Glass artware paint spraying machine

A handicraft and painting machine technology, which is applied in the field of glass handicraft production and processing, can solve problems affecting the normal production of employees, threats to employee safety, environmental pollution in the workshop, etc., and achieve the effects of ensuring physical health, improving the working environment, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the present invention. Apparently, the described embodiments are only illustrative partial implementations of the present invention, and are not intended to limit the scope of the present invention. , any equivalent changes and modifications made by those skilled in the art without departing from the concepts and principles of the present invention shall fall within the protection scope of the present invention.

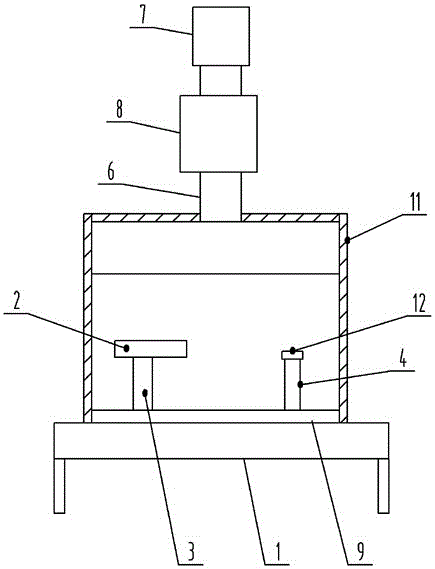

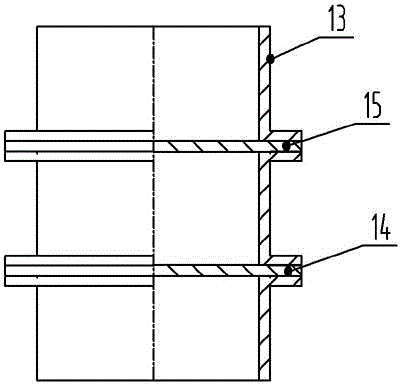

[0021] see Figure 1-3 , among the figures, the painting machine for glass handicrafts of the present invention includes a painting device and a paint processing device, wherein the painting device includes a workbench 1, a spray gun 2 and its support 3, a lifting rotating rod 4, and the paint processing device includes a And the closed casing 5 outside the spray gun and the lifting and rotating rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com