Section bar surface rust-proof spraying device used after aluminum alloy door and window machining

A technology for aluminum alloy doors and windows and spraying devices, which is applied in spraying devices, liquid spraying devices, spray booths, etc., can solve the problems of high pollution by operators and difficult control of spray paint quality, and achieve the effect of preventing spraying on the glass surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

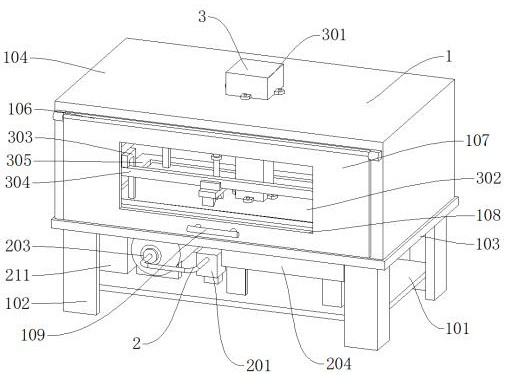

[0038] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, the painting mechanism 2 includes an air pump 201, a motor 202, an air tank 203, a storage tank 204, a mixing valve 205, a first feeding pipe 206, a second feeding pipe 207, a slider 208, a support 209, and a spray nozzle 210 , Power distribution cabinet 211, the rear end of air pump 201 is provided with motor 202, one side of air pump 201 is provided with gas tank 203, one side of gas tank 203 is provided with power distribution cabinet 211, and the rear end of gas tank 203 is provided with mixing valve 205, the upper end of the mixing valve 205 is provided with a storage tank 204, the rear end of the mixing valve 205 is provided with a first delivery pipe 206, and the upper end of the first delivery pipe 206 is provided with a second delivery pipe 207, the second delivery One end of the pipe 207 is provided with a slider 208, the lower end of the slider 208 is provided with a ...

Embodiment 2

[0041] Such as Figure 7 , Figure 8 As shown, the difference between Embodiment 2 and Embodiment 1 is that the hatch assembly includes a slide rail 110, a second hatch 111, a second handle 113, and a second observation window 112, and the front end of the housing 104 is provided with a slide rail 110, and the slide The lower end of the rail 110 is provided with a second cabin door 111, the middle of the second cabin door 111 is provided with a second observation window 112, and one side of the second observation window 112 is provided with a second handle 113, and the slide rail 110 and the casing 104 are connected by screws. connection, the slide rail 110 is connected with the second cabin door 111 by screws, the second cabin door 111 is welded with the second handle 113, the slide rail 110 is used to slide the second cabin door 111 along it, and the second observation window 112 is used for Observe the situation in the casing 104 during work, and the second handle 113 is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com