Movable log saw board device

A mobile, power device technology, applied in circular saws, clamping devices, loading devices, etc., can solve the problems of large equipment occupation area, complex facilities, high construction cost, and achieve low production costs, high operating efficiency, and transition. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited in any way. Any changes or improvements made based on the teaching of the present invention belong to the protection scope of the present invention.

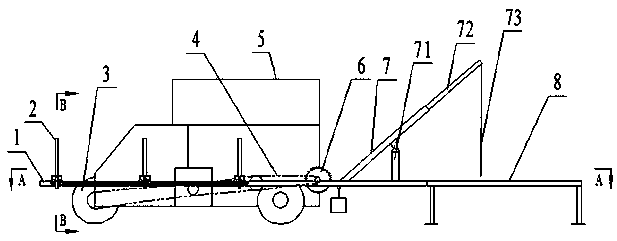

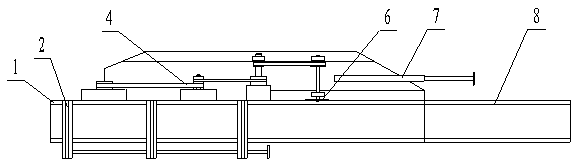

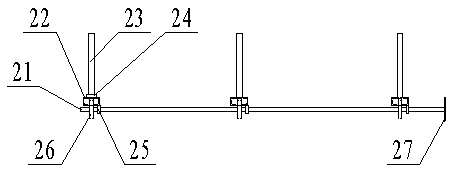

[0012] like Figure 1~4 As shown, the present invention comprises vehicle frame, and the bottom of vehicle frame is provided with traveling mechanism 3, and the front end of vehicle frame is driver's cab, and the top of vehicle frame is provided with tool box 5, and one side of vehicle frame is provided with fixed track 1, and fixed track 1 The length of the fixed track 1 is adapted to the length of the vehicle body. The tail of the fixed track 1 is movable to be provided with a movable track 8, and the upper part of the fixed track 1 is movable to install a clamping platform mechanism 2, and the clamping platform mechanism 2 can be left and right on the fixed track 1 and the movable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com