Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

63results about How to "Realize automatic painting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

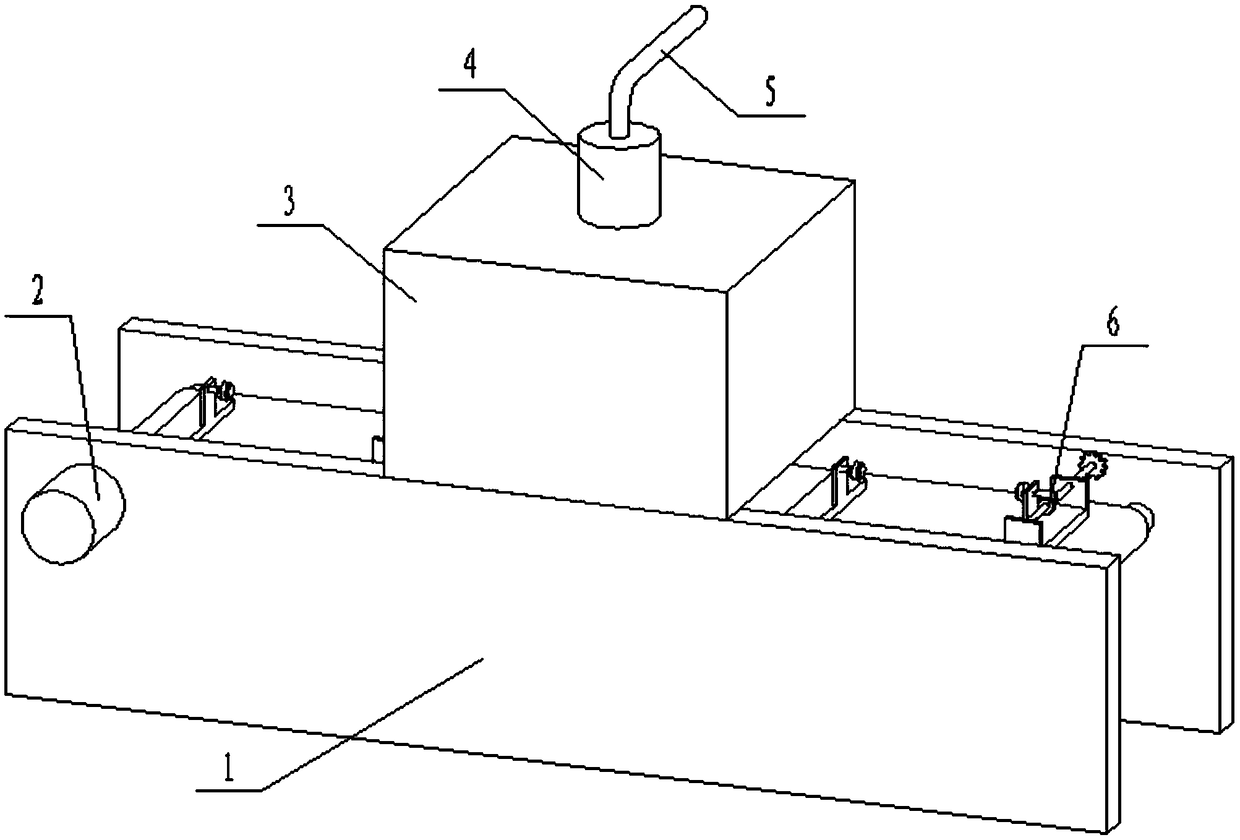

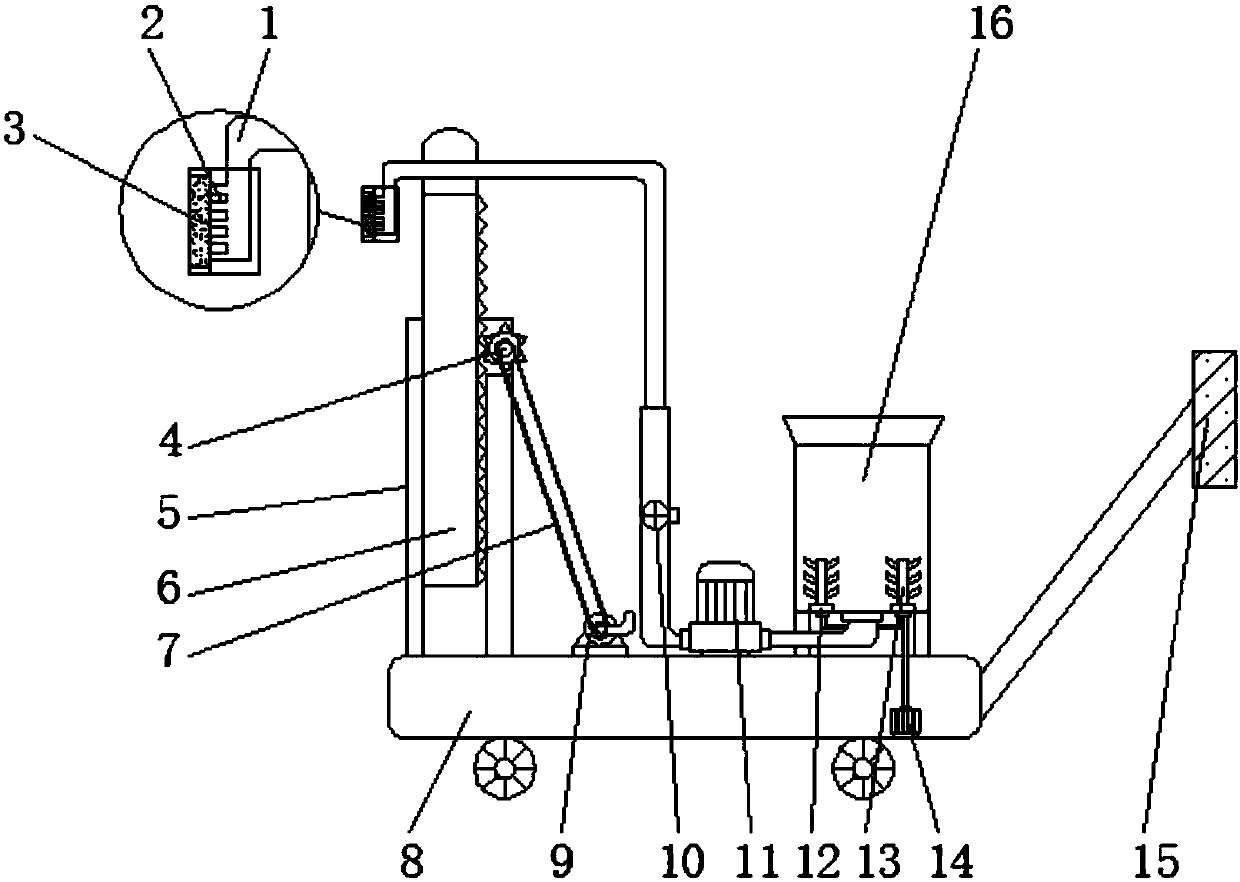

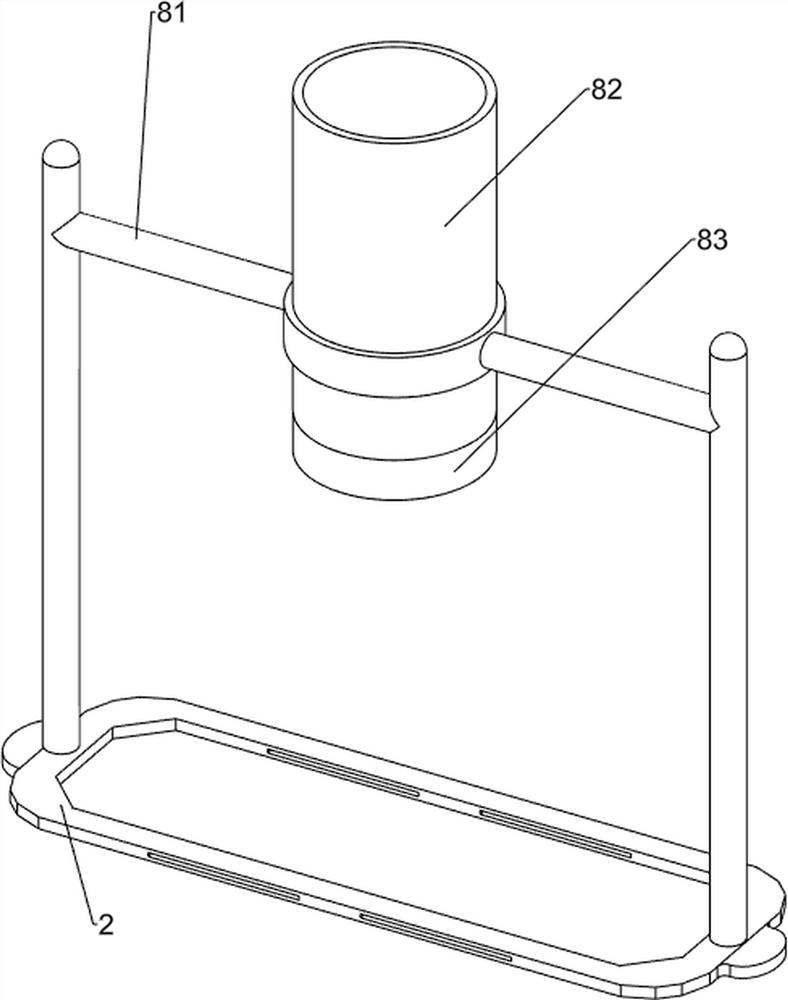

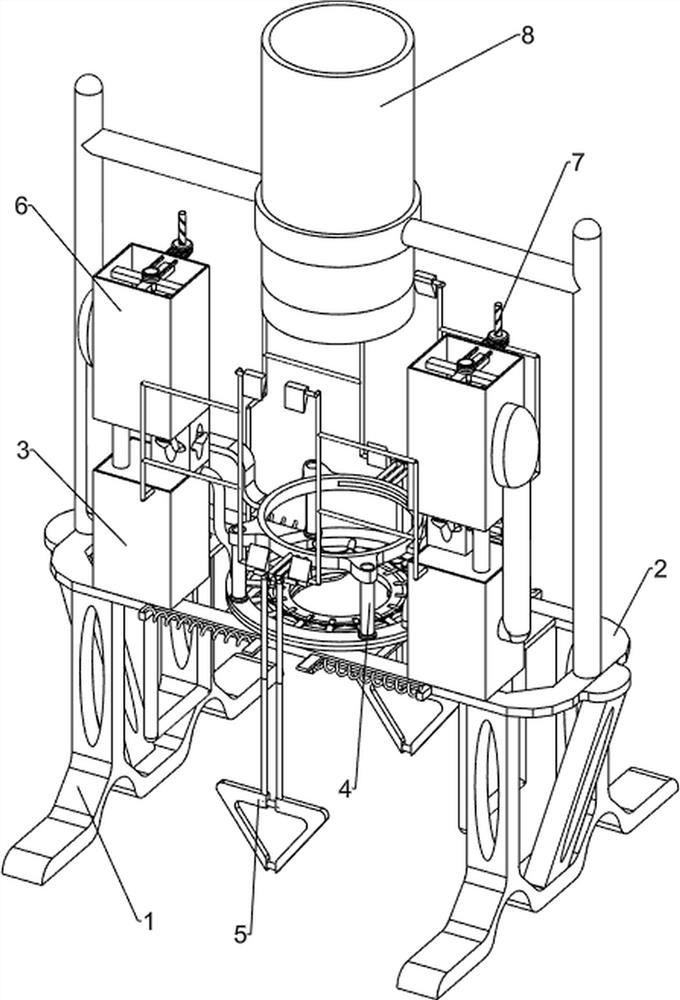

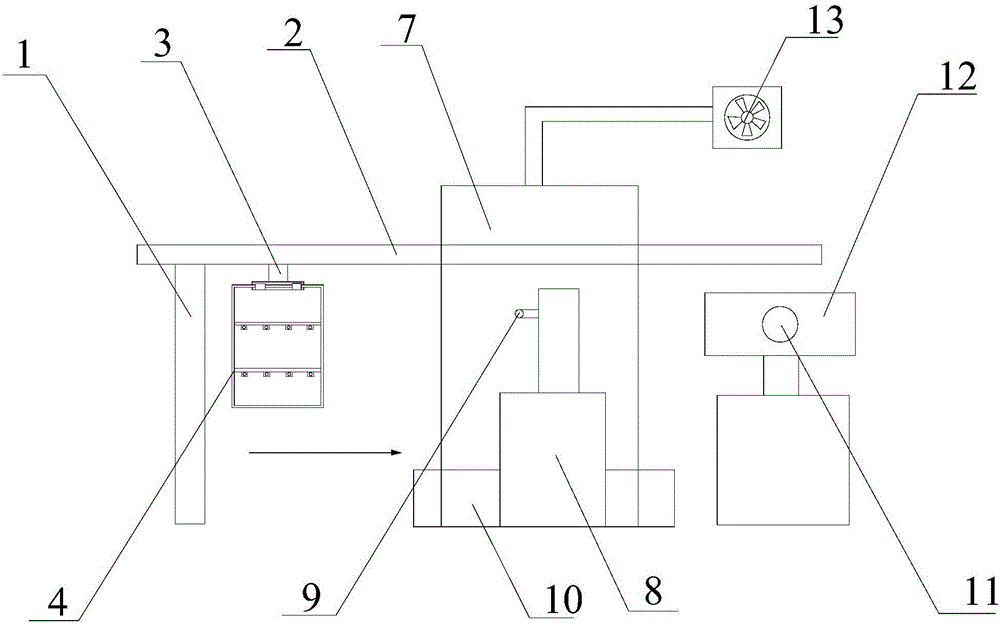

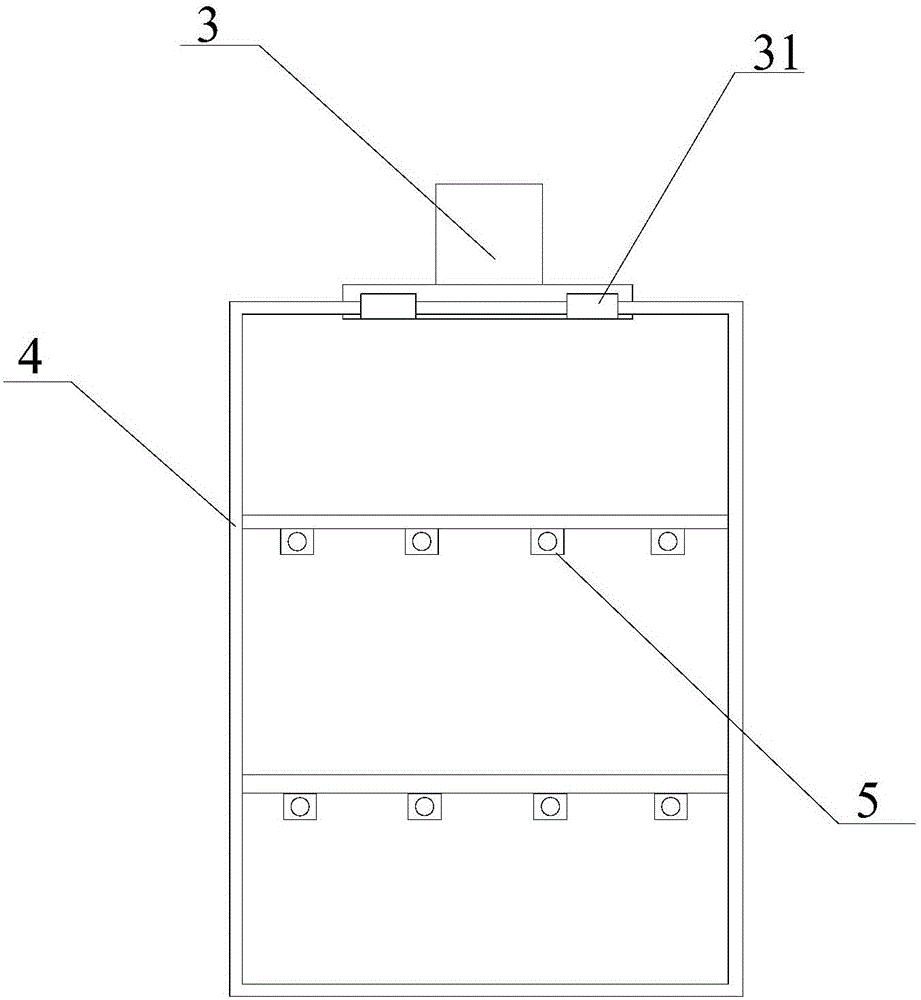

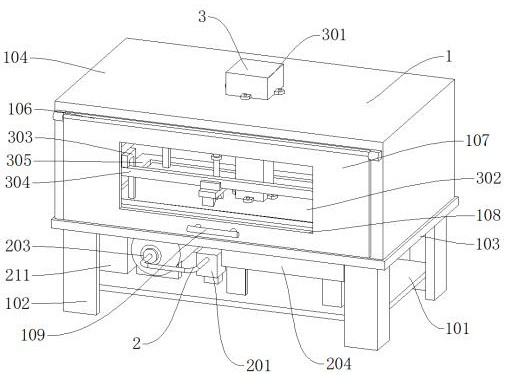

Environment-friendly building pipe paint spraying device

ActiveCN108654877ARealize automatic deliveryRealize automatic paintingSpraying apparatusEngineeringExhaust pipe

The invention discloses an environment-friendly building pipe paint spraying device. The environment-friendly building pipe paint spraying device comprises a rack, a conveying motor is arranged on oneside of the rack, a toothed bar is arranged on one side of the inner wall of the rack, a conveying roller is arranged in the rack, the conveying roller is fixedly connected with the conveying motor,a conveying belt is arranged on the outer side of the conveying roller, a clamping mechanism is arranged on the surface of the conveying belt, a box body is arranged at the upper end of the rack, an air suction pump is arranged at the upper end of the box body, the air suction pump communicates with the box body, the exhaust end of the air suction pump is provided with an exhaust pipe connected with a water box, a bearing plate is arranged in the box body, and a nozzle is arranged at the bottom of the bearing plate. The device has the beneficial effects that automatic conveying and automatic paint spraying of pipes can be achieved, the paint spraying effect is good, the efficiency is high, in the paint spraying process, paint mist generated by paint spraying can be absorbed, and the phenomenon that due to paint mist drifting, the health of an operator is affected is avoided.

Owner:杨智萍

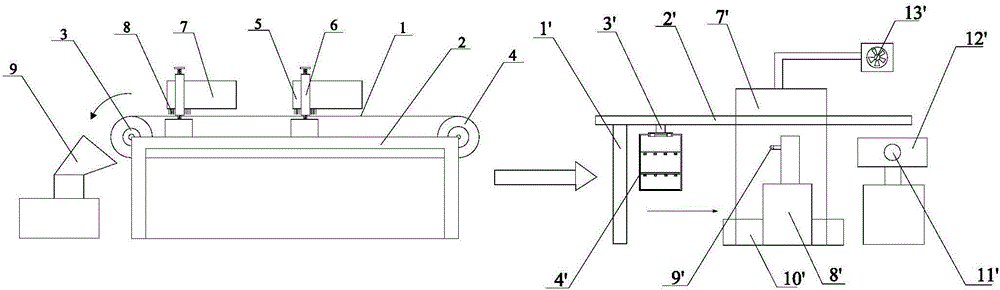

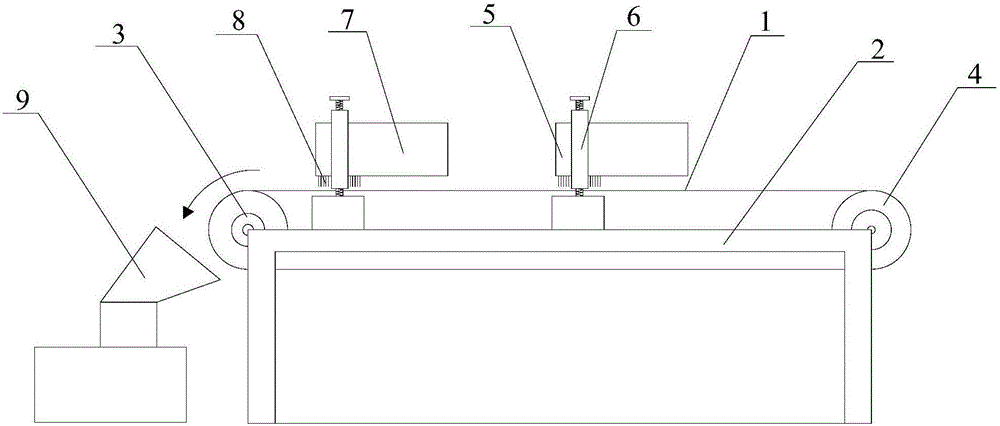

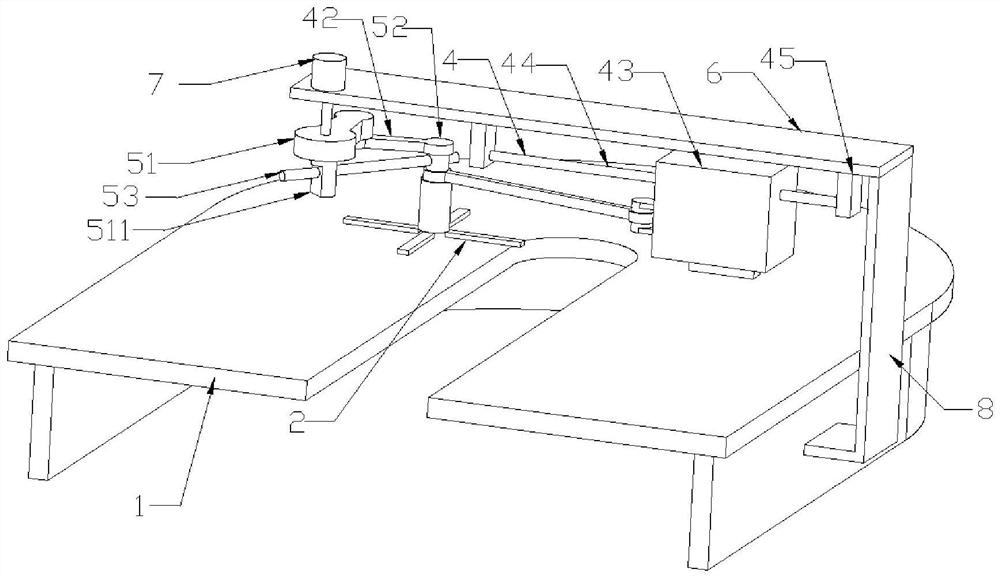

System for coating sealing paint on woody packing box

ActiveCN102179345ARealize automatic paintingEvenly paintedLiquid surface applicatorsCoatingsBrush deviceEngineering

The invention discloses a system for coating sealing paint on a woody packing box. The system comprises a first conveying device, a second conveying device and a third conveying device; the first conveying device is provided with a packing box placement area, a paint dipping area, a first paint brushing device, and a first conveying belt cleaning device; the third conveying device is provided with a second paint brushing device; the first paint brushing device is provided with a slide rail arranged on a first machine frame, a side brush roller arranged on the slide rail, an adjustment motor arranged on the first machine frame, a top brush roller seat body arranged on the first machine frame and a top brush roller arranged on the top brush roller seat body; the second paint brushing device is provided with a slide rail arranged on a third machine frame, and a side brush roller arranged on the slide rail, and an adjustment motor; and the first conveying belt cleaning device is provided with a conveying belt cleaning brush roller. The system has the characteristics of realizing full-automatic paint brushing, brushing paint uniformly, saving manual operation and time, reducing production cost greatly, improving the quality of a product and keeping a conveying belt clean, and the like.

Owner:DONGGUAN MINGFENG PACKAGING CO LTD

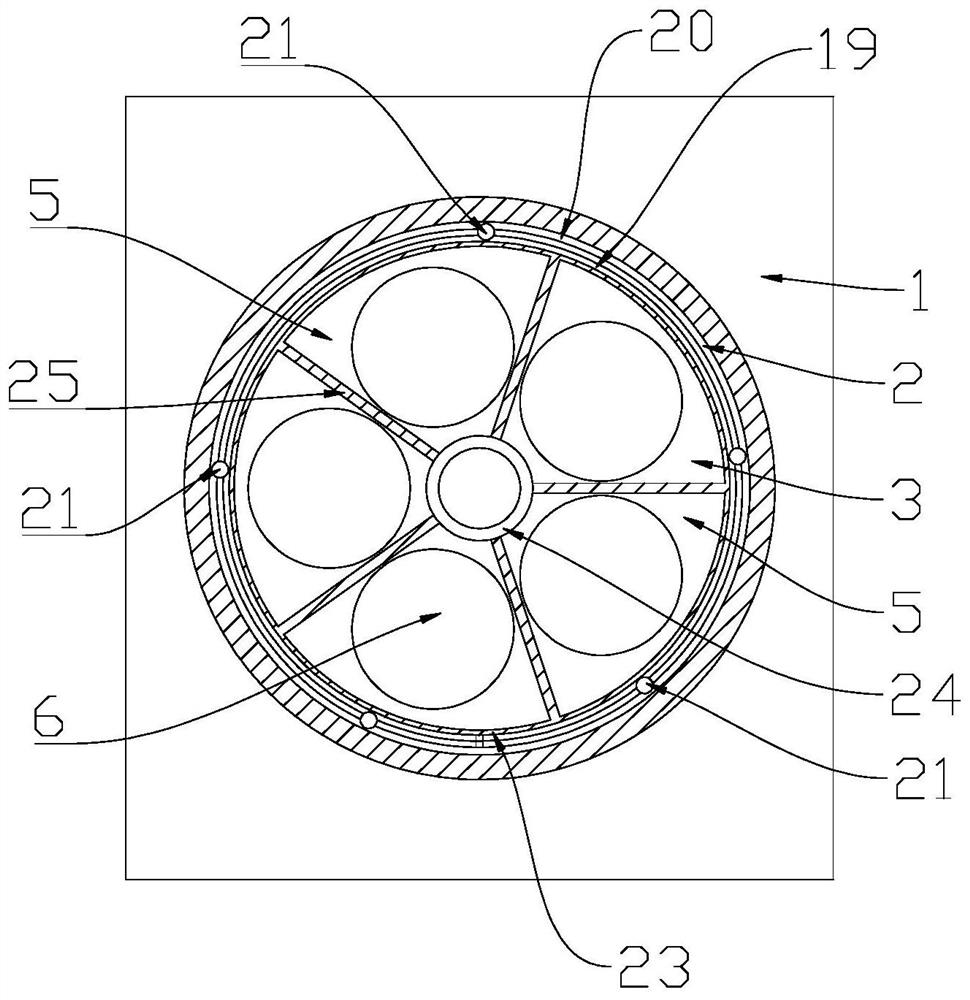

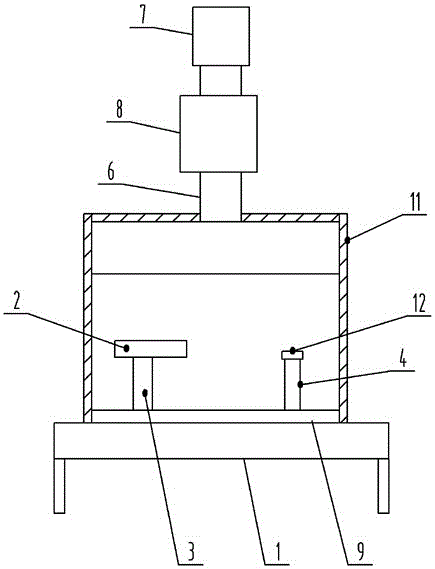

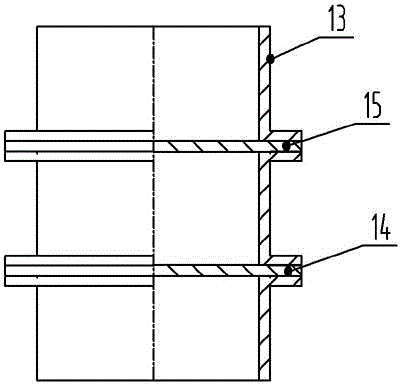

Automatic paint spraying device for inner wall of pipeline

Owner:江苏英斯坦福环境科技有限公司

Automatic paint spraying achieving method for automobile maintenance

InactiveCN108745837ARealize automatic paintingRealize maintenance painting workLiquid surface applicatorsSpraying apparatusAutomatic controlPaint robot

The invention discloses an automatic paint spraying achieving method for automobile maintenance. The automatic paint spraying achieving method for automobile maintenance includes the following steps that S1, a maintaining vehicle enters a paint spraying room through a track, and the vehicle is positioned; S2, the paint spraying position is subjected to uniformization grinding, after grinding is completed, attaching and protecting are performed on the periphery of the paint spraying position, and after attaching and protecting are completed, a certain detection landmark is arranged on the boundary of the paint spraying position; and S3, a paint spraying robot performs automatic measurement on the paint spraying position, the measurement can be real-time measurement in the paint spraying process, measurement can also be performed before paint spraying, and after measurement is completed, a spraying gun is controlled to perform paint spraying operation under the condition without measurement according to a measured three-dimensional shape and measured coordinate information. The automatic paint spraying achieving method for automobile maintenance has the beneficial effects that it canbe achieved that after vehicle sheet metal maintenance, automatic paint spraying is performed at the maintained portion, the paint spraying amount, the paint spraying portion and the area are automatically controlled, an automatic paint spraying system replaces manual work, and the paint spraying work of automobile maintenance is achieved.

Owner:MIT AUTOMOBILE SERVICE

Adjustable rust removal paint spraying device for building steel tubes

InactiveCN107344154AReasonable structureInnovative designPretreated surfacesCoatingsDrive shaftArchitectural engineering

The invention discloses an adjustable rust-removing and painting device for building steel pipes, which comprises a bottom plate, a support frame is connected to the upper left side of the bottom plate, a feeding box is connected to the left end of the support frame, and a fixing frame is connected to the upper and lower ends of the inside of the feeding box to fix There is a feed roller in the middle of the frame, a fixed cylinder is connected to the right end of the support frame, a rotating screw is installed inside the fixed cylinder, a rotating gear is connected to the outer middle of the rotating screw, a driving gear is meshed at the lower end of the rotating gear, and a driving shaft is connected to the middle of the left end of the driving gear , the left end of the drive shaft is connected to the drive motor, the middle part of the rotating screw is connected to the slider, the outer side of the slider is evenly connected to the guide block, the outer side of the guide block is connected to the installation groove, the middle part of the installation groove is connected to the connecting rod, the right end of the connecting rod is connected to the tie rod, and the middle part of the tie rod A grinding wheel frame is connected, a grinding wheel is connected to the middle part of the grinding wheel frame, and a paint spraying box is connected to the upper right side of the bottom plate. The invention satisfies the needs of derusting steel pipes with different diameters, and at the same time realizes automatic painting of the derusted steel pipes.

Owner:阮霞伟

Environment-friendly fishing rod painting device and process

InactiveCN110918338APerfect painting processQuality assuranceRevolution surface grinding machinesPretreated surfacesPolishingElectric machinery

The invention discloses an environment-friendly fishing rod painting device and process. The environment-friendly fishing rod painting device includes a worktable, fixing frames, a three-jaw chuck, arotating shaft, a first motor, a fishing rod polishing component, a fishing rod painting component, a hinge, a top cover, a recovery tank, and a paint injection port. The fixing frames are symmetrically welded to the outer walls of the two sides of the top of the worktable. The three-jaw chuck is rotatably mounted on the outer walls of the opposite middle parts of the fixing frames on both sides of the top of the worktable through a rotation shaft. The environment-friendly fishing rod painting device has relatively simple and compact structure and a high level of automation. The fishing rod polishing component can completely and uniformly polish the outer surface of the fishing rod by a polishing wheel, so that the later painting is more uniform. The fishing rod painting component can automatically paint the surface of the fishing rod. The fixed speed of each motor ensures the uniform painting, and improves the painting process of the fishing rod to ensure the painting quality of the fishing rod.

Owner:福清市海威钓具有限公司

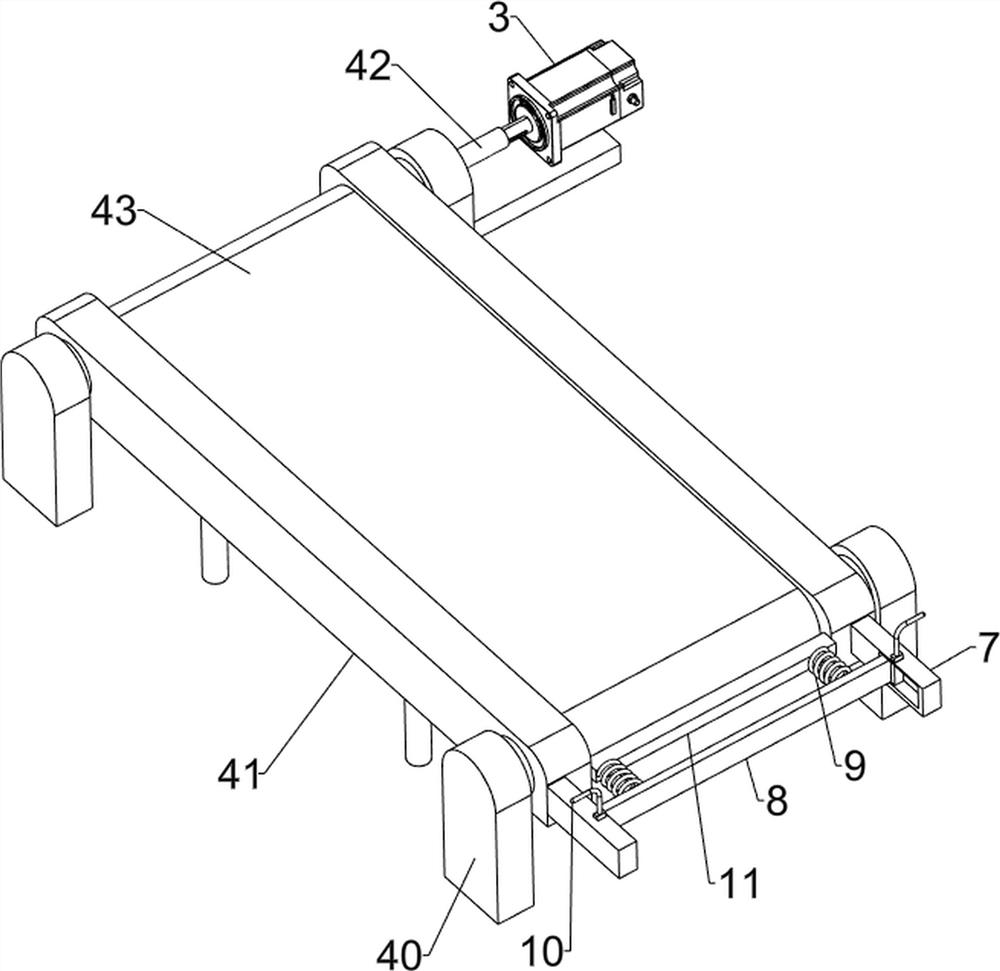

Wood stick paint dyeing equipment for furniture

InactiveCN112221772AEvenly paintedEasy to cleanSpraying apparatusConveyor beltIndustrial engineering

The invention relates to paint dyeing equipment, in particular to wood stick paint dyeing equipment for furniture. The invention provides the wood stick paint dyeing equipment for furniture capable oftransmitting wood sticks automatically, spraying paint to the wood sticks uniformly and being convenient to clean residual paint on the surface of a conveyor belt. The wood stick paint dyeing equipment for furniture comprises a bottom plate and a supporting plate, wherein the supporting plate is arranged on one side of the top of the bottom plate; a servo motor arranged on the left rear side of the top of the bottom plate; a conveying mechanism arranged on the top of the bottom plate, wherein components of the conveying mechanism penetrate through the supporting plate; a paint spraying mechanism arranged on the side, close to the servo motor, of the top of the bottom plate; and a stripping mechanism arranged on the middle side of the top of the bottom plate, wherein components of the stripping mechanism are connected to the components of the conveying mechanism. By matching the servo motor, the conveying mechanism, the paint spraying mechanism, the stripping mechanism and a scraper plate, effects of transmitting the wood sticks, uniformly spraying paint to the wood sticks and being convenient to clean residual paint on the surface of the conveyor belt can be achieved.

Owner:吴小冬

Container for cold storage

InactiveCN101274697ARealize automatic weldingRealize automatic paintingLarge containersTank wagonsEngineeringCold storage

The invention relates to a refrigerated container. The soleplate of the refrigerated container comprises a floor arranged in the container body, an assistant corrugated floor arranged outside the container body, and a foaming material layer which is filled between the floor and the assistant floor; the assistant floor is connected with a bottom side beam and comprises a plurality of peaks and troughs with the same shape and arranged at intervals, and the part between the peak and the trough is an wave inclined edge. The refrigerated container is characterized in that the included angle between the wave inclined edge and the horizontal direction is less than 45 degrees. Compared with the prior art, the refrigerated container has the advantages of high welding quality, convenient painting, low cost, high production efficiency and good rigidness, etc.

Owner:CHINA INTERNATIONAL MARINE CONTAINERS (GROUP) CO LTD +1

Building wall surface automatic painting robot and method

ActiveCN112031347ARealize automatic paintingAchieve scrapingBuilding repairsStructural engineeringMechanical engineering

The invention relates to the field of building equipment, in particular to a building wall surface automatic painting robot. The robot is characterized by comprising a walking mechanism capable of walking along a preset route, a supporting plate supported on the walking mechanism in a manner of moving up and down, a rolling brush rotatably supported on the supporting plate along the vertical axis,used for painting a wall surface to be painted and capable of moving back and forth in the painting direction relative to the supporting plate and moving back and forth in the direction close to or far away from the wall surface so as to be in contact with the wall surface when the wall surface is painted, two first sliding rails arranged in parallel, supported on the supporting plate and extending in the painting direction, a first sliding block supported on the first sliding rails in a sliding mode in the painting direction, a hollow rod rotatably arranged on the first sliding block along the vertical axis, a coating box and a pump, wherein a U-shaped structure is arranged at one end of the hollow rod, the two ends of the rolling brush are rotatably supported on the two sides of the U-shaped structure respectively, at least the middle part of the U-shaped structure is of a hollow structure communicated with the interior of the hollow rod, a plurality of openings are formed in one side, facing the rolling brush, of at least the middle part of the U-shaped structure, the coating box is used for storing the prepared coating, the other end of the hollow rod is communicated with thecoating box through a hose, and the pump is arranged on the hose and used for conveying the coating in the coating box to the rolling brush. The robot can achieve automatic painting of the wall surface.

Owner:HEBEI TIANXIN CONSTR GRP CO LTD

Wall surface decoration painting device with continuous painting function

The invention discloses a continuous painting device for wall surface decoration, which comprises a PVC hose, a brush and a fixed base. One side of the telescopic rod is rotatably connected to the card gear through a block, and the card gear is rotatably connected to the rotating shaft through a conveyor belt. The top of the fixed base is located on one side of the support rod. connection, the interior of the PVC hose is provided with a solenoid valve for controlling the PVC hose. In the present invention, a telescopic rod is sleeved inside the support rod, and one side of the telescopic rod is rotationally connected to the locking gear through a block, and the locking gear is connected to the rotating shaft through a transmission belt. The top of the telescopic rod is provided with a brush, so when the rotating shaft It will drive the brush to move up and down, so it can realize automatic painting, and at the same time, the high part of the wall can be easily painted, saving time and effort.

Owner:CHENGDU ZHONGFU LIXIANG TECH

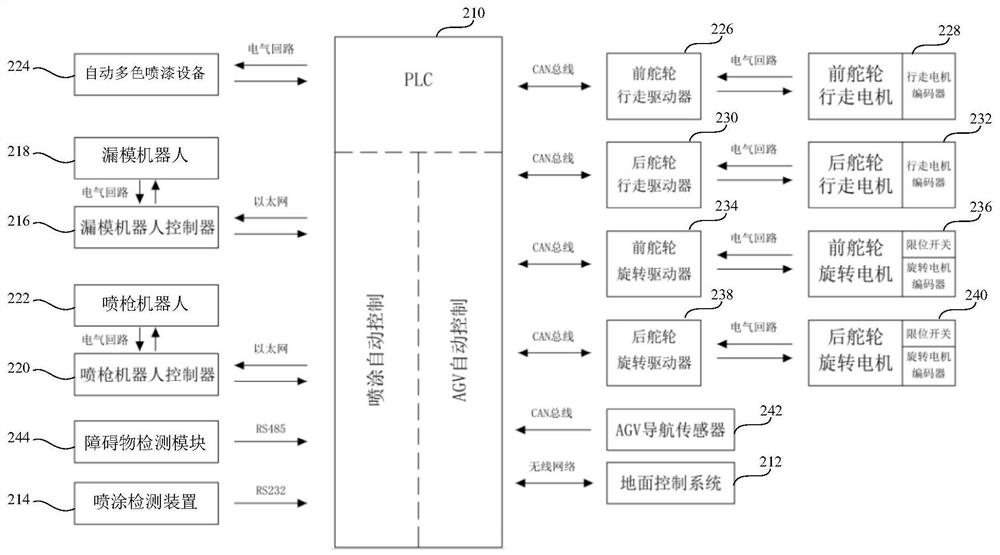

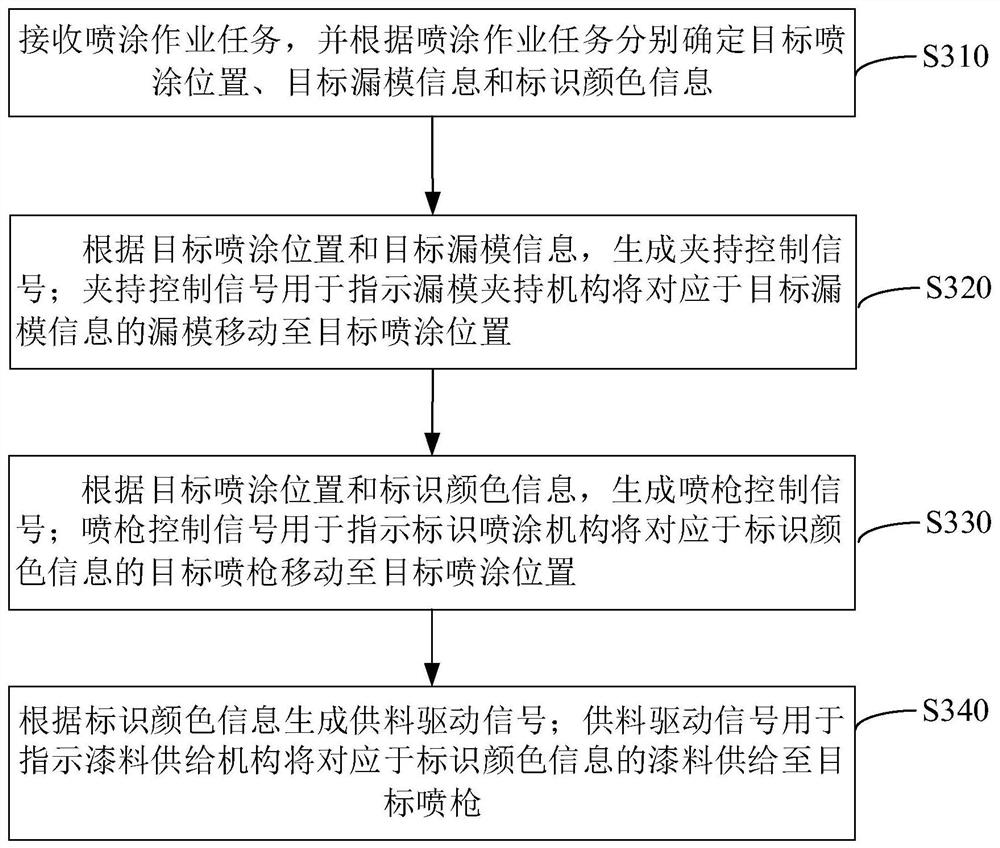

Spraying robot control system, method and device and computer equipment

The invention relates to a spraying robot control system, method and device and computer equipment. The spraying robot control system comprises a central control device, a stripping pattern control device, a spray gun control device and a paint spraying control device; the central control device is used for receiving a spraying operation task and determining a target spraying position, target stripping pattern information and identification color information according to the spraying operation task; the stripping pattern control device is used for generating a clamping control signal according to the target spraying position and the target stripping pattern information so as to indicate the stripping pattern clamping mechanism to move a stripping pattern corresponding to the target stripping pattern information to the target spraying position; the spray gun control device is used for generating a spray gun control signal according to the target spraying position and the identification color information, so that an identification spraying mechanism moves a target spray gun corresponding to the identification color information to the target spraying position; and the paint spraying control device is used for generating a supply driving signal according to the identification color information so as to indicate a paint supply mechanism to supply paint corresponding to the identification color information to the target spray gun. In this way, full-automatic intelligent spraying of a spraying robot is achieved.

Owner:SHENHUA RAIL & FREIGHT WAGONS TRANSPORT +1

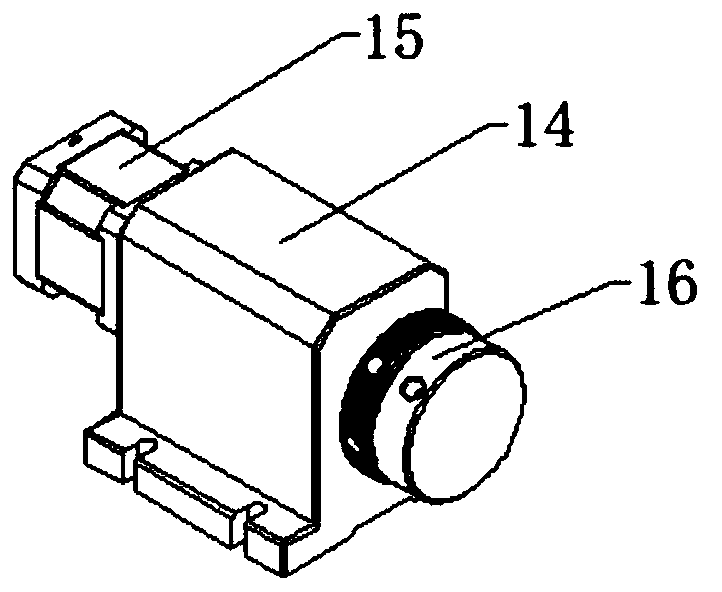

Processing device for air inlet cylinder cover

InactiveCN106181691ARealize automatic grinding processImprove painting efficiencyGrinding machine componentsBelt grinding machinesEngineeringGas transmission

The invention discloses a processing device for an air inlet cylinder cover. The processing device comprises an automatic sand grinding machine device and a paint spraying device which are sequentially joined to each other, wherein the automatic sand grinding machine device is composed of an abrasive belt, a rack, a driving wheel and a driven wheel; the driving wheel and the driven wheel are horizontally arranged on the rack; the abrasive belt wraps the outer edges of the driving wheel and the driven wheel; material stopping plates are transversely arranged above the abrasive belt; the two ends of each material stopping plate are fixed to the rack on the two sides of the abrasive belt; an interval is left between the bottom end of each material stopping plate and the upper surface of the abrasive belt; the paint spraying device is composed of a bracket; a transportation sliding rail is arranged at the upper end of the bracket and is provided with a moving lifting hook; a frame-shaped hanger is arranged at the bottom of the moving lifting hook and is provided with bolt holes; the bolt holes are fit to gas transmission pipes of the air inlet cylinder cover to enable the air inlet cylinder cover to sleeve the bolt holes; the transportation sliding rail penetrates through a paint spraying chamber; a paint spraying machine is arranged in the paint spraying chamber and is provided with an infrared sensor; and a drying device is arranged at the back end of the paint spraying chamber.

Owner:宿州市明兴金属制造有限公司

Anti-rust paint spraying device for scale prevention of steel drum

ActiveCN112756133ARealize the spray paint effectRealize automatic paintingSpraying apparatusMetallurgySpray nozzle

The invention relates to a spraying device, in particular to an anti-rust paint spraying device for scale prevention of a steel drum. The invention provides the anti-rust paint spraying device for scale prevention of the steel drum, and through the anti-rust paint spraying device, the two hands of people are liberated, the productivity is improved, and spraying is uniform. The anti-rust paint spraying device for scale prevention of the steel drum comprises supporting legs, a long fixing plate, a paint spraying mechanism, a pull-down mechanism and a discharging mechanism; the long fixing plate is arranged between the upper portions of the two supporting legs; the paint spraying mechanism is arranged on the long fixing plate; the pull-down mechanism is arranged on the long fixing plate; and the discharging mechanism is arranged on the pull-down mechanism and the long fixing plate, and the discharging mechanism is matched with the pull-down mechanism. According to the anti-rust paint spraying device for scale prevention of the steel drum, a pressurizing barrel bottom cover is driven to slide upwards in a pressurizing barrel, and under the action of pressure, paint enters a hollow circular ring through a hose, so that paint is sprayed to the steel drum through a spraying nozzle.

Owner:济宁源盛包装容器有限公司

Paint spraying device for air inlet cylinder cover

InactiveCN106000723AImprove painting efficiency and uniformityReduce pollutionPretreated surfacesCoatingsEngineeringMechanical engineering

The invention discloses a spraying device for an air intake cylinder head, which comprises a bracket, the upper end of the bracket is provided with a transport slide rail, the transport slide rail is provided with a mobile hook, and the bottom of the mobile hook is provided with a frame-shaped hanger. The frame-shaped hanger is provided with a bolt hole, and the bolt hole fits with the gas delivery pipe of the intake cylinder head, so that the intake cylinder head can be set on the bolt hole; the transport slide rail passes through the spray booth, and the spray booth There are paint sprayers on both sides of the paint sprayer, infrared sensors are arranged on the paint sprayer, and a drying device is arranged at the rear end of the paint spray booth. The invention has the advantages that the cylinder head is driven to move to the spray booth by the transport slide rail and the mobile hook, and then sprayed by the paint sprayers on both sides, which improves the painting efficiency and uniformity of the cylinder head; Automatic paint spraying; the pollution to the environment is reduced through the liquid spray collection box and the air pump device; the invention has simple structure, convenient operation and improves the paint spraying efficiency of the cylinder head.

Owner:宿州市明兴金属制造有限公司

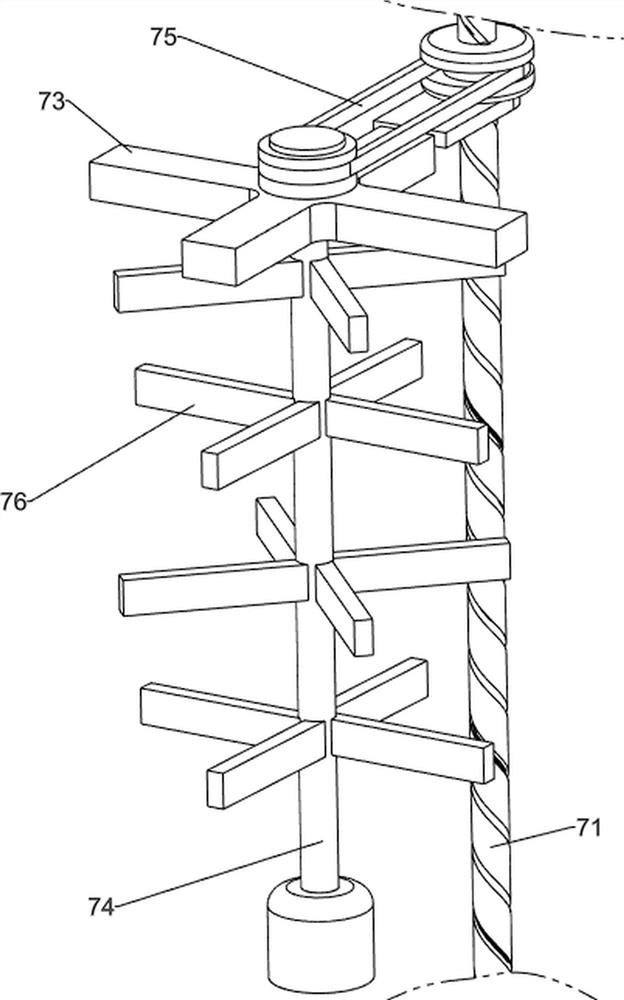

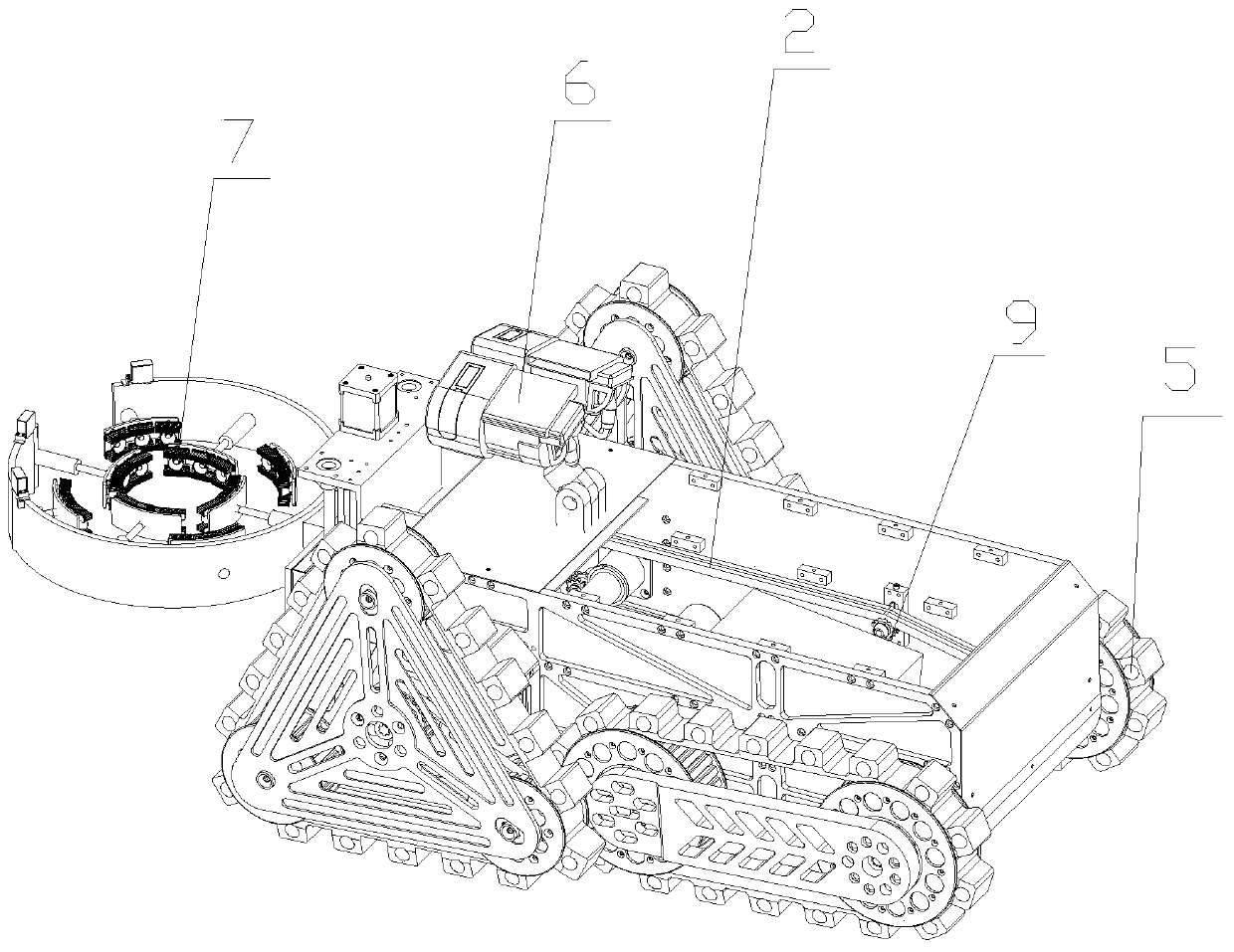

Fully automatic tree skirt painting robot and painting method

ActiveCN105613153BRealize automatic paintingReduce labor intensityPlant protective coveringsControl systemComputer module

Owner:SHANDONG GUOXING SMARTECH CO LTD

Grille production device

InactiveCN109465123ARealize automatic paintingFree laborMovable spraying apparatusDrive wheelTransmission belt

The invention relates to the technical field of grille production devices, in particular to a grille production device. The grille production device comprises a square supporting bottom plate, a threaded sleeve and a first bearing are jointly connected with a first ball screw, two second bearings are jointly connected with a second ball screw, a spraying head is fixed at the top of a moving block,one end of the second ball screw is provided with a first servo motor, one side of a feeding pump switch is provided with a storage barrel, a stirring mechanism is arranged on a storage barrel cover,a second servo motor is arranged on one side of the feeding pump, one side of the second servo motor is provided with a PLC controller, an output shaft of the second servo motor is fixedly connectedwith a driving wheel, a driven wheel is arranged on one side of the driving wheel, a transmission belt is between the driving wheel and the driven wheel, and the driving wheel and the driven wheel areconnected through the transmission belt. The grille production device can reduce the labor intensity of grille coating spraying work, is more automatic, has high work efficiency and is convenient touse.

Owner:浙江祥盛汽车科技有限公司

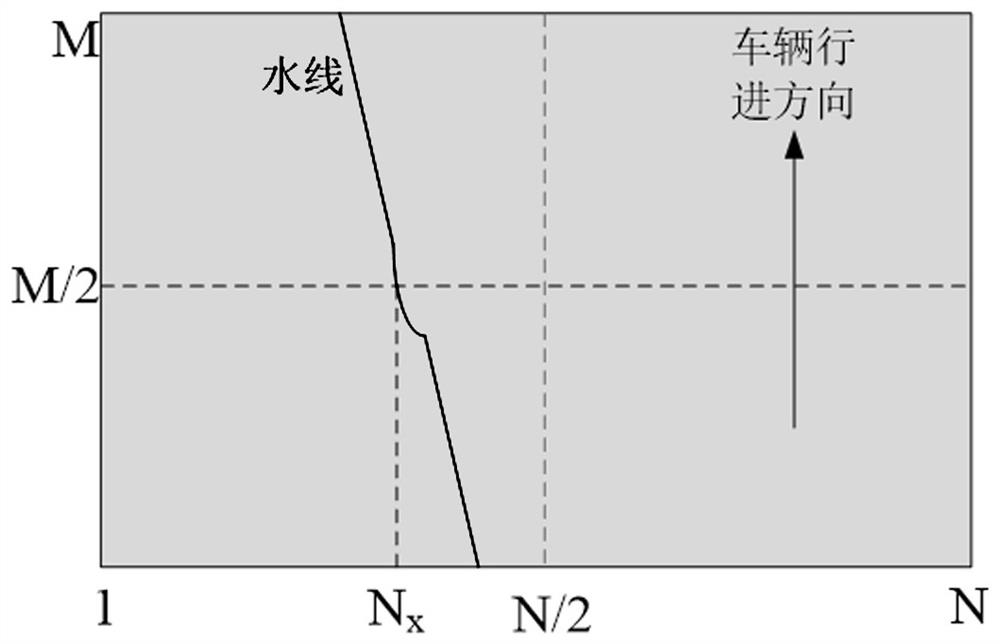

Highway unmanned scribing method based on image navigation

ActiveCN112706835ARealize automatic paintingReduce labor intensityImage enhancementImage analysisSteering angleComputer graphics (images)

A highway unmanned scribing method based on image navigation comprises the steps of firstly, collecting an image a waterline drawn on a road surface, and obtaining a straight line where the waterline is located by filtering, stretching and binarizing the image; detecting a driving error of an automatic marking vehicle, determining the grade of the driving behavior of the marking vehicle according to the driving error and the change rate of the driving error, calculating the steering angle according to a PD controller, and controlling the automatic form of the automatic marking vehicle. Automatic painting of the road surface is realized, the labor intensity of marking personnel is reduced, the working efficiency is improved, the precision of landmark marking is ensured, the beneficial effects are substantial, and the method is worthy of popularization.

Owner:济南北方交通工程咨询监理有限公司 +1

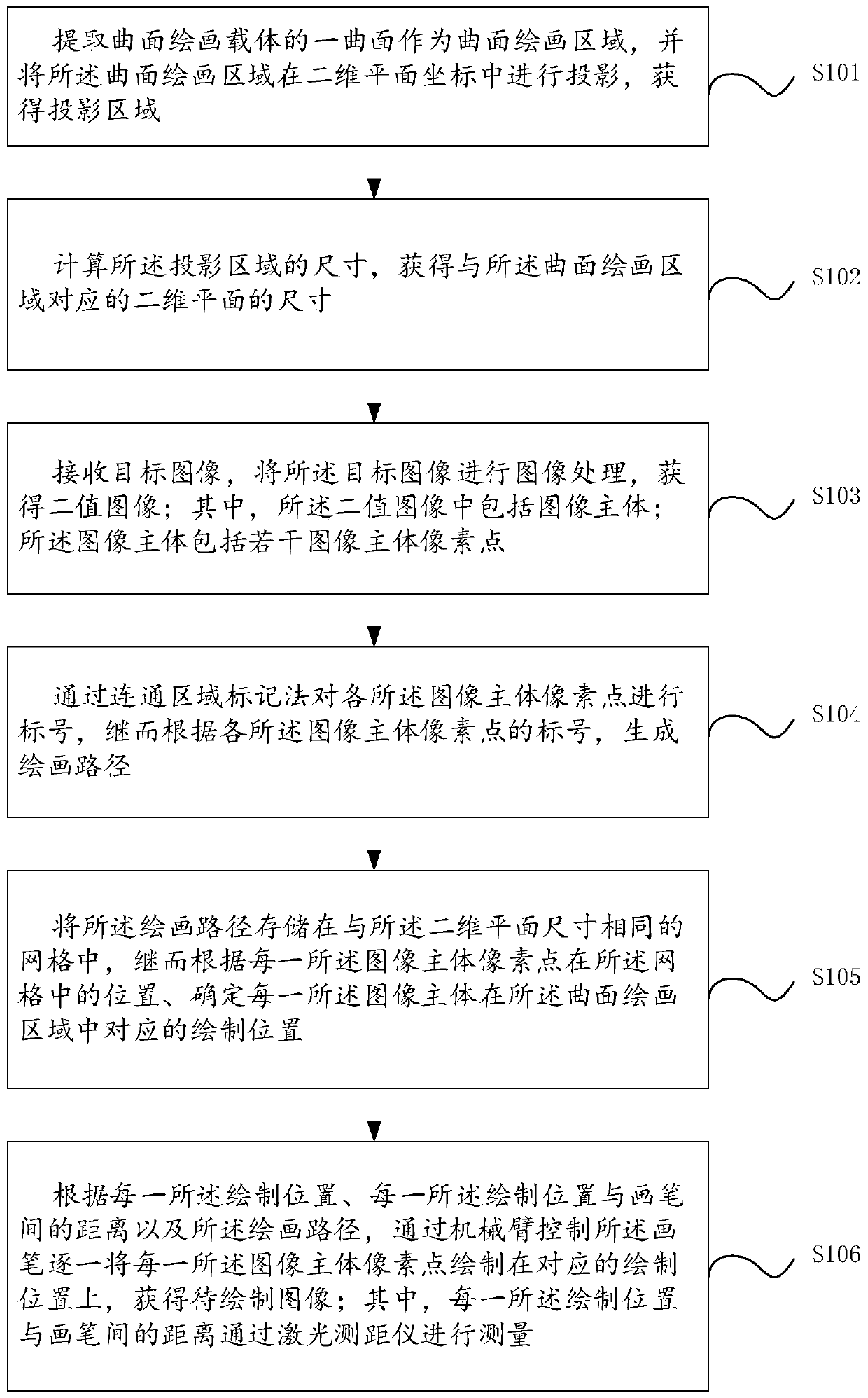

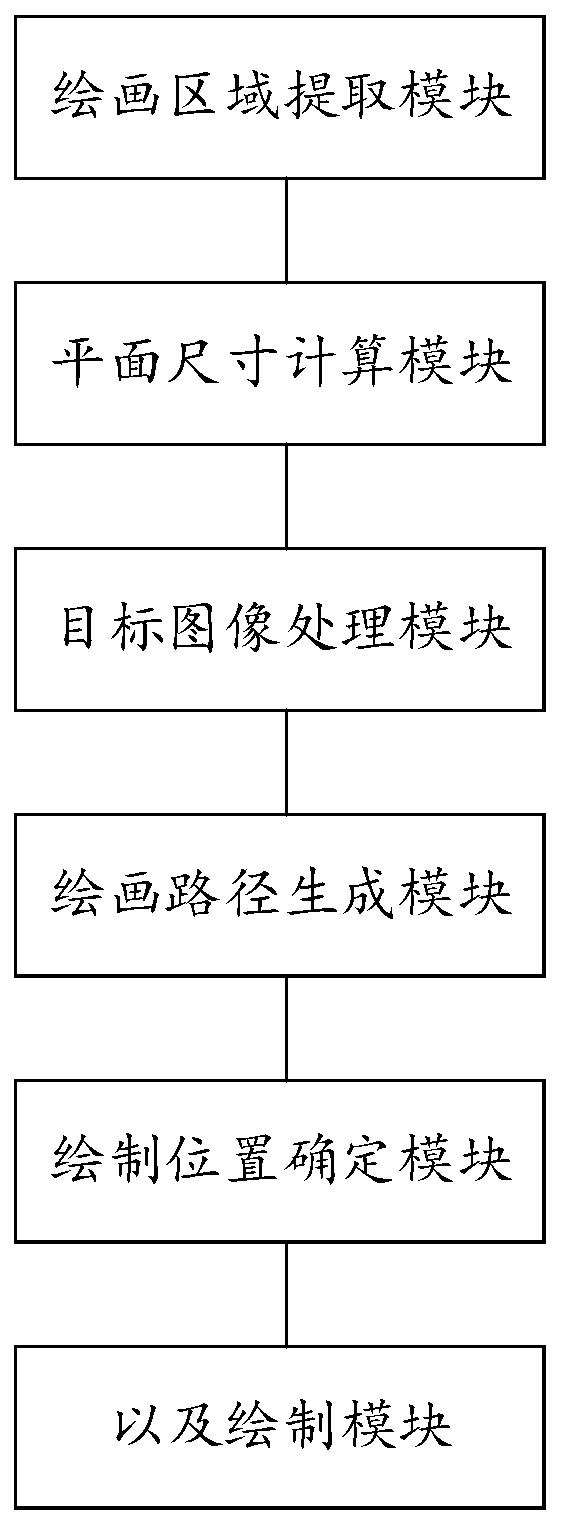

Drawing method, device and system based on curved surface drawing carrier

InactiveCN110587599ARealize automatic paintingRealize intelligent automationProgramme-controlled manipulatorImage analysisImaging processingComputer graphics (images)

The invention discloses a drawing method, device and system based on a curved surface drawing carrier. The method comprises the steps that a curved surface drawing area is extracted from the curved surface drawing carrier, the curved surface drawing area is projected in a two-dimensional plane coordinate to obtain a projection area, and the size of the projection area is calculated to obtain the size of a two-dimensional plane; a target image is received, and the target image is subjected to image processing to obtain a binary image; pixel points of each image main body in the binary image arenumbered through a connected area marking method, and a drawing path is generated; the drawing path is stored in a grid with the same size as the two-dimensional plane, and then the drawing positionof each image main body is determined according to the positions of the pixel points of each image main body in the grid; and according to each drawing position, the distance between each drawing position and a drawing pen and the drawing path, the pixel points of each image main body are drawn one by one on the corresponding drawing positions. According to the method, device and system, automaticdrawing on the curved surface drawing carrier can be realized, and the labor cost is saved.

Owner:GUANGDONG INTELL VISION TECH CO LTD

Traffic guardrail reflective tape automatic smearing device

InactiveCN109382253AReasonable structureFunctionalLiquid surface applicatorsCoatingsRoad surfaceEngineering

The invention discloses a traffic guardrail reflective tape automatic smearing device. The traffic guardrail reflective tape automatic smearing device comprises a surrounding protecting rack, a rotating disk, a smearing cylindrical body, and smearing sponge blocks; the internal side bottom surface of the surrounding protecting rack is fixedly connected with a motor; the top of a rotating shaft ofthe motor is fixedly connected with the bottom surface of the rotating disk; the panel surface of the rotating disk is fixedly connected with positioning columns; the top of each positioning column isrotatingly connected with a gear; the top surface of each gear is fixedly connected with a stand column; the rod body of each stand column is fixedly connected with one end of a telescopic rod, and the other end of the telescopic rod is fixedly connected with a panel surface of a supporting protecting plate; the panel surface of the rotating disk is fixedly connected with the smearing cylindricalbody; the top end of the smearing cylindrical body is fixedly arranged at the bottom surface of a top plate. The traffic guardrail reflective tape automatic smearing device can be used for batch spraying coating before traffic guardrail installation, and reducing workload of workers in spraying coating along streets; operation is not limited by weather conditions; and cleaning work caused by dropping of paint on the roads is avoided.

Owner:何振中

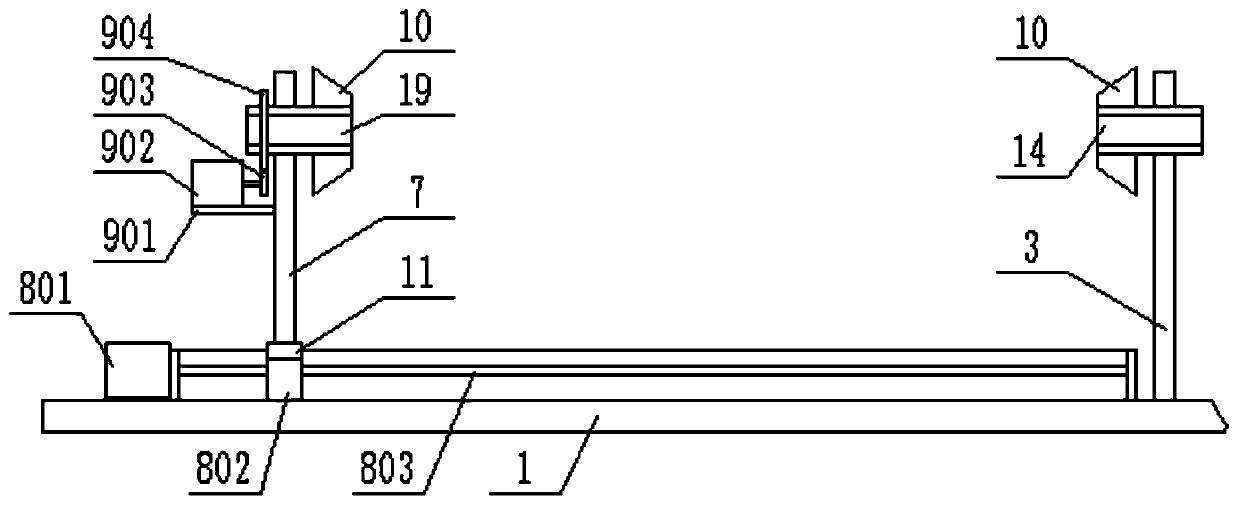

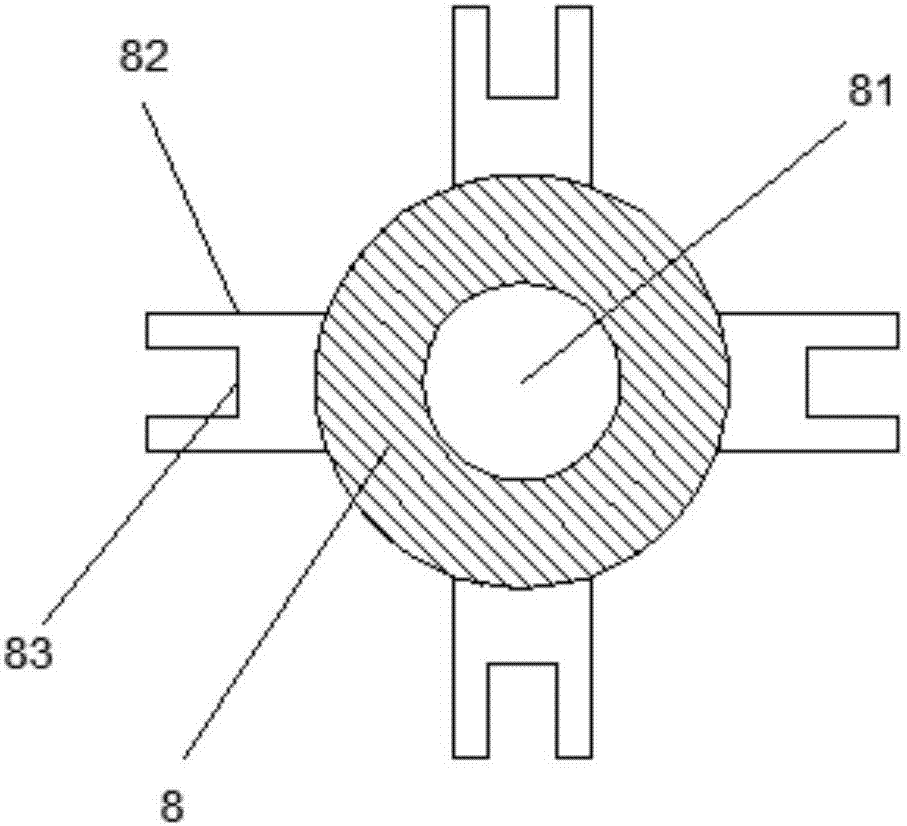

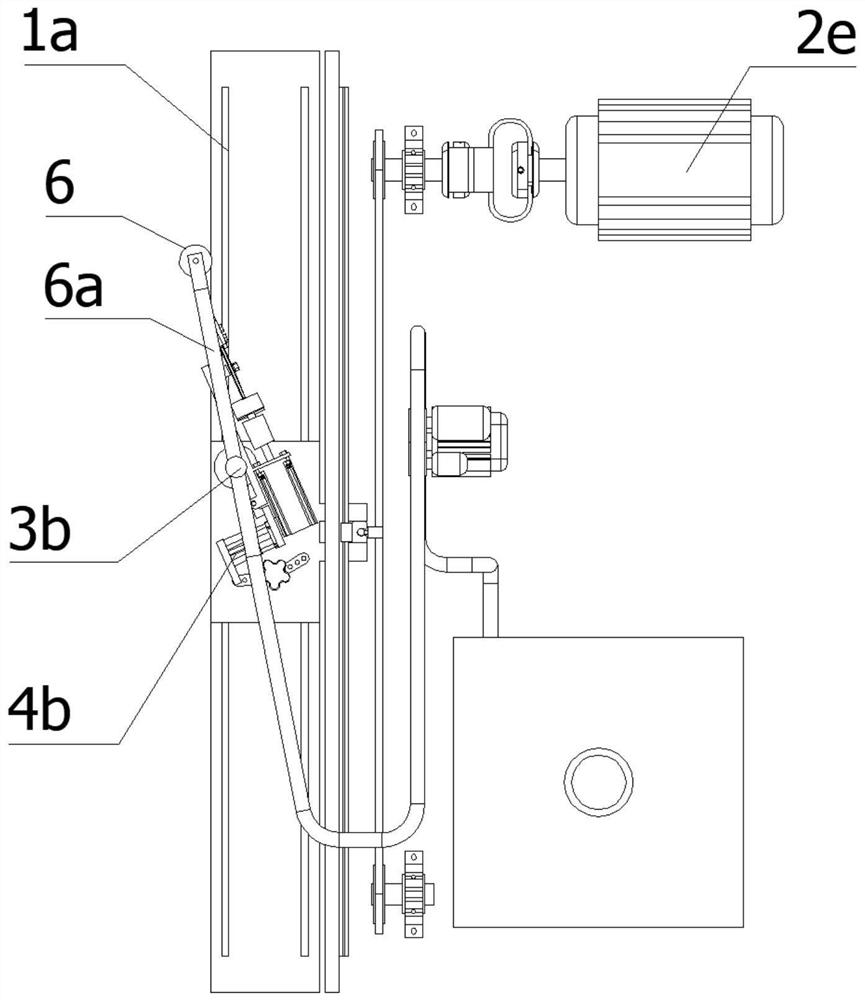

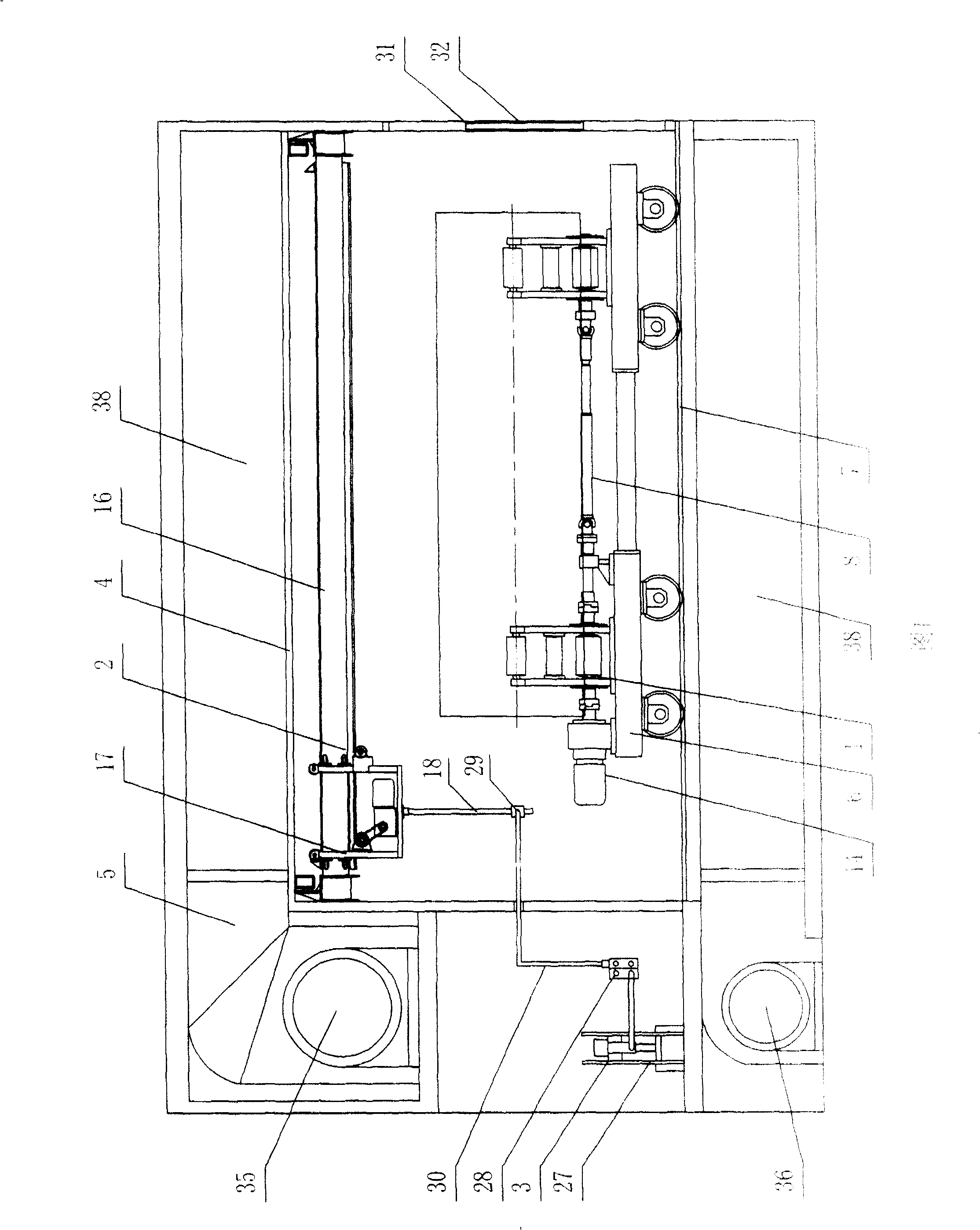

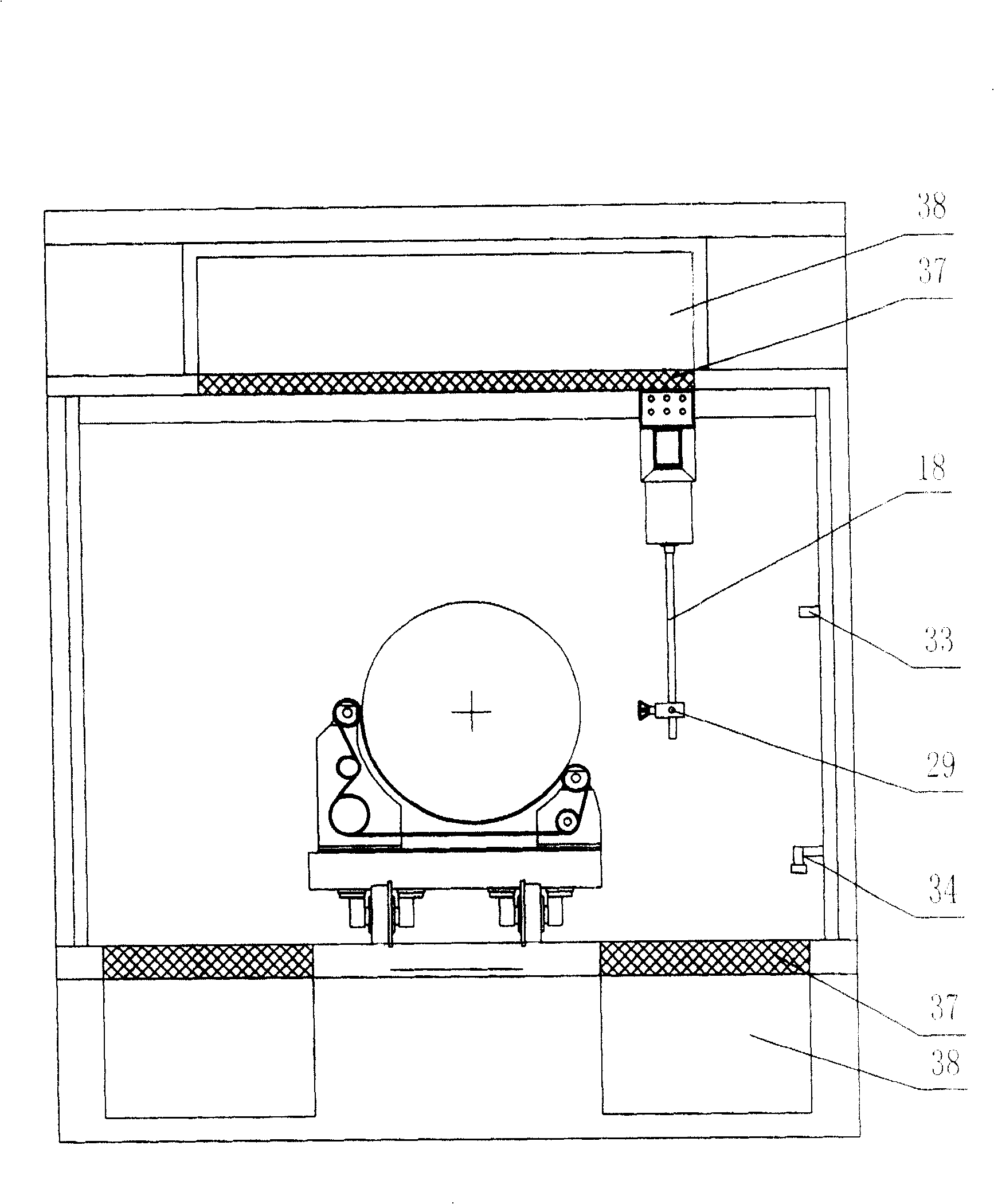

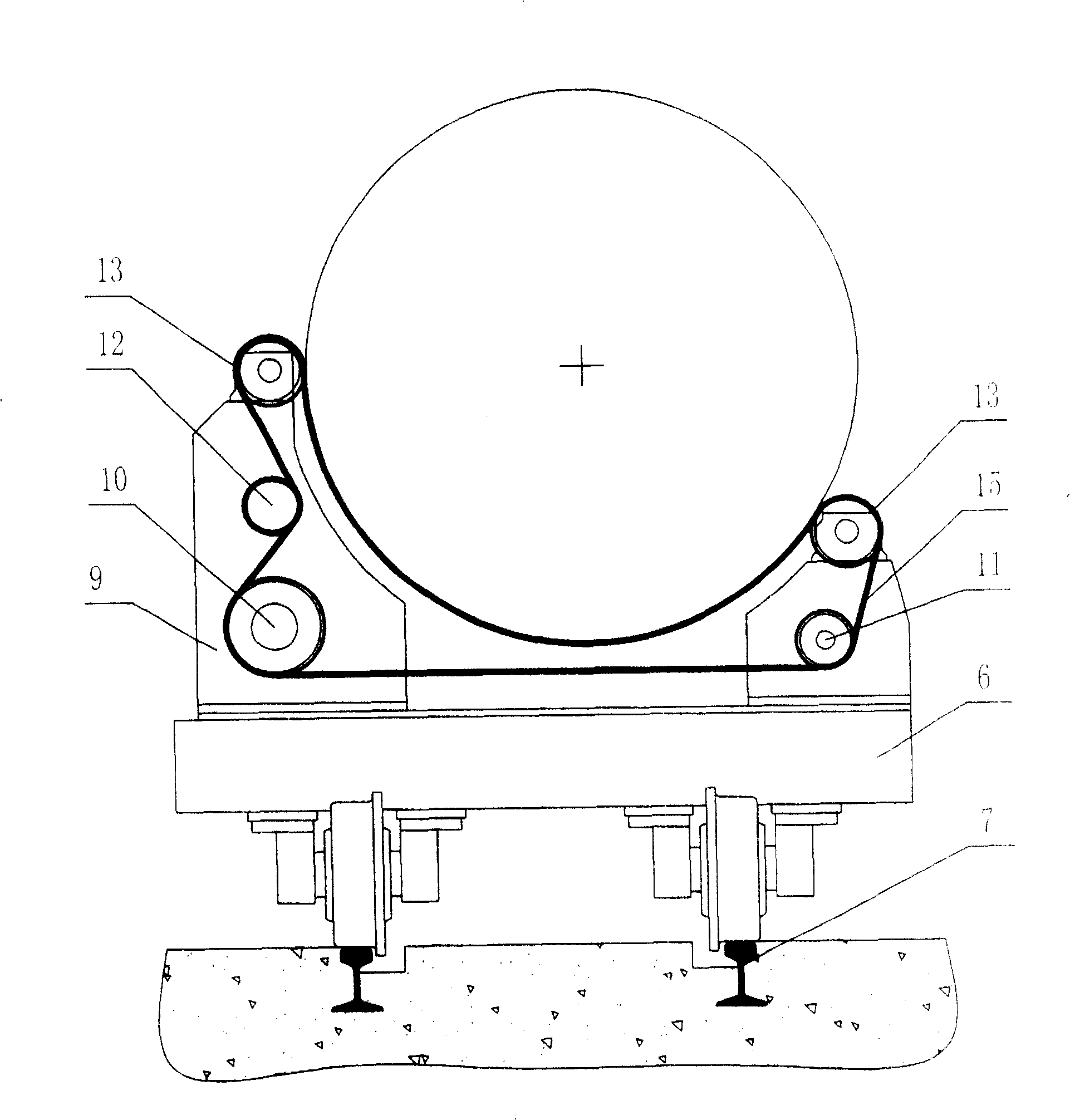

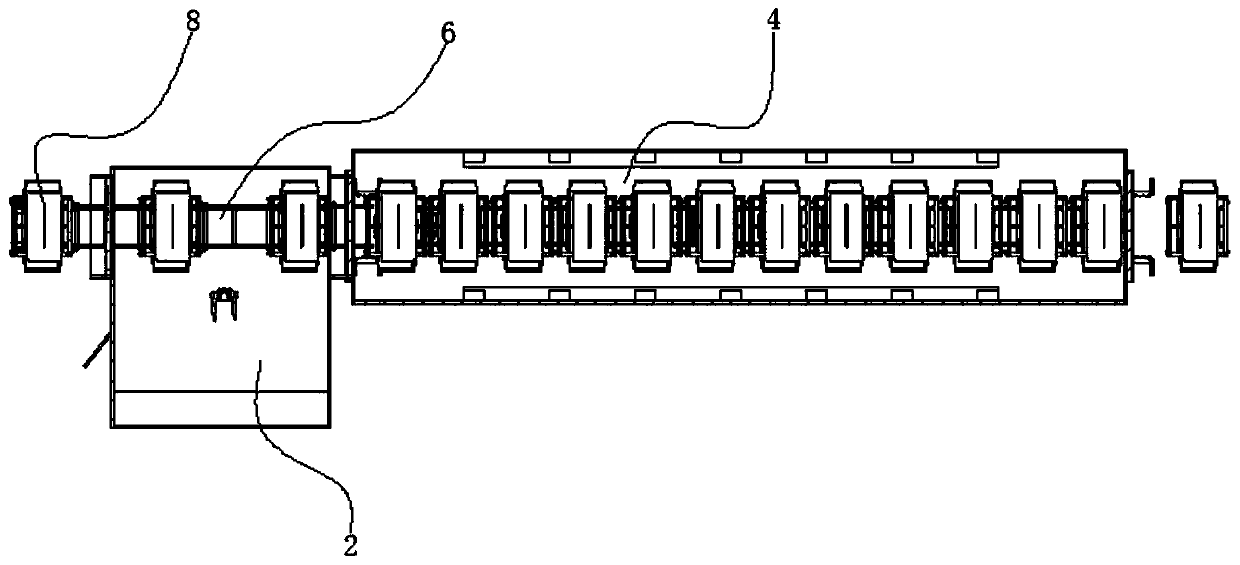

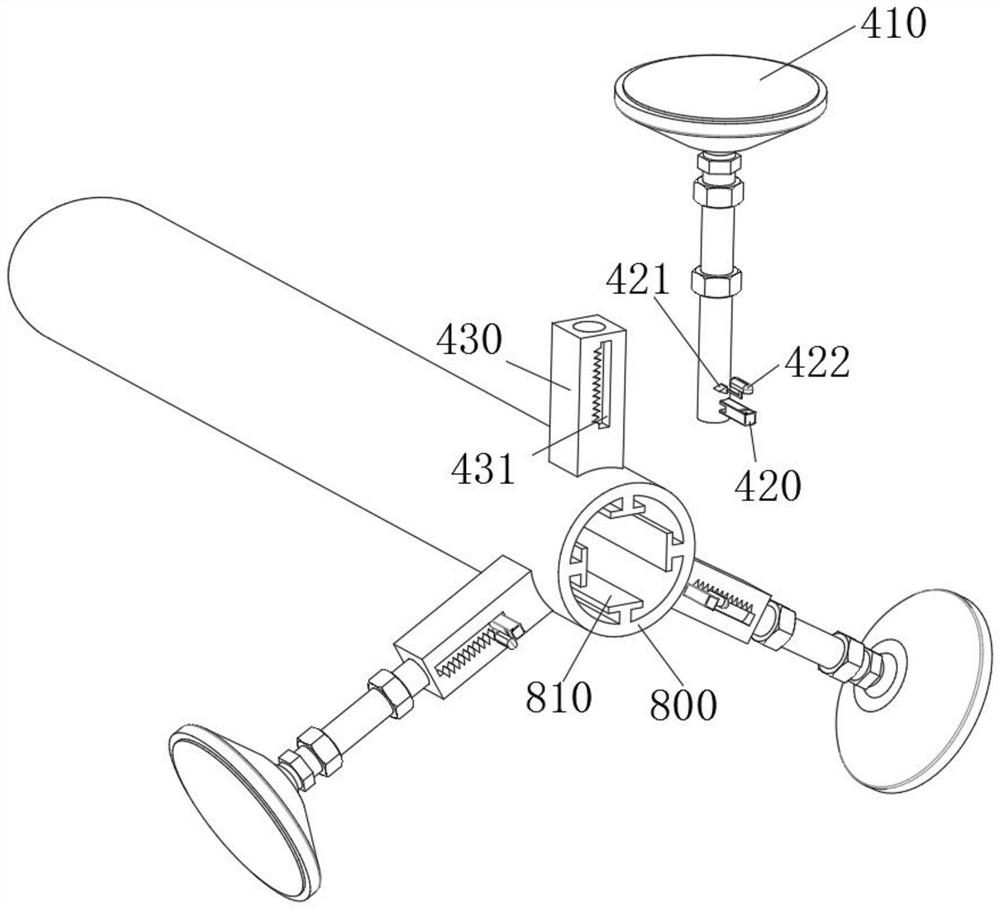

Automatic lacquer spraying system for surface of rotating body

InactiveCN100450641CRealize automatic paintingHigh degree of automationLiquid surface applicatorsSpraying apparatusBogieLacquer

The present invention relates to a kind of automatic lacquer spraying system for the surface of rotating body, especially large rotating body. The automatic lacquer spraying system includes a spray booth, a bearing bogie inside the spray booth, a supporting and rotating device on the bogie, a spray gun moving mechanism, a cantilever bracket extending from the spray gun moving mechanism, an automatic spray gun connected to the cantilever bracket, and a pressure lacquer source connected via pipeline to the automatic spray gun. The present invention has the advantages of automatic operation, high coating quality, high production efficiency, safe and environment friendly operation condition, etc.

Owner:HONGYANG MACHINERY FACTORY

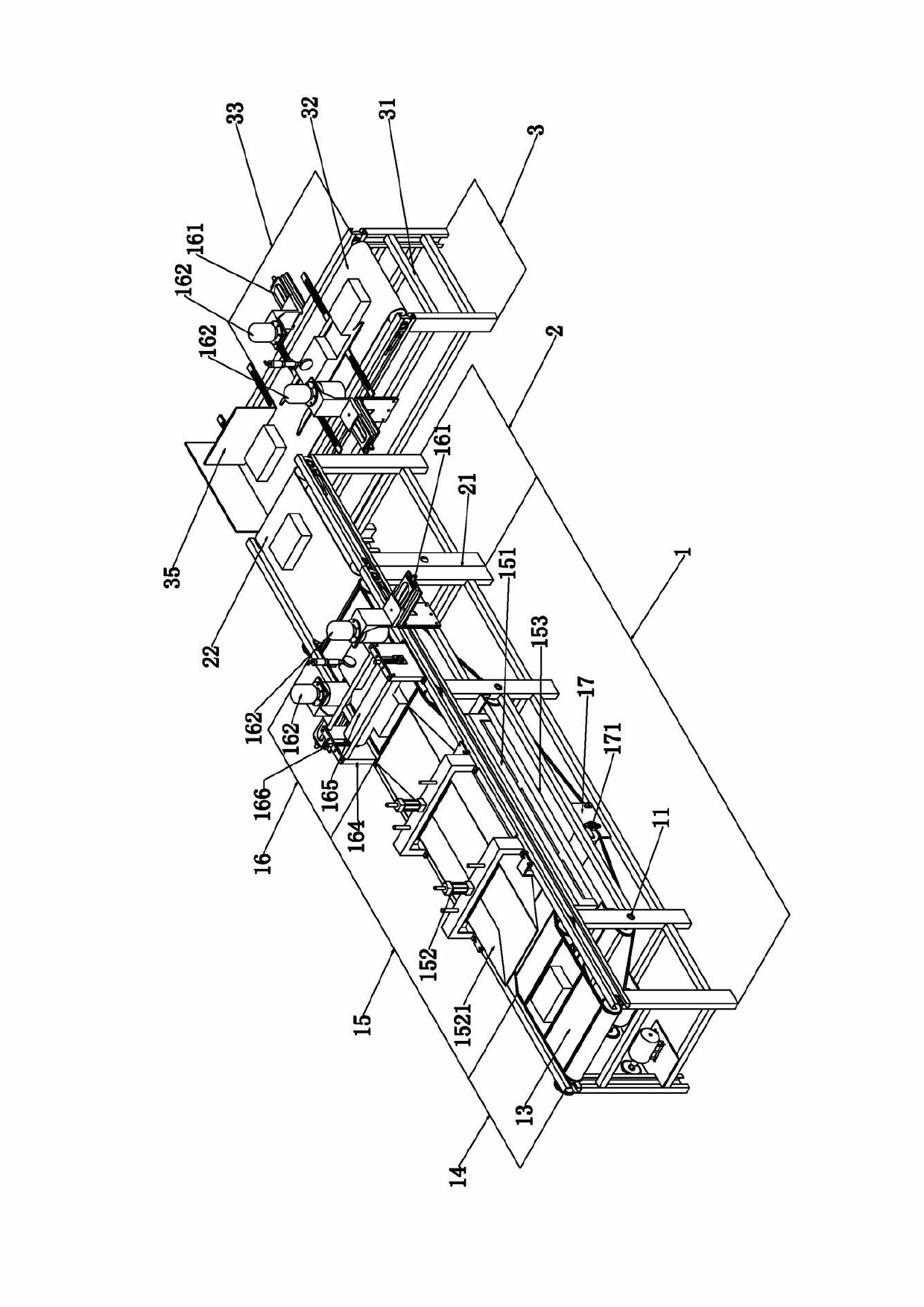

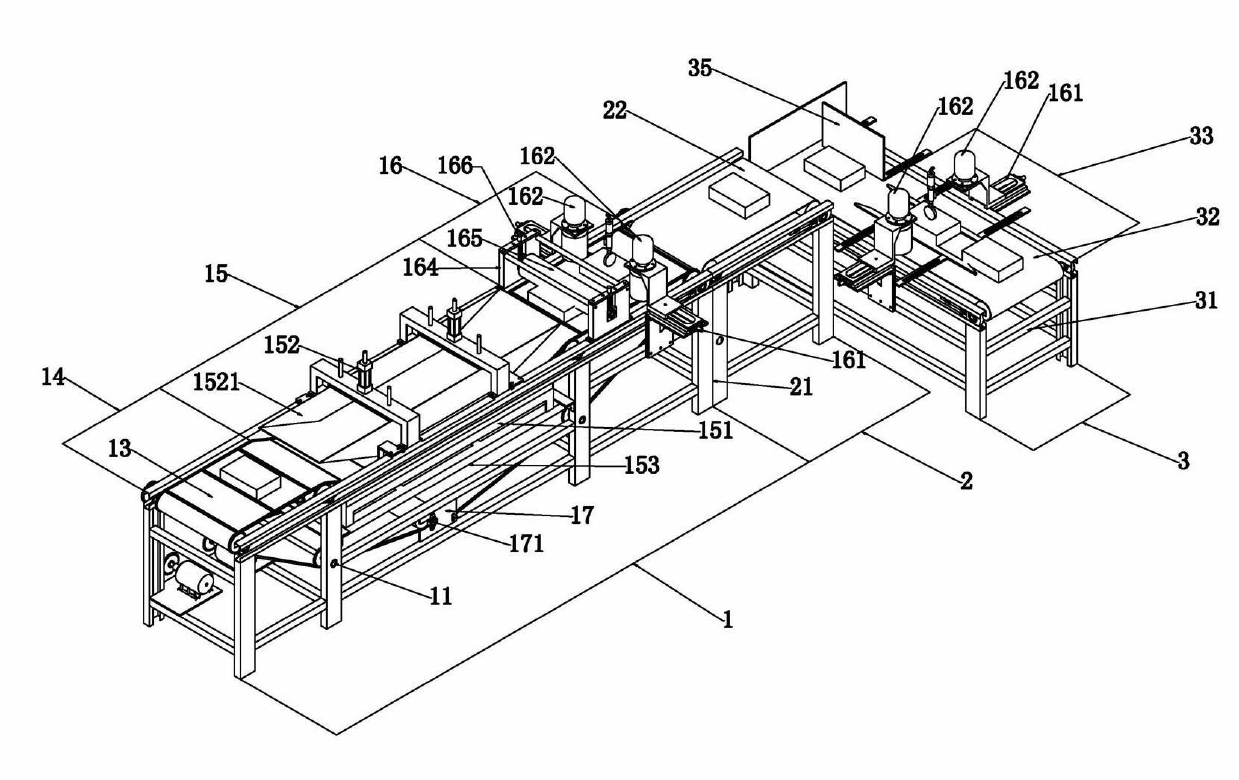

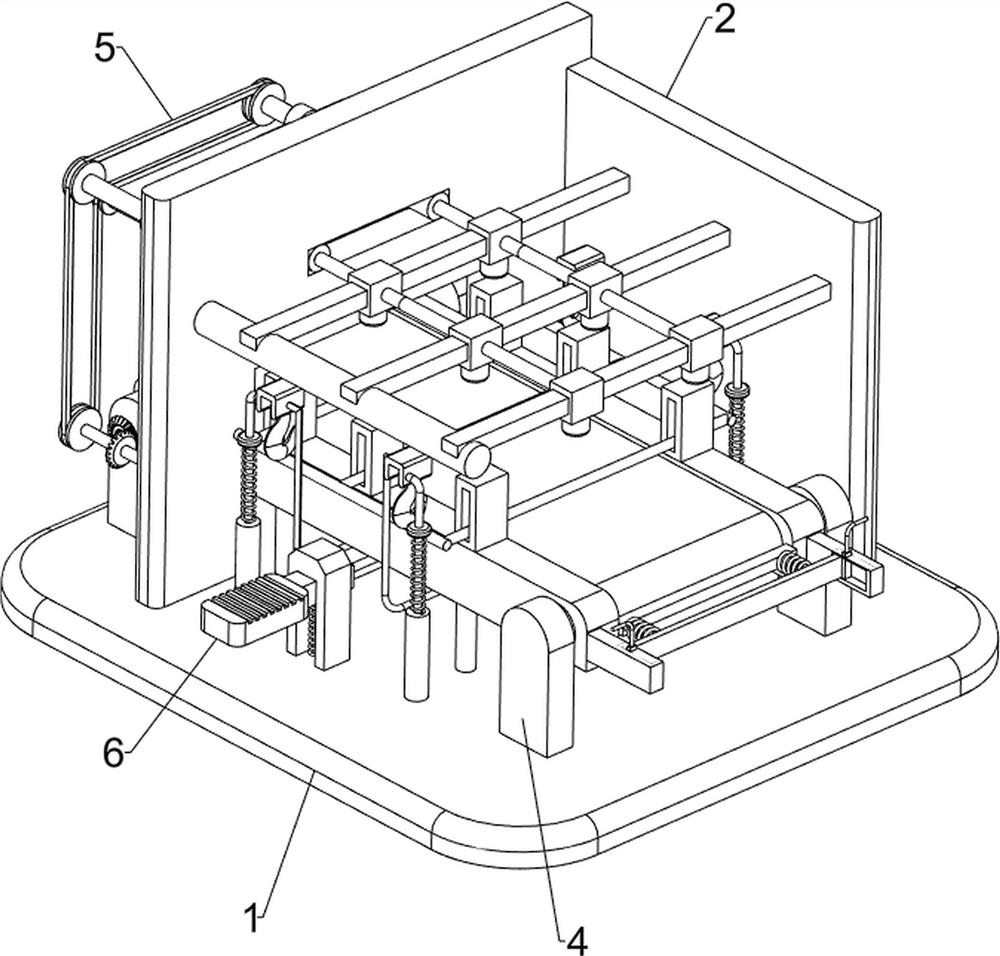

Multifunctional automatic furniture painting production line

PendingCN110124925AReduce configurationReduce consumptionSpray boothsProduction lineOperational costs

The invention discloses a multifunctional automatic furniture painting production line and belongs to the technical field of painting equipment. The multifunctional automatic furniture painting production line comprises a body, a feeding port and a discharging port. The feeding port is formed in one end of the body, and the discharging port is formed in the other end of the body. The multifunctional automatic furniture painting production line has the beneficial effects that the structure is simple, the operation is convenient, and the use effect is good; online no-landing production, automatic transportation and automatic operation are realized, the number of assigned painters is reduced, the labor intensity is reduced, the labor efficiency is remarkably improved, and the space can be maximized; and the cost of space occupation is remarkably reduced; due to the fact that the whole process is operated in a closed and insulated space, the precise control over the environmental parameters of each stage can be automatically realized according to the process requirements, and the energy consumption can be remarkably reduced by reducing the space occupation; and the space is compact, and the total amount of the VOC emission can be reduced, so that the investment and operating costs of VOC processing equipment are reduced.

Owner:佛山市卡勒美智能科技有限公司

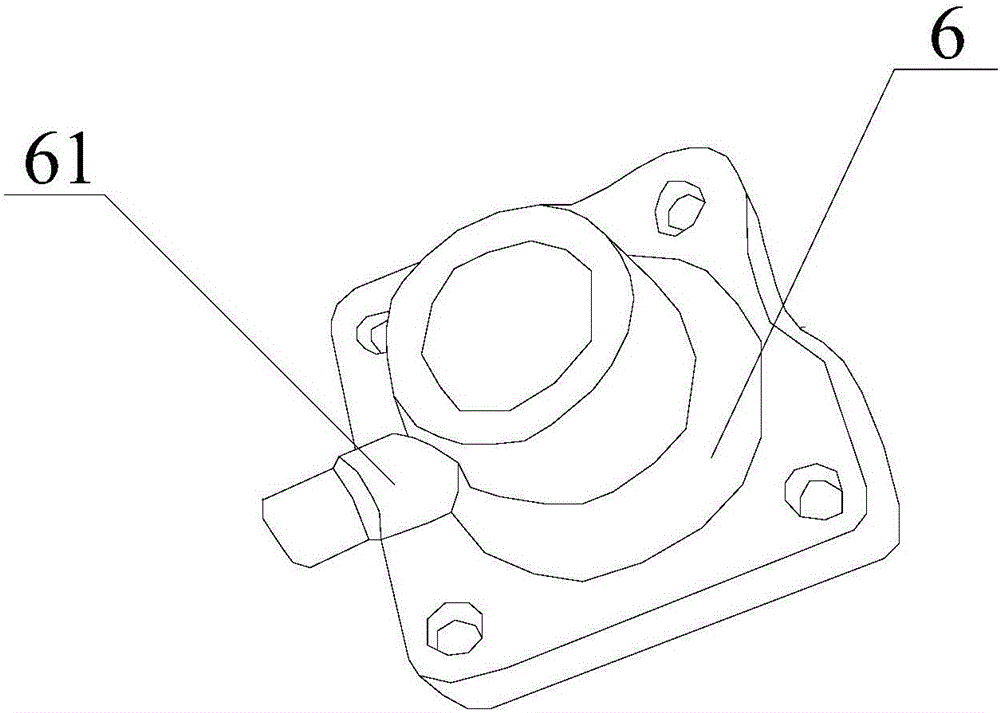

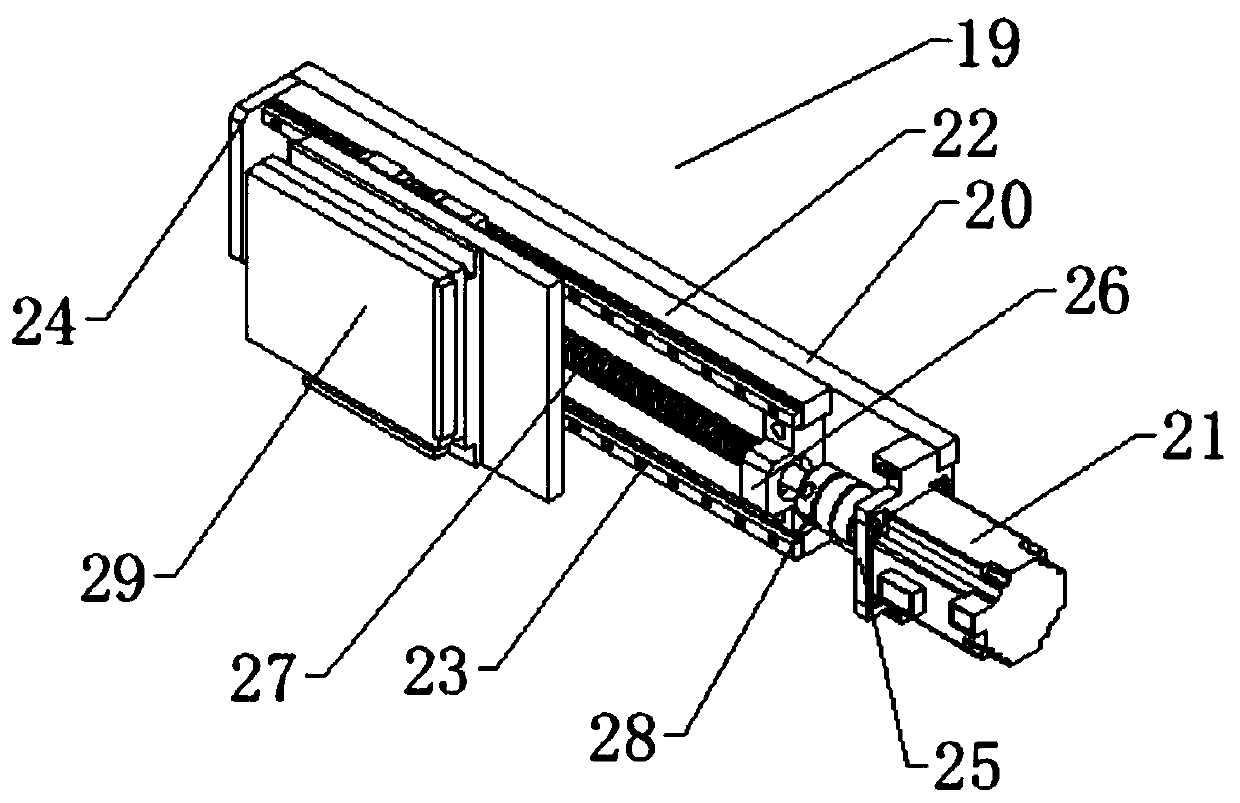

A spraying device for the production and treatment of HVAC pipe fittings

ActiveCN112588483BRealize automatic paintingImprove spraying efficiencySpraying apparatusPipe fittingElectric machine

The invention relates to the technical field of heating transportation, in particular to a spraying device for the production and treatment of HVAC pipe fittings, which includes a bottom plate and two fixing frames, the two fixing frames are respectively slidably connected to the two ends of the bottom plate, and the two fixing frames A first inner column and a second inner column are respectively arranged therebetween. In the present invention, the second motor rotates to drive the gear to rotate, and the gear and the rack are meshed to make the outer cylinder slide to the side of the second inner column. When the pipeline passes through the paint spray wheel, the paint spray wheel starts to completely smear the paint on the On the outer wall of the pipe, the rotation of the first inner column and the second inner column is driven by the first motor, so that the pipe can rotate in a circle. Rely on, the pipe will be rotated relative to the paint plate so that the paint on the pipe is completely distributed evenly, which improves the quality of the spray pipe and makes the paint smear more even.

Owner:周凯锋

Paint spraying equipment for machining

InactiveCN109127254AImprove stabilityAvoid shakingLiquid spraying apparatusSpray boothsMotor driveLow speed

The invention discloses paint spraying equipment for machining, and relates to the technical field of machining. The paint spraying equipment comprises a shell. The interior of the shell is fixedly connected with a partition matched with the shell, a containing mechanism is mounted on the left side of the upper surface of the partition, a rotating mechanism is mounted on the inner bottom wall of the shell, the inner bottom wall of the shell is fixedly connected with a storage bin, the upper surface of the containing bin fixedly communicates with a through pipe, the top end of the through pipepenetrates through the partition and stretches to the upper surface of the partition, and the left side face of the storage bin fixedly communicates with a discharge pipe. According to the paint spraying equipment for machining, through the arrangement of a low-speed motor, a rotary rod and a containing disc, the low-speed motor drives the rotary rod to rotate, the rotary rod drives the containingdisc to rotate, and a workpiece body put on the upper surface of the containing plate rotates. Paint is sprayed more uniformly, the whole paint spraying equipment can achieve automatic paint sprayingof mechanical workpieces, manual paint spraying is avoided, and the working efficiency is improved.

Owner:盐城新时代智能检测设备制造厂

Section bar surface rust-proof spraying device used after aluminum alloy door and window machining

ActiveCN112371388ARealize automatic paintingPrevent sprayingLiquid spraying apparatusSpray boothsEngineeringMachining

The invention discloses a section bar surface rust-proof spraying device used after aluminum alloy door and window machining. The section bar surface rust-proof spraying device comprises a supportingmechanism used for supporting the device, a paint spraying mechanism used for spraying paint and a lifting mechanism used for lifting the paint spraying mechanism, wherein the paint spraying mechanismis arranged in the supporting mechanism; the lifting mechanism is arranged on the upper side of the paint spraying mechanism; the lifting mechanism is in sliding connection with the paint spraying mechanism; the lifting mechanism is connected with the supporting mechanism through screws; and the paint spraying mechanism is connected with the supporting mechanism through screws. According to the section bar surface rust-proof spraying device, by arranging a guide rail and a sliding block, manual operation can be replaced, and automatic paint spraying is achieved; and by arranging a base plate,rust-proof paint can be effectively prevented from being sprayed to the surface of glass.

Owner:湖南壹品堂门窗加工有限公司

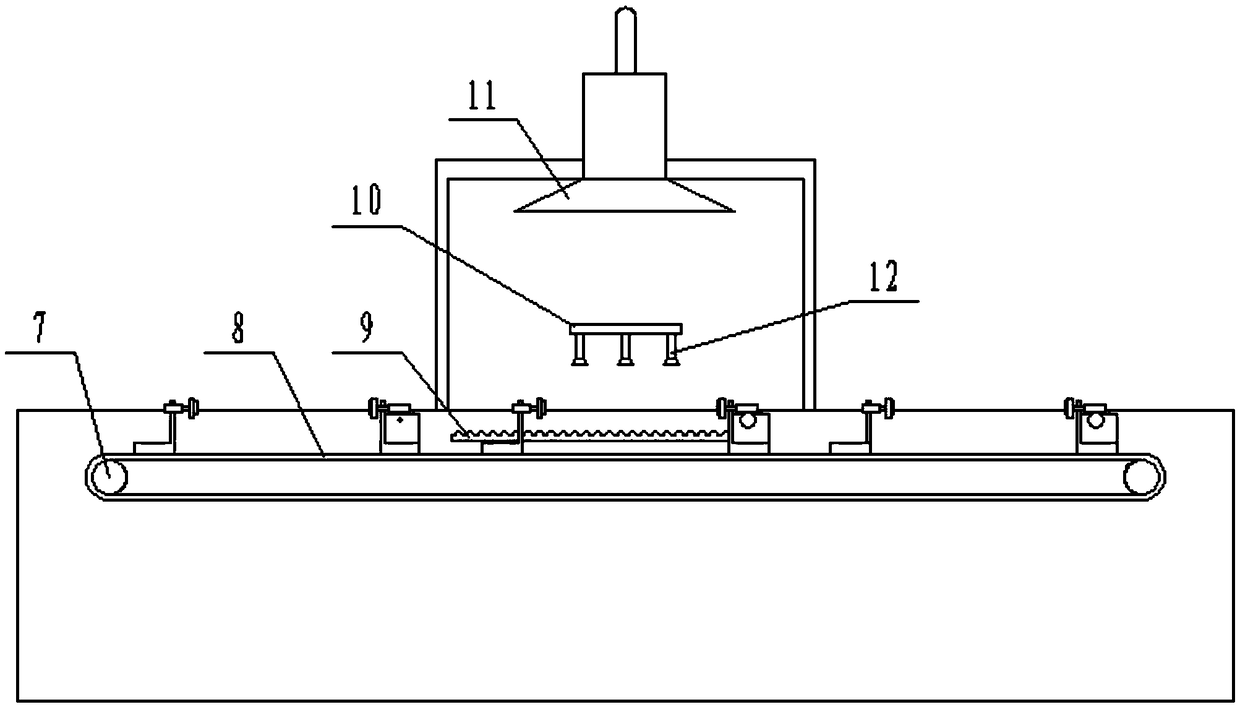

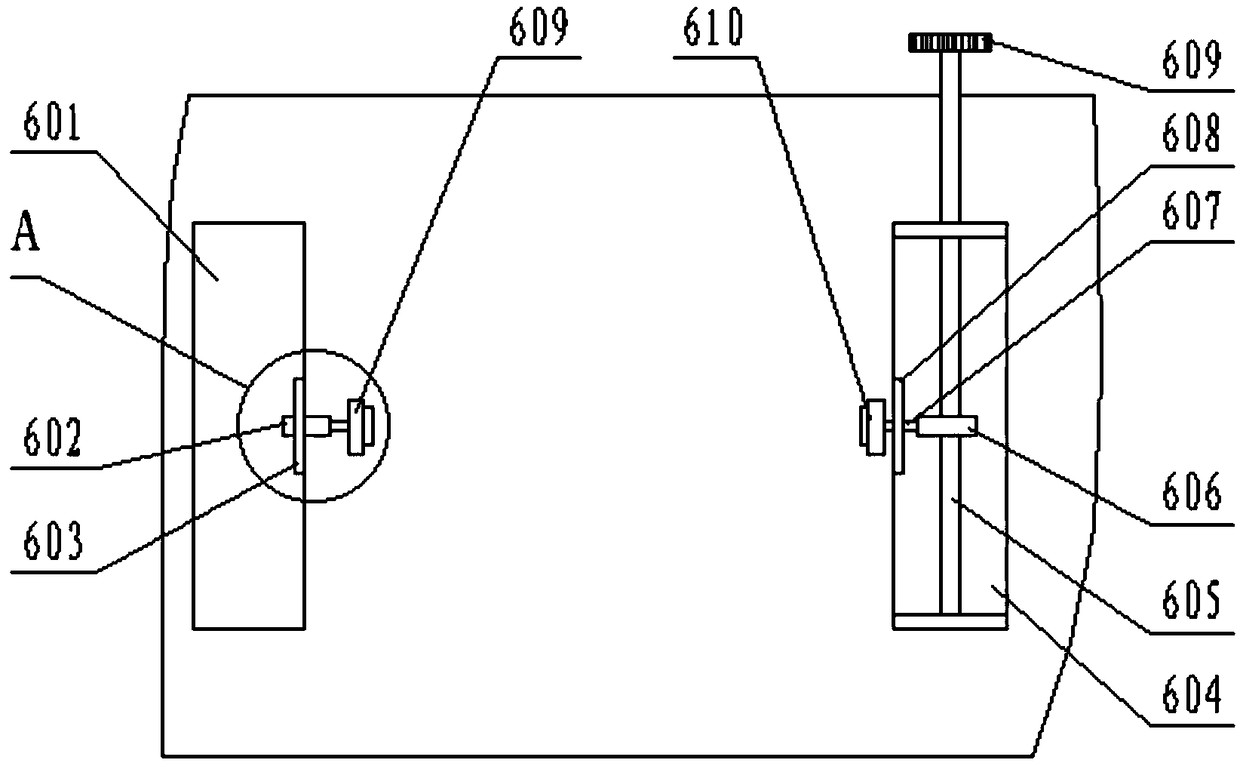

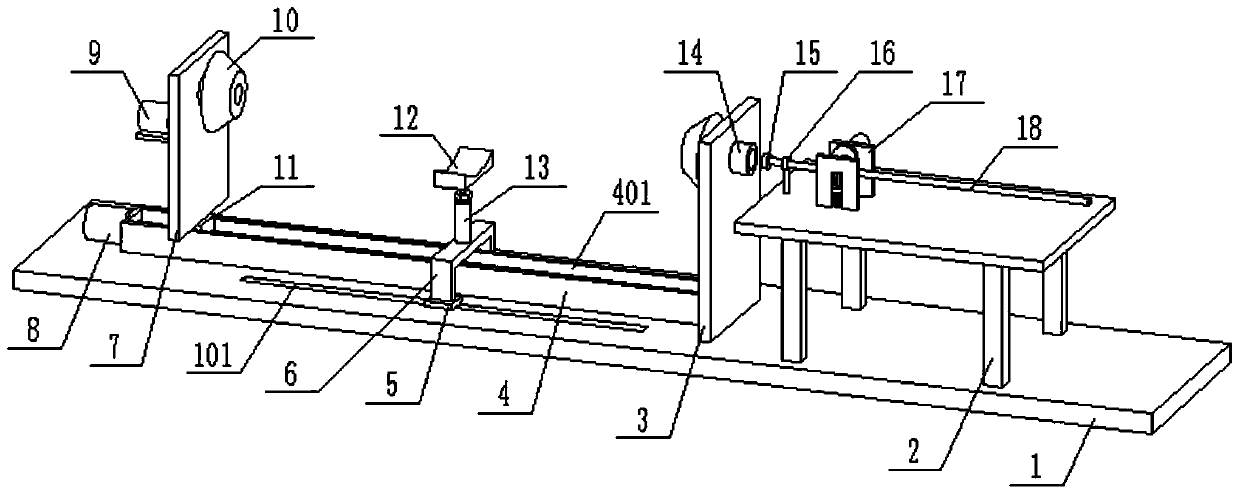

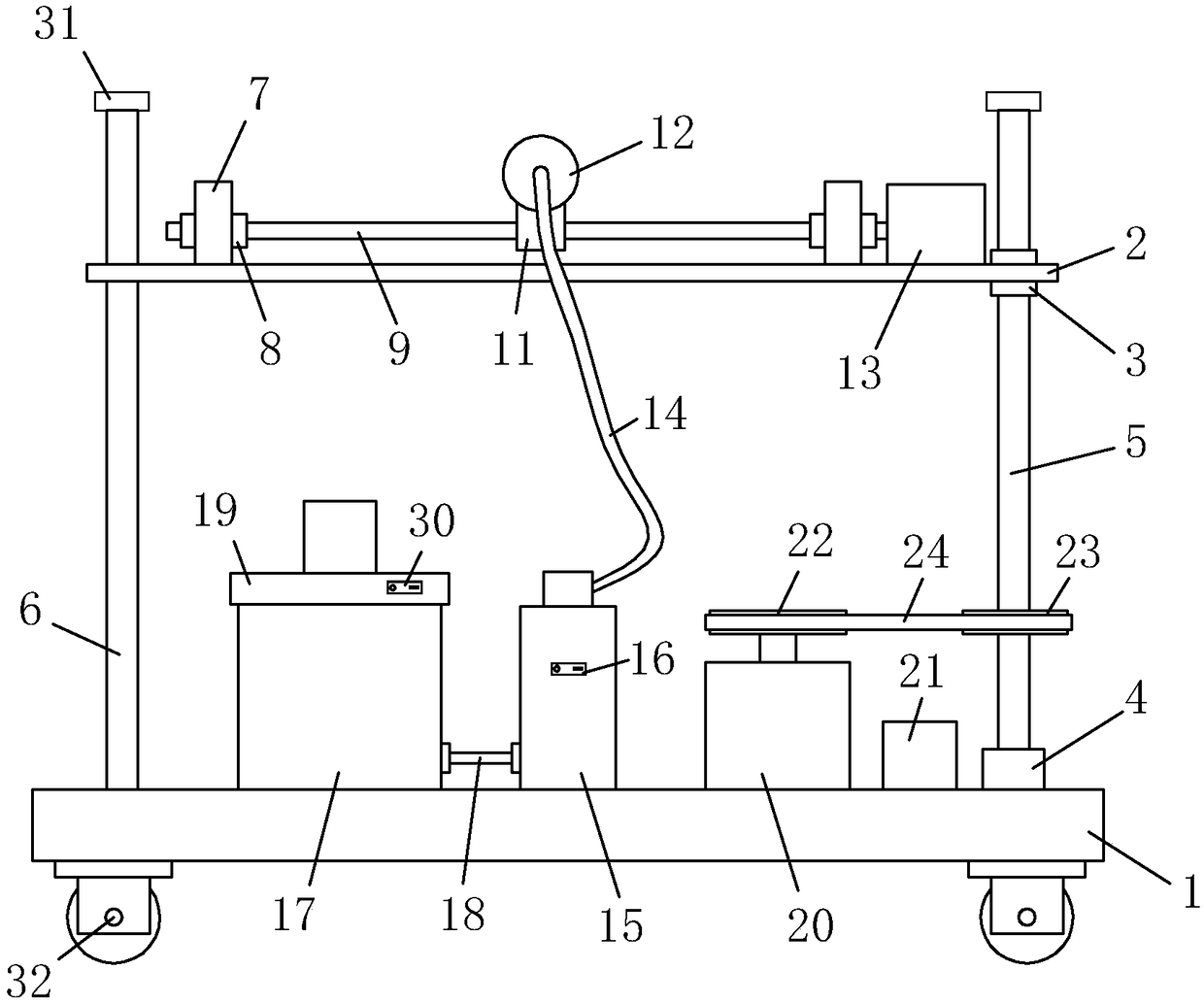

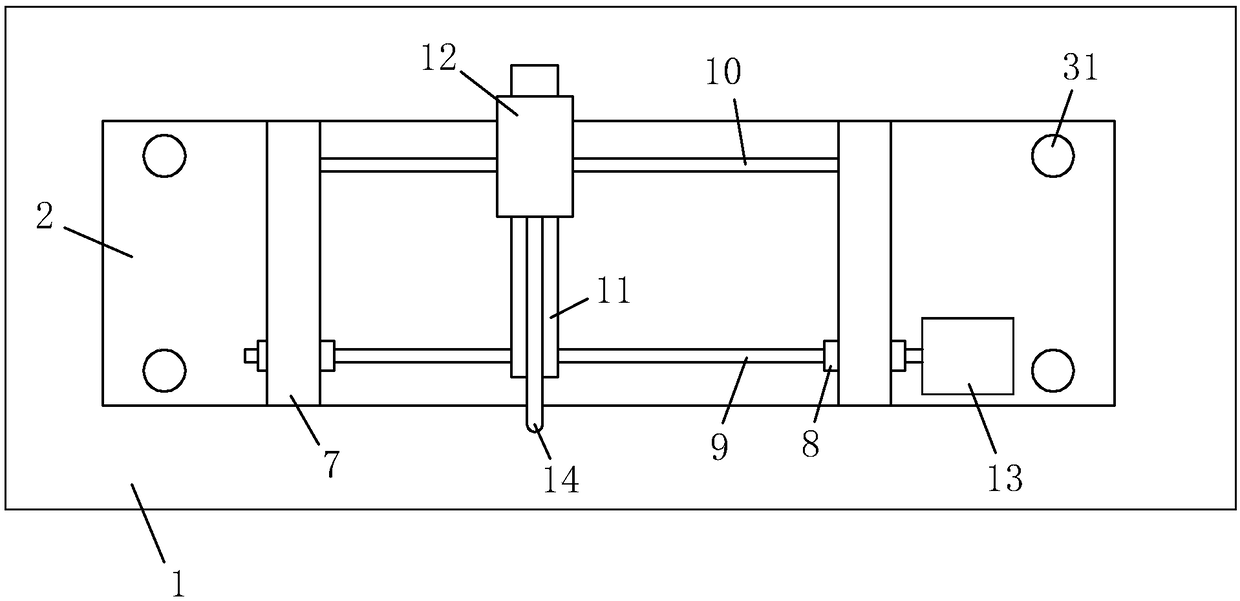

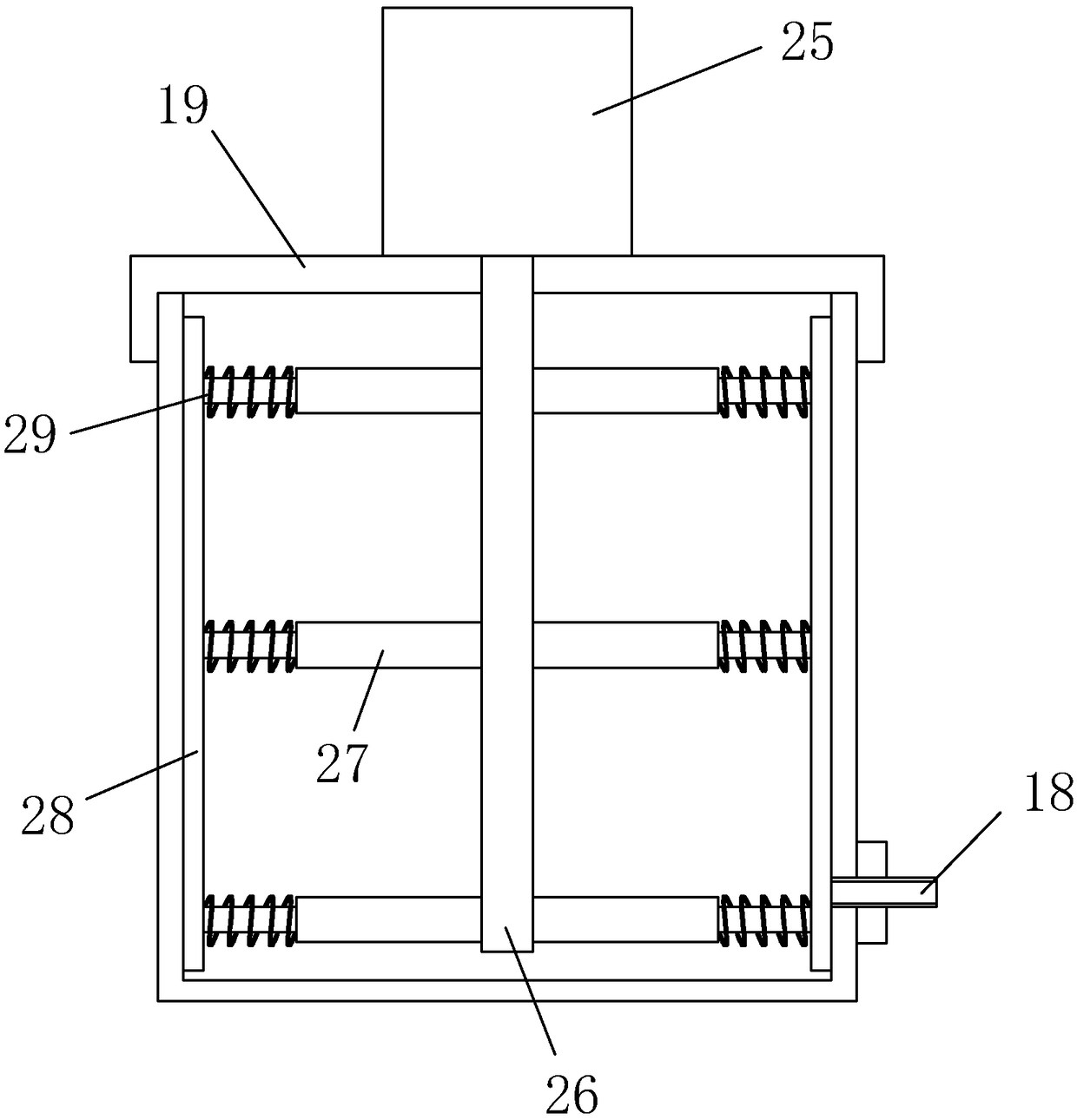

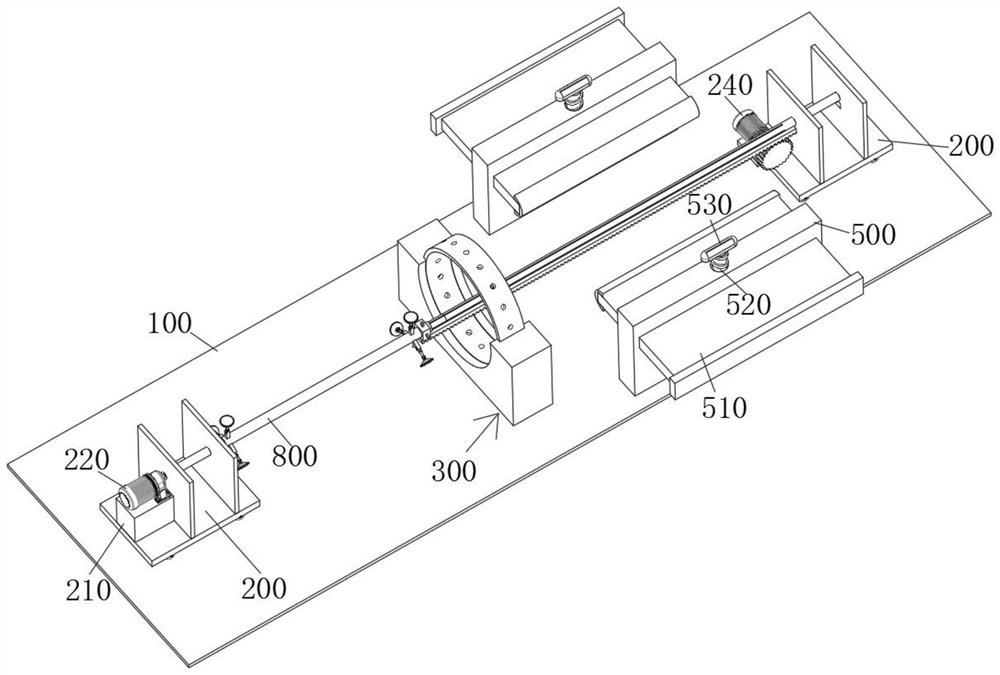

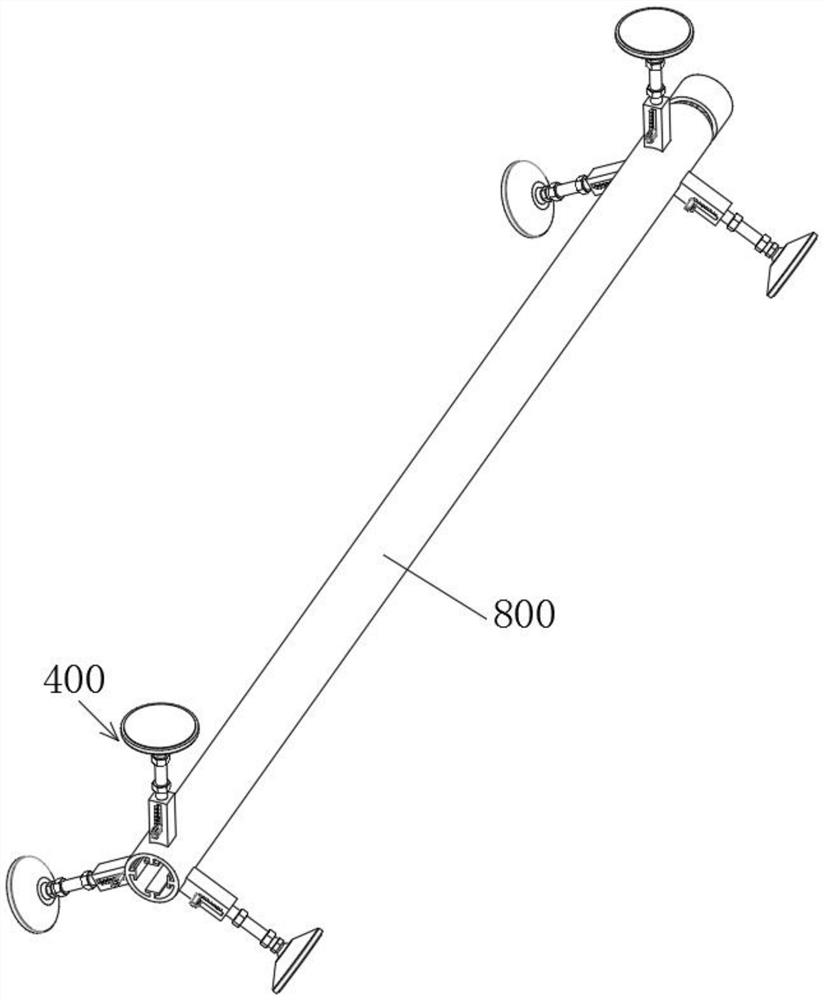

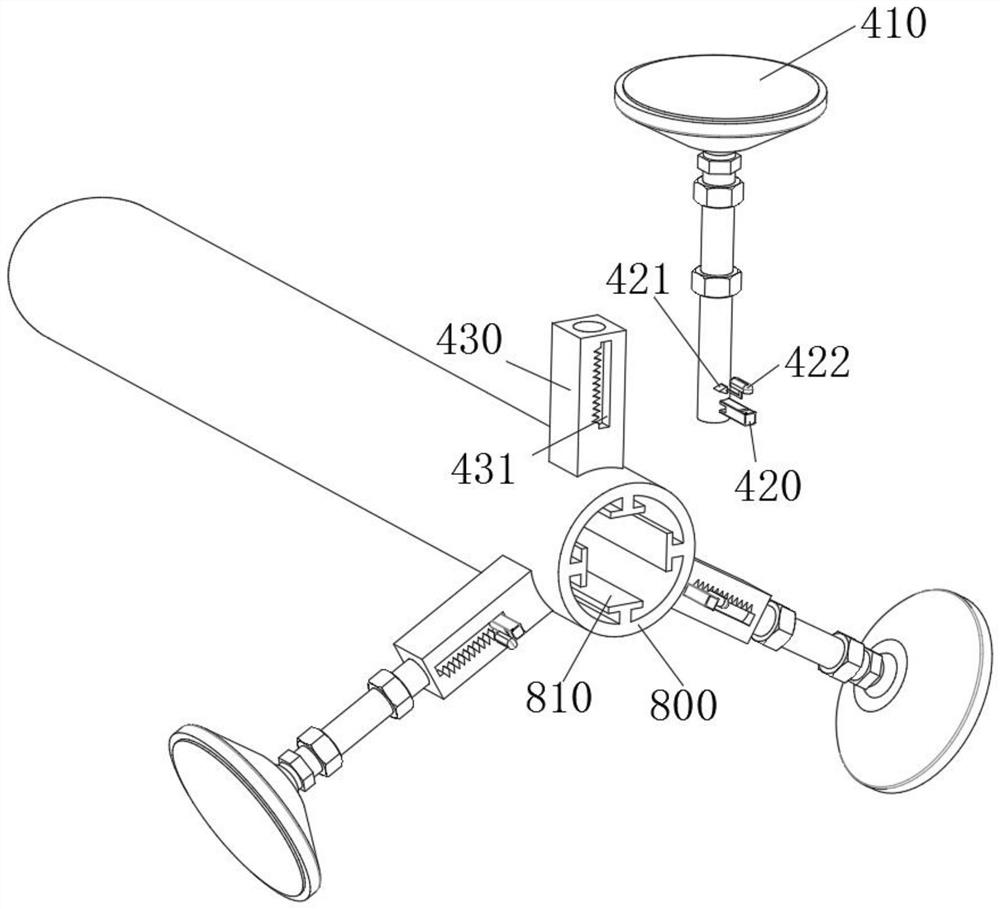

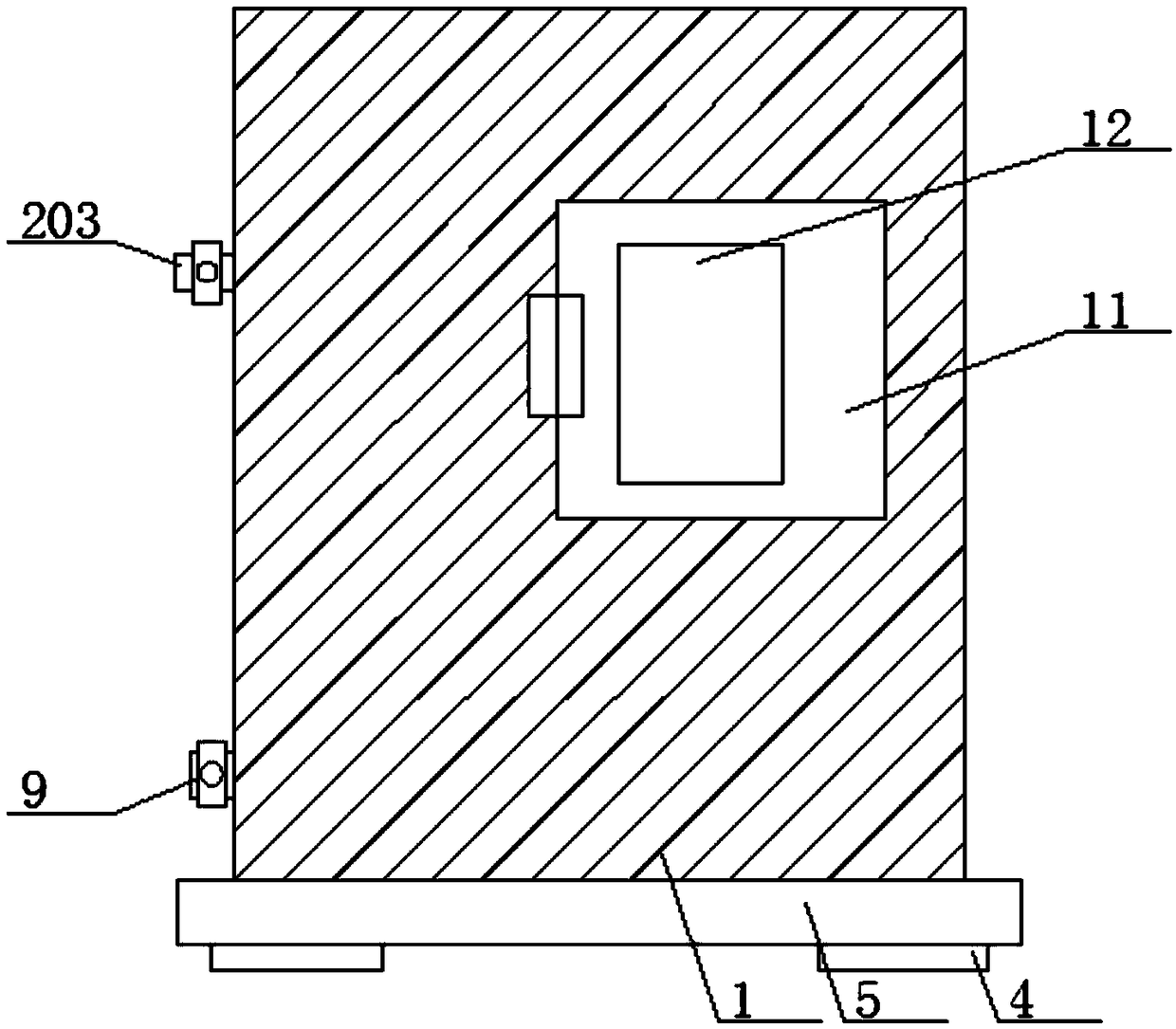

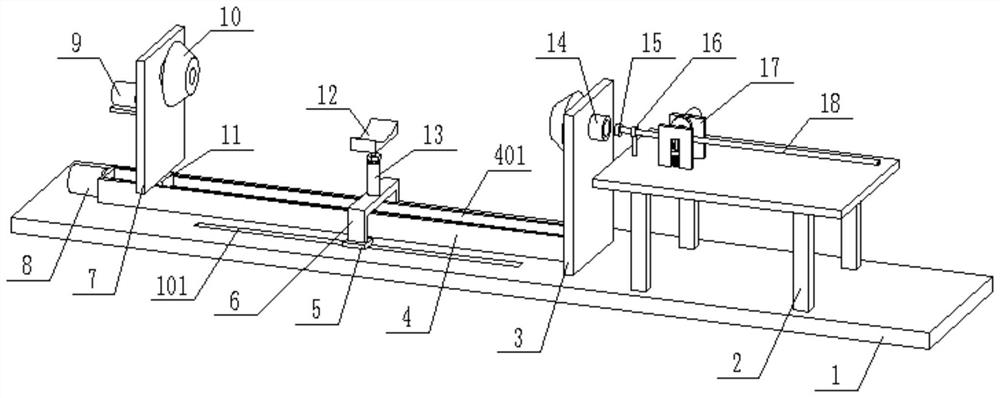

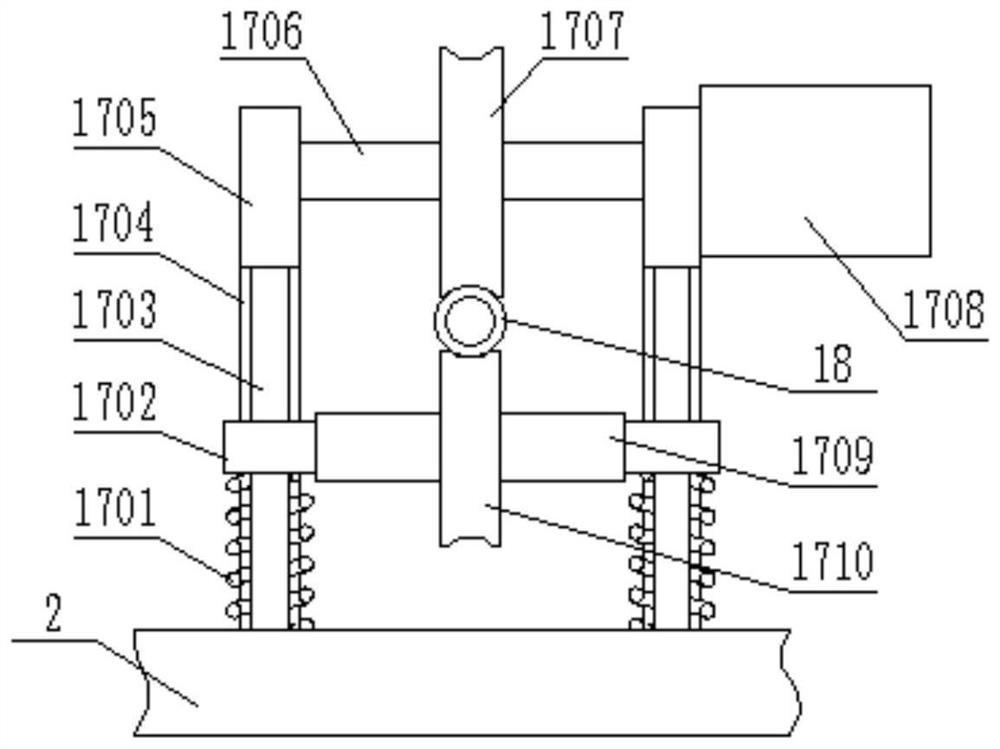

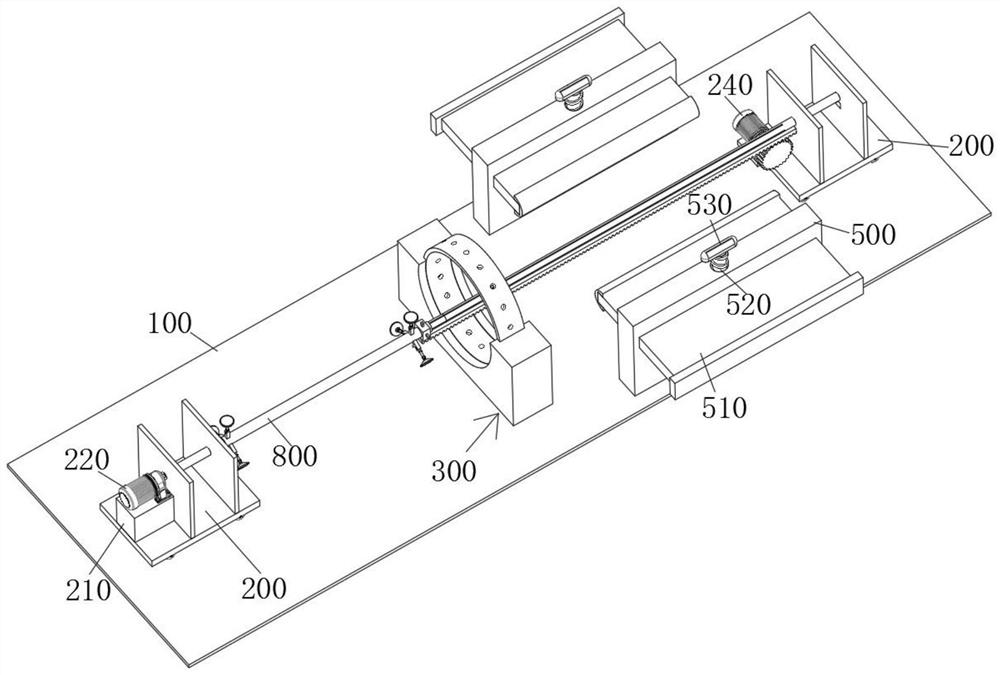

An automatic paint spraying device for the inner wall of a pipeline

ActiveCN109876975BRealize automatic paintingIncrease productivityLiquid surface applicatorsSpraying apparatusFixed bearingSpray nozzle

The invention discloses an automatic paint spraying device for the inner wall of a pipeline. The automatic paint spraying device comprises a fixed substrate, wherein the upper end of the fixed substrate is sequentially provided with a guide rail, a fixed vertical plate and a bearing platform in the length direction; the upper end of the guide rail is provided with a sliding groove; a moving seat and a moving mechanism are arranged in the sliding groove; and a movable vertical plate is arranged at the upper end of the moving seat; the upper parts of the movable vertical plate and the fixed vertical plate are respectively provided with a movable bearing pipe and a fixed bearing pipe through bearings; the outer sides of the movable bearing pipe and the fixed bearing pipe are each provided with a clamping sleeve; the upper end of the bearing platform is provided with a guide ring; a paint guide pipe is slidably mounted in the guide ring; and a spray nozzle is mounted at the end part, closeto the fixed bearing pipe, of the paint guide pipe. The automatic paint spraying device has the beneficial effects that automatic paint spraying on the pipeline can be achieved, the paint spraying effect is good, the paint spraying efficiency is high, and the pipeline production efficiency is improved; and meanwhile, paint mist diffusion is avoided, so that the health of operators is not affected.

Owner:江苏英斯坦福环境科技有限公司

Paint spraying device for glass product decoration

ActiveCN114534969ARealize automatic paintingImprove spraying efficiencySpray boothsReciprocating motionIndustrial engineering

The invention relates to the technical field of glass product processing, and discloses a glass product decoration paint spraying device which comprises a paint spraying assembly and further comprises a U-shaped conveying belt mechanism, a fanning assembly, a driving mechanism and an adjusting mechanism. The paint spraying assembly can be driven by a driving mechanism to do horizontal reciprocating motion above one end of the U-shaped conveying belt mechanism. The driving mechanism can be driven by the adjusting mechanism to change the stroke of horizontal reciprocating motion of the paint spraying assembly. The fanning assembly is driven by the driving mechanism to do circular motion above the other end of the U-shaped conveying belt mechanism. The paint spraying stroke is convenient to adjust, the cost is low, and pre-airing is achieved.

Owner:安徽沃蓝新材料科技有限公司

Spraying device for heating and ventilation pipe fitting production treatment

ActiveCN112588483ARealize automatic paintingImprove spraying efficiencySpraying apparatusElectric machinePipe fitting

The invention relates to the technical field of heating conveying, in particular to a spraying device for heating and ventilation pipe fitting production treatment. The device comprises a bottom plateand two fixing frames, wherein the two fixing frames are slidably connected to the two ends of the bottom plate correspondingly, and a first inner column and a second inner column are arranged between the two fixing frames correspondingly. According to the spraying device, a second motor rotates to drive a gear to rotate, the gear meshes with a rack, an outer cylinder slides towards one side of the second inner column, when a pipeline passes through a paint spraying wheel, the paint spraying wheel is started, paint is completely smeared on the outer side wall of the pipeline, and a first motor drives the first inner column and the second inner column to rotate, so that the pipeline can circumferentially rotate, when the pipeline passes through a coating plate, a sponge roller of the coating plate slides to be extruded and attached to the side wall of the pipeline, and the pipeline can rotate relative to the coating plate, so that the paint on the pipeline is completely and uniformly distributed, the quality of pipeline spraying is improved, and the paint is more uniformly smeared.

Owner:周凯锋

Metal pipeline surface paint spraying device

InactiveCN111054541AEvenly paintedRealize automatic paintingSpraying apparatusElectric machineryEngineering

The invention relates to the technical field of paint spraying, and particularly relates to a metal pipeline surface paint spraying device which comprises a base. A bearing seat is arranged on the upper right side of the base. The upper side of a supporting plate is fixedly connected with an adjusting assembly. The adjusting assembly comprises an adjusting base, an adjusting hand-cranking wheel and a locking valve. The left side of an adjusting rod is rotationally connected with a metal pipe positioning seat. The right side of a motor mounting base is rotationally connected with a mounting connecting base. The outer wall of the mounting connecting base is sleeved by a metal pipe mounting base. A paint spraying moving mechanism is arranged on the front surface of the bearing seat. The paintspraying moving mechanism comprises a bearing plate and a drive motor. A movable mounting plate is slidably connected with the inner wall of a movable sliding groove. A paint spraying head is arranged on the inner wall of a semicircular spraying pipe. Automatic paint spraying can be achieved through the moving paint spraying mechanism. Through cooperation with rotation of a metal pipeline, overall paint spraying can be more uniform, and the paint spraying efficiency and quality are improved.

Owner:嘉兴君宏汽车配件有限公司

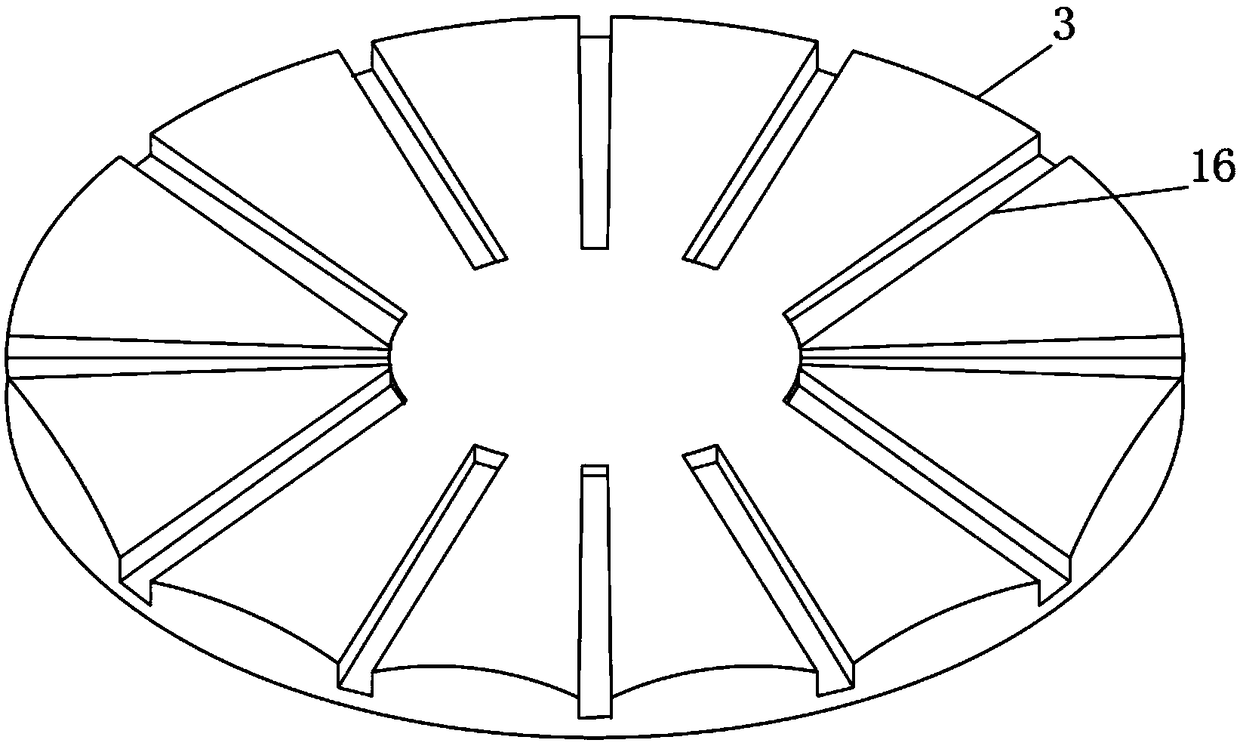

Wheel assembly painting device

PendingCN111921776AHigh degree of automationIncrease productivityPretreated surfacesCoatingsElectric machineryEngineering

The invention discloses a wheel assembly painting device. The wheel assembly painting device comprises a mounting plate, wherein a circular opening is formed in the mounting plate; a circular rotary plate is mounted in the circular opening; the circular rotary plate is driven by a main motor to rotate; the front surface of the circular rotary plate is divided into a plurality of divided areas; a rotary disc is mounted in each divided area, the rotary disc is separately driven by a rotary motor to rotate, and the front surface of the rotary disc is equipped with a plurality of clamping claws; the front surface of the mounting plate is fixedly equipped with a surface cover, and the inner surface of the surface cover is divided into a plurality of mounting regions; an inlet and outlet is formed in the surface cover; the inlet and outlet communicates with one mounting region; and the rest of the mounting regions internally comprise a plurality of pre-heating regions, a plurality of paint spraying regions and a plurality of drying regions. The wheel assembly painting device disclosed by the invention realizes continuous loading and automatic painting of a wheel assembly, improves automation degree of the wheel assembly painting work, improves production efficiency, and reduces influences on body health of a worker in a painting process.

Owner:ZHEJIANG HONGYUAN WHEEL

Glass artware paint spraying machine

The invention belongs to the technical field of glass artware production and processing, and in particular relates to a glass artware paint spraying machine. The glass artware paint spraying machine comprises a paint spraying device and a paint processing device, wherein the paint spraying device comprises a work table, a spraying gun, a support frame of the spraying gun, and an ascending and descending rotating rod; the paint processing device comprises a sealed cover case arranged on the top of the work table and at the outside of the spray gun and the ascending and descending rotating rod; the top of the cover case is provided with an air pipe and a fan; a paint filter is arranged on the air pipe, and comprises a tube body, a metal wire net layer and an active carbon cotton filtering layer; the metal wire net layer and the active carbon cotton filtering layer are in horizontal arrangement along the inner cavity of the tube body from bottom to top. The glass artware paint spraying machine has the advantages that the work intensity of workers can be reduced; the work efficiency is improved; the work environment of the workers is obviously improved; the body health of the workers is ensured.

Owner:CHANGXING KEYI GLASS HANDICRAFT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com