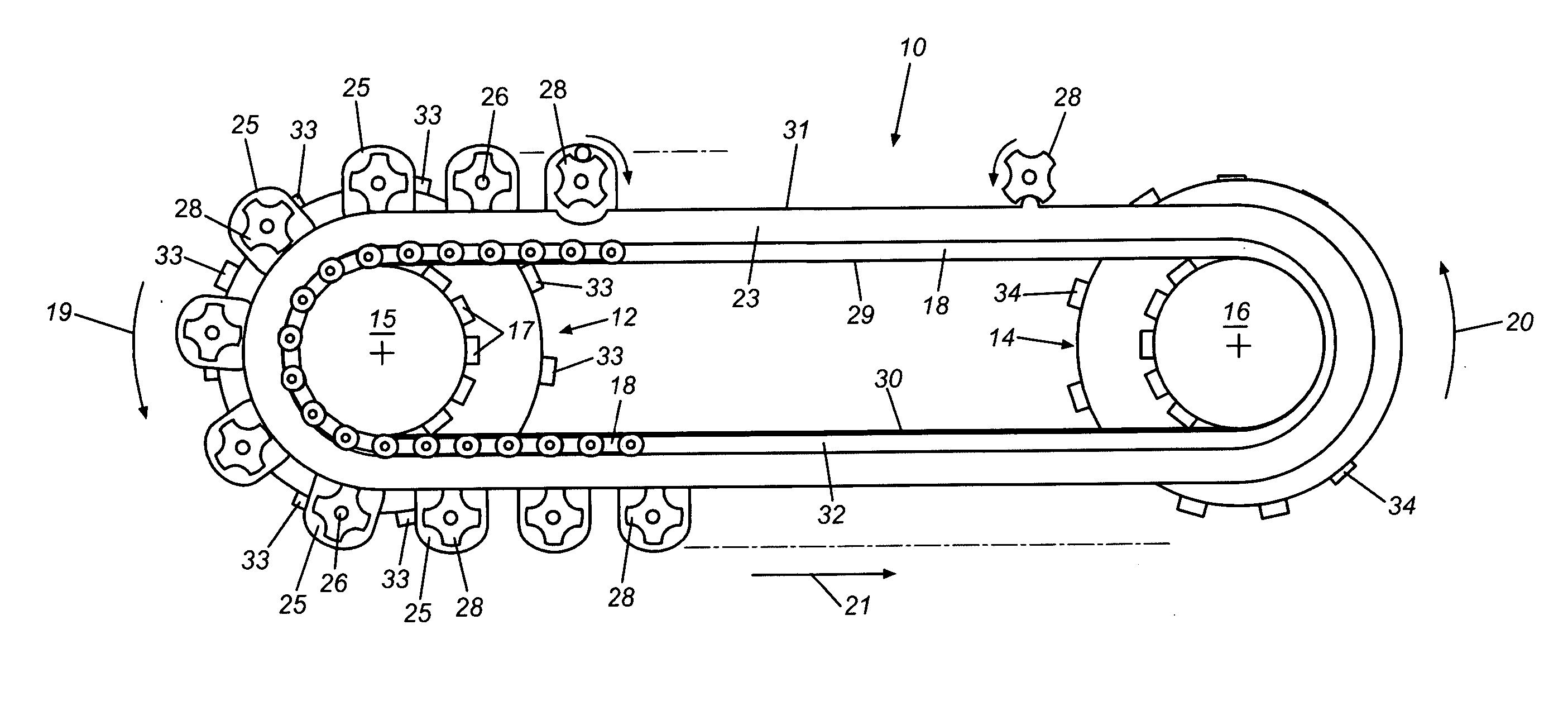

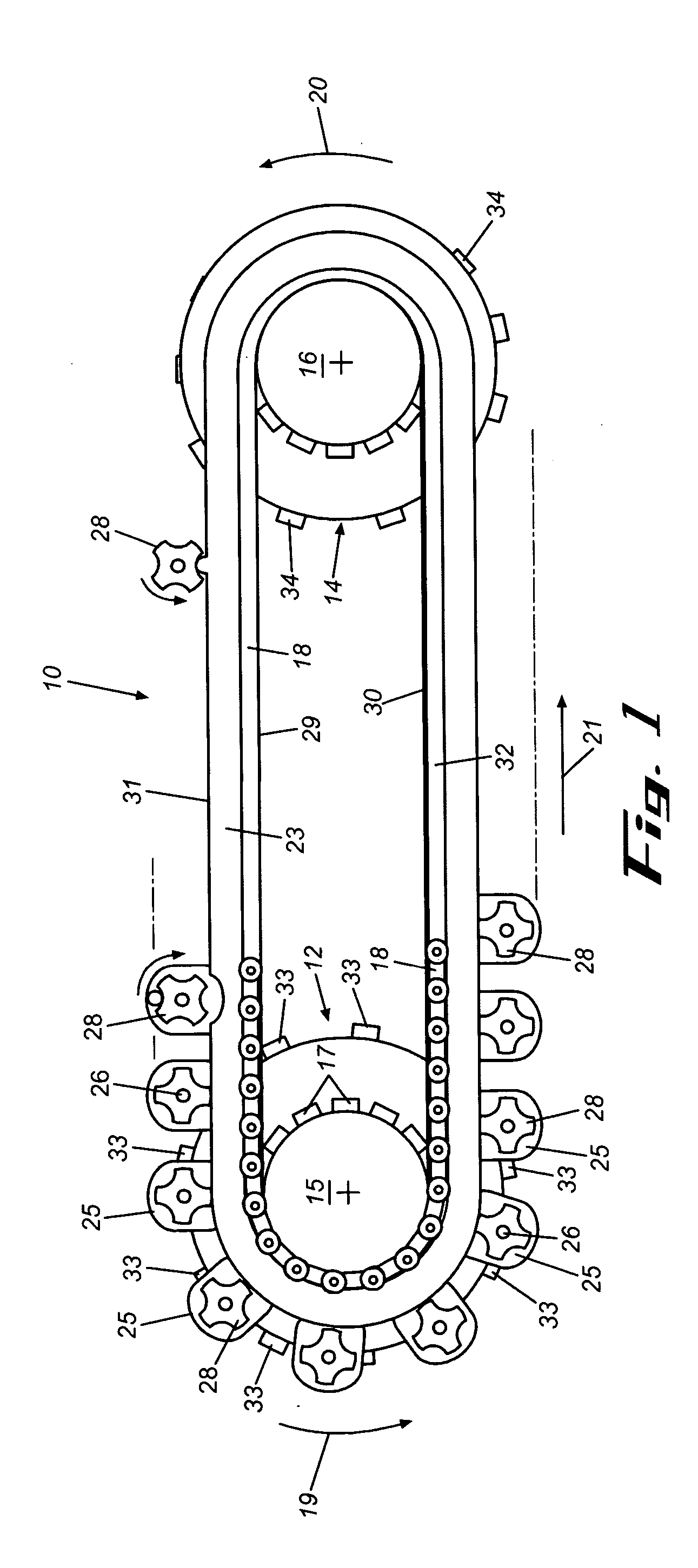

Poultry paw cutter and related methods

A poultry paw cutting apparatus can include a conveyor that conveys a plurality of shackles. Each of the shackles can be adapted to hold a poultry paw. A chain can receive the poultry paws from the shackles at a first location and can convey the poultry paws substantially in unison with the shackles to a second location. The poultry paws can be released from the shackles at the second location. A paw cutting station can be positioned along the chain. A first guide member can be located along the chain substantially between the second location and the paw cutting station. The first guide member can be adapted to press the poultry paws against the chain. A method of cutting a poultry paw is also disclosed.

Owner:PERDUE FOODS PRODS

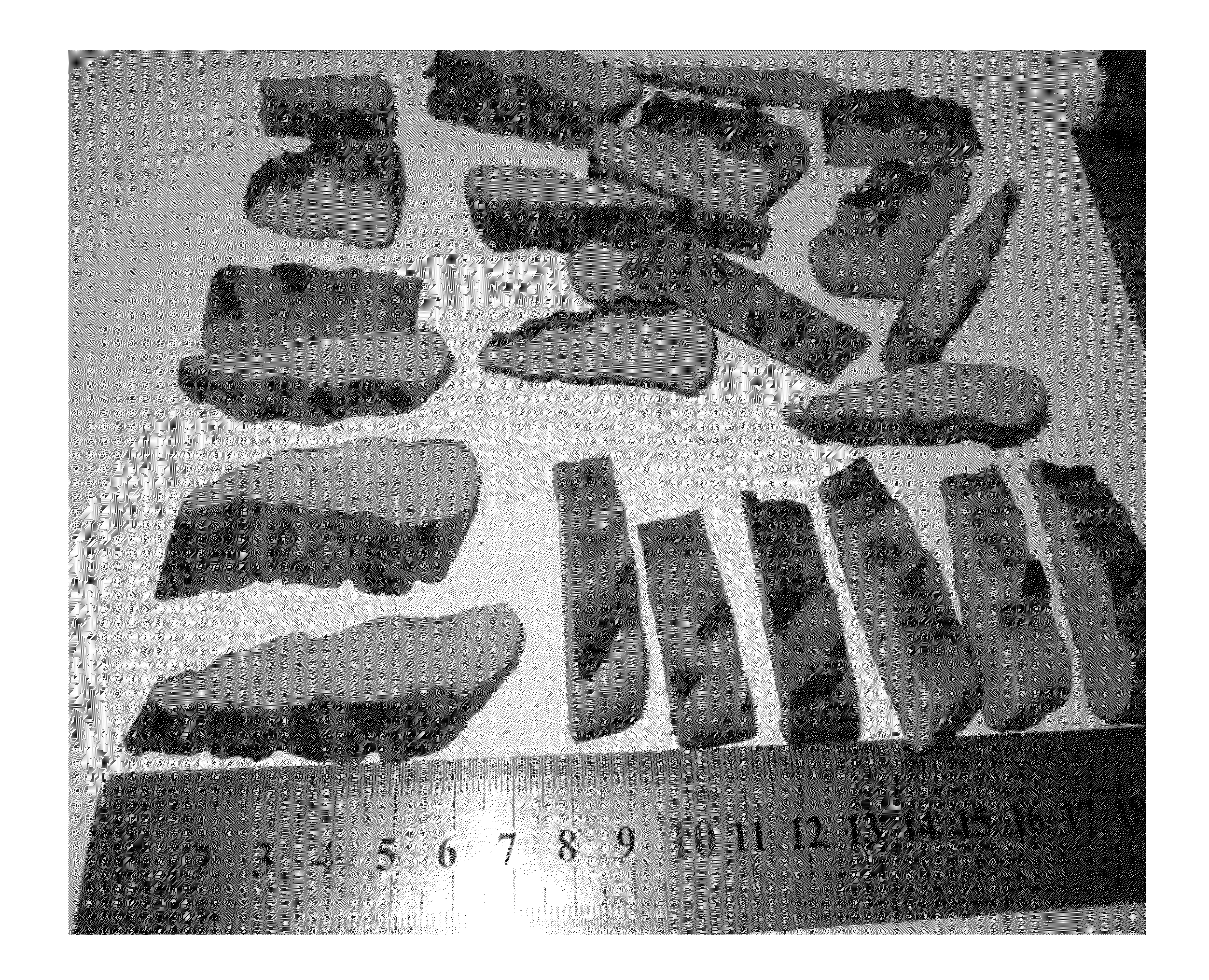

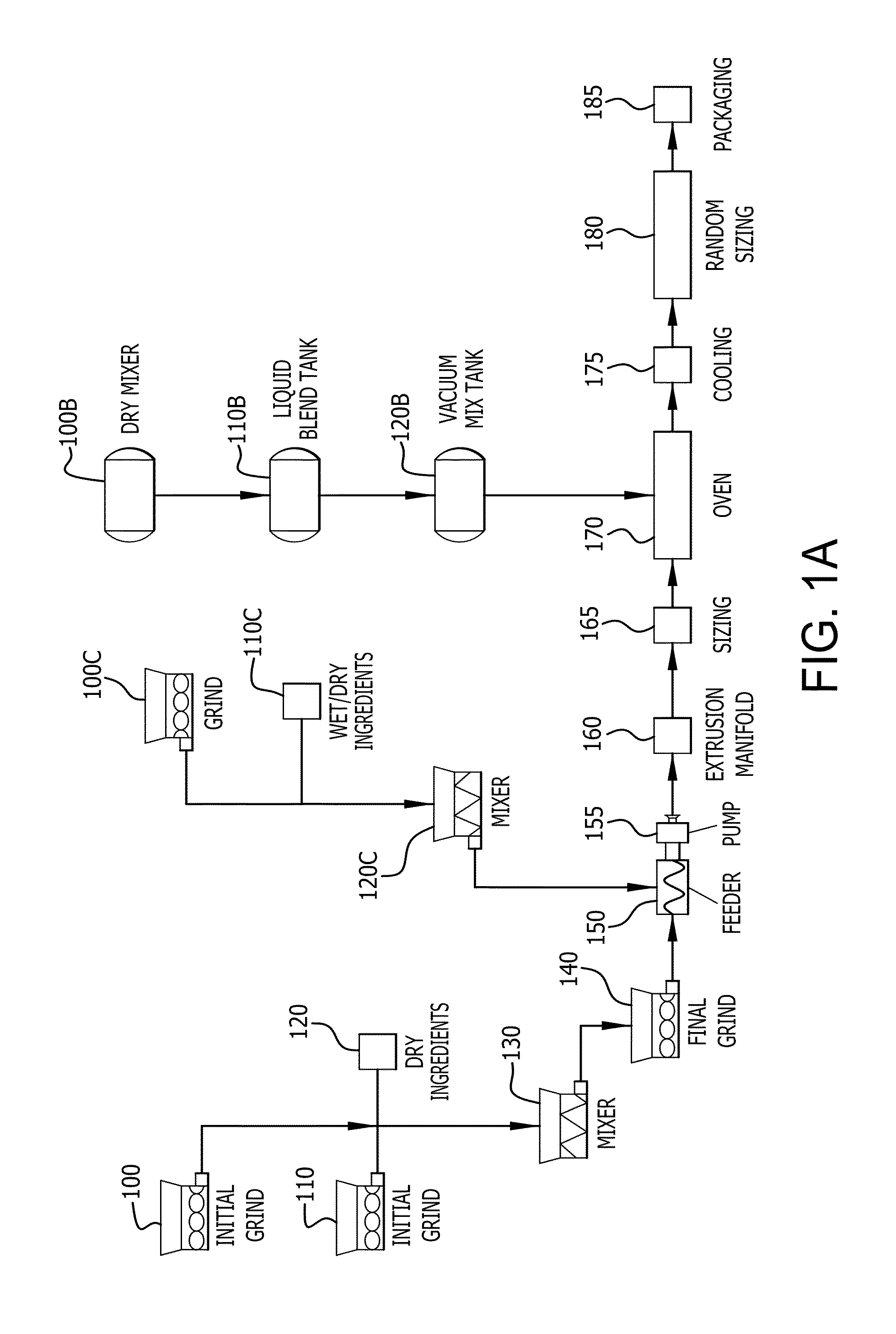

Apparatus, Systems and Methods for Manufacturing Food Products

ActiveUS20120237648A1Improve nutritional qualityFeeding-stuffProteins working-up by texturisingPreservativeEngineering

Processes, systems, and articles of manufacture are disclosed relating to edible meat pieces obtained from a continuous process where each piece generally appears to be home cooked on a grill or cooked in a smoke house with randomized sear and grill marks and smoke aroma. The invention, in its various embodiments, provides processes for manufacturing shelf-stable food treats comprising: starting with proteinaceous material (ground or whole), mixing the proteinaceous material with preservatives and flavor enhancers to form a foodstuff, extruding proteinaceous material (if ground) through at least one die opening that is at least partially irregular to form at least one strip of extrudate, cooking the extrudate or whole proteinaceous material to form a cooked product, coating the cooked product with a basting solution, grilling the basted products to obtain grilled products with searing, grill marks, and smoke aroma; and cutting the grilled product at a cutting angle into pieces.

Owner:BIG HEART PET INC

Method of making bird wing and breast products and products made in accordance with the method

A method of cutting a whole bird to form bird meat products comprises: removing a portion of each of the wings of the bird including the wing tip sections and the center, two bone sections; removing both of the breasts and the drumettes of the wings from the remainder of the bird leaving the drumettes attached to the removed breasts; and cutting through each of the removed breasts along cut lines extending approximately one third of the distance along the length of each of the removed breasts and generally parallel to the bones of the removed drumettes to create two breast products and two breast / drumette products. In one embodiment the breast products are cut in half lengthwise to form smaller breast products.

Owner:SKIPPACK CREEK CORP +1

Poultry breast meat apportioning method

InactiveUS6921326B2Increase productionUniform volumeSplitting instrumentsMetal working apparatusBiotechnologyPhysiology

A method for apportioning larger poultry breast wherein two primary meat products are produced by cutting predetermined cutlet shapes from the rearward one half of each breast half. Additionally cut are two or more preparative secondary meat products from the thicker shoulder forward region of each breast half. These preparative secondary meat products are severed horizontally in half to produce four secondary meat products.

Owner:SMITH JEFFREY P

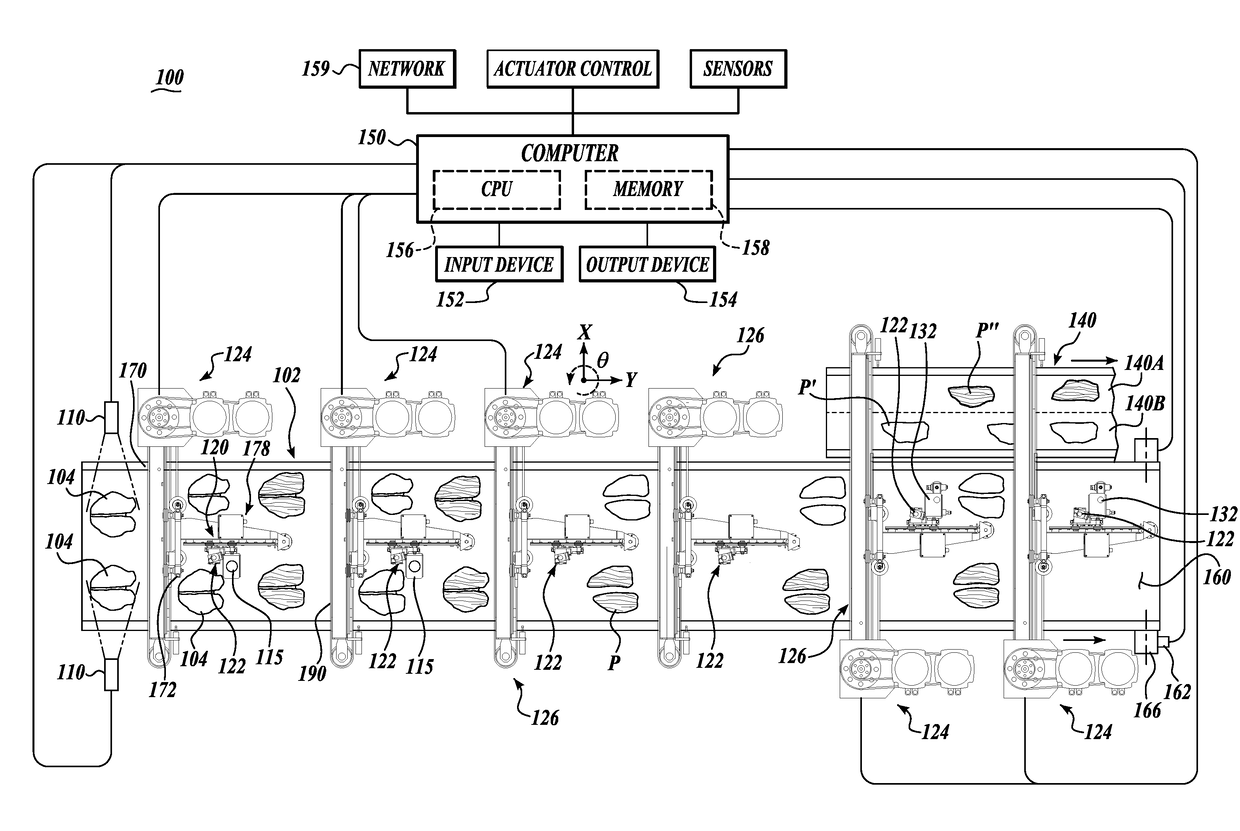

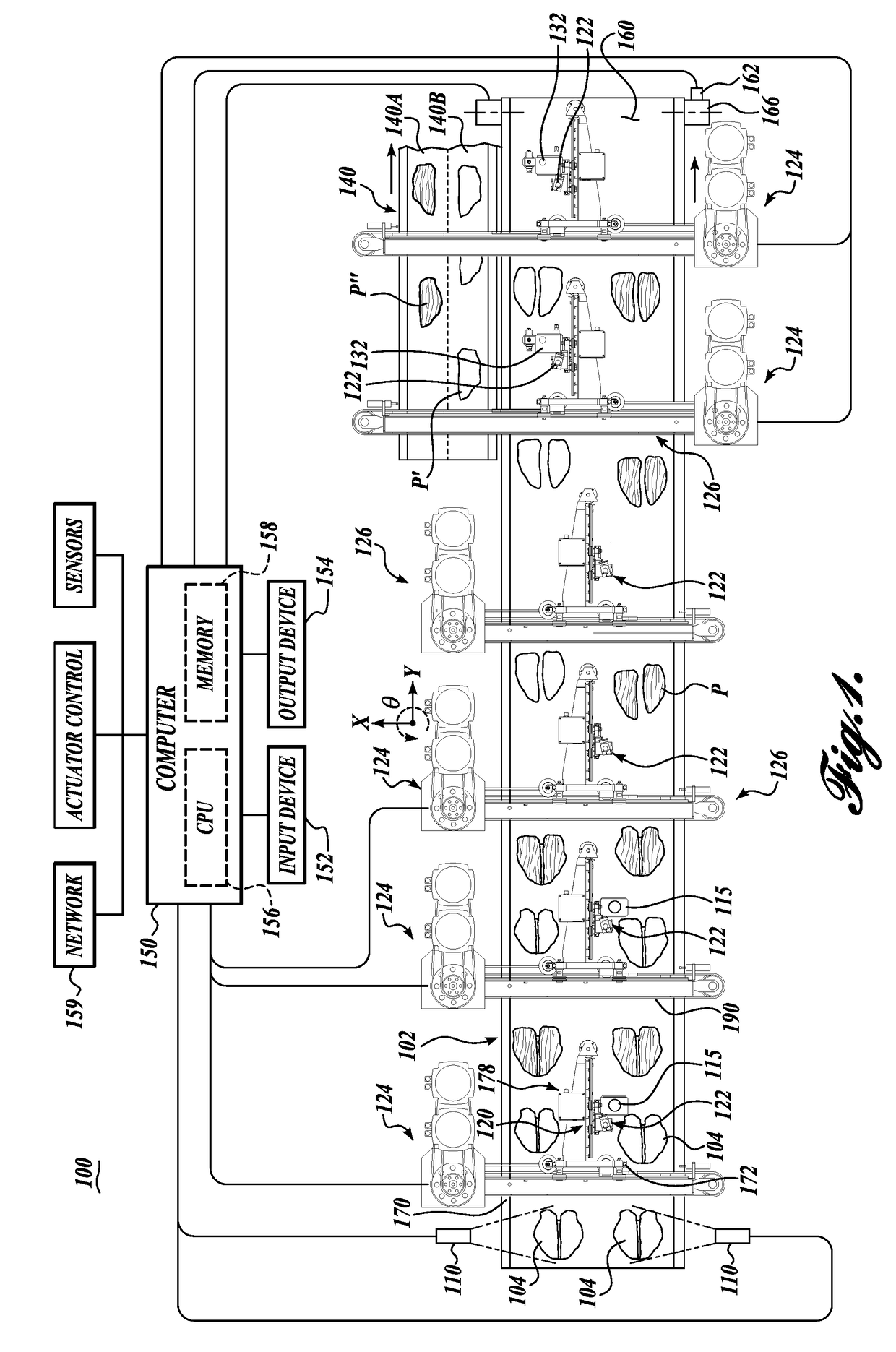

System and method for assessment of a workpiece in a continuous flow process

A system for measuring physical properties of a workpiece in motion which includes a conveyance assembly for conveying the workpiece, a scanning assembly for scanning the workpiece, and a measurement assembly for measuring at least one physical property of the workpiece while the workpiece is in motion.

Owner:JOHN BEAN TECH CORP

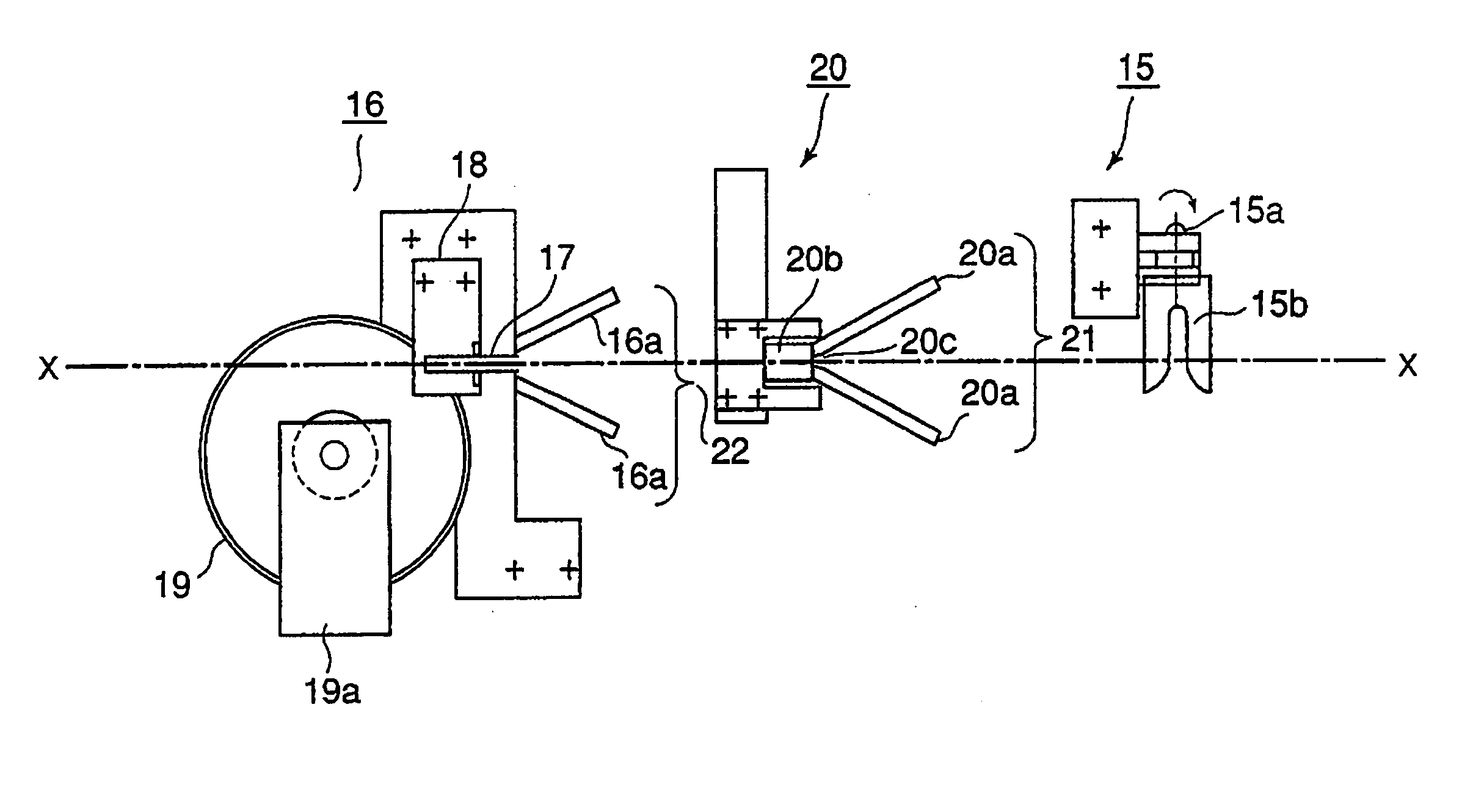

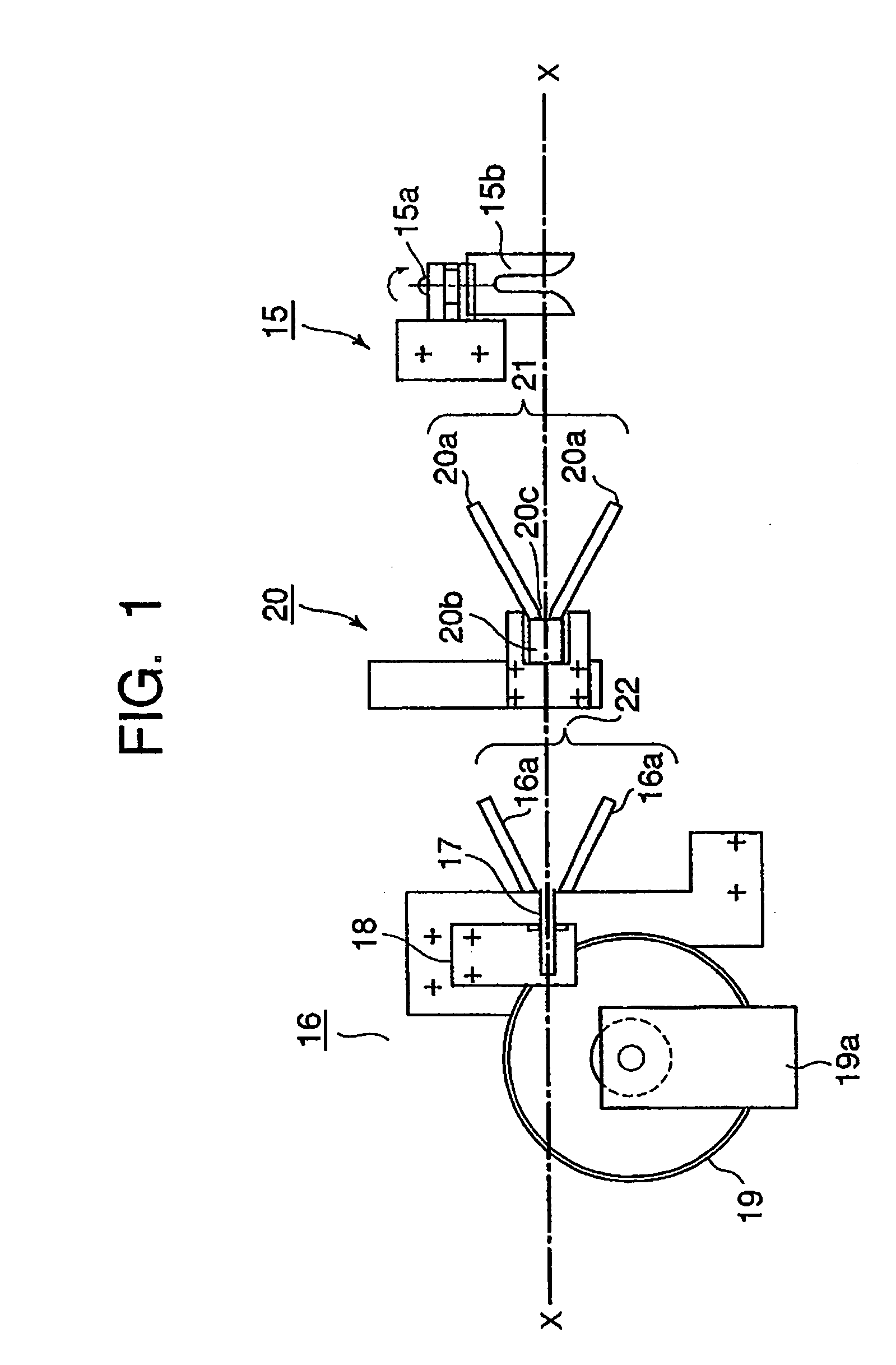

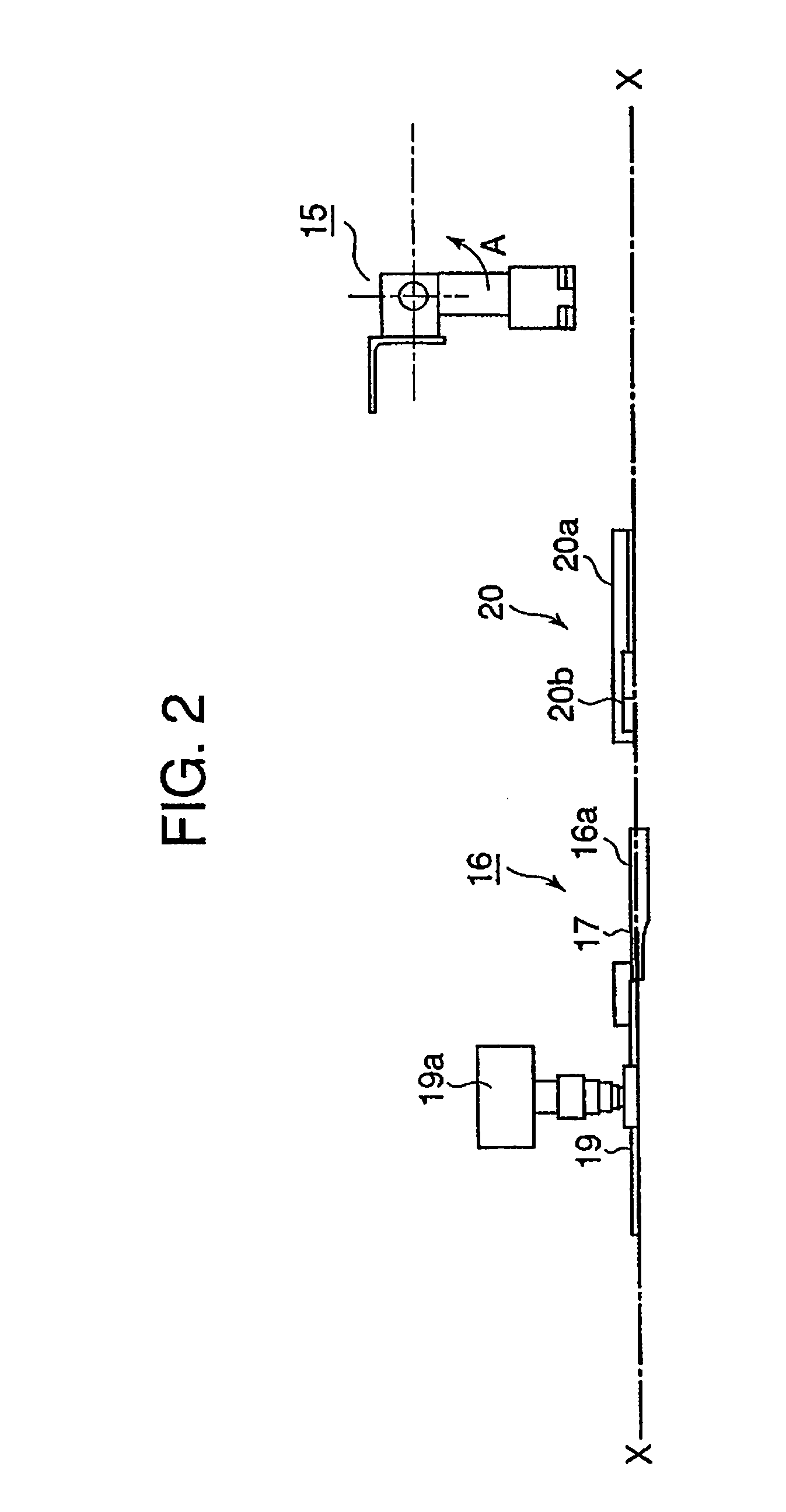

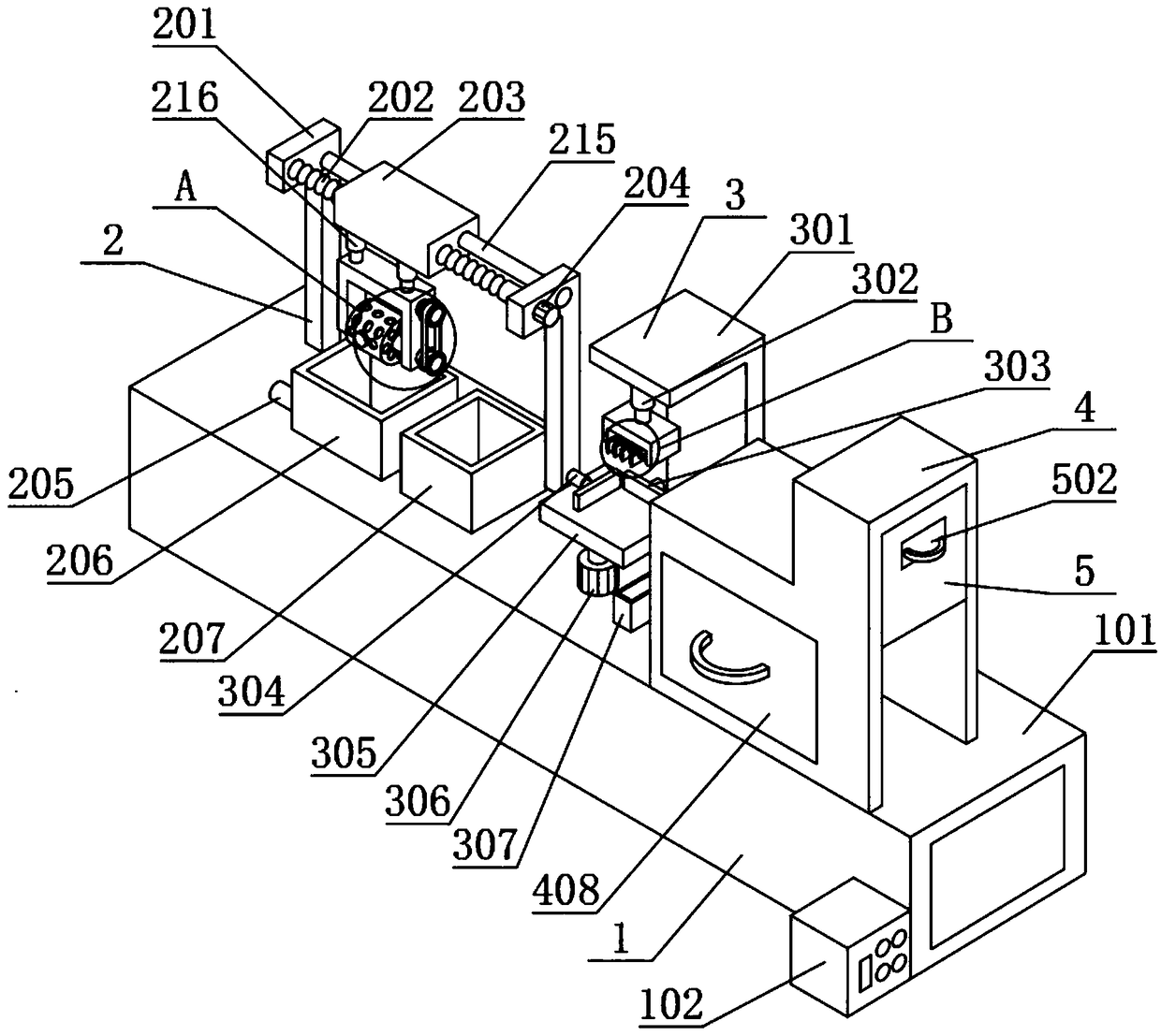

Method and apparatus for separating thigh meat and oyster meat

A method and apparatus are provided for separating thigh meat and oyster meat from the thighbone automatically without detecting the boundary of the white cap at an end of the thigh bone and the meat including thigh meat and oyster meat and inserting a cutter into the detected boundary part in the final operation of deboning a thigh-with-bone of an edible beast and bird. The apparatus of the invention for separating thigh meat and oyster meat is composed of a clamper 15, a Y-shaped guide-with-a-groove 20, and a Y-shaped guide-with-a-cutter 16 downstream of the guide 20 provided on the transfer line of the clamper, both guides being provided such that the open end side of Y-shape of each guide is directed toward upstream of transfer of the clamper.

Owner:MAYEKAWA MFG CO LTD

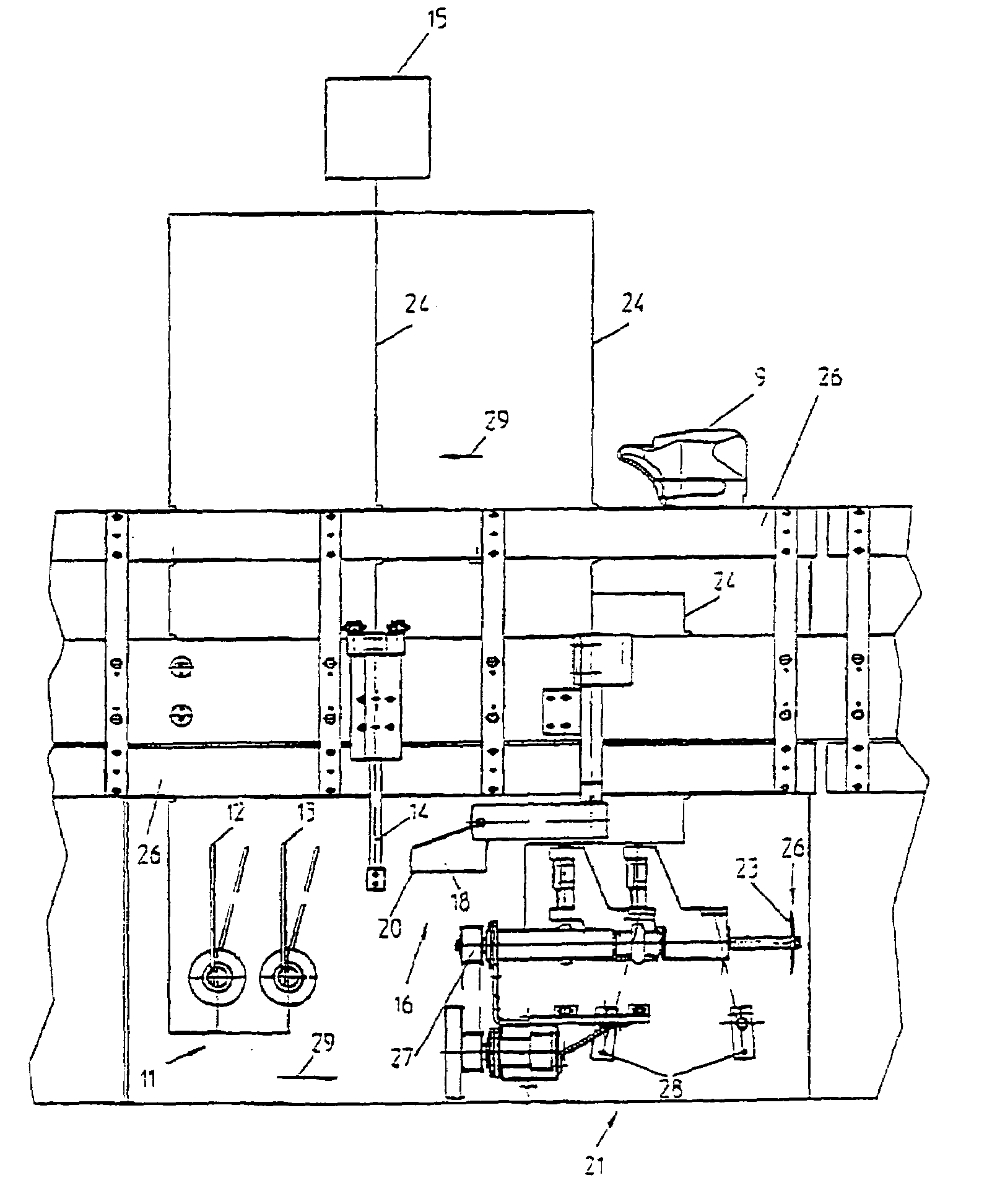

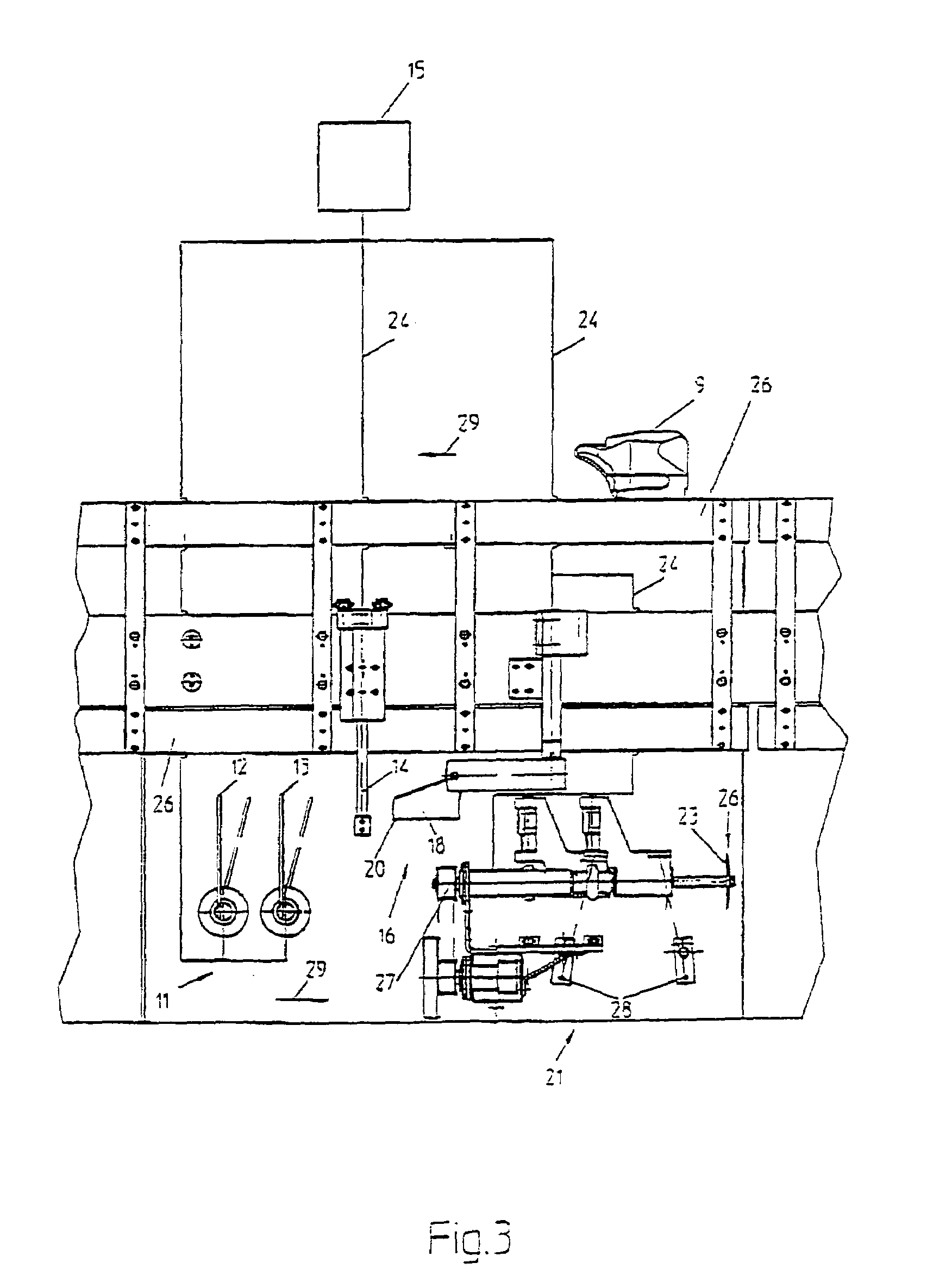

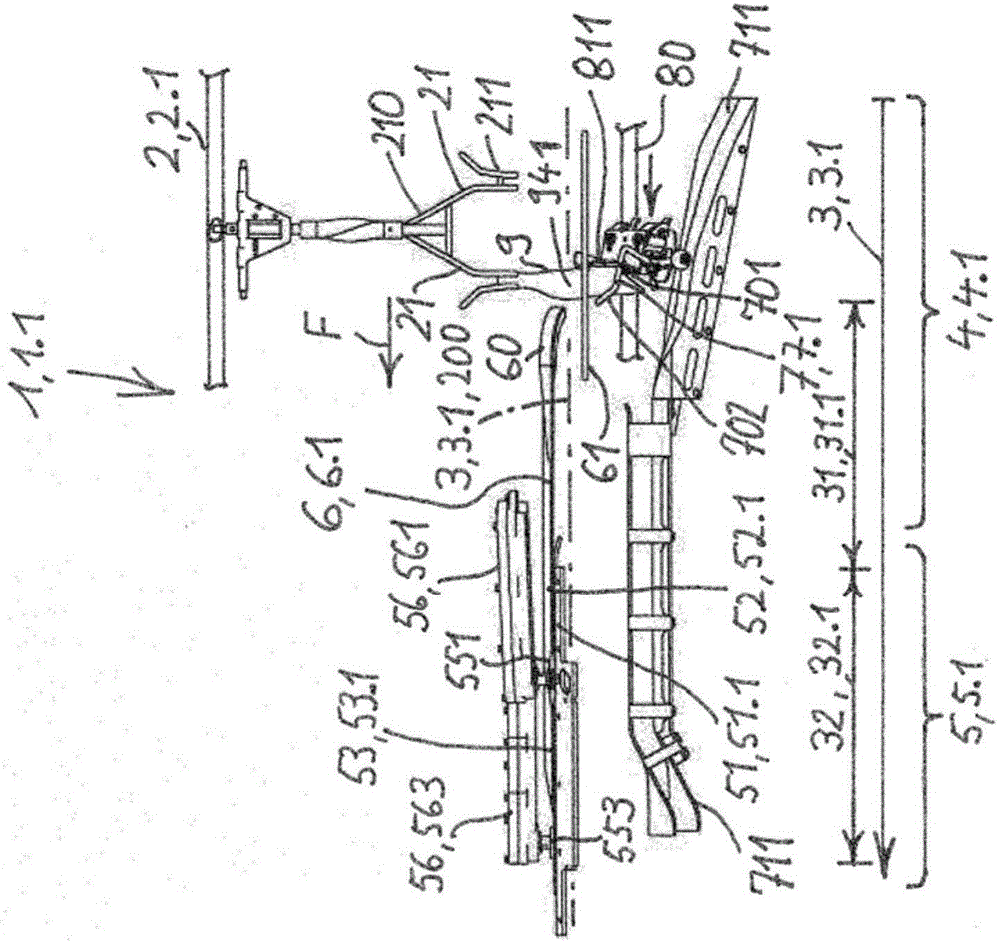

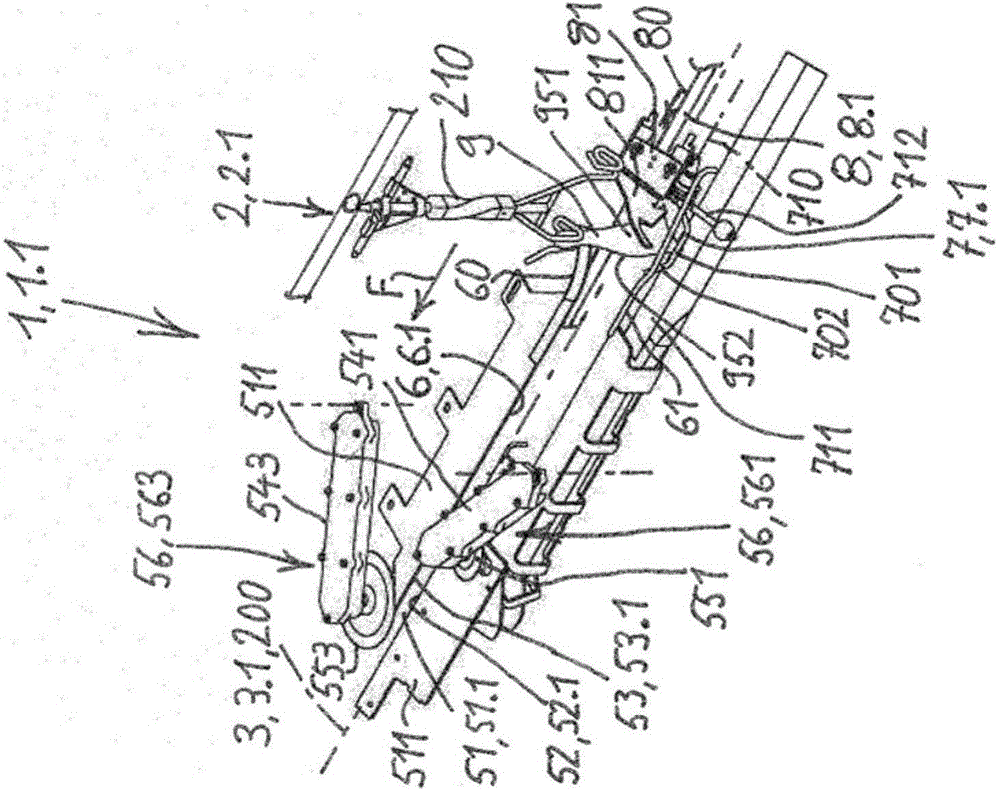

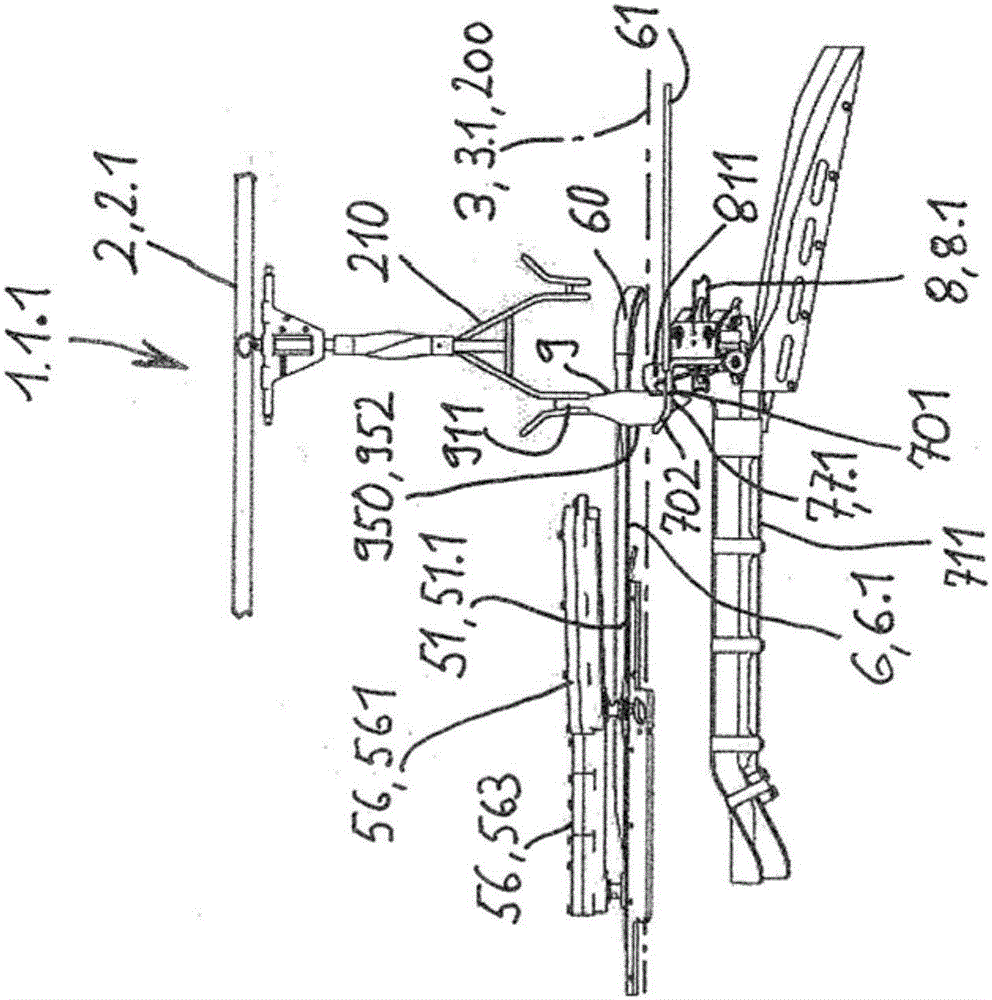

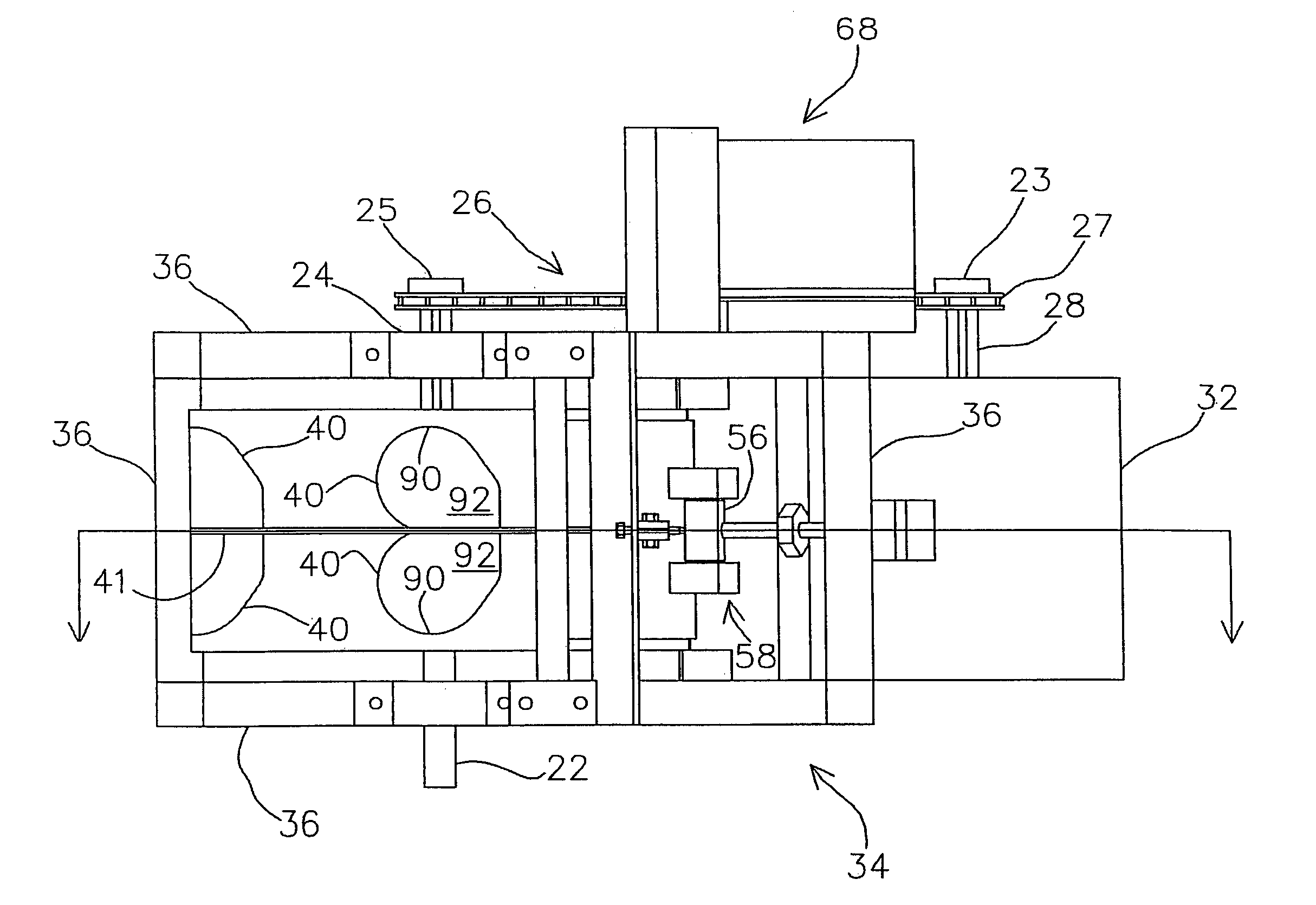

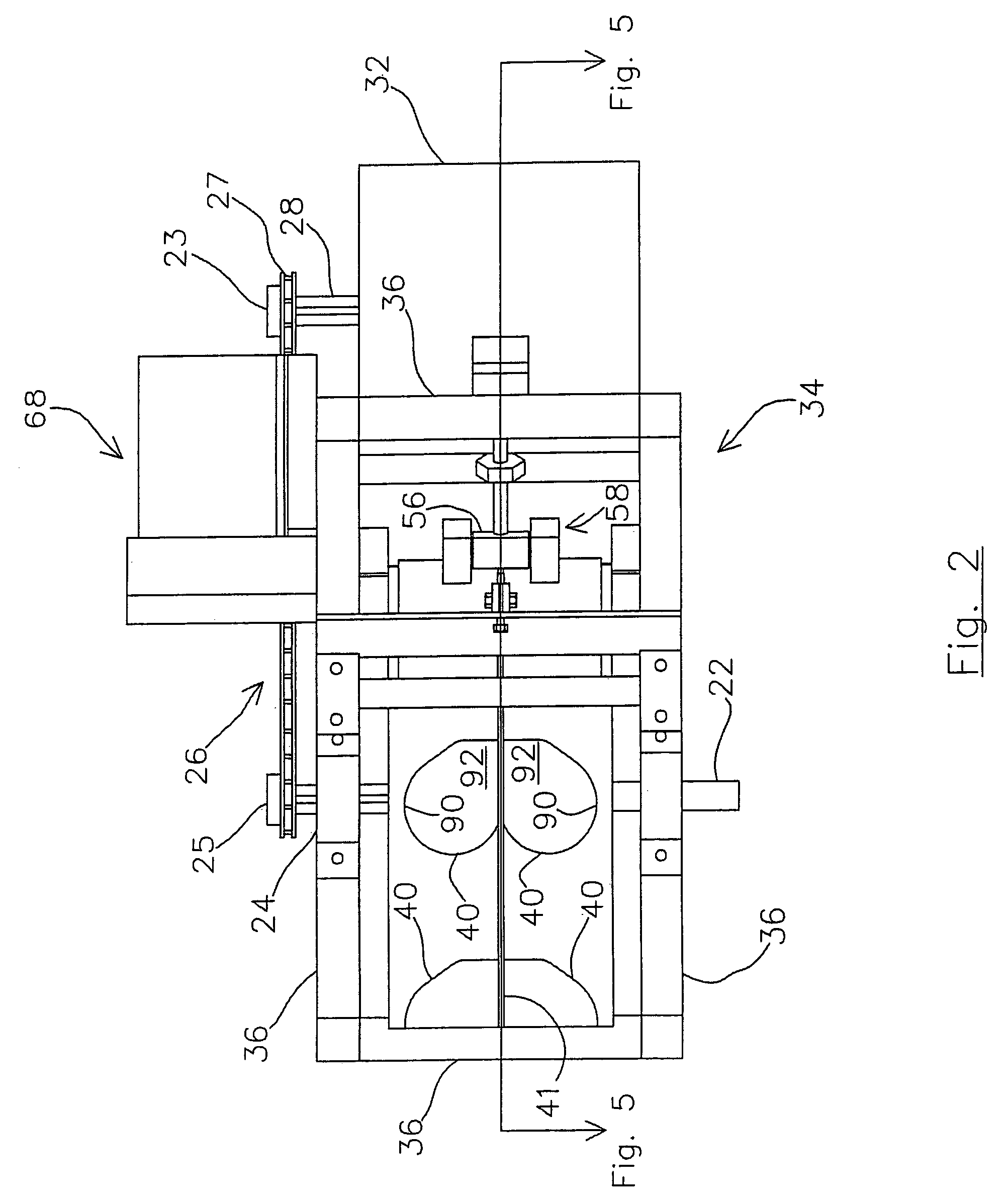

Positioning device for positioning poultry legs conveyed in single file in the conveying direction along a conveyor section and the method comprising said positioning for removing the thigh meat from poultry legs

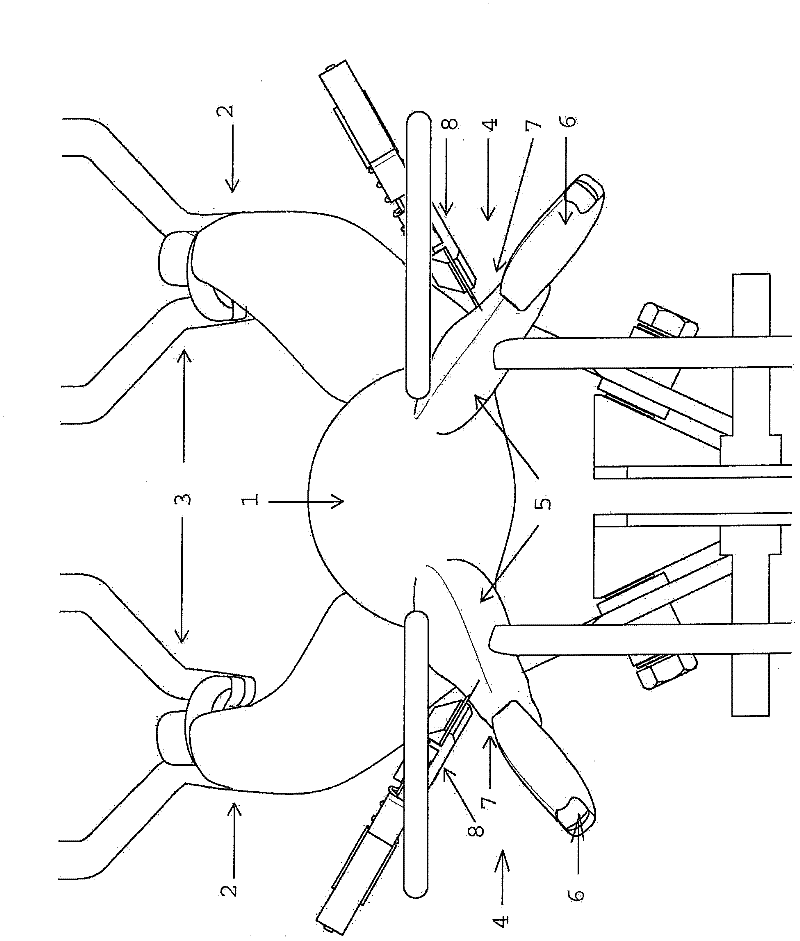

A positioning device (1) for positioning poultry legs (9) conveyed hung in single file comprises a flexing device (4) for flexing and positioning the poultry legs and a stationary holding and guiding device (5). The flexing device (4) forms a hooking device for suspending the poultry leg (9) at the region of the knee joint (93) in a holding and guiding slot (51) of the holding and guiding device (5). Travelling positioning elements (7) are formed by driven press elements which grip the poultry leg (9) from below on an axial leg side (940) to flex and lift said leg. Each travelling positioning element (7) forms, with a stationary positioning element (6), a functional pair of positioning elements (6, 7). One of the two positioning elements (6, 7) engages in the hollow of the knee (95) of the poultry leg (9) while the other positioning element (6.2; 7.1) is configured for placement on the thigh (92) on the front side (941) of the leg. Processing stations (56) can be arranged along the holding and guiding slot (51). In a method, carried out during the conveying, for removing the thigh meat from the poultry legs (9) conveyed in single file, said poultry legs are axially conveyed in a first said positioning device (1.1) with a transverse leading lateral side (950) of the leg and in a second said positioning device (1.2) with an axially leading knee cap side (940) of the leg. Cuts are made at the front side (941) of the leg and at the back side (942) of the leg along the first stationary holding and guiding slot (51.1). Cuts are made at the lateral sides (950) of the poultry leg along the second stationary holding and guiding slot (51.2), and the thigh meat (922) is pushed to the proximal end of the thigh bone (921).

Owner:BAADER FOOD SYST DENMARK AS

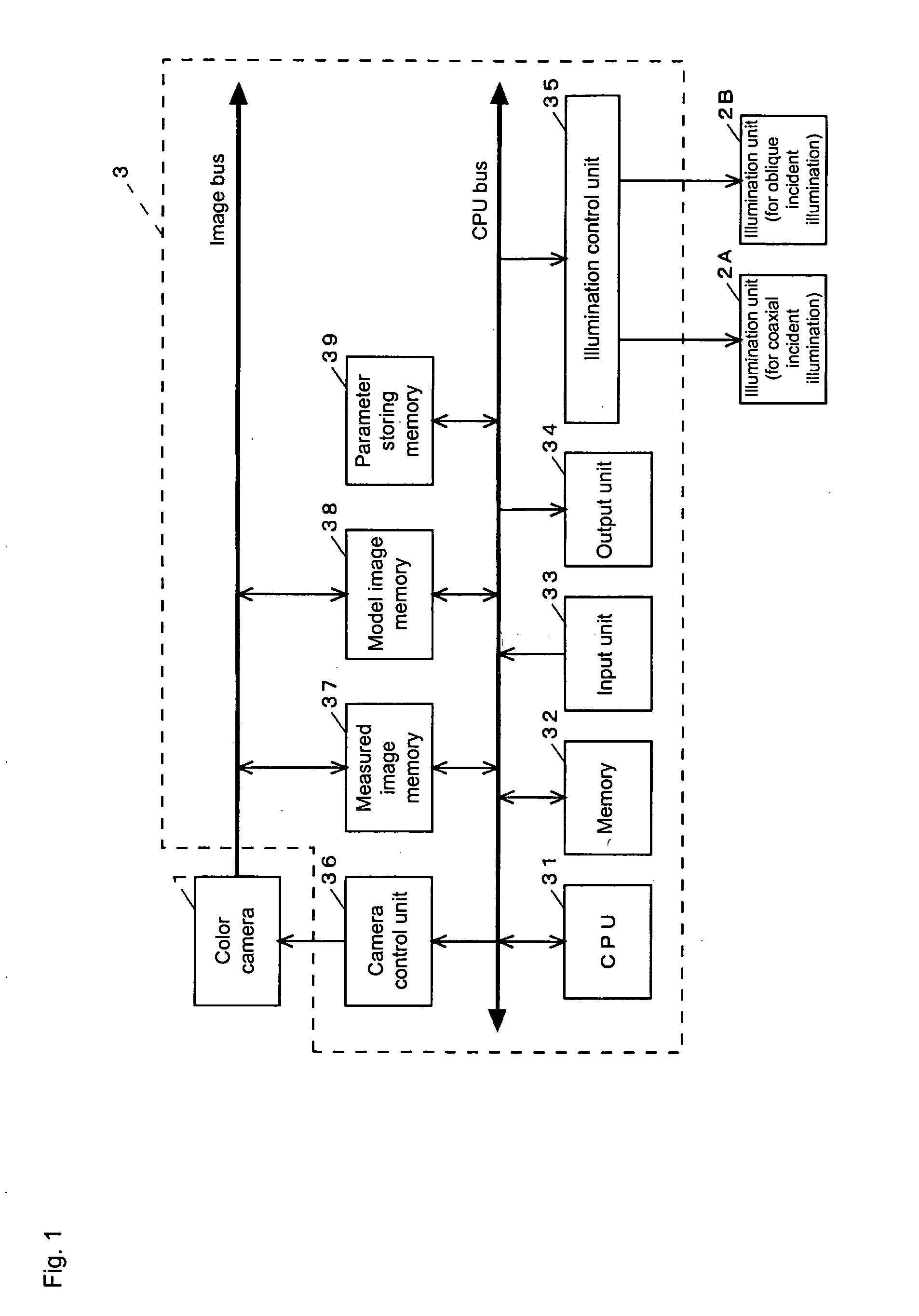

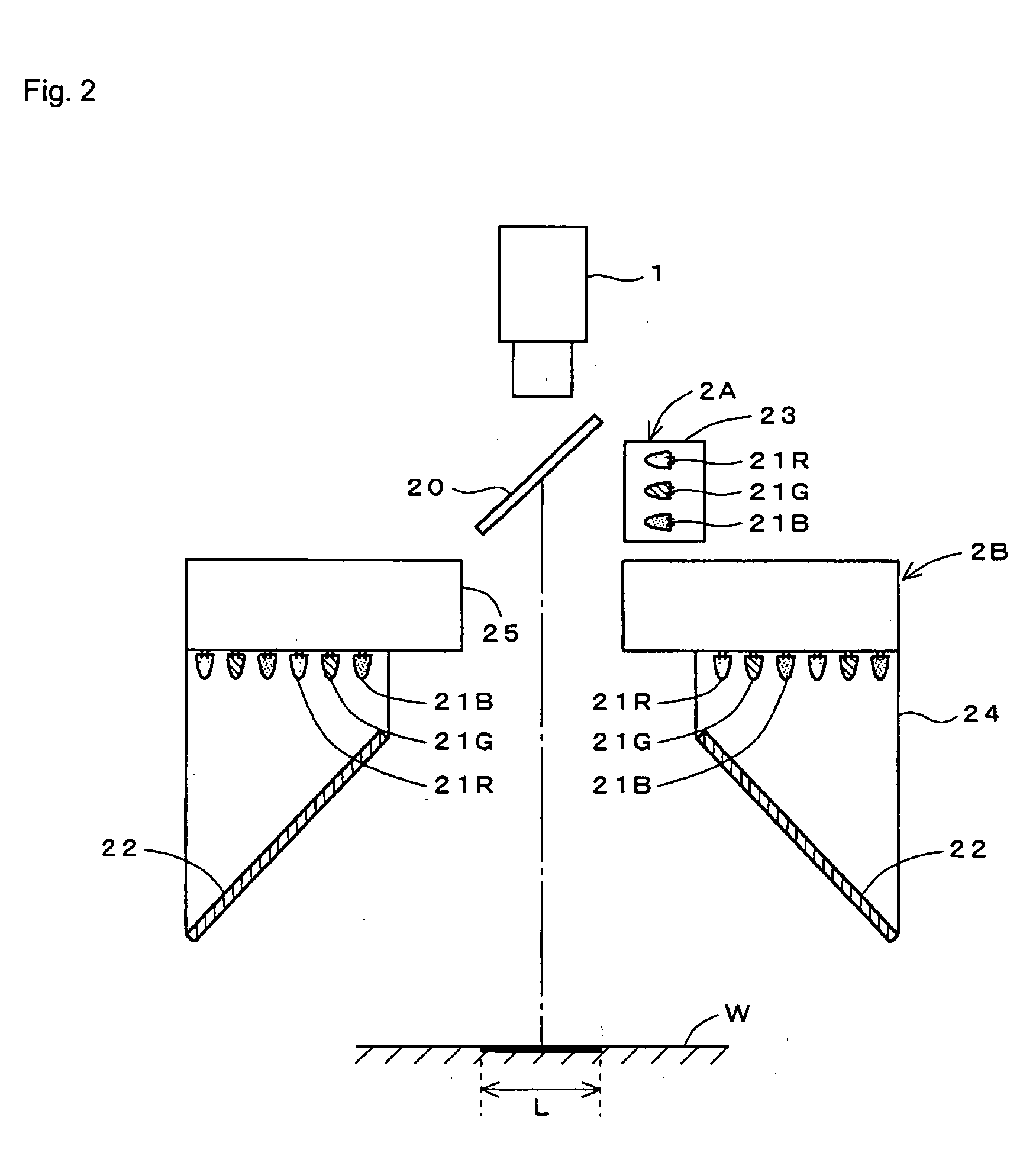

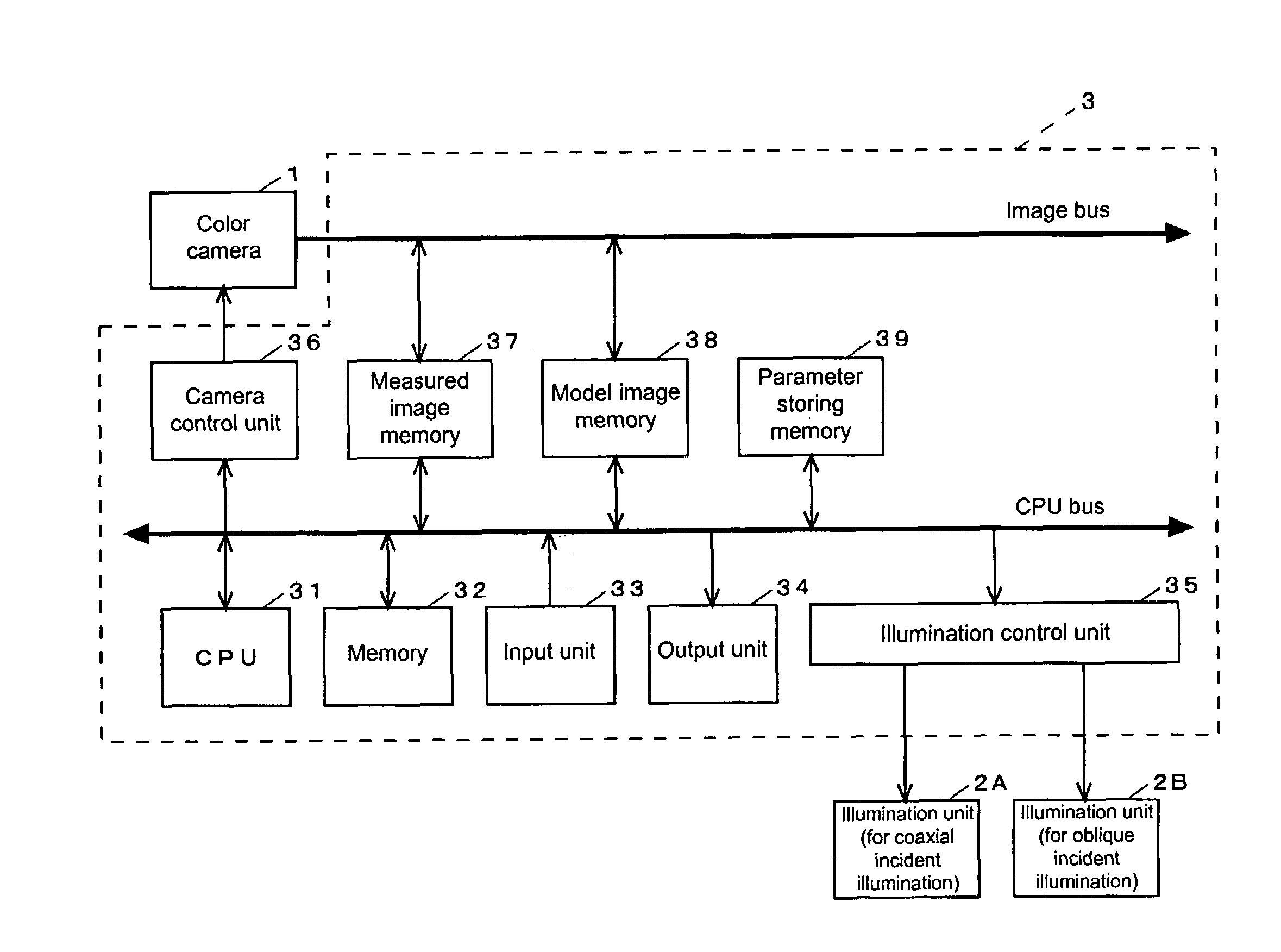

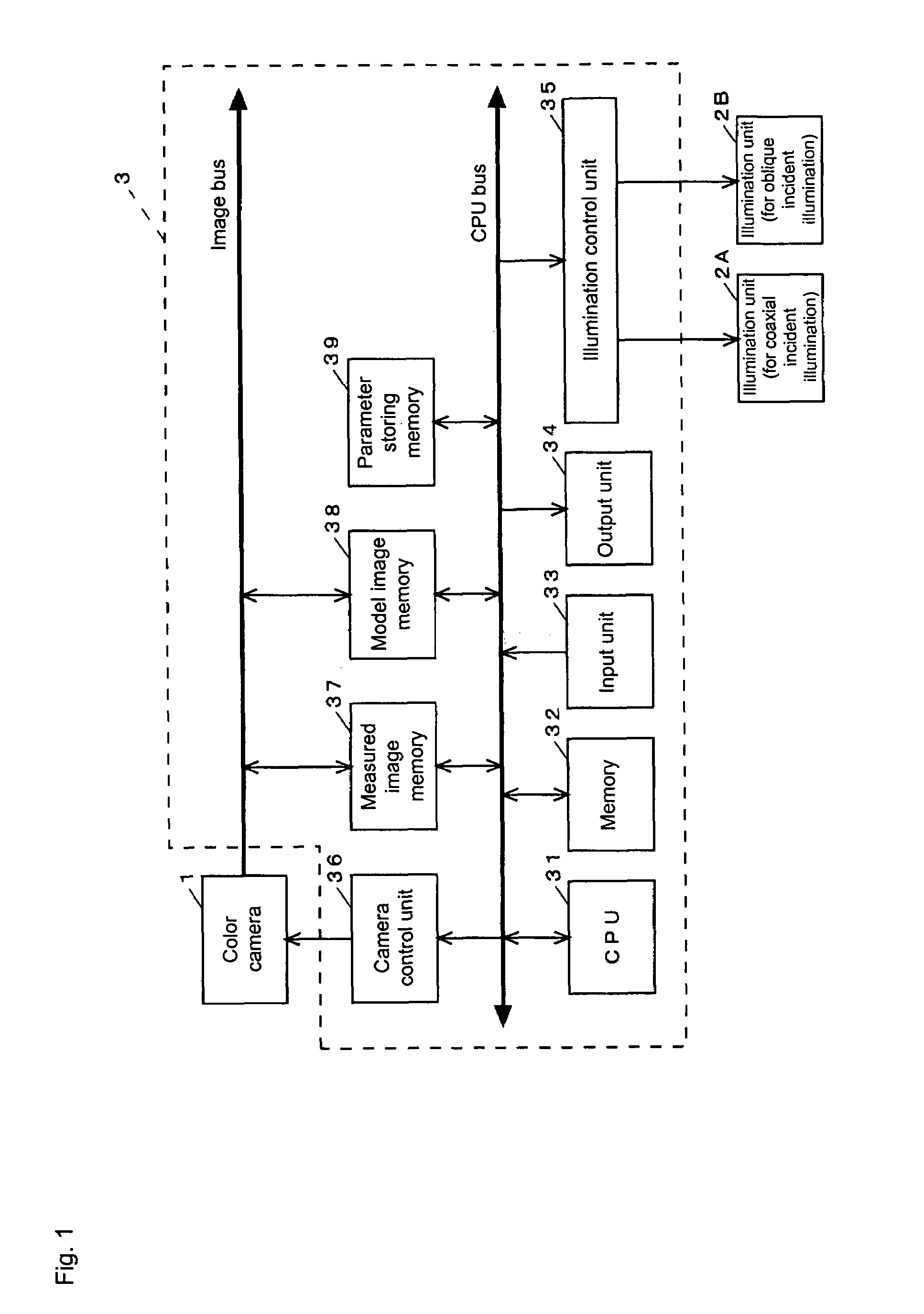

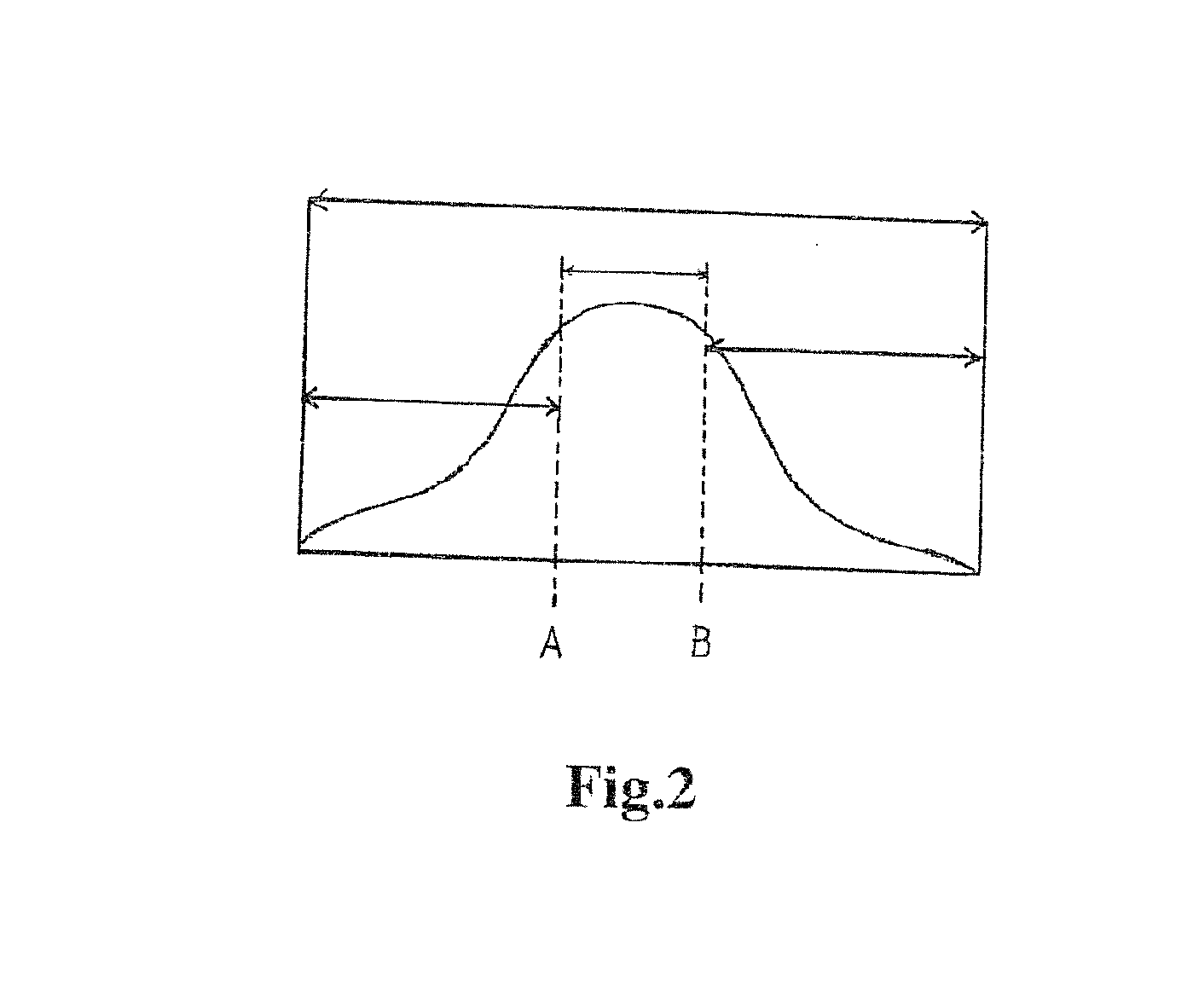

Defect inspection method and defect inspection system using the method

InactiveUS20060251315A1Efficient detectionImprove accuracyImage enhancementImage analysisOptoelectronicsLight source

Owner:ORMON CORP

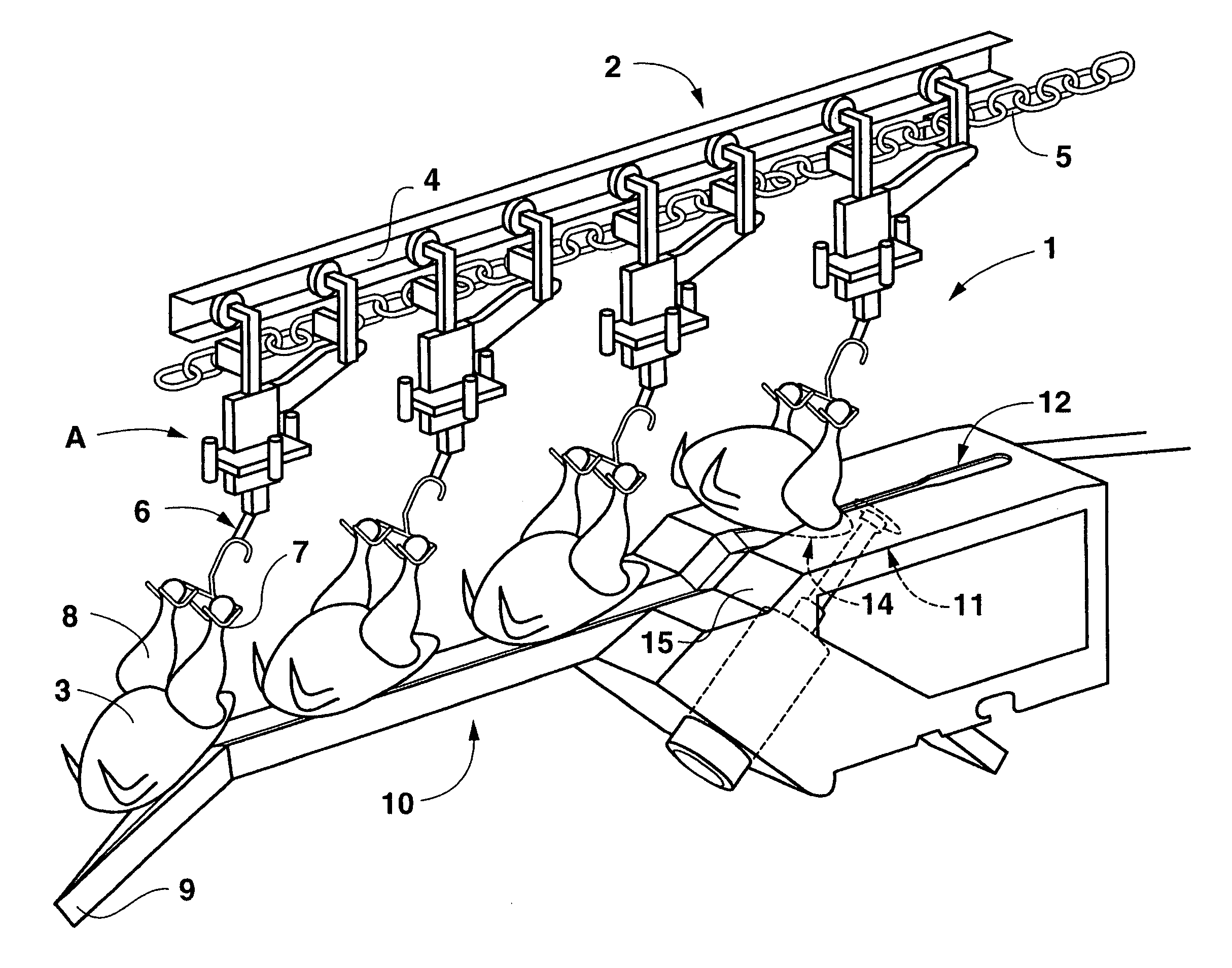

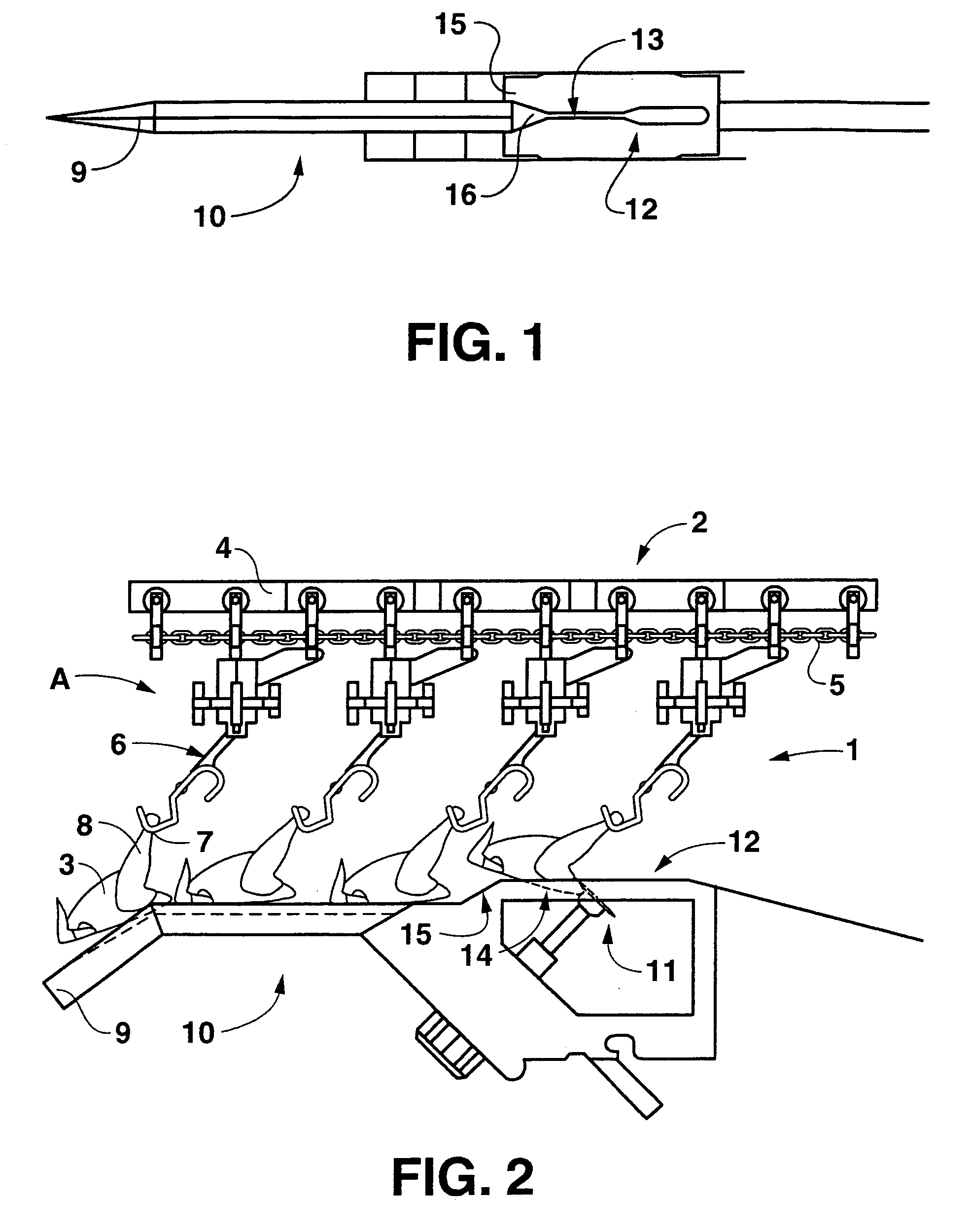

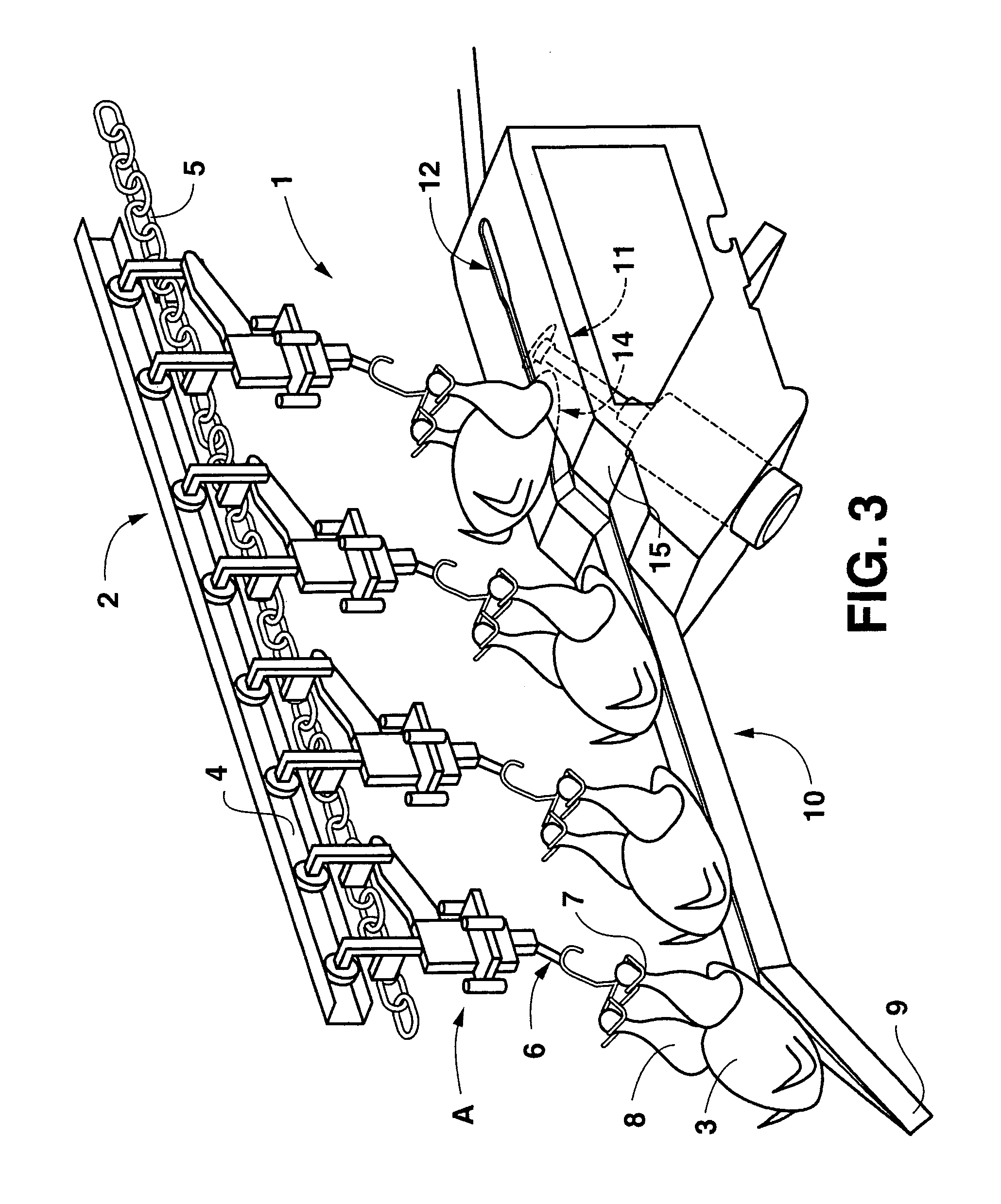

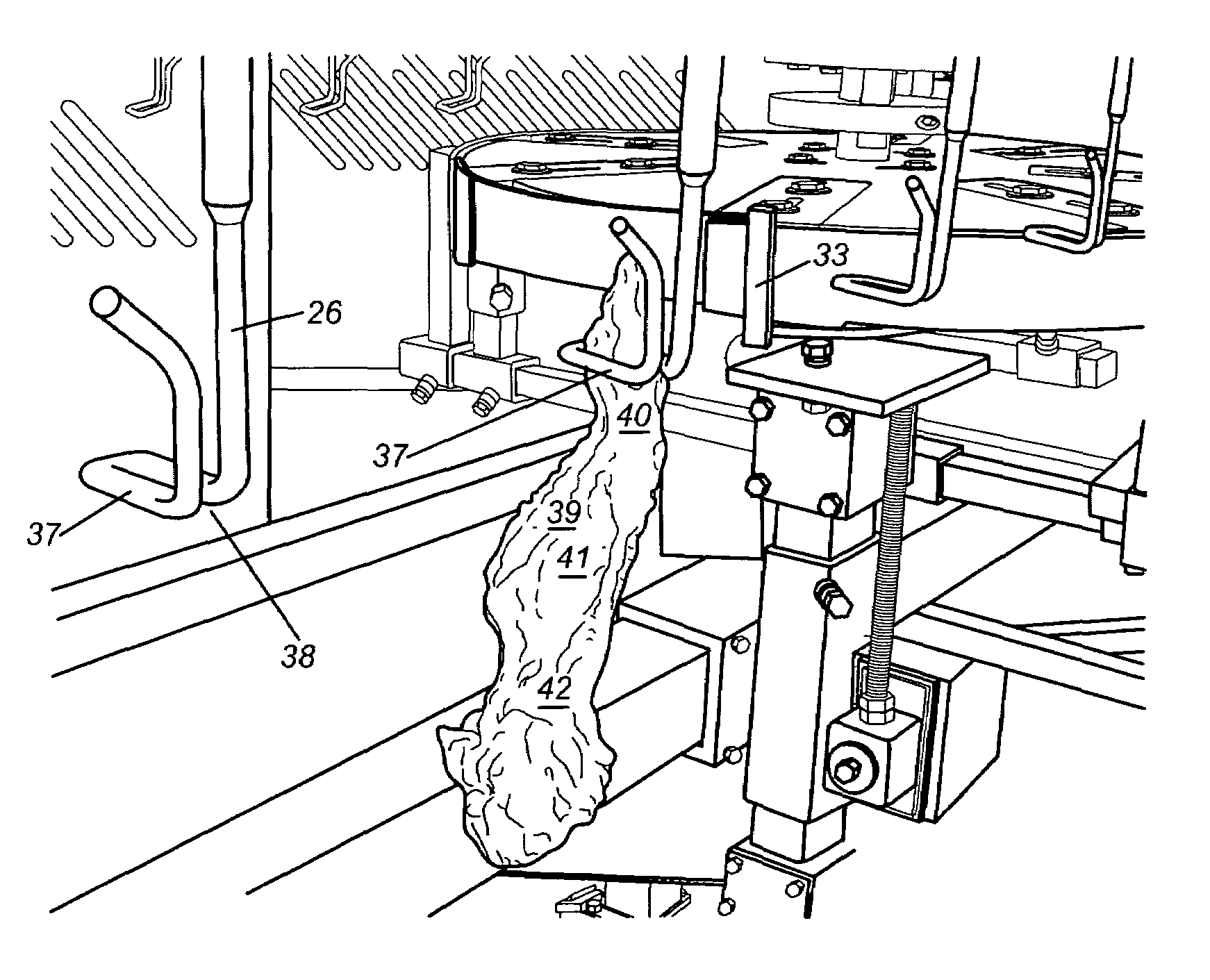

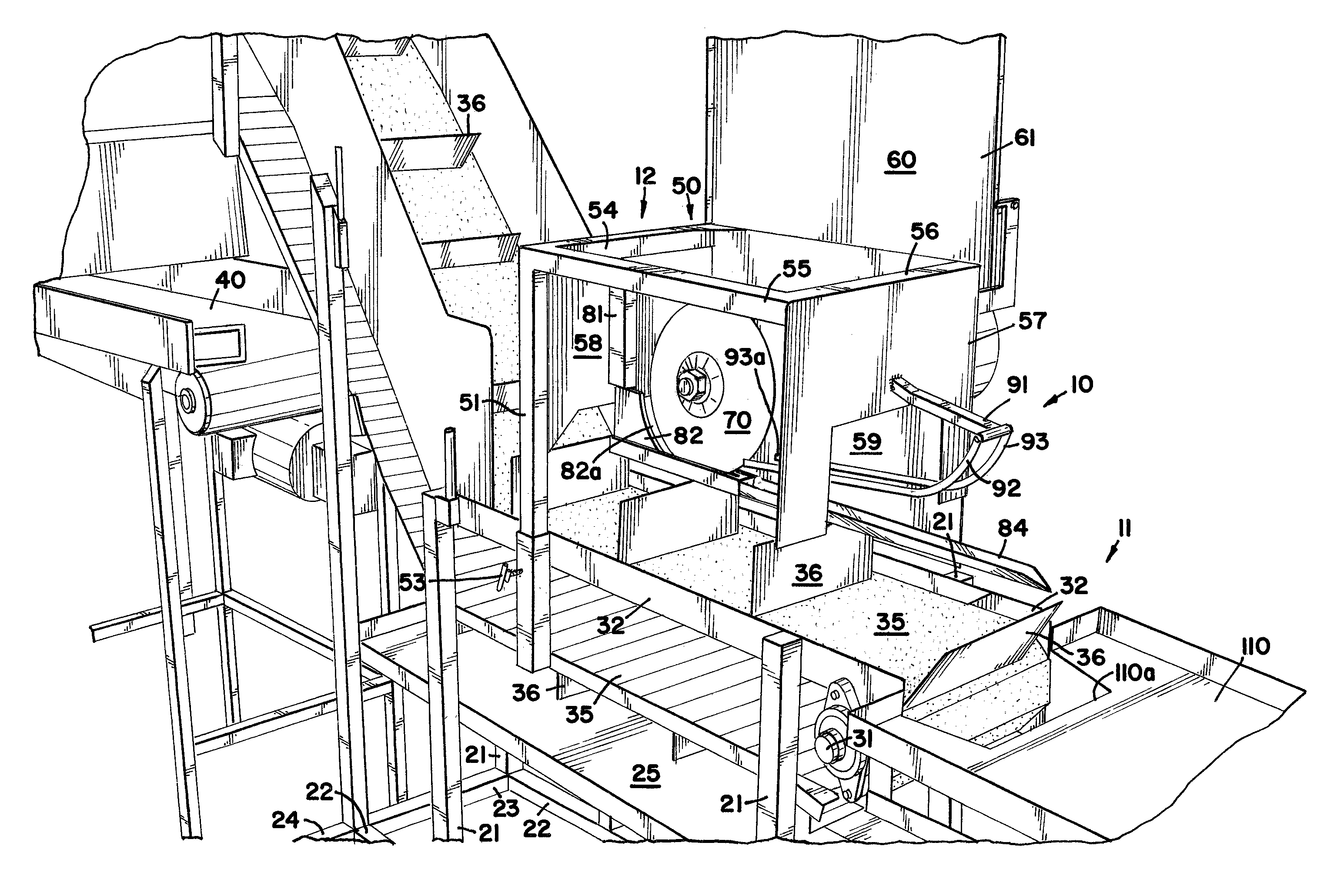

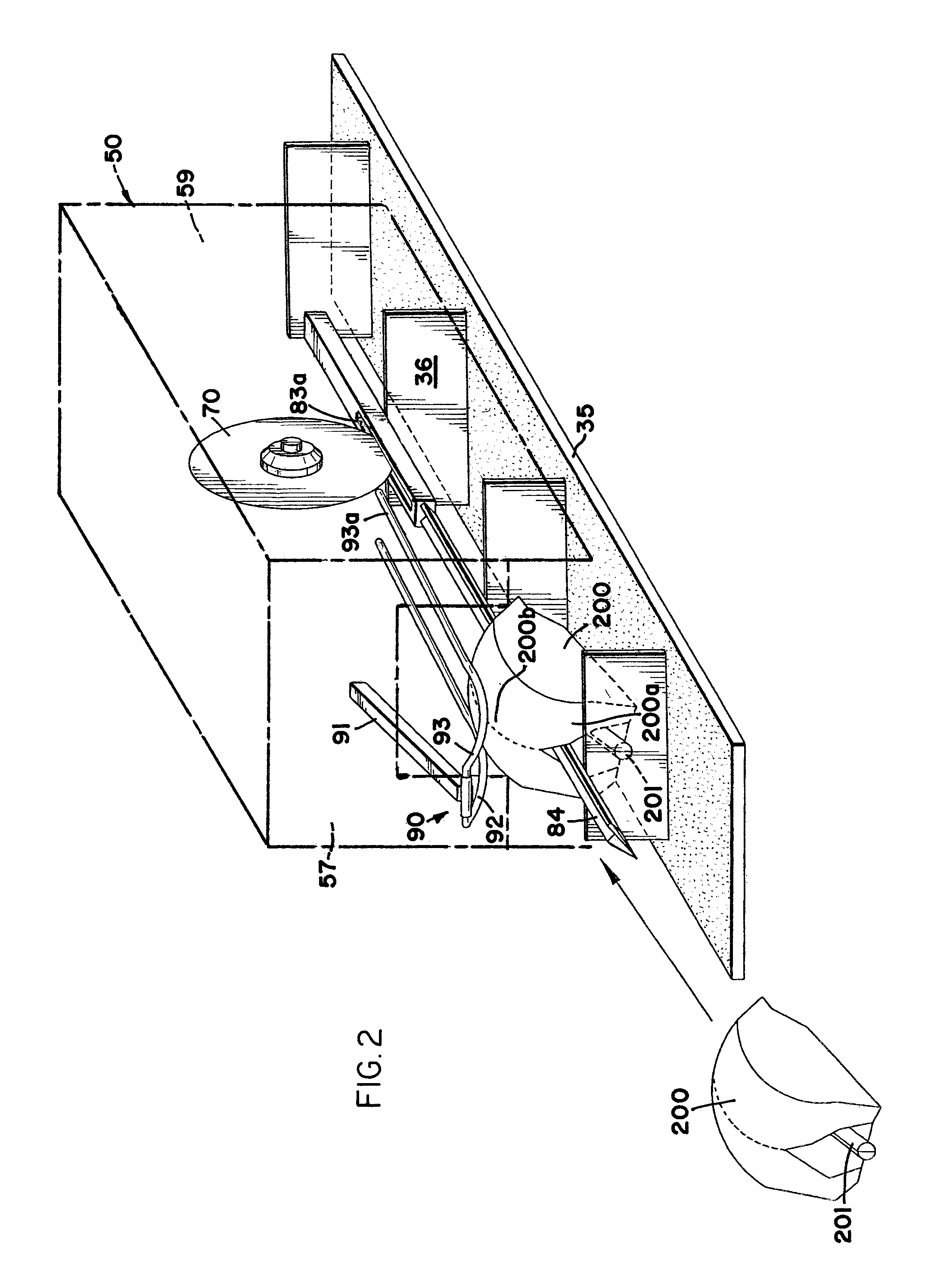

Apparatus and method of edible feet harvest and paw production

InactiveUS20030190880A1Rule out the possibilityEliminate the problemMeat processing plantsSlaughtering accessoriesAbdominal eviscerationEngineering

A method and apparatus for partially cutting hock joints, and letting feet remain attached to the rest of the carcass by skin and one or more tendons, exposing the hock joint by folding feet, and hanging the carcasses in the evisceration shackles by hock joints, the method unambiguously ensures that if a carcass is condemned by an Inspector, the feet belonging to that carcass are condemned as well. Furthermore, this invention solves the even more intractable problem of capturing folded feet, separating feet from the carcass while leaving the carcass still hanging in the shackles, transferring feet into an infeed paw cutter wheel, and cutting knuckle portion to produce chicken paws ready for further processing.

Owner:TYSON FOODS

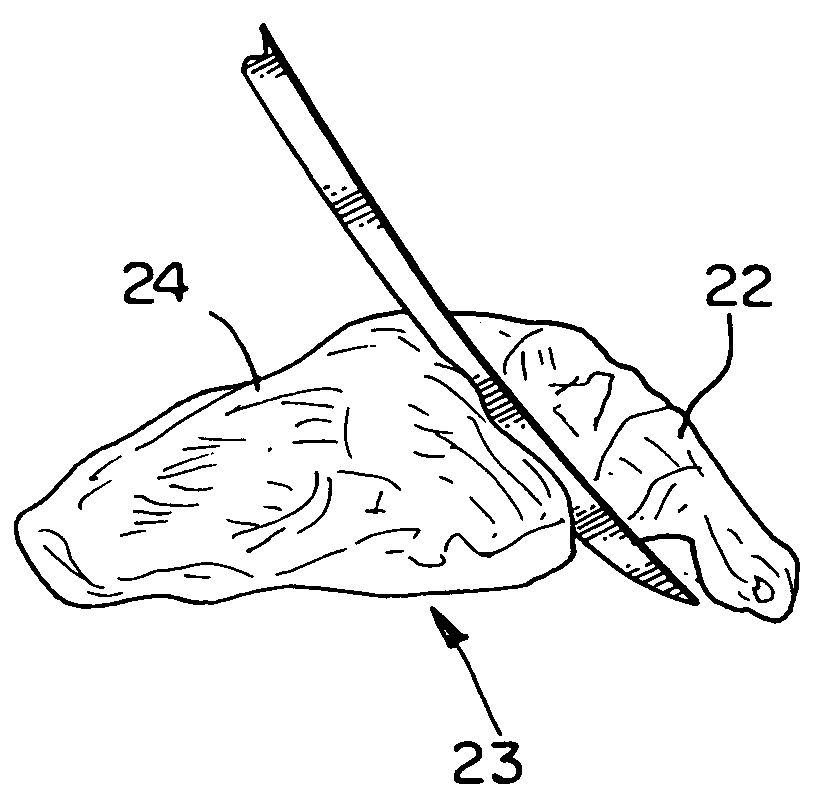

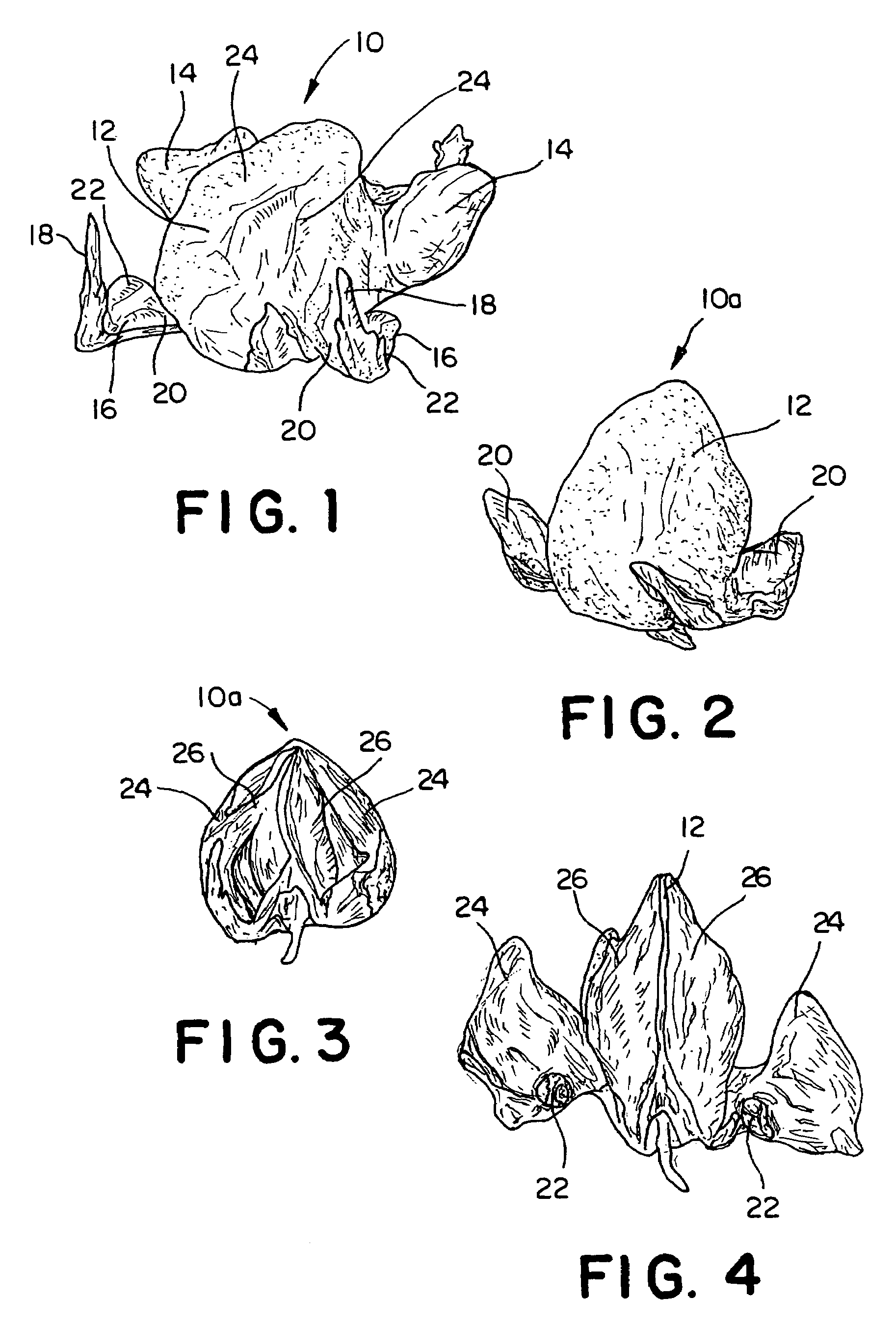

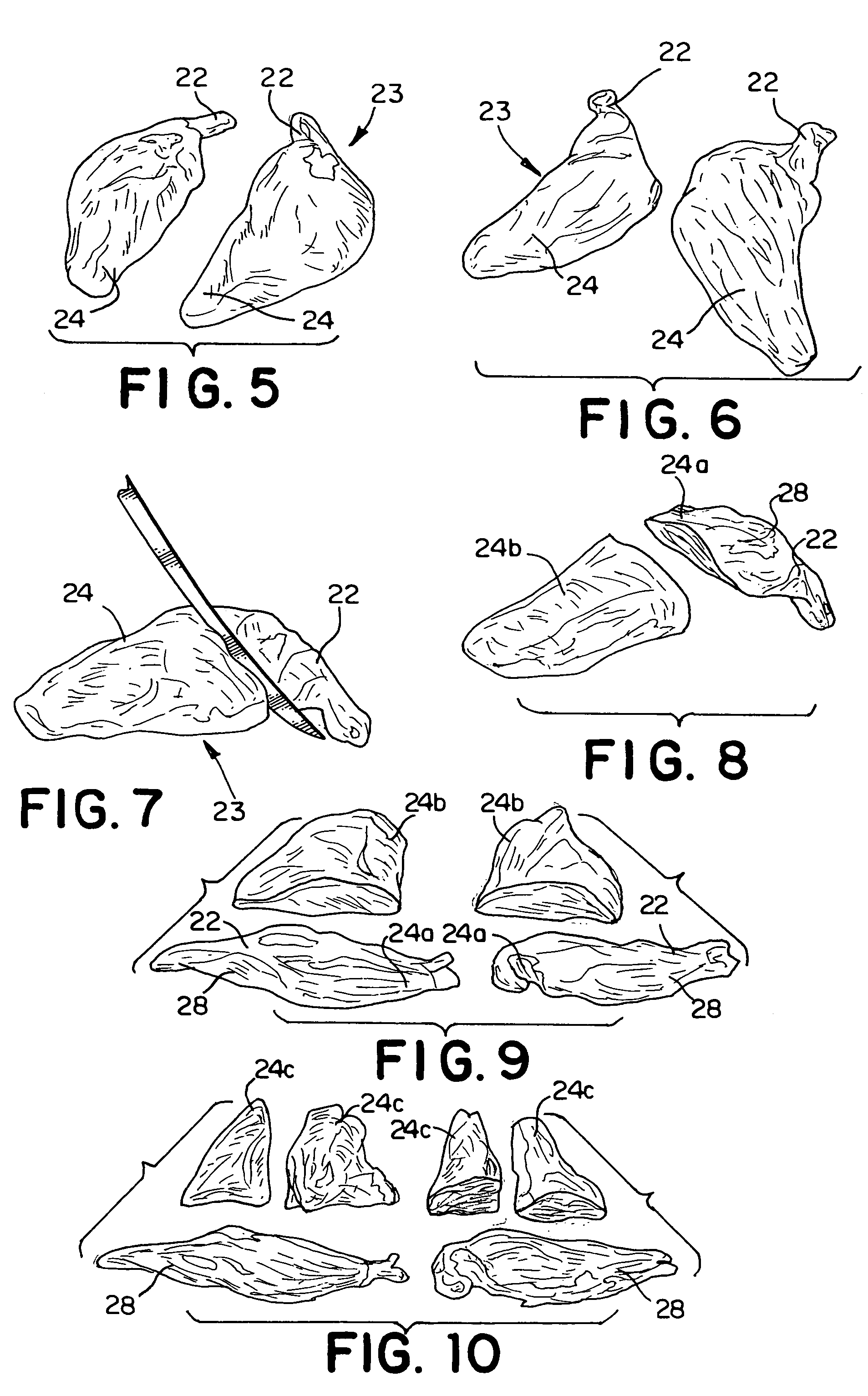

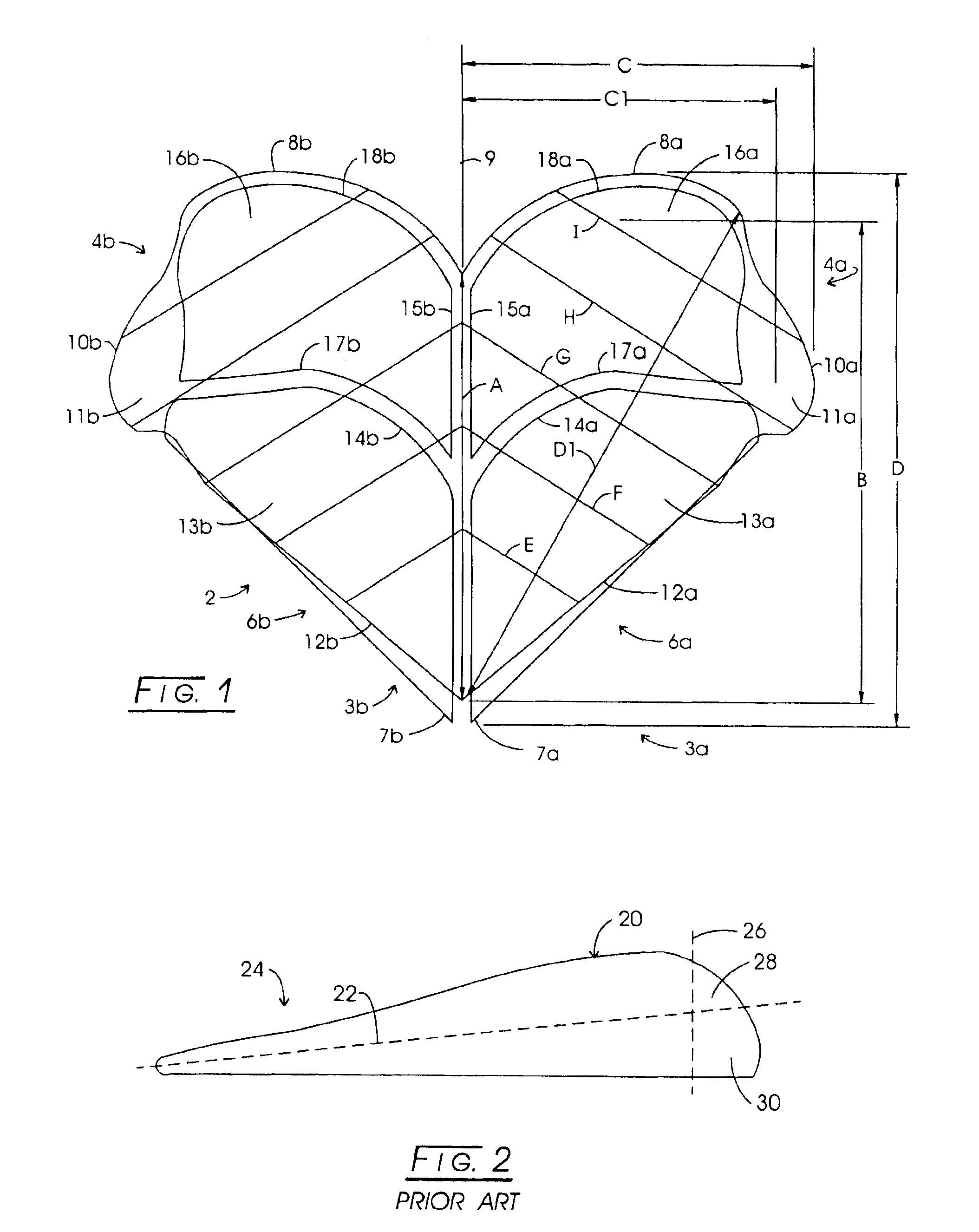

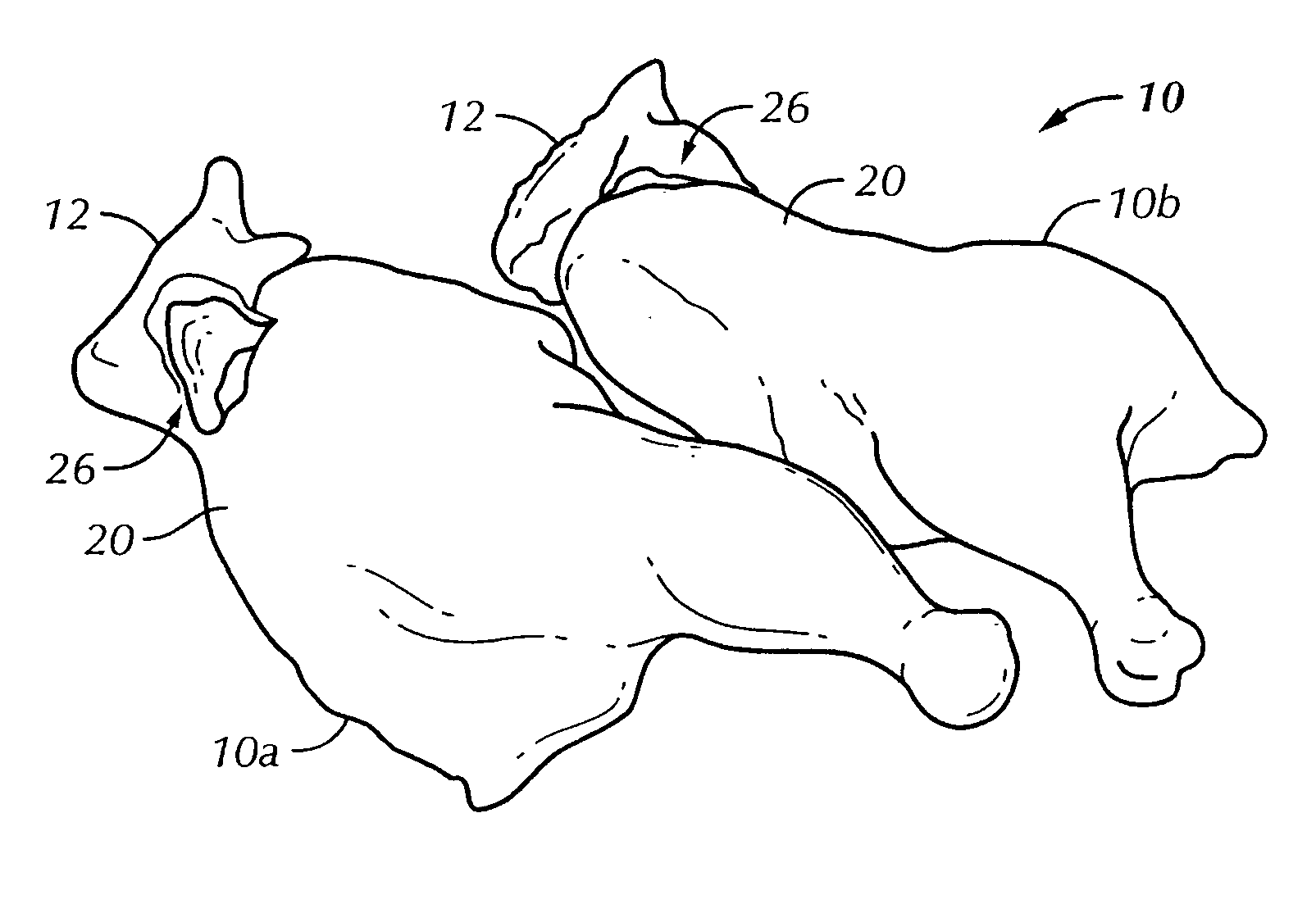

Method of preparing a bird for grilling and resulting bird product

A method for preparing a whole bird for grilling comprises removing the tips from each of the wings of the bird and cutting a notch into each of the joints of each of the wings of the bird. The backbone and attached neck are removed from the bird by cutting along both sides of the backbone where the backbone meets the ribs of the bird. Excess skin and fat are removed from the bird proximate the thighs and the skin is removed from the bird around the breasts so that the whole bird is separated into two relatively flat halves. A notch is cut into the knee joint between each of the drumsticks and thighs of the bird and each of the thighs is partially separated from the rest of the body of the bird at the hip joint.

Owner:BANK OF AMERICA NAT TRUST & SAVINGS ASSOC +1

Poultry breast portion sizing apparatus

ActiveUS7204748B2Highly uniform in shape and weightIncrease profitabilityMeat processing plantsDividing poultryPortion sizeMechanical engineering

Owner:PRIME EQUIP GRP LLC

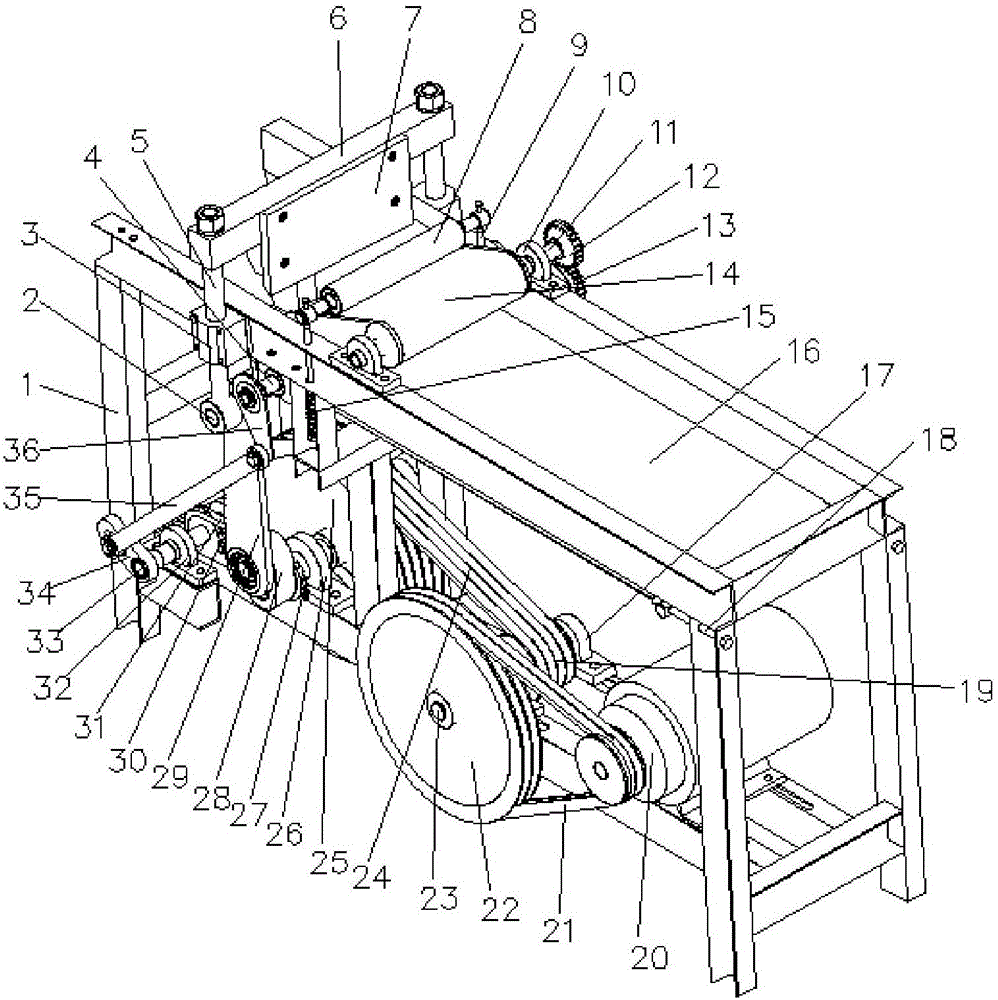

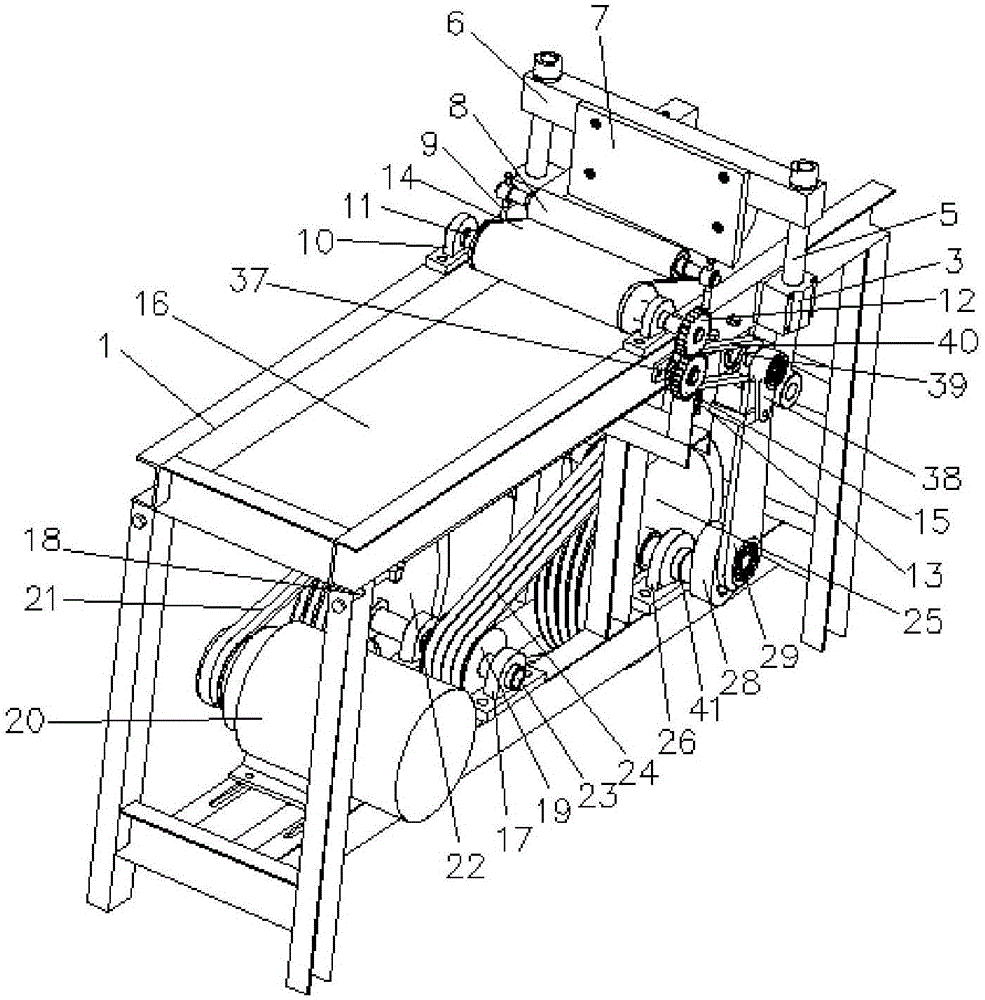

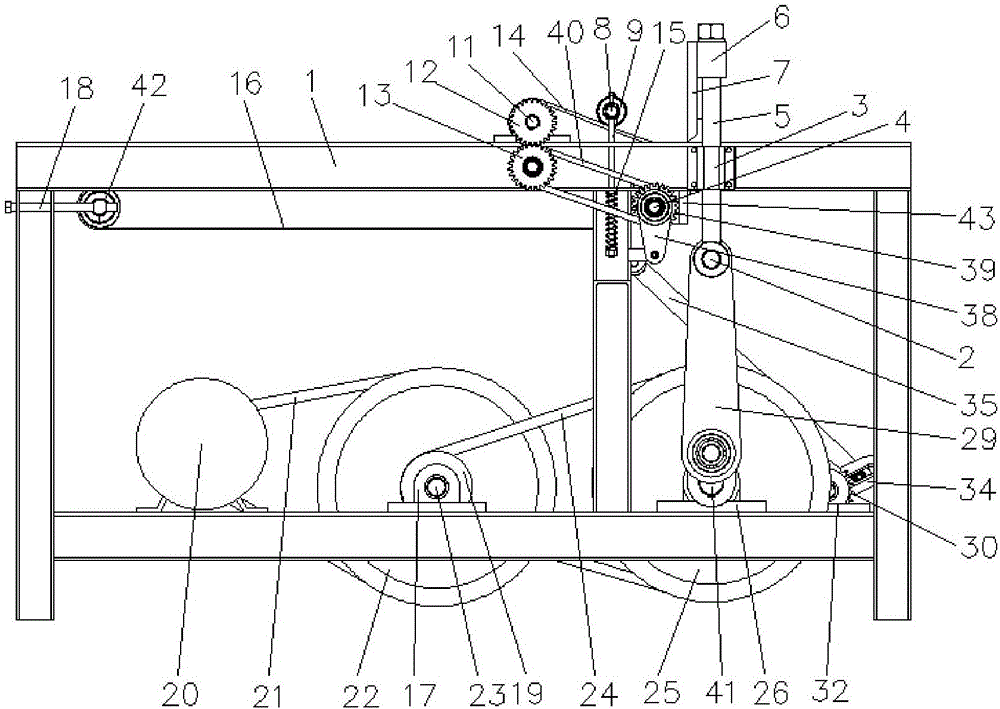

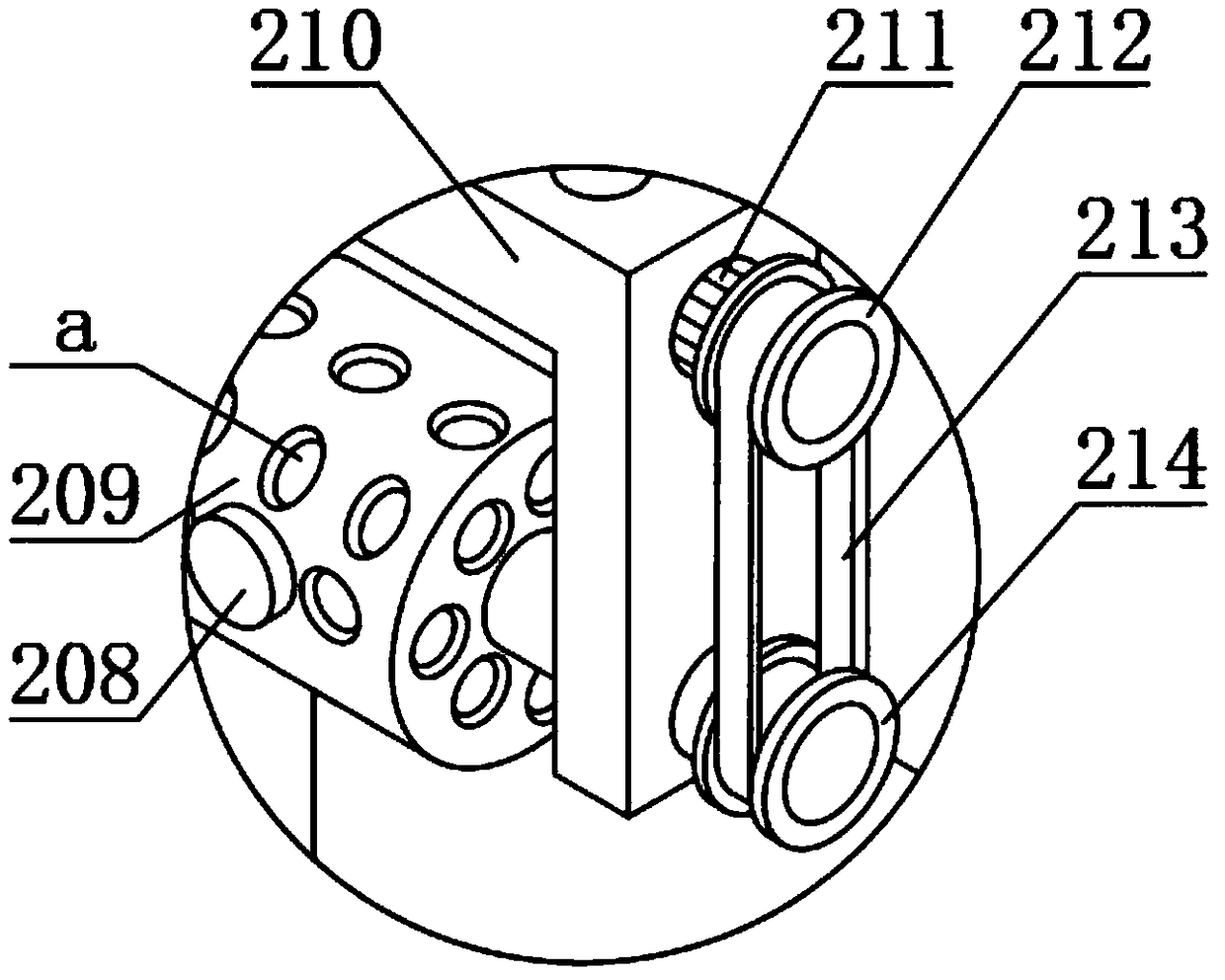

Full-automatic poultry meat dicing device

InactiveCN106819045ASafe and reliable workImprove transmission efficiencyPoultry processing support devicesPoultry transferring/conveying devicesEngineeringHigh transmission

The invention discloses a fully automatic poultry meat cutting device, which belongs to the technical field of poultry meat processing. The full-automatic poultry meat cutting device includes a support and a feeding belt installed on the support, a cutting mechanism, a pressing mechanism and a transmission mechanism, the cutting mechanism is located at one end of the support and the cutting opening of the cutting mechanism is connected One end of the feeding belt is matched, the pressing mechanism is located above the feeding belt and close to one end of the cutting mechanism, the pressing mechanism is connected with the bracket, and the feeding belt, cutting mechanism and pressing mechanism are all connected with the transmission mechanism Connection, linkage is realized through the transmission mechanism. The invention has high transmission efficiency, has the function of pressing the meat piece, can fix the poultry piece at the cutting edge, not only can cut the boned poultry meat, but also can effectively solve the problem that the existing technology cannot be fixed on the workbench and cause cutting out The size of the meat pieces is different, and the meat pieces are easy to splash, causing the meat pieces to be polluted and wasted and increasing the labor cost of cleaning the contaminated meat pieces.

Owner:GUANGXI CHUNMAO INVESTMENT CO LTD

Defect inspection method and defect inspection system using the method

InactiveUS7446864B2Improve accuracySuitable for detectionImage enhancementImage analysisOptoelectronicsLight source

Owner:ORMON CORP

Method and apparatus for cutting the second joint of a poultry wing and product therefrom

InactiveUS8342919B1Reduce manufacturing costStable structurePoultry deboningDividing poultryReciprocating motionSacroiliac joint

A conveyor with juxtaposed blocks moves along a path of travel, certain of the blocks have recesses which receive second joints of the wings of poultry. The second joints are arranged sidewise to the path of travel of the conveyor, in the recesses and are successively passed beneath a support frame where a hold down plate and knife is reciprocated as the support frame is towed by the conveyor to cut the flesh and skin between the ulna and radius bones and one or both cartilages, which join the ends of the bones. When cutting a cartilage, the bones are urged apart as the cut is made.

Owner:MAUER JAMES E +1

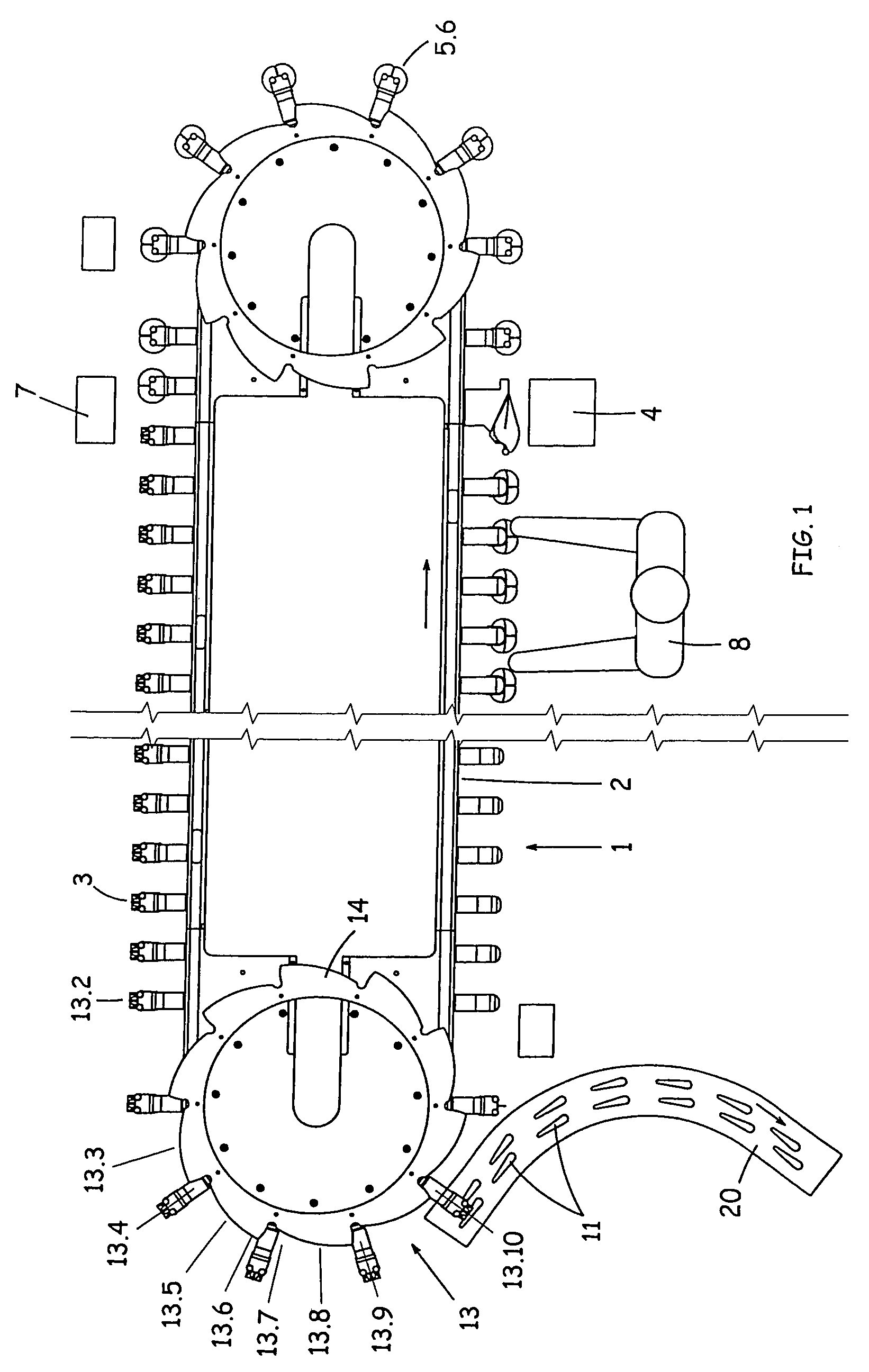

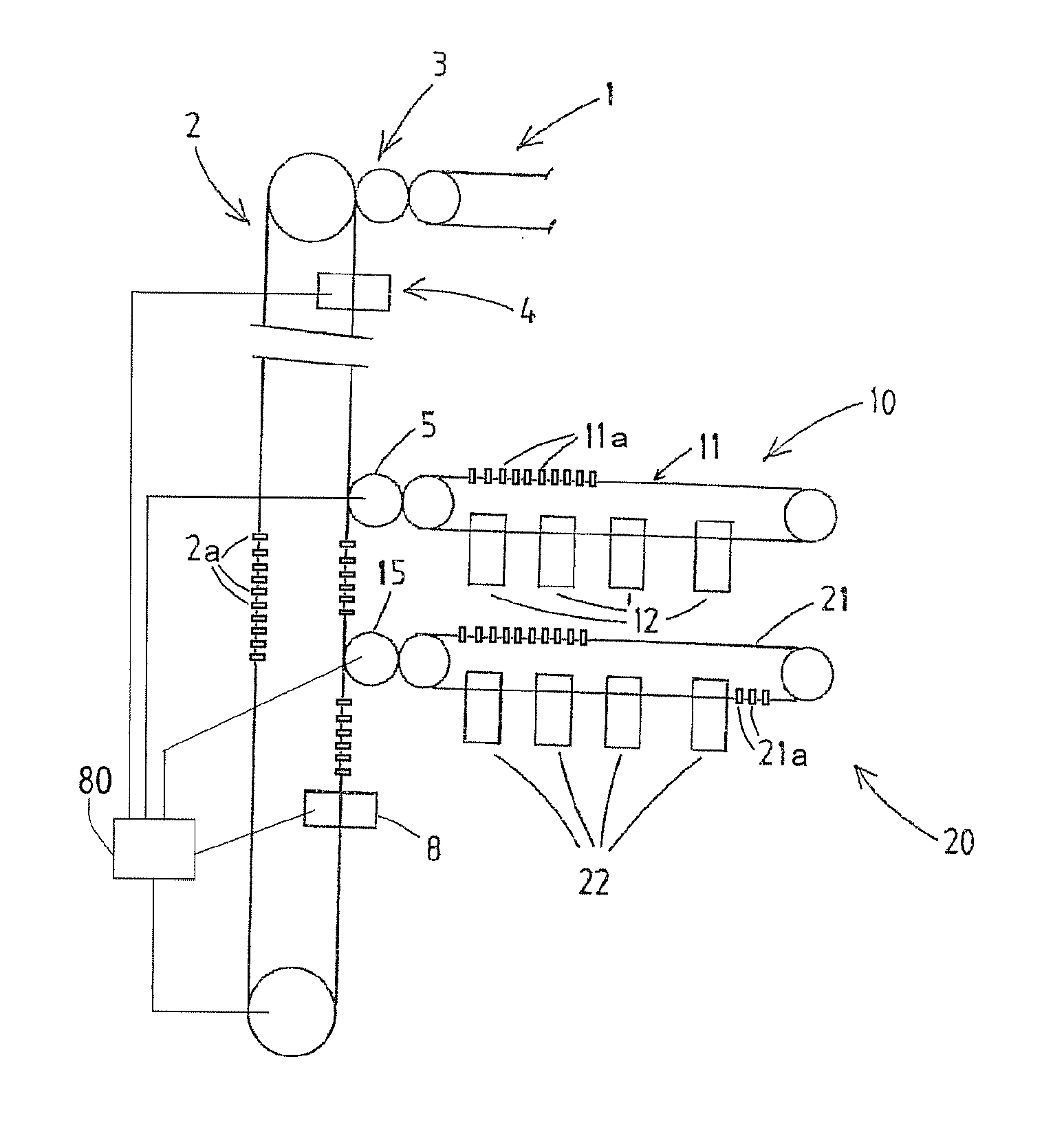

Method and installation for processing slaughtered poultry

ActiveUS20150150272A1Raise the possibilityAvoid a lot of problemsMeat processing plantsSlaughterhouse arrangementsEngineeringFodder

Method for processing slaughtered poultry, wherein oven-ready carcasses of slaughtered poultry are conveyed by a feed conveyor (2), said feed conveyor having an endless track and carriers (2a) that are moved along said track, the feed conveyor carrier being adapted to support one carcass suspended from its legs. Each individual carcass is subjected at least one of: a determination of the individual carcass weight by a weighing device (4), a determination of the individual carcass size by an imaging device. For dividing the carcasses into parts use is made of a first cut-up line (10) and a second cut-up line (20), wherein each cut-up line has an associated cut-up line conveyor (11, 21), said cut-up line conveyor having an endless track and carriers (11a, 21a) that are moved along said track, each cut-up line conveyor carrier being adapted to support one carcass suspended from its legs. Each cut-up line comprises one or more cutting devices (12, 22) arranged along the track, which one or more cutting devices divide a carcass supported by a cut-up line conveyor carrier into parts.

Owner:MAREL STORK POULTRY PROCESSING

Method and apparatus for processing a wing of a poultry carcass while the wing is attached to said poultry carcass

Owner:MEYN FOOD PROCESSING TECH BV

Duck meat dicing device

InactiveCN109258760AAchieve cleaningRealize transportationPoultry cleaning/disinfectionMeat/fish preservation by freezing/coolingIce storageEngineering

The invention relates to the technical field of duck meat processing, in particular to a duck meat dicing device which comprises a main device, a washing device, a cutting device, a storing device andan ice adding device. The washing device is fixedly connected with the top of the main device, the cutting device is arranged on the right side of the washing device and is fixedly connected with themain device, the storing device is fixedly connected with the right side of the top of the main device, and the ice adding device is fixedly connected with the inner side of the right end of the storing device. The duck meat dicing device has the advantages that the duck meat dicing device is provided with a storing shell, a guide plate and a first door plate, collecting barrels can periodicallyrotate, accordingly, duck meat can be collected, the collecting barrel replacing time can be shortened for workers, and the collecting efficiency can be improved; the duck meat dicing device is provided with an ice storage tank, a second door plate, an ice outlet pipe, a fixing plate, a third electric telescopic rod and a check block, accordingly, ice cubes can be periodically added into the collecting barrels under the effect of the ice storage tank, the freshness of the duck meat can be guaranteed under the effects of the ice cubes, and the shelf life of the duck meat can be prolonged.

Owner:湖南芷江和翔鸭业有限公司

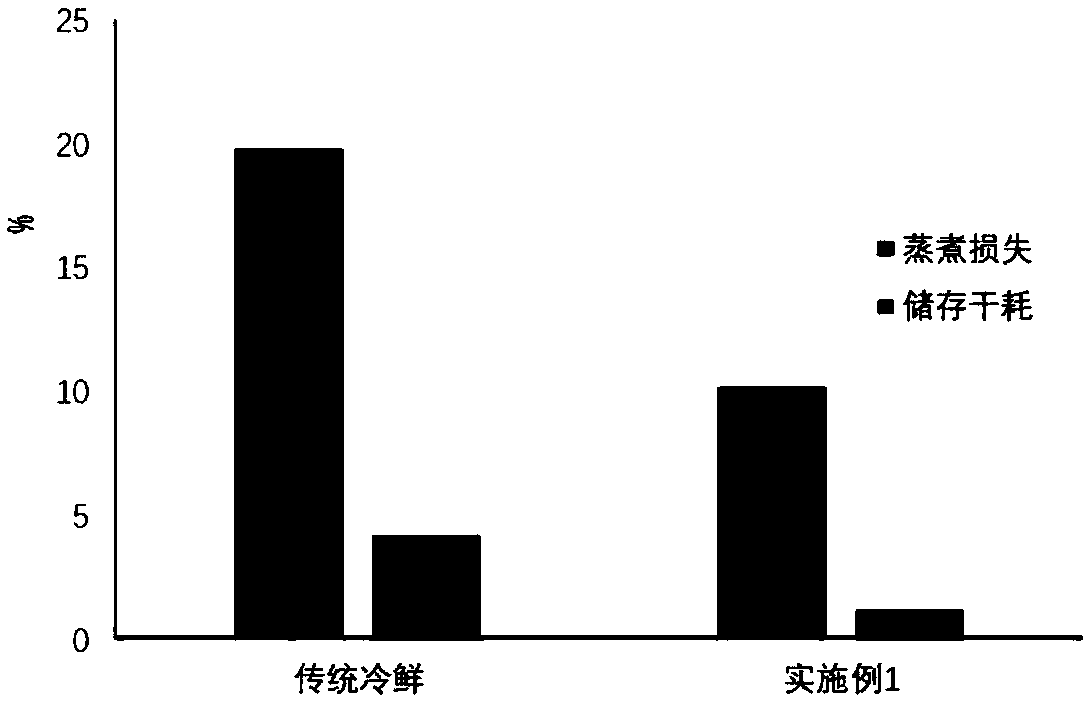

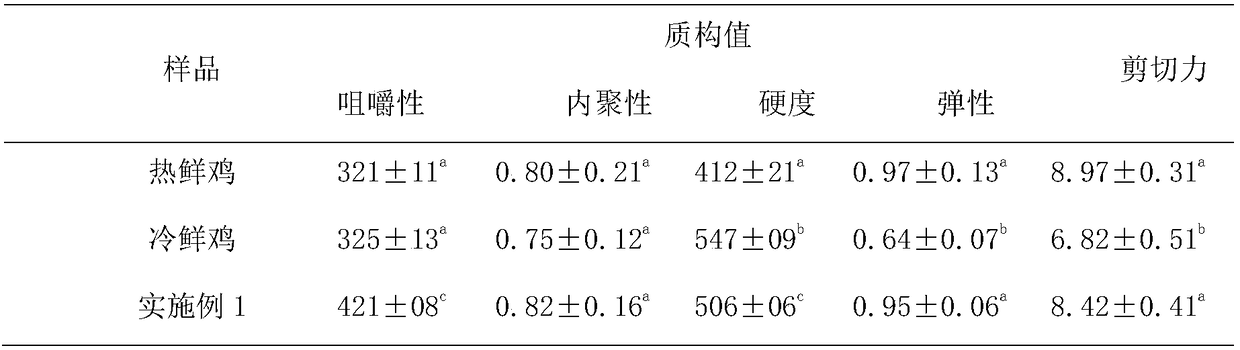

Yellow chicken raw material production method applicable to Chinese food cooking mode and product

ActiveCN109221964AReduce toughnessLess appearancePoultry cleaning/disinfectionMeat/fish preservation by freezing/coolingWater bathsWarm water

The invention discloses a yellow chicken raw material production method applicable to a Chinese food cooking mode. The method comprises the following steps that the slaughtered and cleaned yellow chicken is shaped; acid discharge tenderization treatment is not performed; in warm water being 50 to 60 DEG C, water bath blanching enzyme deactivation is directly performed; the enzyme deactivation treatment time is 20 to 30 min. The processing method of cold fresh yellow chicken has the advantages that temperature reduction acid discharge and tenderization treatment are not performed in the processing process; the processing method can overcome the defect that water can be easily generated in the stir-frying and stewing process of the cold fresh yellow chicken; the steaming and boiling loss iseffectively reduced; the dish quality is high; the dry mouthfeel cannot be generated in the chewing process; in the product storage process, the water loss is little; the weight loss is little. The invention also provides a cold fresh yellow chicken product.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com