System for coating sealing paint on woody packing box

A packing box and lacquer coating technology, which is applied to the device and coating of the surface coating liquid, which can solve the problems of not achieving the effect, wasting manpower and time, and affecting the effect of dipping paint, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

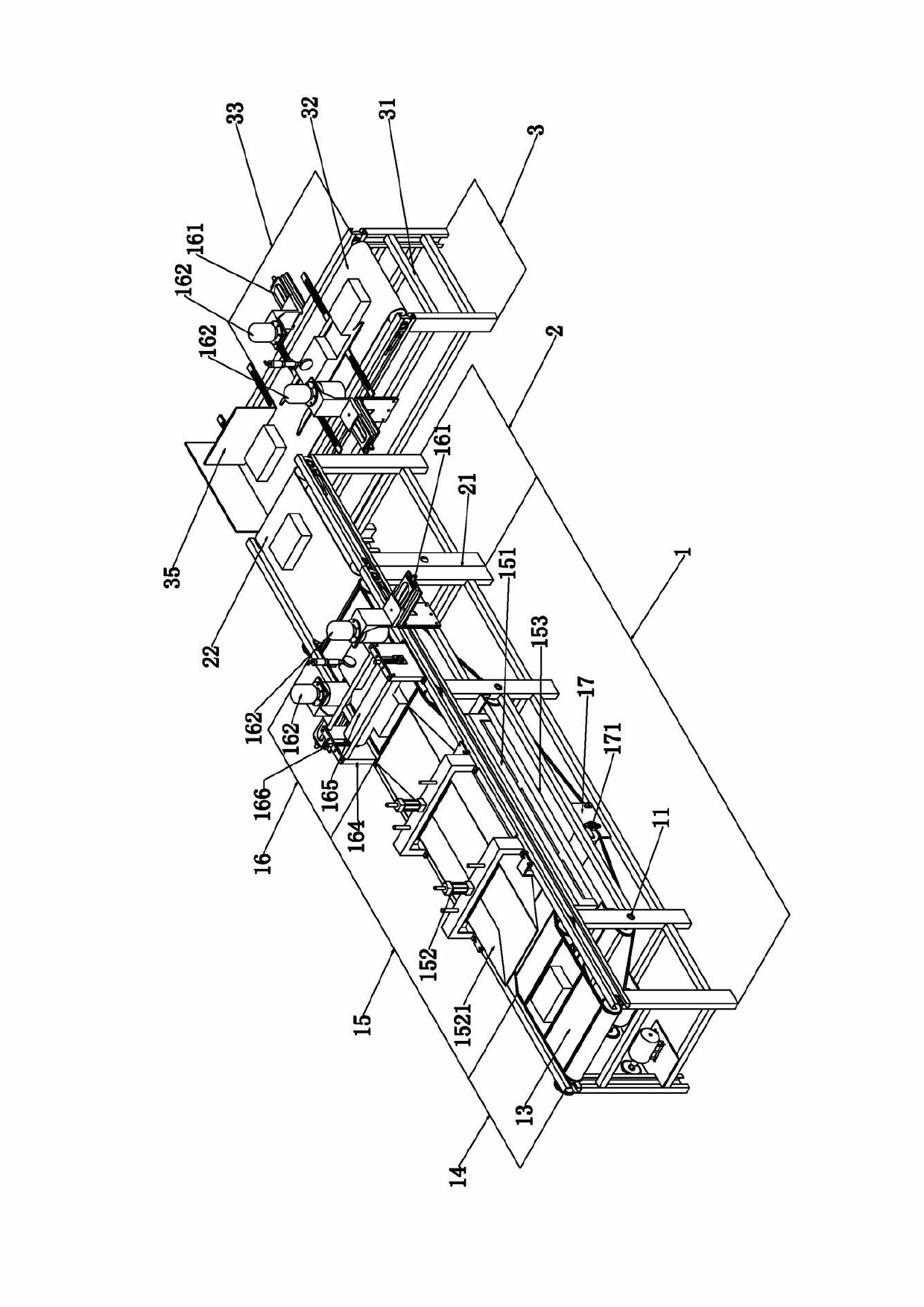

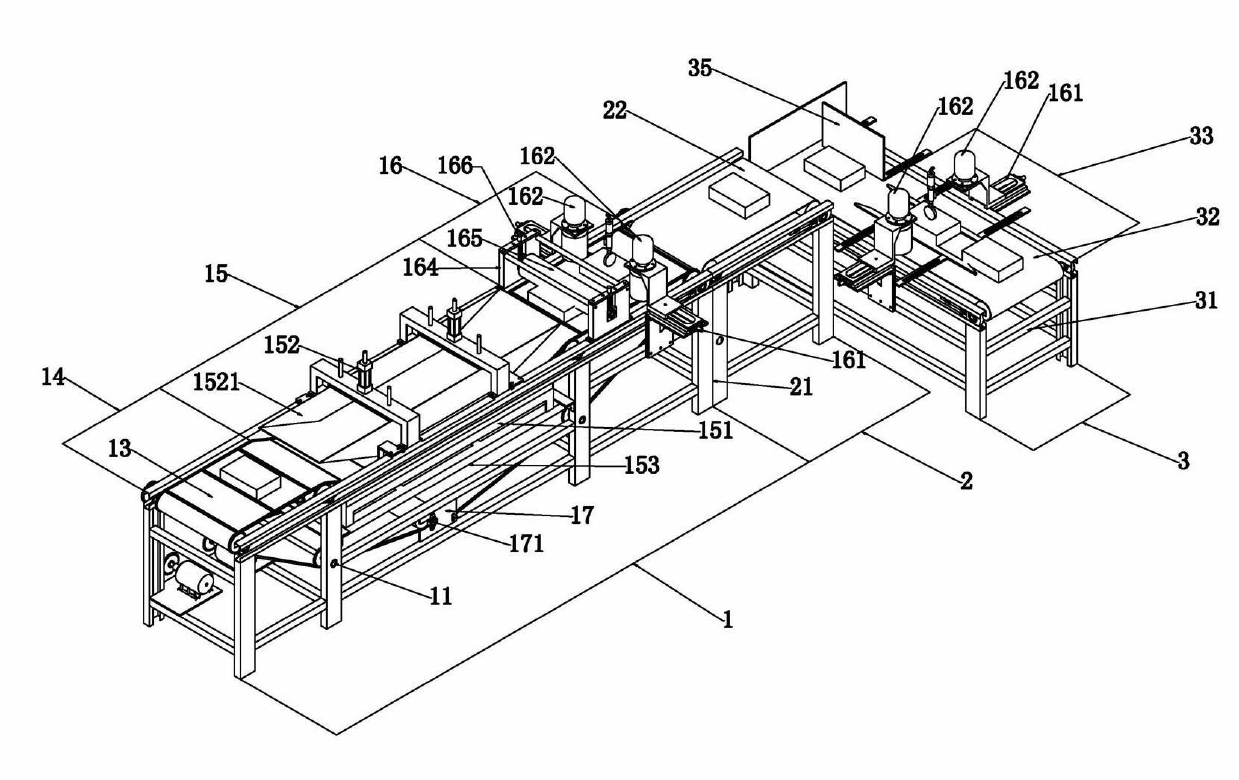

[0058] The wooden packing box sealing paint coating system of the present embodiment is as follows: figure 1 As shown, it includes a first conveying device 1, a second conveying device 2 and a third conveying device 3;

[0059] The first transmission device 1 is provided with: the first frame 11, the first conveyor belt 12 installed on the first frame 11, the first conveyor belt motor installed on the first frame 11, and arranged in sequence along the first conveyor belt 13 advancing direction There is a packing box placement area 14, a paint dipping area 15, a first painting device 16 and a first conveyor belt cleaning device 17;

[0060] The second transmission device 2 is provided with: a second frame 21, a fast conveyor belt 22 installed on the second frame 21, a second conveyor belt motor installed on the second frame 21;

[0061] The 3rd transmission device 3 is provided with: the 3rd frame 31, the 3rd conveyor belt 32 that is installed in the 3rd frame 3, the 3rd conve...

Embodiment 2

[0075] A sealing paint coating system for wooden packaging boxes, other structures are the same as in Embodiment 1, the difference is that the height adjuster 166 is electrically connected to the adjustment motor, and the adjustment motor realizes automatic control of the brush roller 164 on the top surface .

Embodiment 3

[0077] A sealing paint coating system for wooden packaging boxes, other structures are the same as in Embodiment 1, the difference is that in order to prevent the packaging boxes from popping up at the end of the third conveying device 3 away from the exit, a baffle can also be provided at this end.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com