Paint spraying equipment for machining

A paint spraying equipment and machining technology, applied in spray booths, spray devices, liquid spray devices, etc., can solve problems such as inability to separate workers from paint, uneven paint spraying, and large human injuries, so as to improve overall practicability and reduce friction. force, avoid wear and tear damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

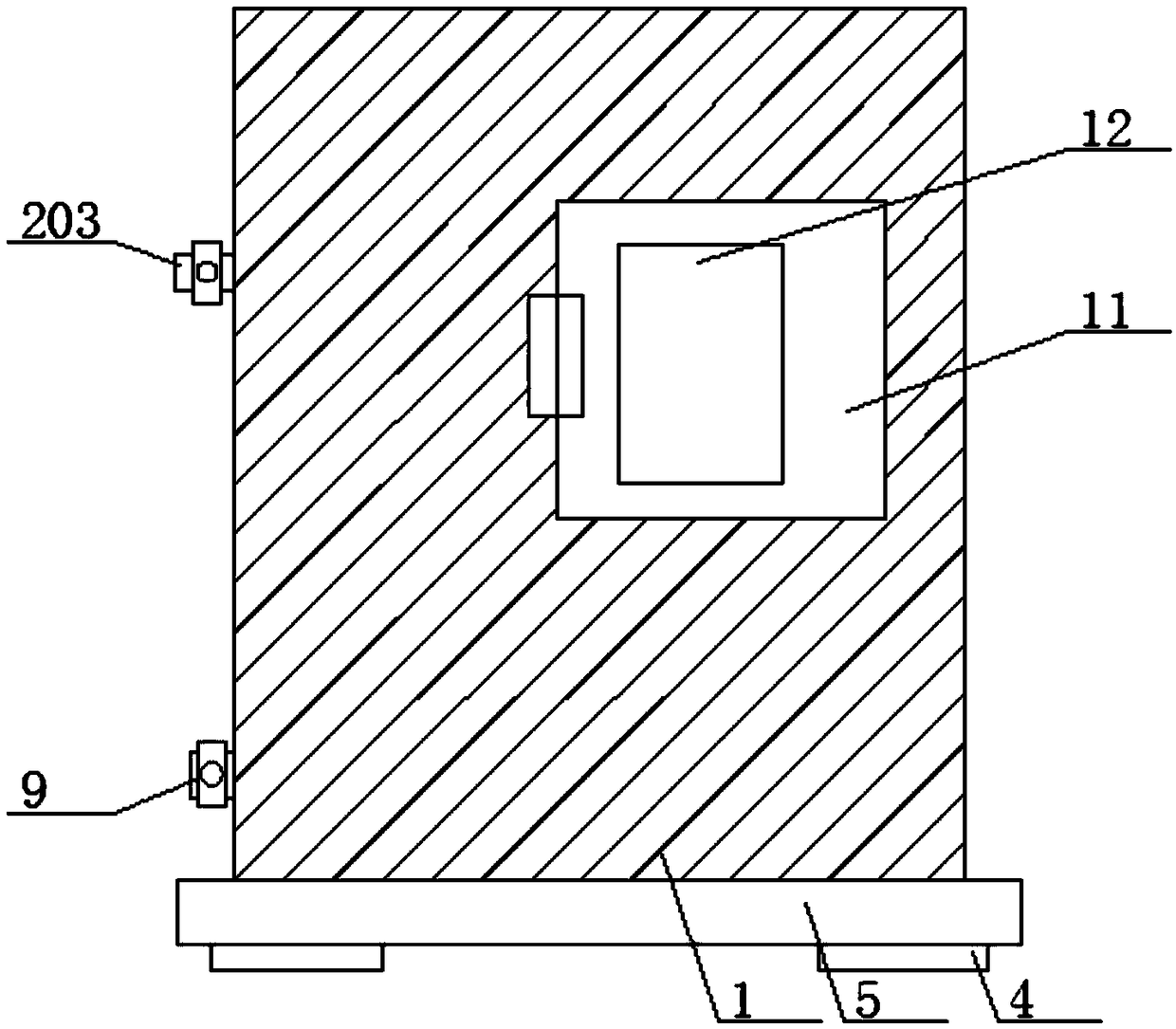

[0020] Such as Figure 1-3 As shown, the present invention provides a technical solution: a kind of painting equipment for mechanical processing, including a housing 1, the bottom surface of the housing 1 is fixedly connected with a fixing seat 5, and the size of the upper surface of the fixing seat 5 is greater than the size of the bottom surface of the housing 1, which can effectively Increase the overall stability of the shell 1, avoid the painting equipment from shaking due to external force during the work process, resulting in the failure of the workpiece painting, the four corners of the bottom surface of the fixing seat 5 are fixedly connected with rubber pads 4, each glue The bottom surface of the pad 4 is provided with anti-slip lines 10, which can effectively increase the friction between the bottom surface of the fixed seat 5 and the ground, and prevent the painting equipment from sliding on the ground, which will affect the overall use. The internal fixed connectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com