Anti-rust paint spraying device for scale prevention of steel drum

A technology of spraying device and anti-rust paint, applied in the direction of spraying device, etc., can solve the problems of low work efficiency, high labor intensity, endangering health, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

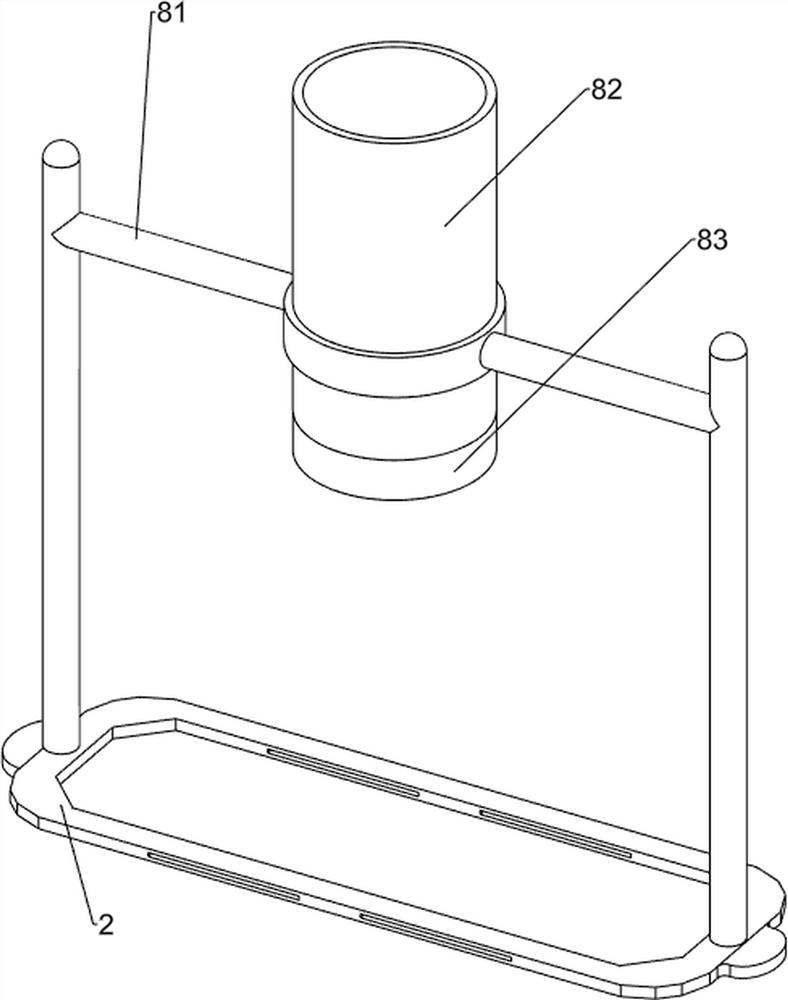

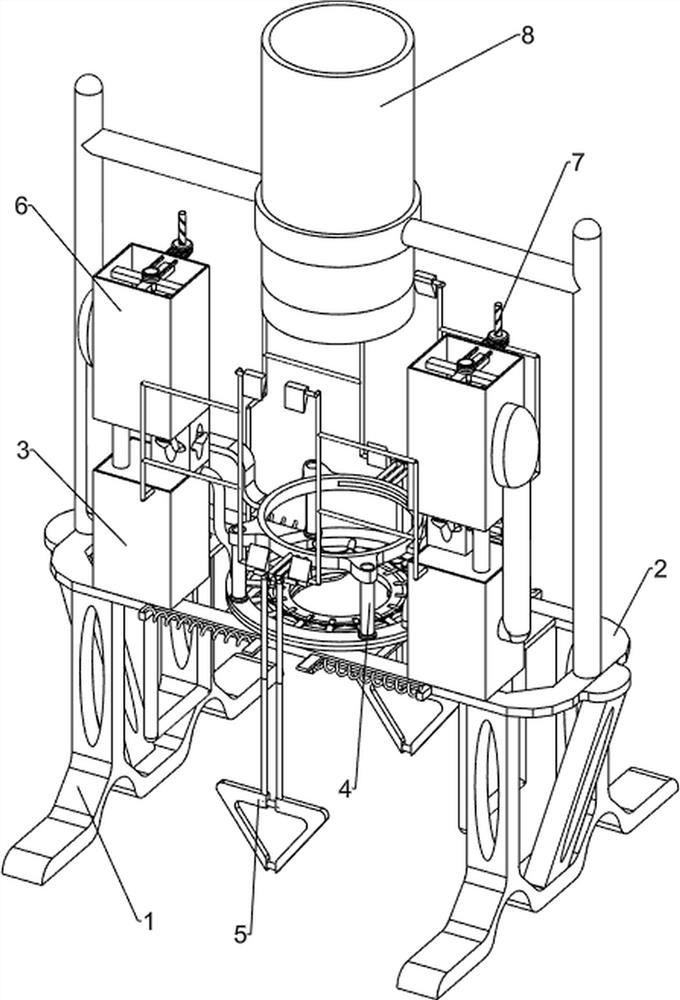

[0063] A kind of anti-rust paint spraying device for steel drum anti-scaling, such as figure 1 As shown, it includes a support foot 1, a long fixed plate 2, a paint spraying mechanism 3, a pull-down mechanism 4 and a blanking mechanism 5, and a long fixed plate 2 is provided between the upper parts of the two support feet 1, and a paint spraying mechanism is arranged on the long fixed plate 2. Mechanism 3, the long fixed plate 2 is provided with a pull-down mechanism 4, the pull-down mechanism 4 and the long fixed plate 2 are provided with a blanking mechanism 5, and the blanking mechanism 5 cooperates with the pull-down mechanism 4.

[0064] When people need to paint the steel drum, they can use this anti-rust paint spraying device for steel drum anti-scaling. First, people put the steel drum on the paint spraying mechanism 3, then start the pull-down mechanism 4, and the pull-down mechanism 4 drives the paint spraying mechanism 3 Operation, that is, realize the effect of aut...

Embodiment 2

[0066] On the basis of Example 1, such as Figure 2-5As shown, the painting mechanism 3 includes a pressurized barrel 31, a push rod 32, a hollow ring 33, a nozzle 34 and a hose 35, and the left and right sides of the long fixed plate 2 are symmetrically provided with a pressurized barrel 31, and two pressurized barrels 31 Bottoms are all slidingly provided with push rods 32, the push rods 32 are slidably connected to the long fixed plate 2, a hollow ring 33 is connected between the inner ends of the two push rods 32, and a plurality of nozzles 34 are uniformly arranged inside the hollow ring 33 A hose 35 is connected between the top of the two pressurized barrels 31 and the hollow ring 33 .

[0067] First, people put the paint into the pressurized barrel 31 and hold the steel barrel on the hollow ring 33, then people manually pull the hollow ring 33 upwards, and the hollow ring 33 moves upward while driving the push rod 32 to move upward, thereby driving The bottom cover of ...

Embodiment 3

[0073] On the basis of Example 2, such as Figure 6-9 Shown, also comprise paint-adding mechanism 6, add paint mechanism 6 and include the 3rd fixed bar 61, paint bucket 62 and connecting hard bar 63, two pressurized barrels 31 upper sides are all connected with connecting hard bar 63, both A paint bucket 62 is connected to the tops of each connecting hard rod 63 , and a third fixed rod 61 is connected between the paint bucket 62 and the outside of the pressurized bucket 31 .

[0074] People pour the paint into the pressurized bucket 31, and when the bottom cover of the pressurized bucket 31 moves down with the push rod 32, the paint in the paint bucket 62 enters into the pressurized bucket 31 through the connecting hard rod 63, which realizes The effect of adding paint automatically.

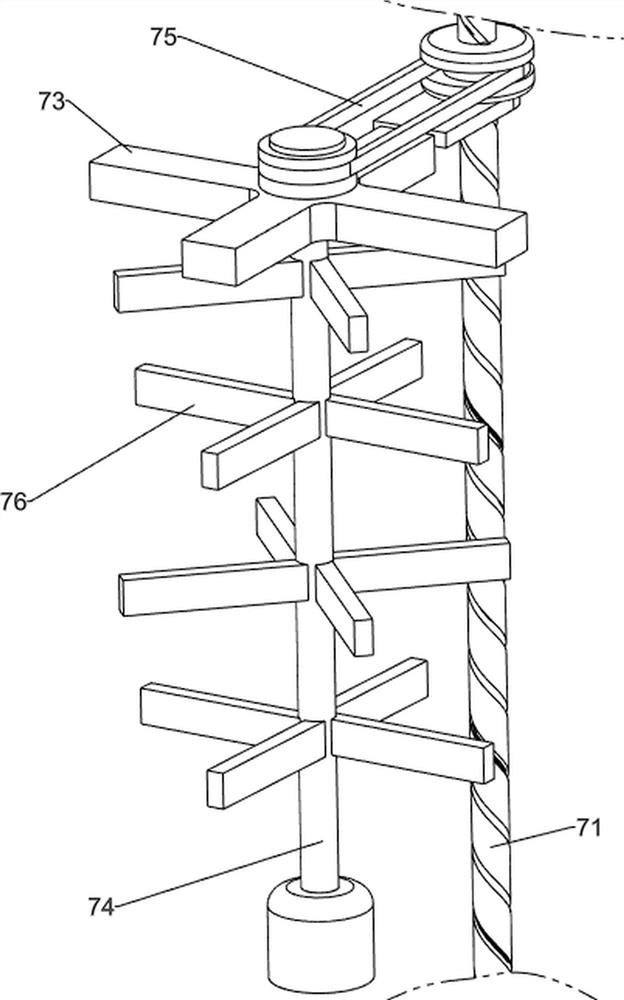

[0075] Also include stirring mechanism 7, stirring mechanism 7 includes threaded rod 71, rotating ring 72, connecting plate 73, rotating post 74, belt pulley assembly 75 and stirring plate 76,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com