A Titanium-Alloy Electron Beam Welding Method for Reducing Base Metal Dilution Rate

An electron beam welding, titanium-aluminum alloy technology, applied in the direction of electron beam welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as solid cracks, poor plasticity of welded joints at room temperature, and reduce the dilution rate of base metals, etc., to achieve welding The seam metal has good plasticity, improves weldability, and relieves the effect of welding residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

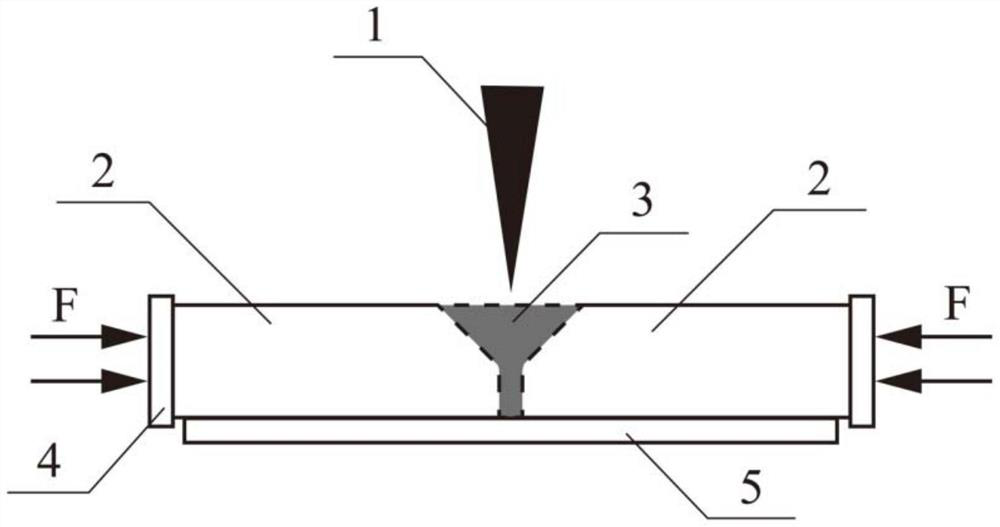

[0019] Specific implementation mode one: combine figure 1 To illustrate this embodiment, a titanium-aluminum alloy electron beam welding method that reduces the dilution rate of the base metal described in this embodiment includes the following steps:

[0020] Step 1: Cutting the bevel: splicing the welding end faces of the titanium-aluminum alloy plates 2 to be welded together, cutting a Y-shaped bevel at the joint, and the outer dimension of the middle layer 3 is the same as that of the Y-shaped bevel;

[0021] Step 2: Assembly: place the middle layer 3 on the Y-shaped groove, and apply a clamping force on the end face of the titanium-aluminum alloy plate 2 to be welded by a welding fixture;

[0022] Step 3: Set welding parameters: place the assembled workpiece in the vacuum chamber of the electron beam welding machine, and then start vacuuming. When the vacuum degree reaches 5×10 -2 Pa, adjust the welding process parameters of electron beam 1: the acceleration voltage is 5...

specific Embodiment approach 2

[0029] Specific implementation mode two: combination figure 1 To describe this embodiment, the thickness of the titanium-aluminum alloy plate 2 to be welded in step 1 of this embodiment is 2 mm to 3 mm. The undisclosed technical features in this embodiment are the same as those in the first embodiment.

specific Embodiment approach 3

[0030] Specific implementation mode three: combination figure 1 To describe this embodiment, the thickness of the titanium-aluminum alloy plate 2 to be welded in step 1 of this embodiment is 2 mm. The undisclosed technical features in this embodiment are the same as those in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com