Wood board painting device

A technology of wood boards and plates, which is applied in the field of wood board painting devices, can solve problems such as unfavorable environmental protection, uneven boards, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

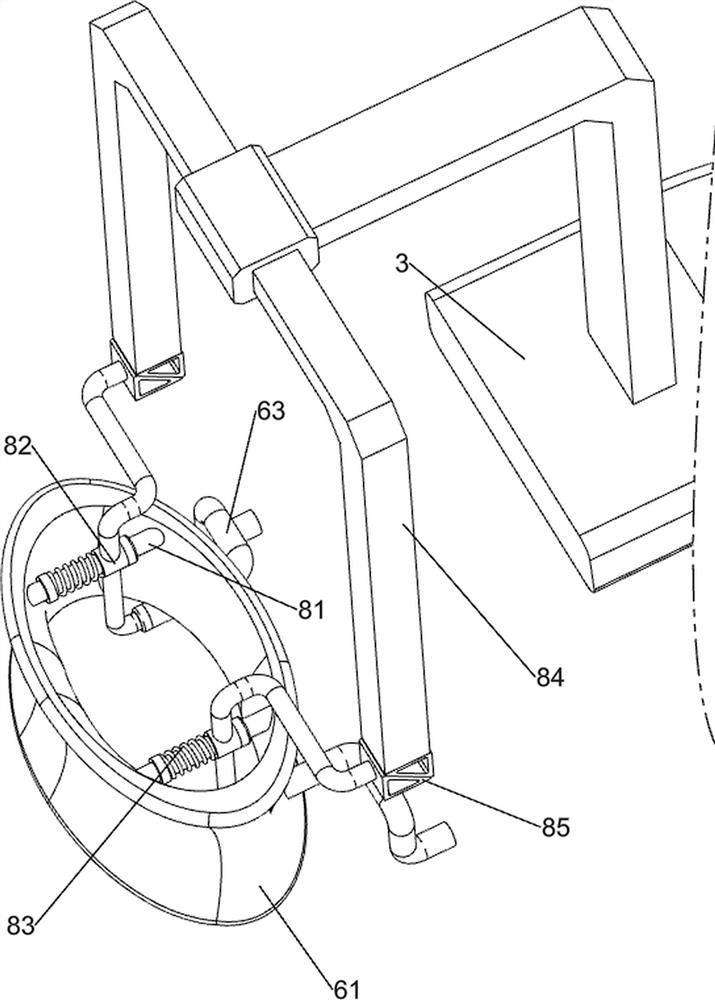

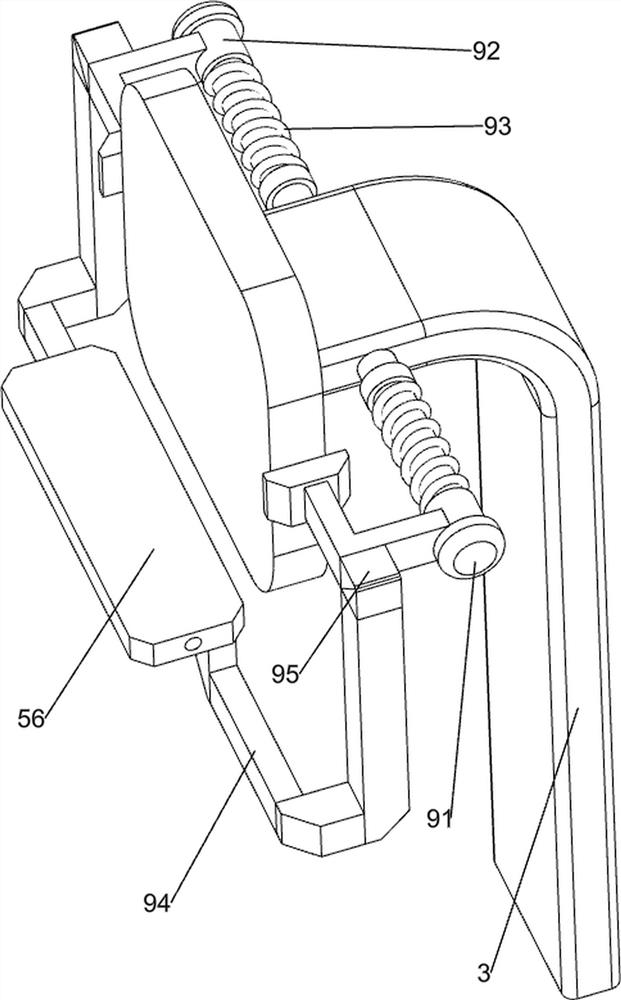

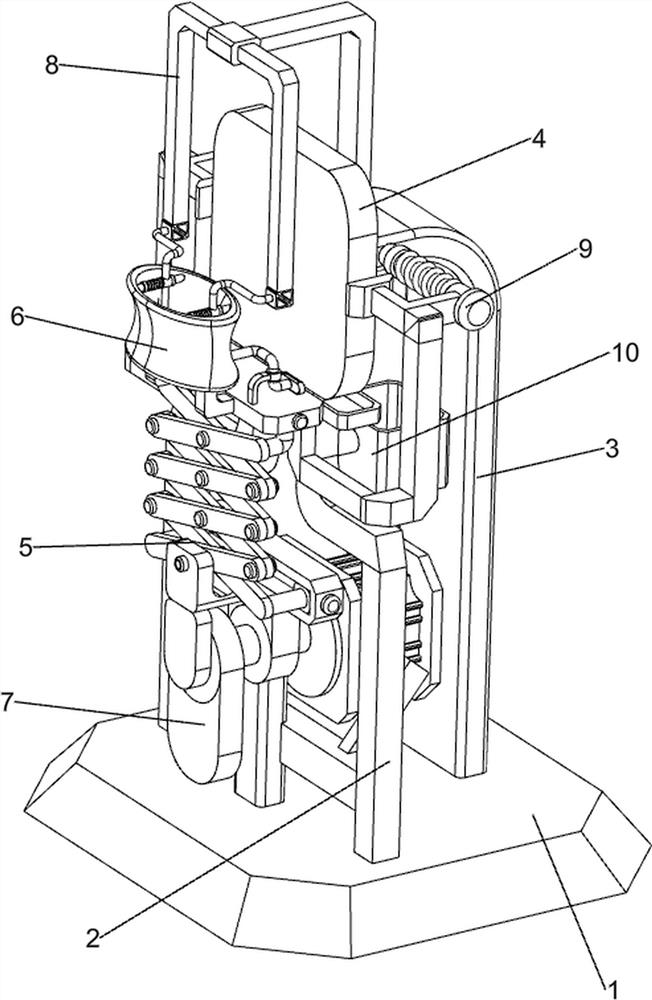

[0030] A device for varnishing wood panels, such as Figure 1-3 As shown, it includes a support base 1, a support pillar 2, a first connecting fixed rod 3, a plank 4, a paint pushing mechanism 5 and a paint spraying mechanism 6, and the front side of the support base 1 is provided with a support pillar 2, and a support pillar 2 A plank 4 is arranged on the top, a first connection and fixing rod 3 is arranged on the upper and rear side of the support base 1, and the top of the first connection and fixing rod 3 is connected with the plank 4, and a paint pushing mechanism 5 is provided on the front side of the supporting base 1, and the paint pushing mechanism 5 The bottom is connected with the bottom of the supporting pillar 2, and the top of the paint pushing mechanism 5 is provided with a painting mechanism 6.

[0031] When people need to paint the planks 4, they can use this device for painting the planks 4. First, people place a plank 4 on the support pillar 2, and move upwa...

Embodiment 2

[0037] On the basis of Example 1, such as Figure 4-7Shown, also comprise automatic driving mechanism 7, and automatic driving mechanism 7 includes the 4th connection fixed rod 71, motor 72, rotating rod 73, cam 74 and hold up block 75, support mainstay 2 bottom left and right sides all are provided with the 4th. Four connection fixed rods 71, a motor 72 is installed between the two fourth connection fixes, the output shaft of the motor 72 is connected with a rotating rod 73, the middle part of the rotating rod 73 passes through the second connecting fixed rod 51, and the top of the rotating rod 73 is provided with a cam 74 , the rotating rod 73 cooperates with the cam 74, and the front end of the rotating rod 73 is provided with a supporting block 75.

[0038] People can start the motor 72, and the rotation of the output shaft of the motor 72 will drive the rotating rod 73 to rotate, thereby driving the cam 74 to rotate. And then drive the paint spraying mechanism 6 to spray...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com