Swing laser filler wire welding method for large-gap butt joint of aluminum alloy sheets

A technology of laser wire filling and aluminum alloy welding wire, applied in laser welding equipment, welding/welding/cutting items, welding equipment, etc., can solve the problems of limited welding size and joint form, low welding efficiency, etc., and reduce the dilution rate , high welding speed, and improved energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

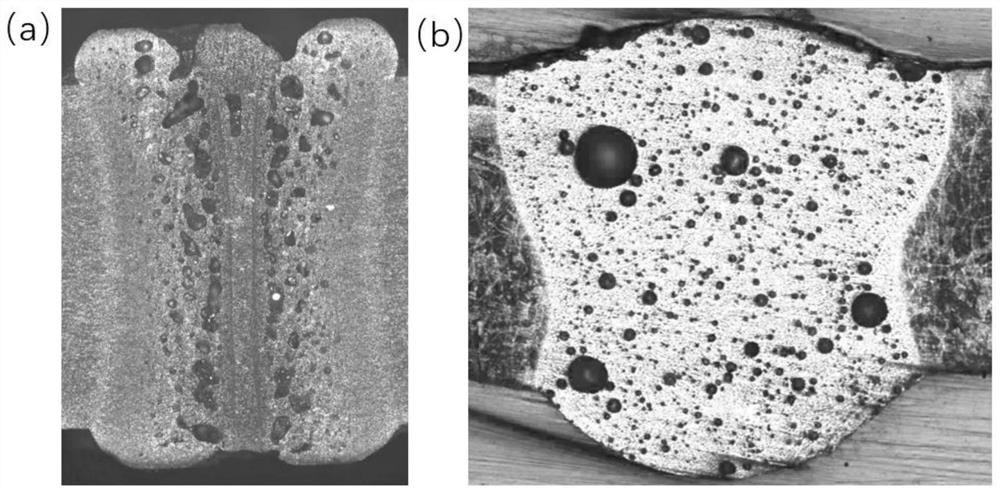

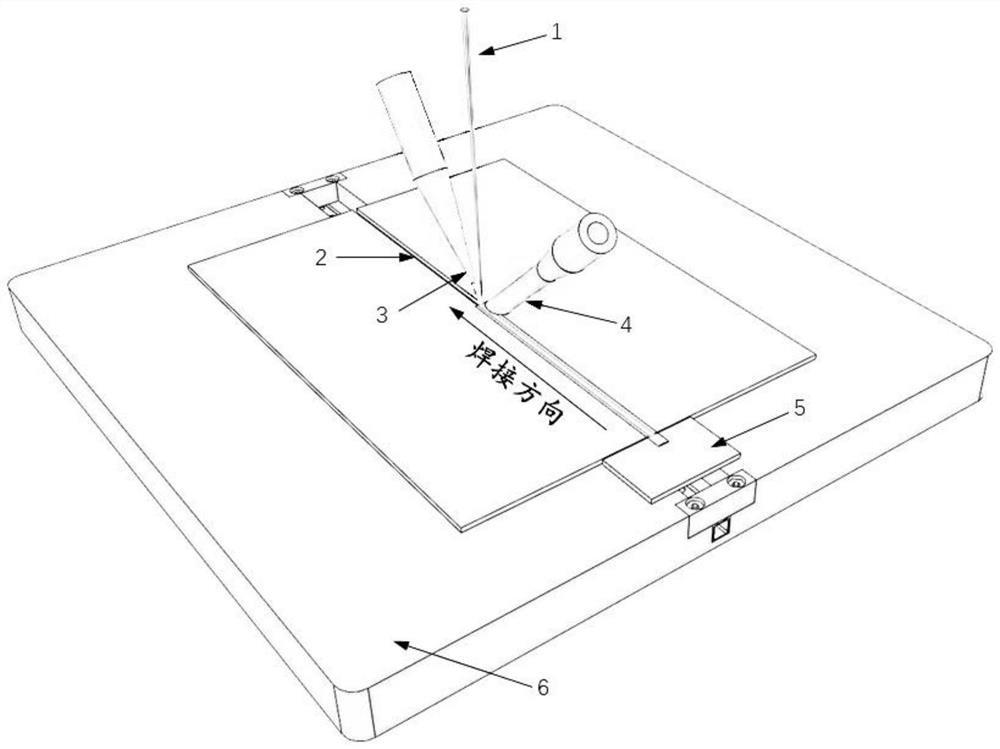

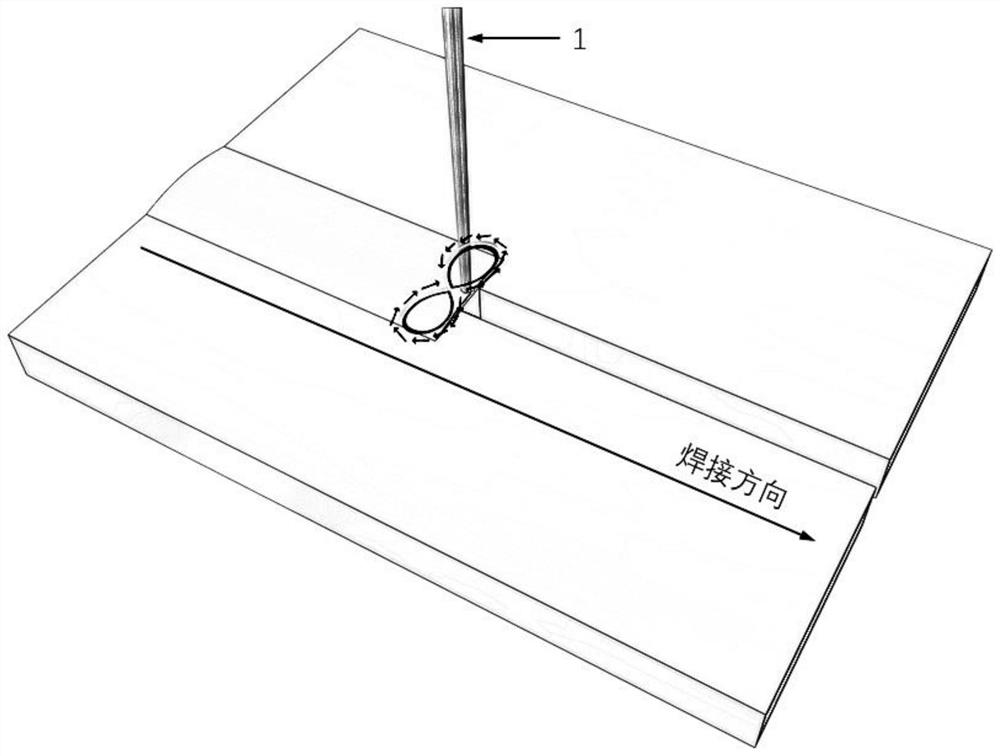

Embodiment 1

[0047] Select 1.6mm thick SiC with 17% volume fraction p / 2009Al composite material is used as the test plate to be welded, and the welding is carried out according to the above-mentioned swing laser wire-filled welding method of large-gap butt joint of aluminum alloy thin plates. The welding parameters are as follows: the welding wire is 5356 aluminum alloy welding wire; Amplitude 1.0mm; swing frequency 200Hz; gap 1.0mm; laser power 3200W; welding speed 4.8m / min; wire feeding speed 11.2m / min.

Embodiment 2

[0049] Select 1.6mm thick SiC with 17% volume fraction p / 2009Al composite material is used as the test plate to be welded, and the welding is carried out according to the above-mentioned swing laser wire-filled welding method of large-gap butt joint of aluminum alloy thin plates. The welding parameters are as follows: the welding wire is 5356 aluminum alloy welding wire; Amplitude 1.0mm; swing frequency 200Hz; gap 1.2mm; laser power 3200W; welding speed 4.8m / min; wire feeding speed 11.2m / min.

Embodiment 3

[0051] Select 1.6mm thick SiC with 17% volume fraction p / 2009Al composite material is used as the test plate to be welded, and the welding is carried out according to the above-mentioned swing laser wire-filled welding method of large-gap butt joint of aluminum alloy thin plates. The welding parameters are as follows: the welding wire is 2319 aluminum alloy welding wire; Amplitude 1.0mm; swing frequency 200Hz; gap 1.0mm; laser power 3500W; welding speed 4.8m / min; wire feeding speed 9.6m / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com