Method for separating meat and bone of fowl and device used by the method

A poultry and ischium technology, which is applied in poultry deboning, poultry segmentation, poultry processing, etc., can solve the problems of reducing production and not ensuring the formation of cutting space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] Referring to the accompanying drawings, a preferred embodiment according to the present invention will be described in detail below. However, it should be recognized that unless otherwise specified, the dimensions, materials and relative positions of the constituent parts in this embodiment are only used for illustrative explanations, and are not intended to limit the scope of the present invention.

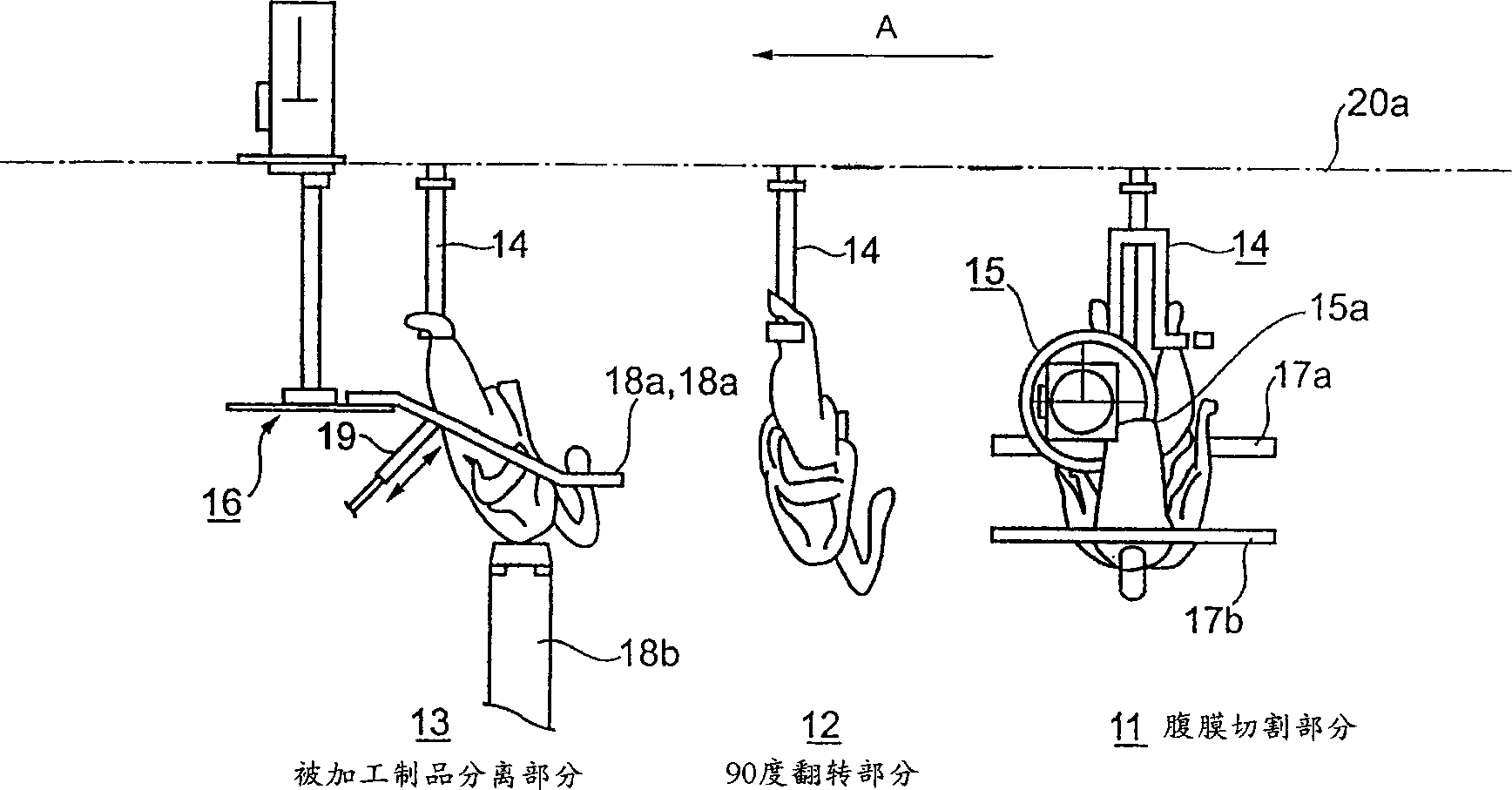

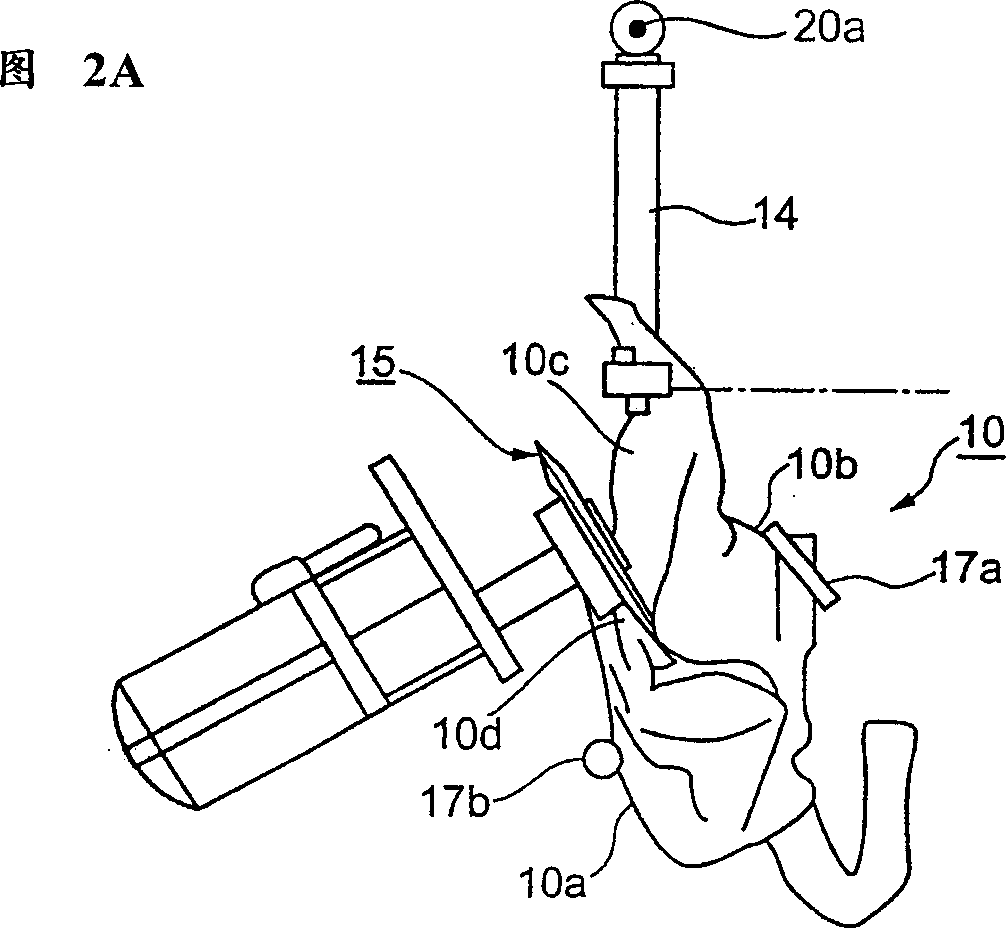

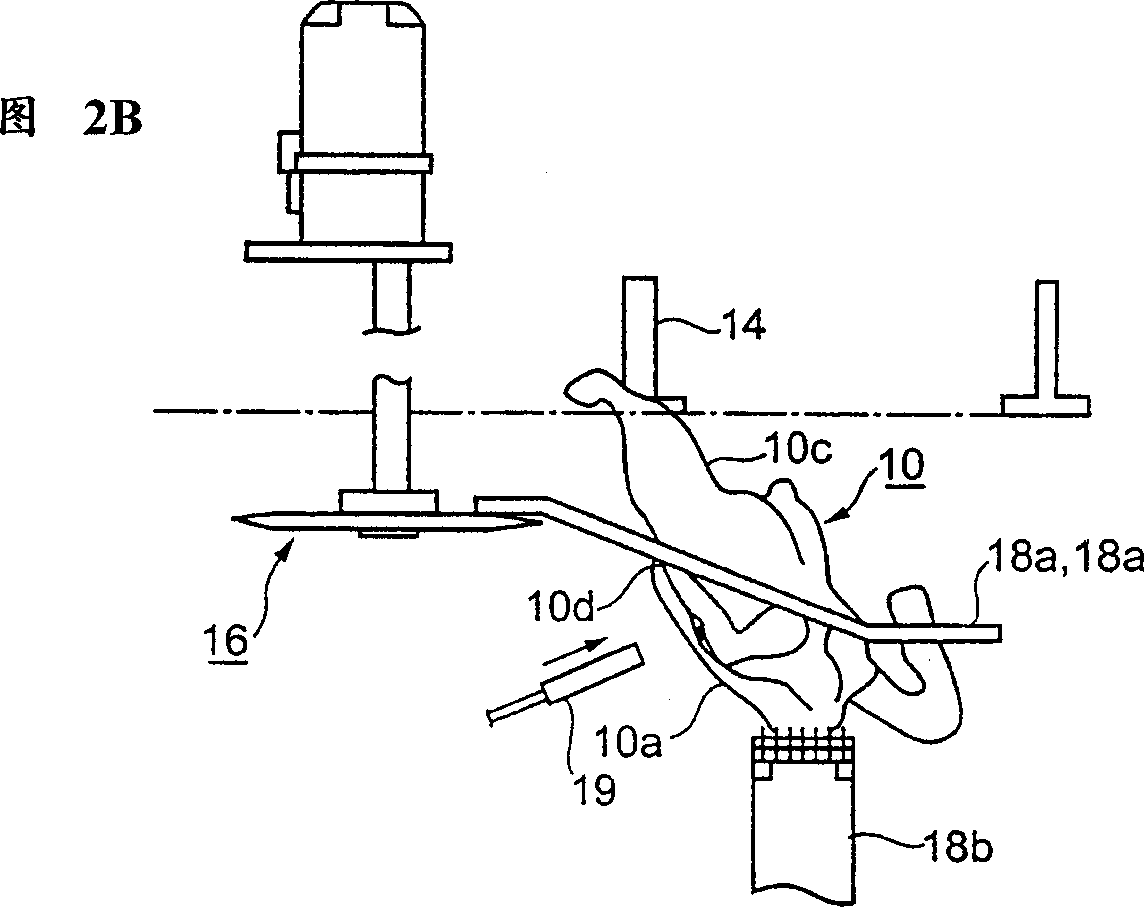

[0077] figure 1Shown is the sequence of operations on the hollow carcass of slaughtered poultry in the first processing step according to the invention and a schematic diagram of the semi-processing device. Figures 2A and 2B are used to show respectively figure 1 Schematic diagram of the cut part of the peritoneum and the separated part of the processed product in .

[0078] image 3 Shown is a schematic view of a stripping device for the thighs of the lower carcass of poultry after slaughter in the second processing step according to the invention. Figure 4 shows th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com