Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

172 results about "Primary position" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

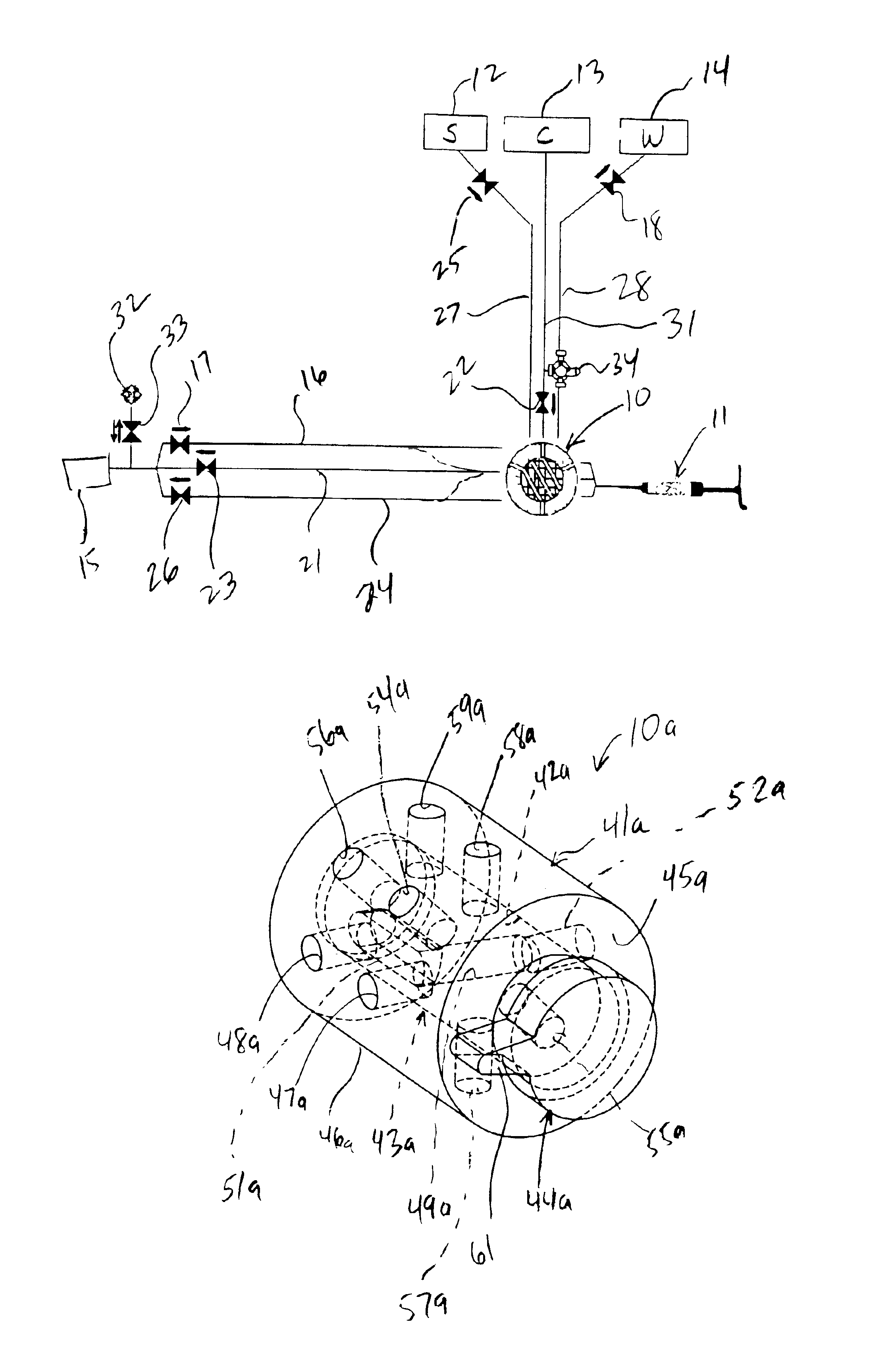

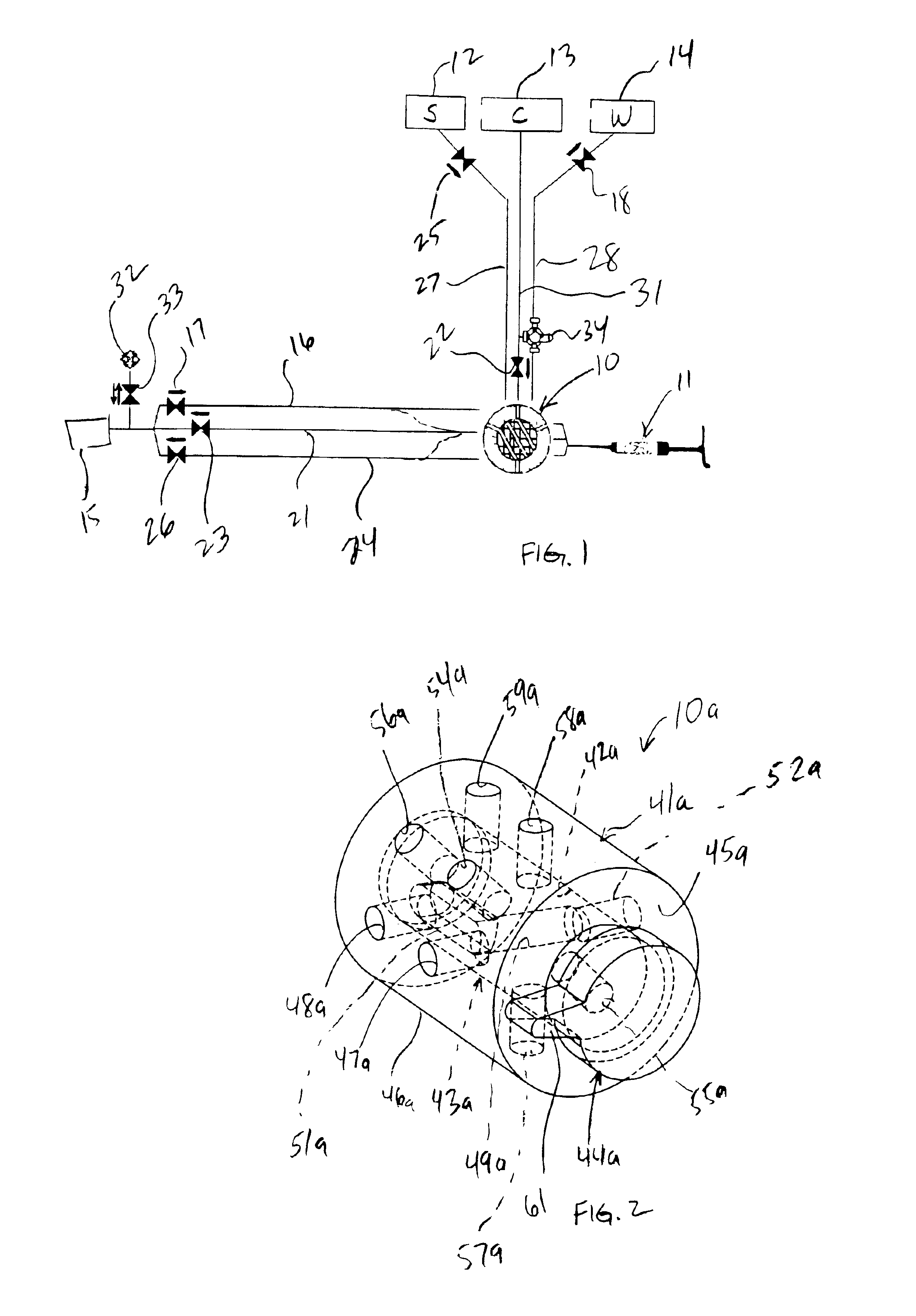

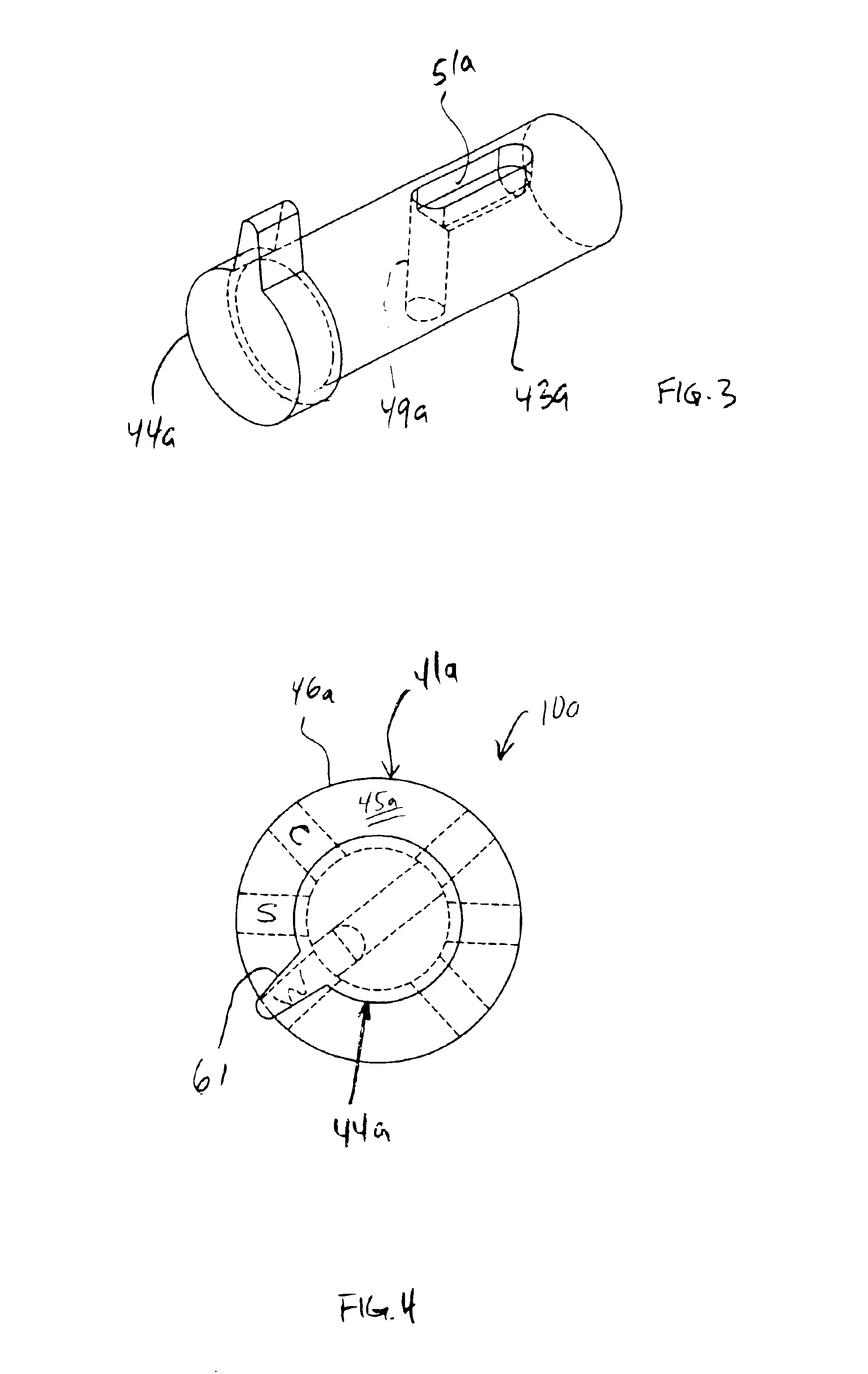

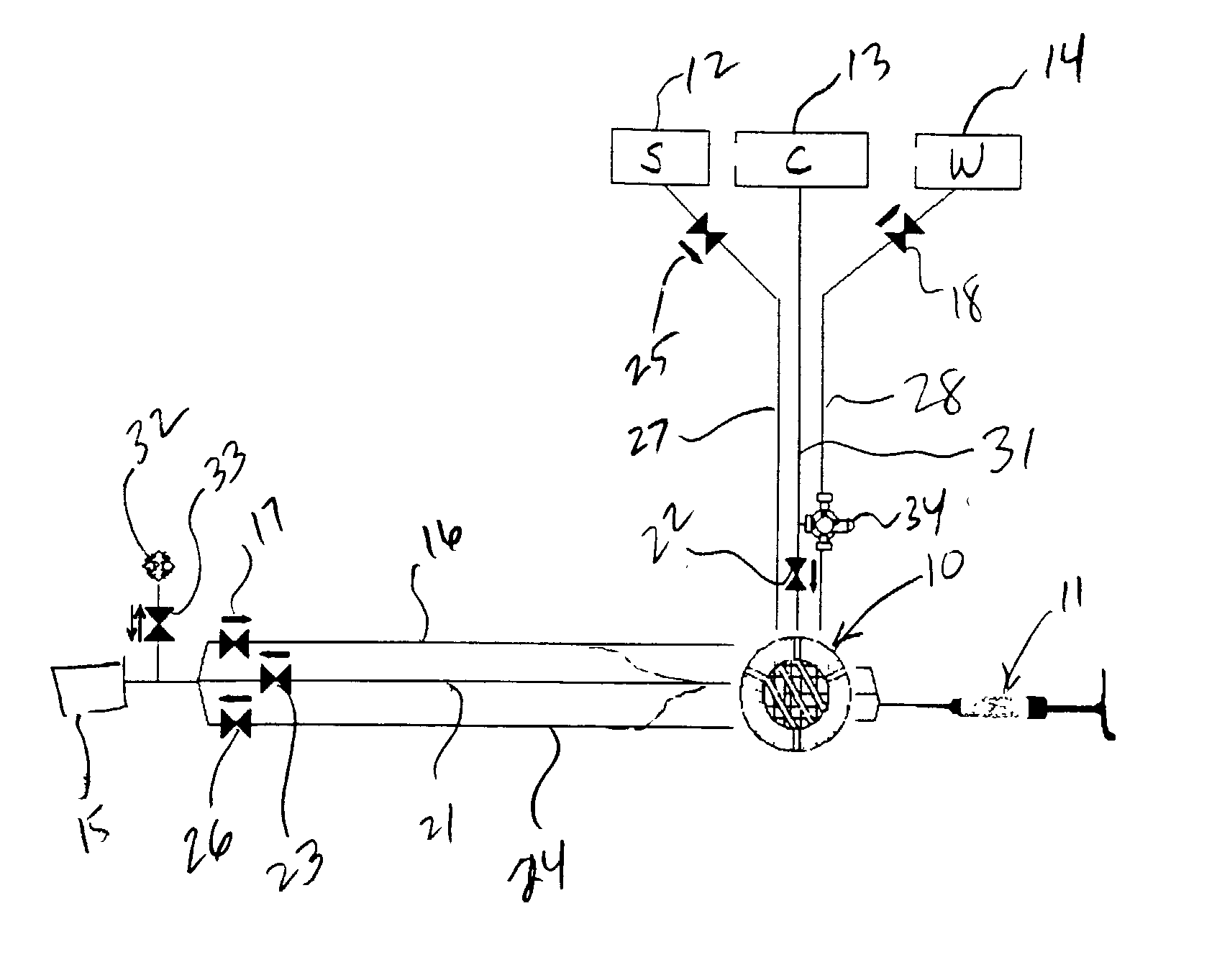

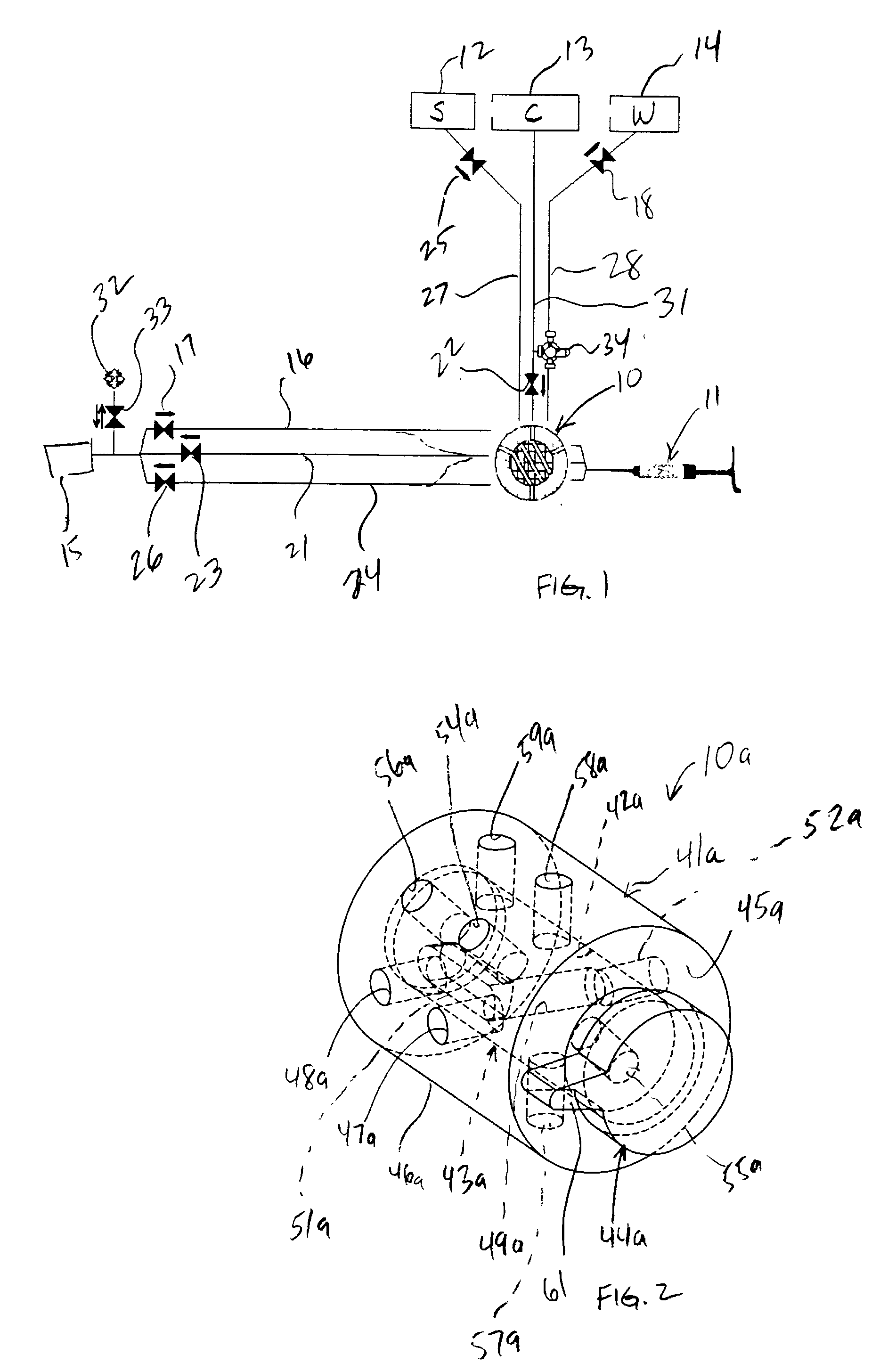

Multiple port fluid control valves

A fluid control valve is disclosed which, with a single valve, can manipulate flow between a saline supply, a contrast supply, a waste dump and a catheter. The control valve includes three primary positions including a contrast position where the valve provides communication between an injector and a contrast supply while isolating the saline supply and catheter. The valve also can be moved to a saline / waste position where the valve provides communication between the injector and the saline supply and / or the waste dump while isolating the contrast supply and catheter. The valve also can be moved to an injection position where the valve provides communication between the injector and the catheter. A single valve provides all three functions. The valve also may provide communication between a pressure transducer and catheter during the saline loading, waste dumping and contrast loading functions. The valve also provides protection or isolation of the pressure transducer during injection procedures.

Owner:MEDLINE INDUSTRIES

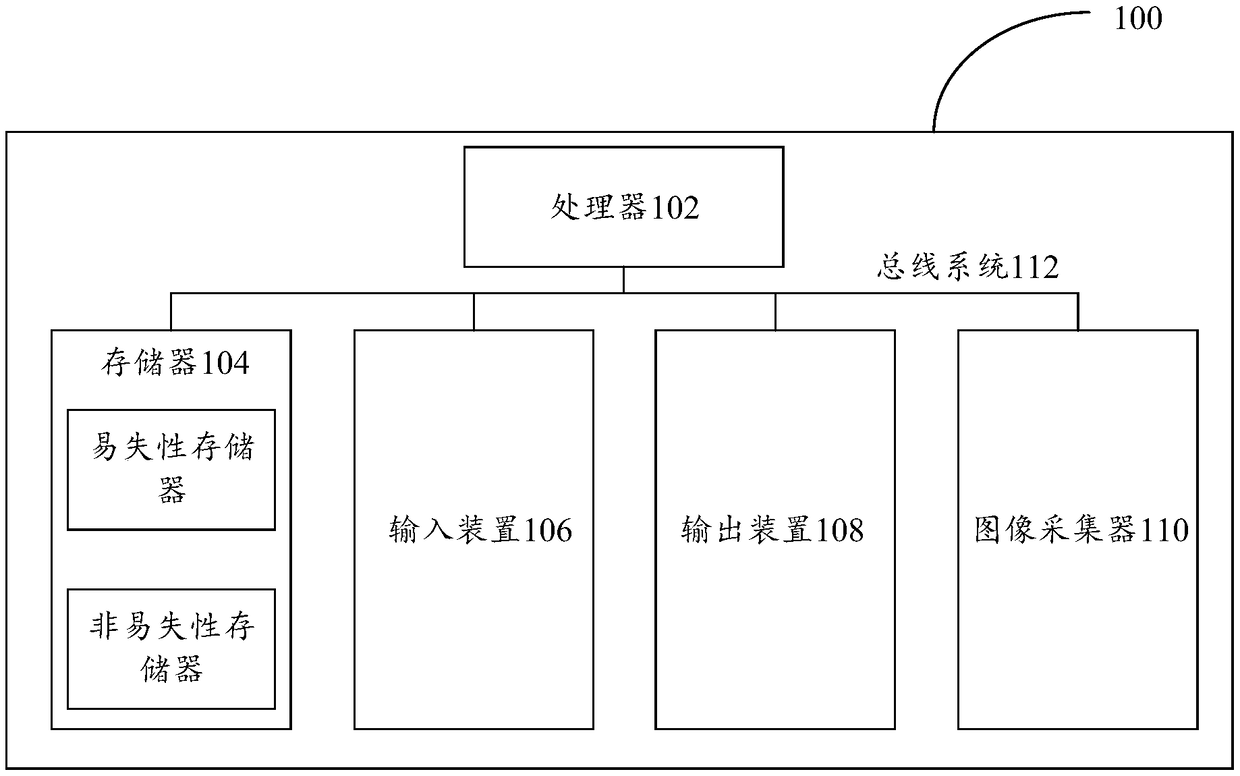

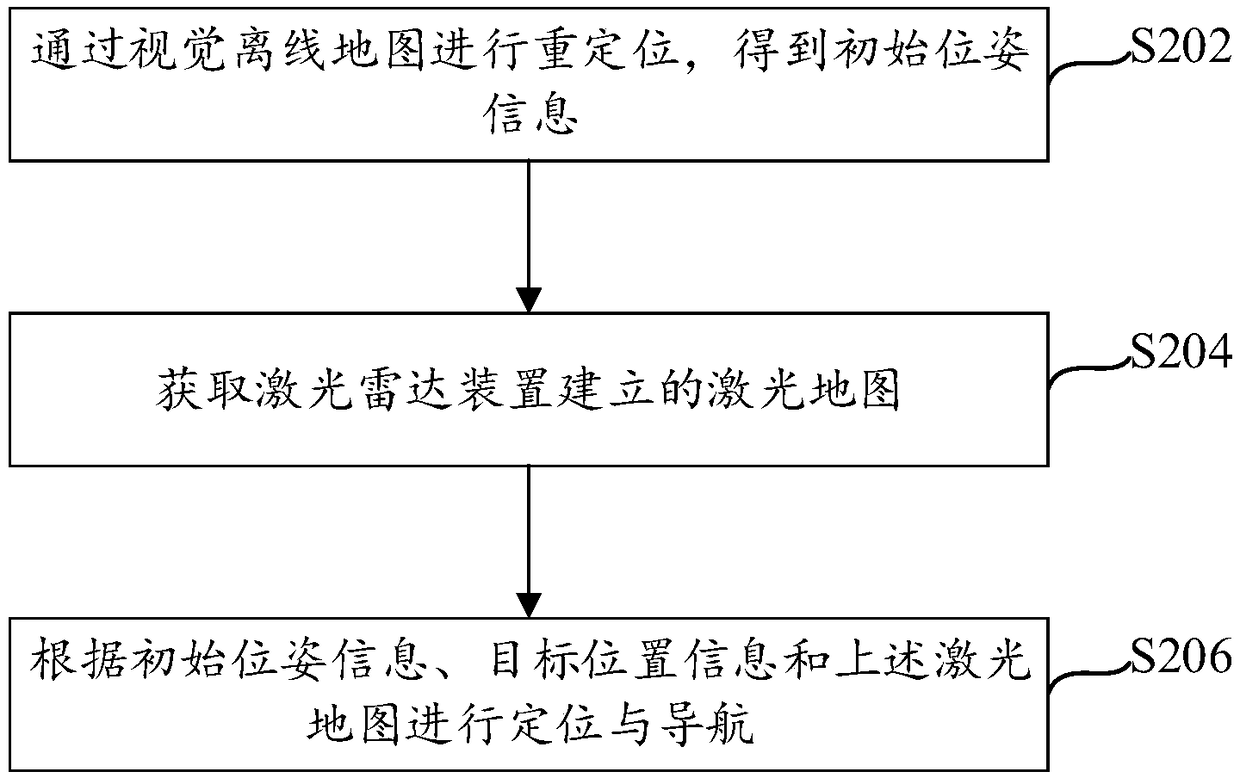

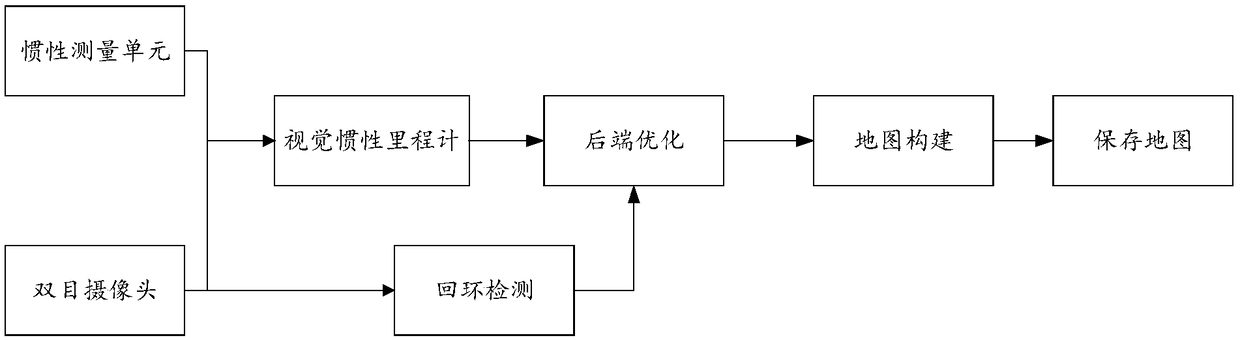

Positioning and navigating method and device and processing equipment

ActiveCN109084732AHigh precisionImprove robustnessPhotogrammetry/videogrammetryNavigation by speed/acceleration measurementsRadarVision based

The invention provides a positioning and navigating method and device and processing equipment, and relates to the technical field of navigation. The method comprises the following steps that re-positioning is conducted by a visual off-line map to obtain primary position gesture information, wherein the visual off-line map is obtained by fusion mapping based on a visual device and an inertial measurement unit; a laser map established by a laser radar device is obtained; and positioning and navigating are conducted based on the primary position gesture information, target position information and the later map. The embodiment of the invention provides the positioning method and device and the processing equipment. Positioning and mapping are conducted simultaneously by the laser radar device and the visual device, excellent re-positioning performance of visual positioning is used for providing primary position and gesture for the laser map, positioning and mapping can be achieved in theunknown environment, the positioning and autonomous navigating functions in a mapped scenario are achieved, and excellent accuracy and robustness are achieved.

Owner:BEIJING KUANGSHI TECH

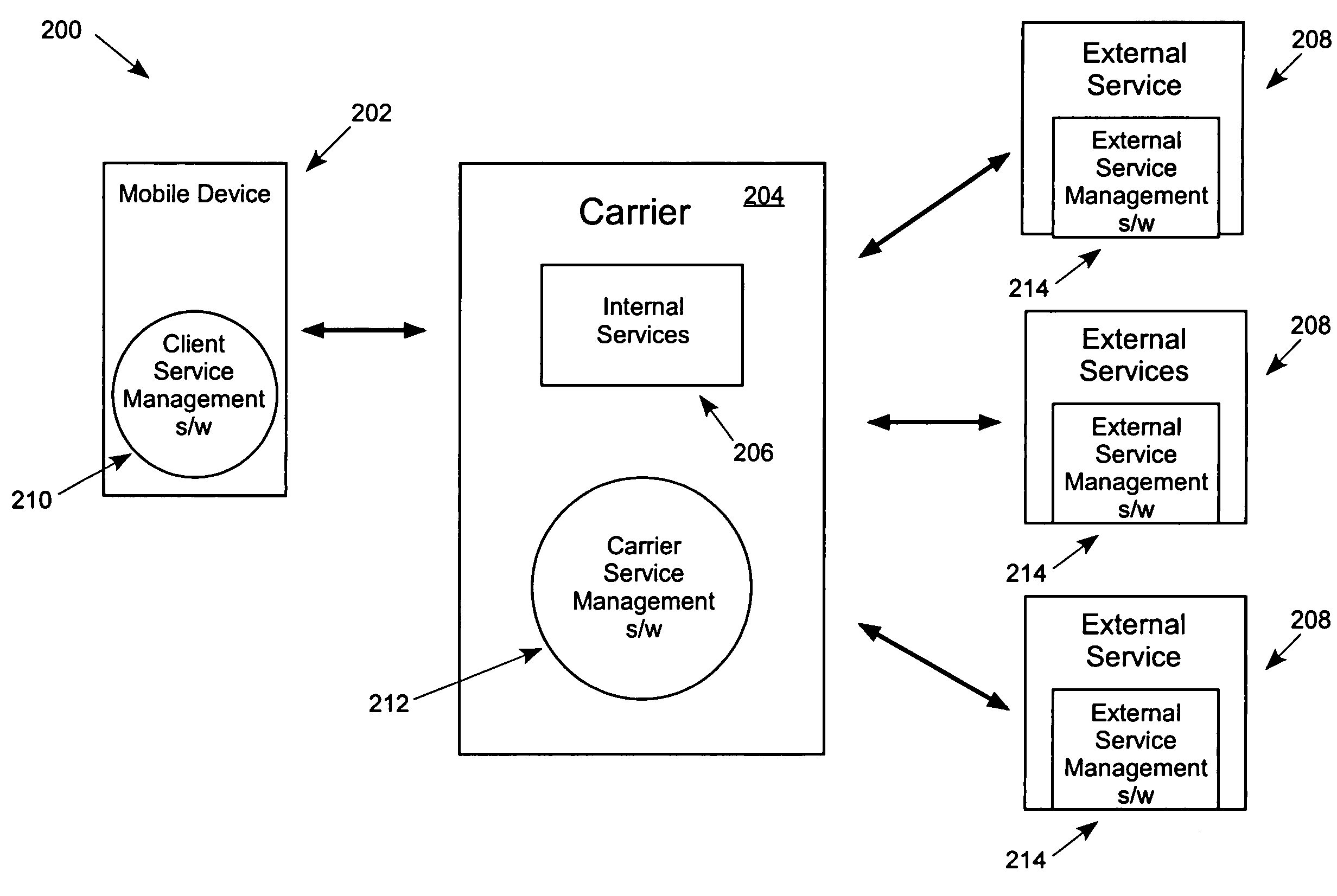

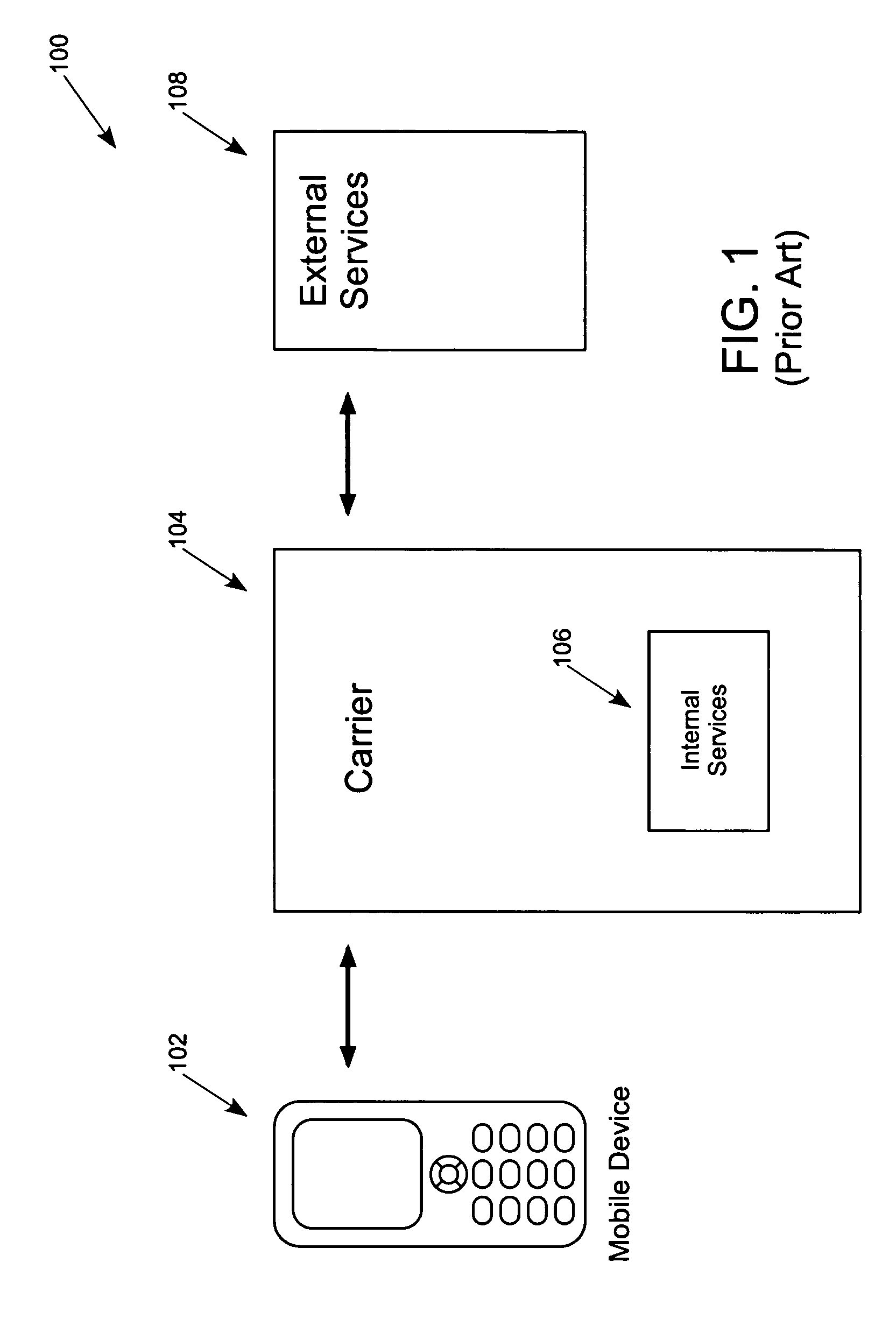

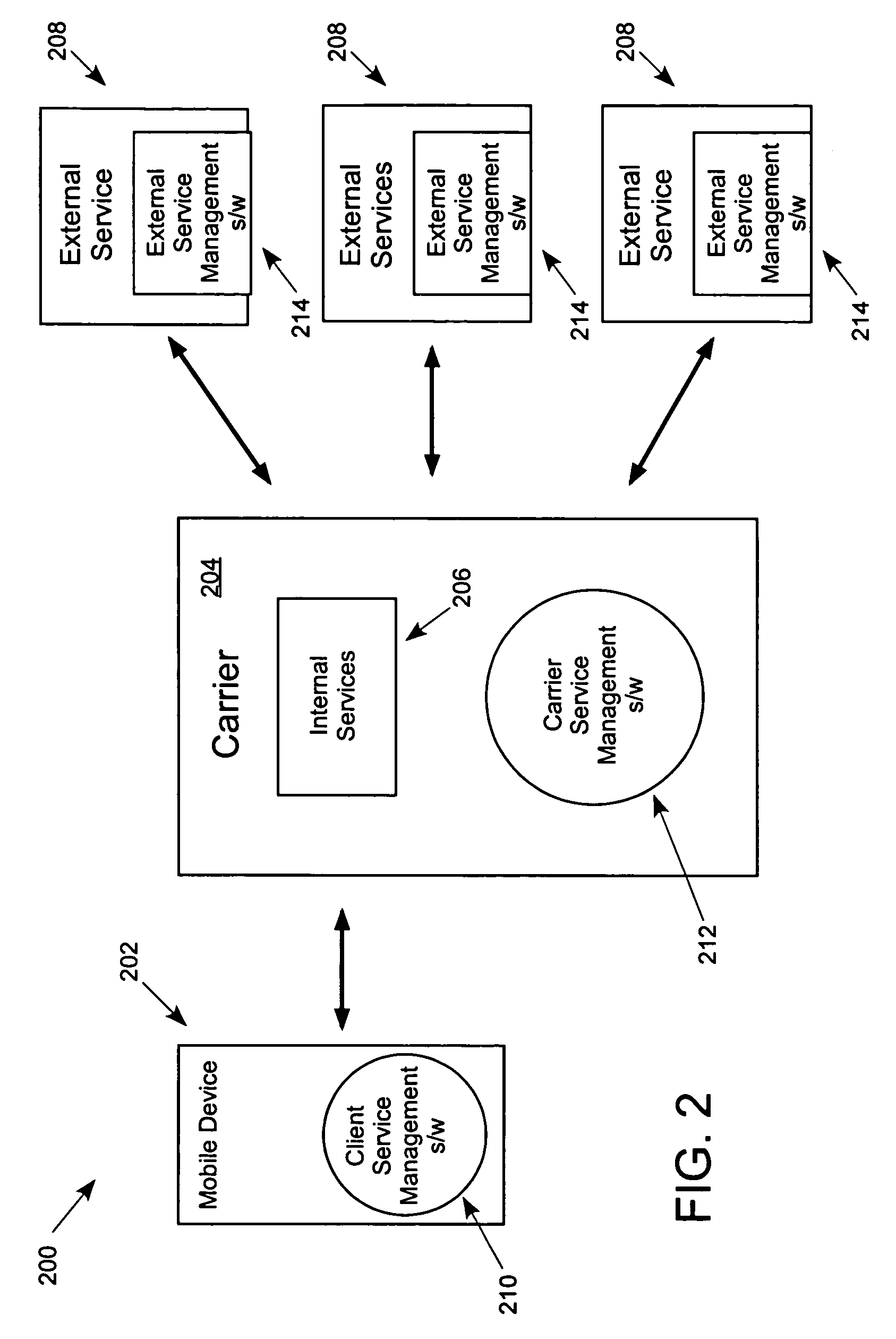

Context based main screen for mobile device

An invention is provided for a context based mobile device display. The context based mobile device display includes a primary service icon representing a service most likely to be utilized by a user within a predefined period of time based on user profile information. The primary service icon is displayed in a primary position on the mobile device display. Also included is a plurality of secondary service icons representing services likely to be utilized by a user within a predefined period of time, however not as likely as the primary service, based on user profile information. The secondary service icons are smaller than the service icon representing the service in the primary position. A plurality of tertiary service icons representing remaining services available to the user are further included in the context based mobile device display. The tertiary service icons are displayed in a tertiary position of the mobile device display.

Owner:ORACLE INT CORP

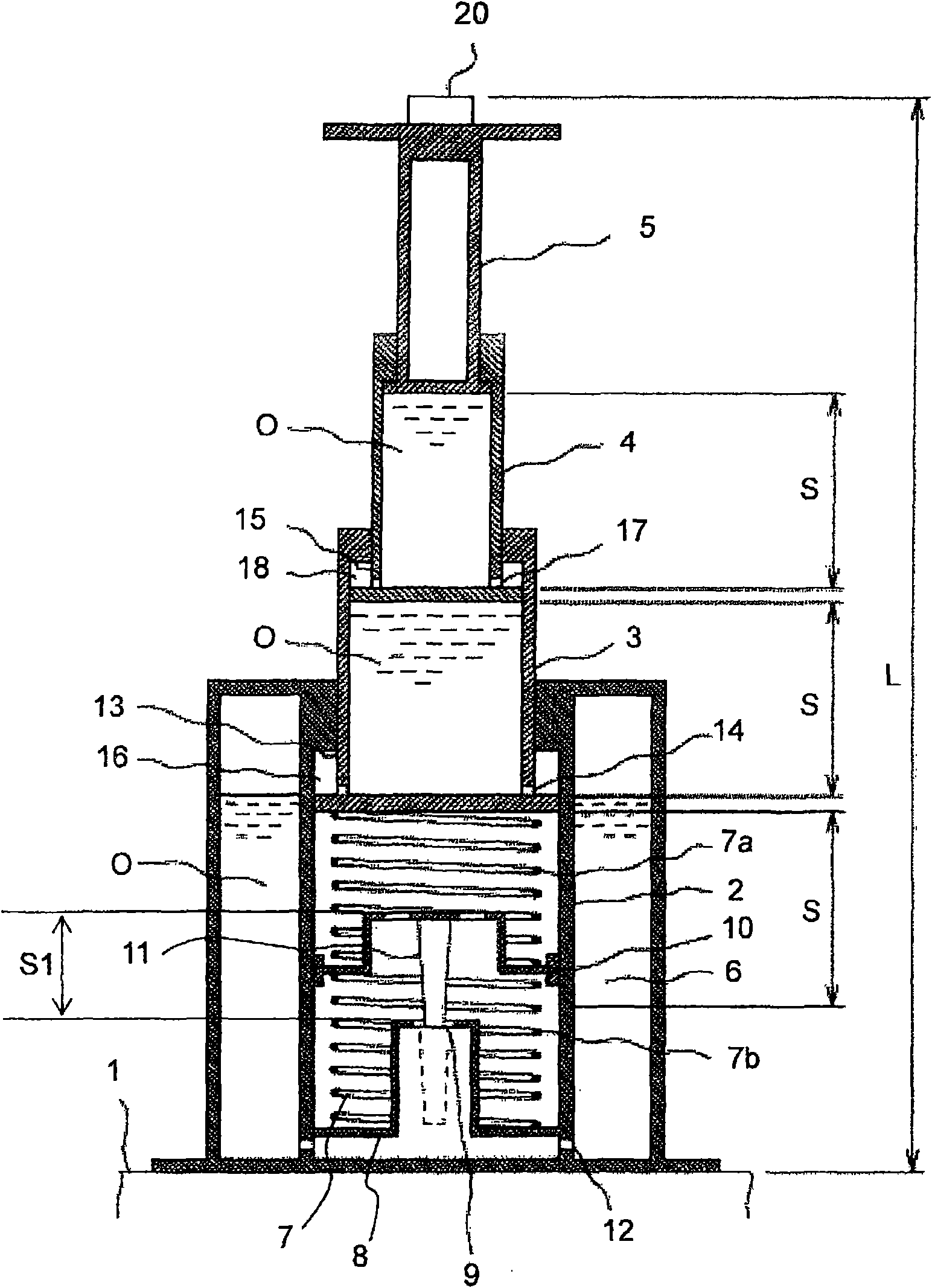

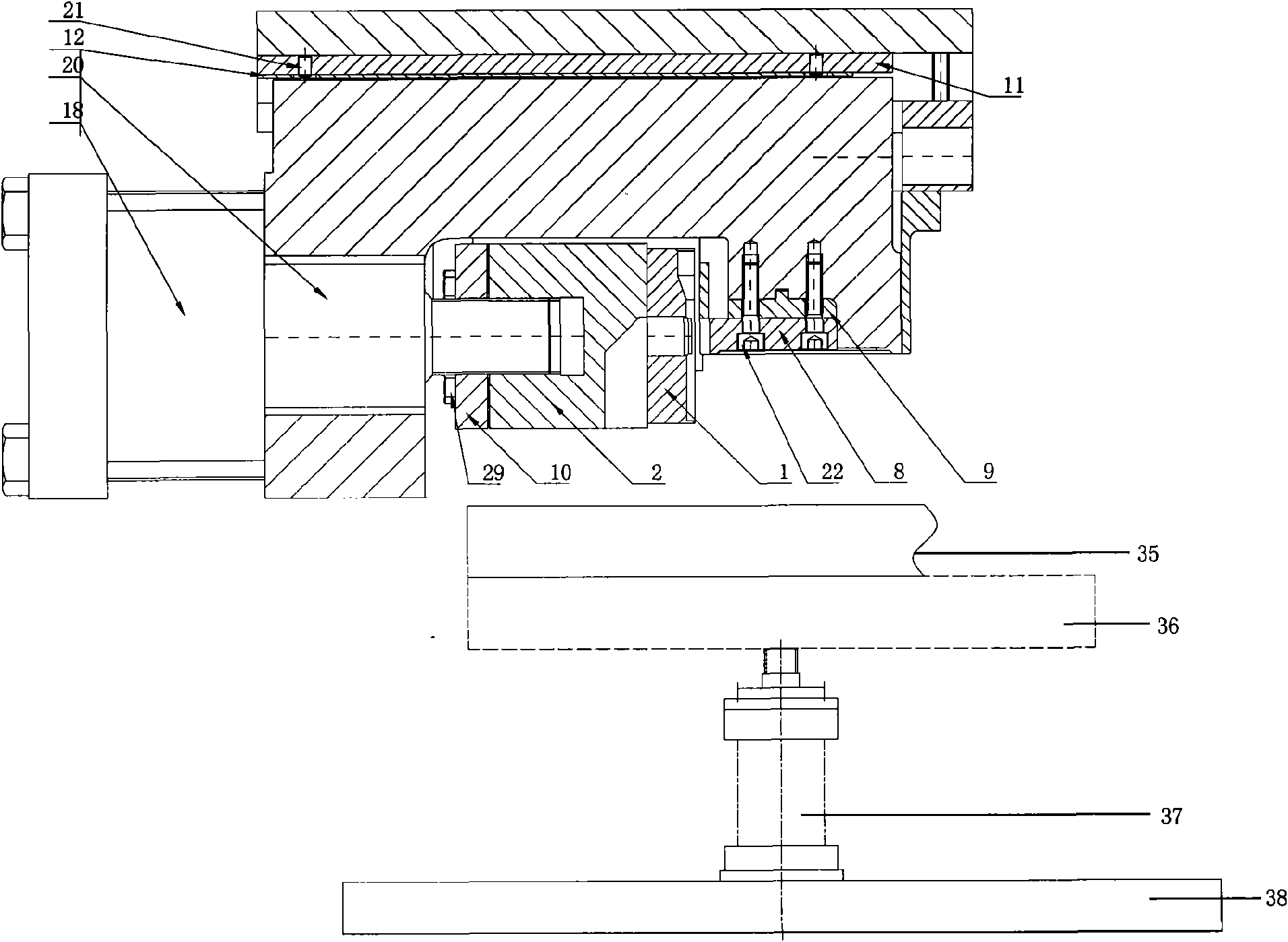

Hydraulic damper for elevator

InactiveCN101597003ALower the altitudeReduced depth sizeSpringsLiquid based dampersHydraulic cylinderCircular disc

The invention provides a hydraulic damper for an elevator capable of reducing whole height. The hydraulic damper for the elevator provided by the invention comprises a hydraulic cylinder and a plurality of plungers. The hydraulic cylinder is vertically arranged in an elevator pit of a lift passage and filled with hydraulic oil. A plurality of plungers are jogged into the hydraulic cylinder in a way of stretching up and down, diameter is gradually reduced from outside to inside, and the plungers are concentrically overlapped with each other. In addition, an orifice for the hydraulic oil to pass through when the plungers drop, a slender conical member, a front end of which is loosely inserted into the orifice, and a returning spring that enables the dropped plungers to return a primary position are arranged in the hydraulic cylinder. In the hydraulic damper for the elevator, the returning spring is composed of a first spring and a second spring in a way of dividing one into two up and down, at the same time, a circular disc with the slender conical member can be arranged between the first spring and the second spring in a way of moving up and down.

Owner:HITACHI LTD +1

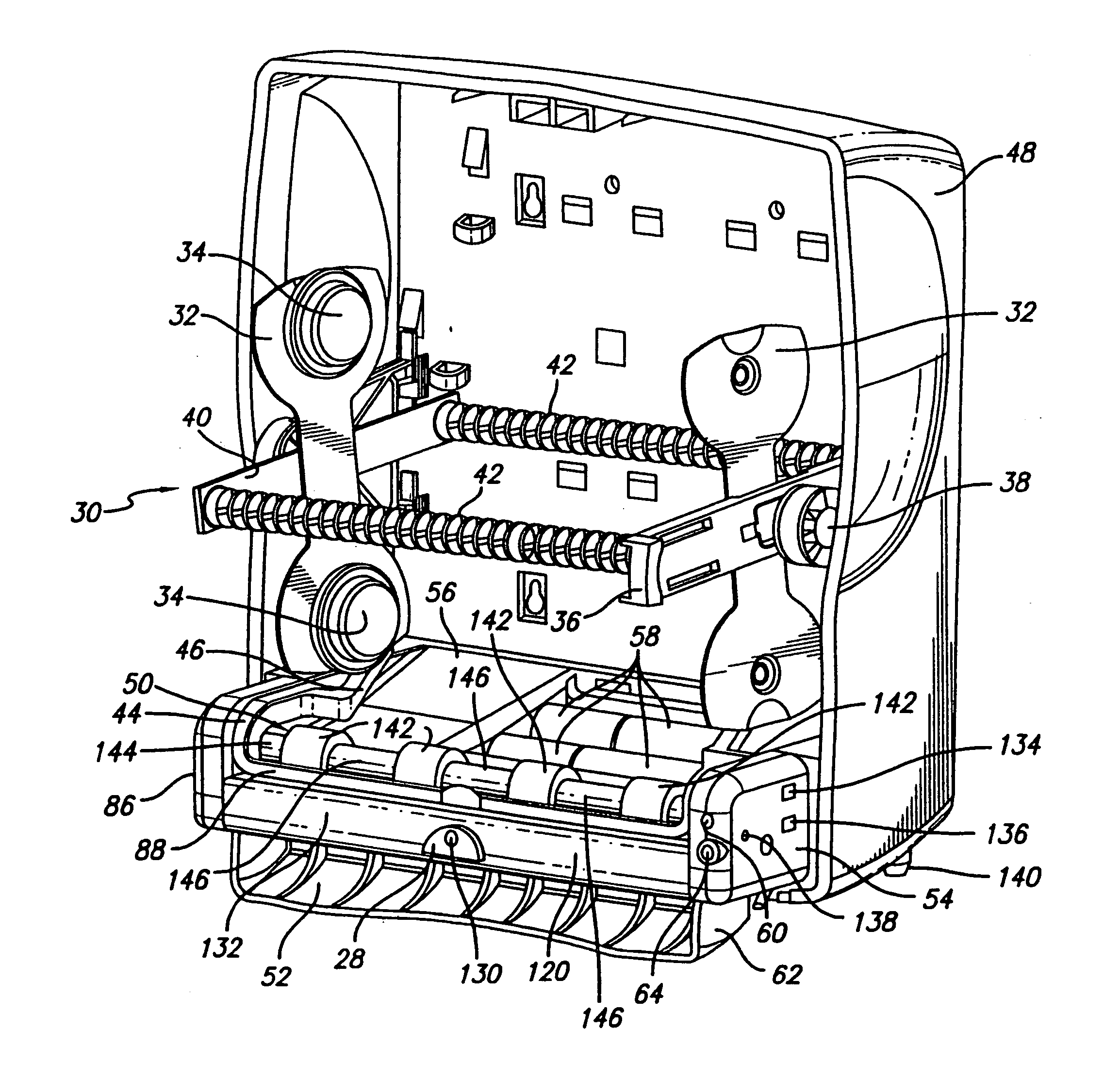

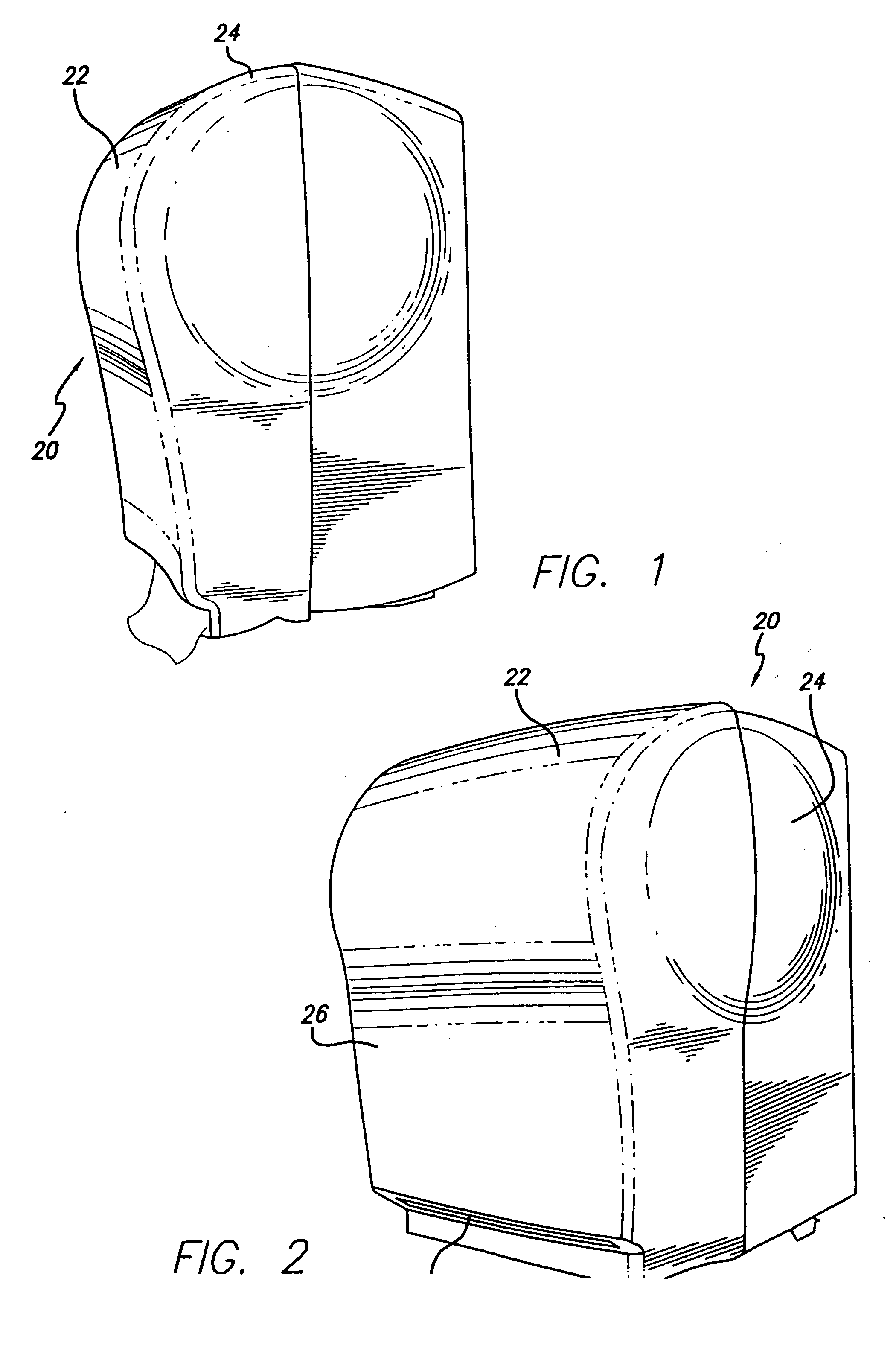

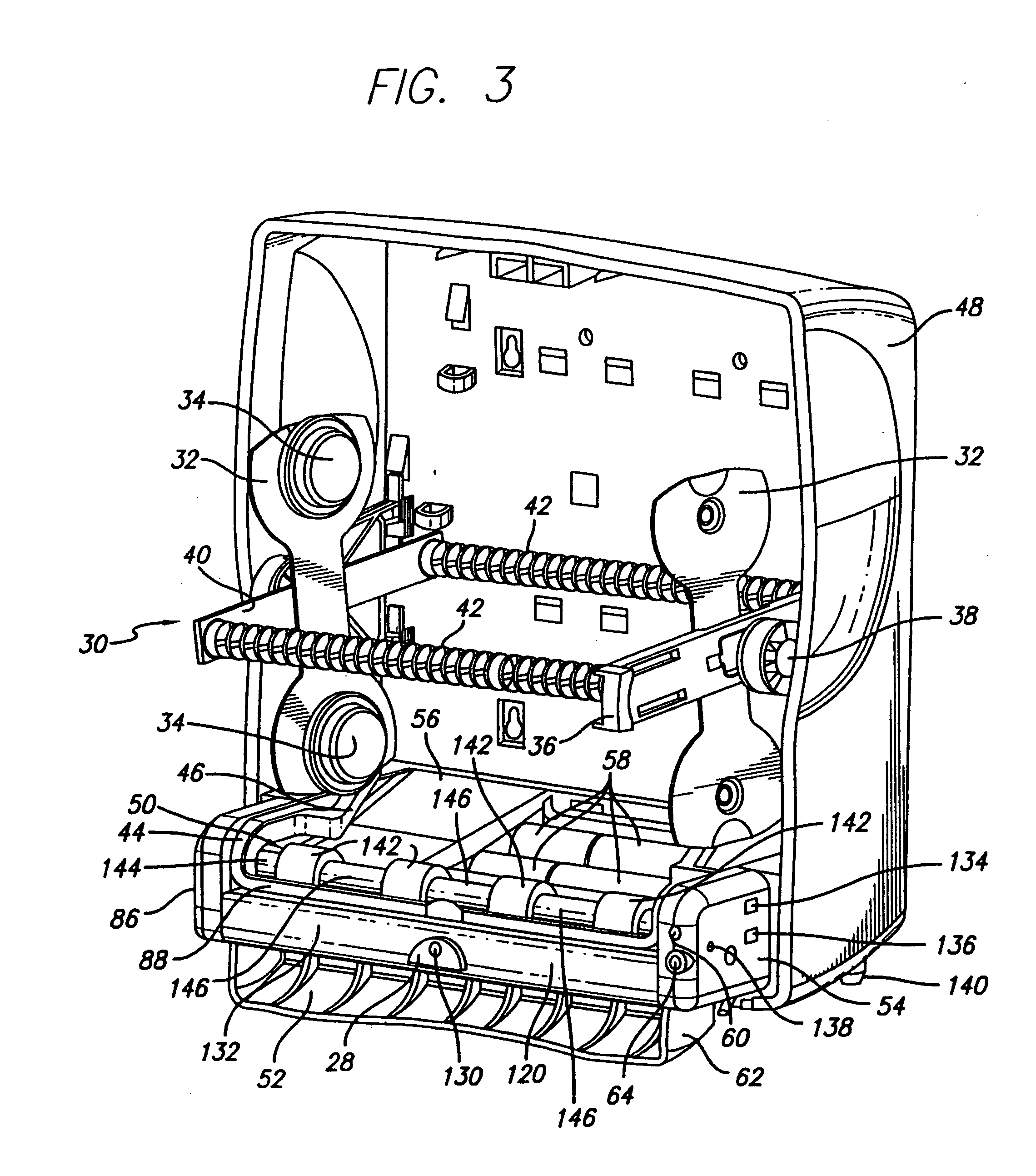

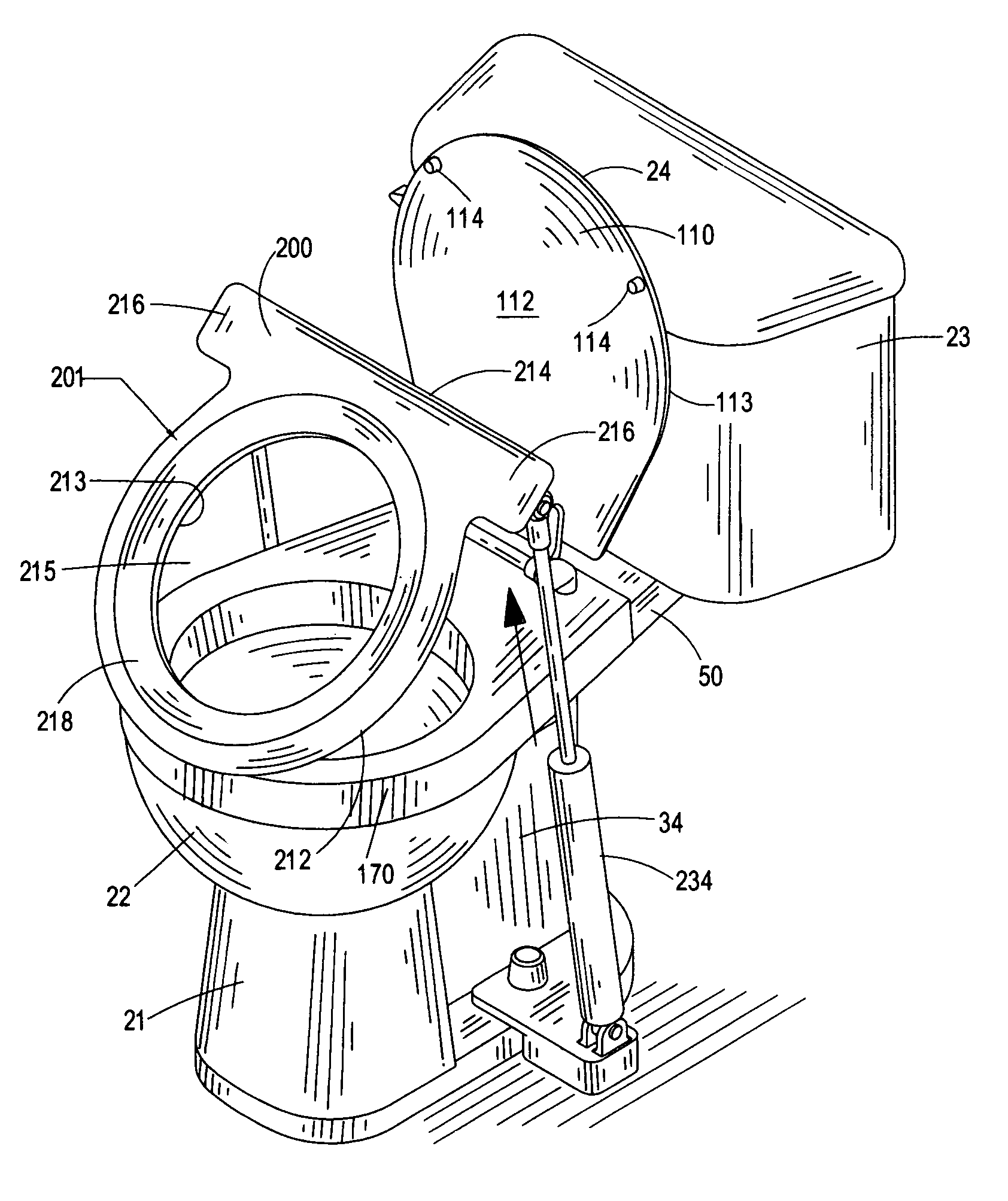

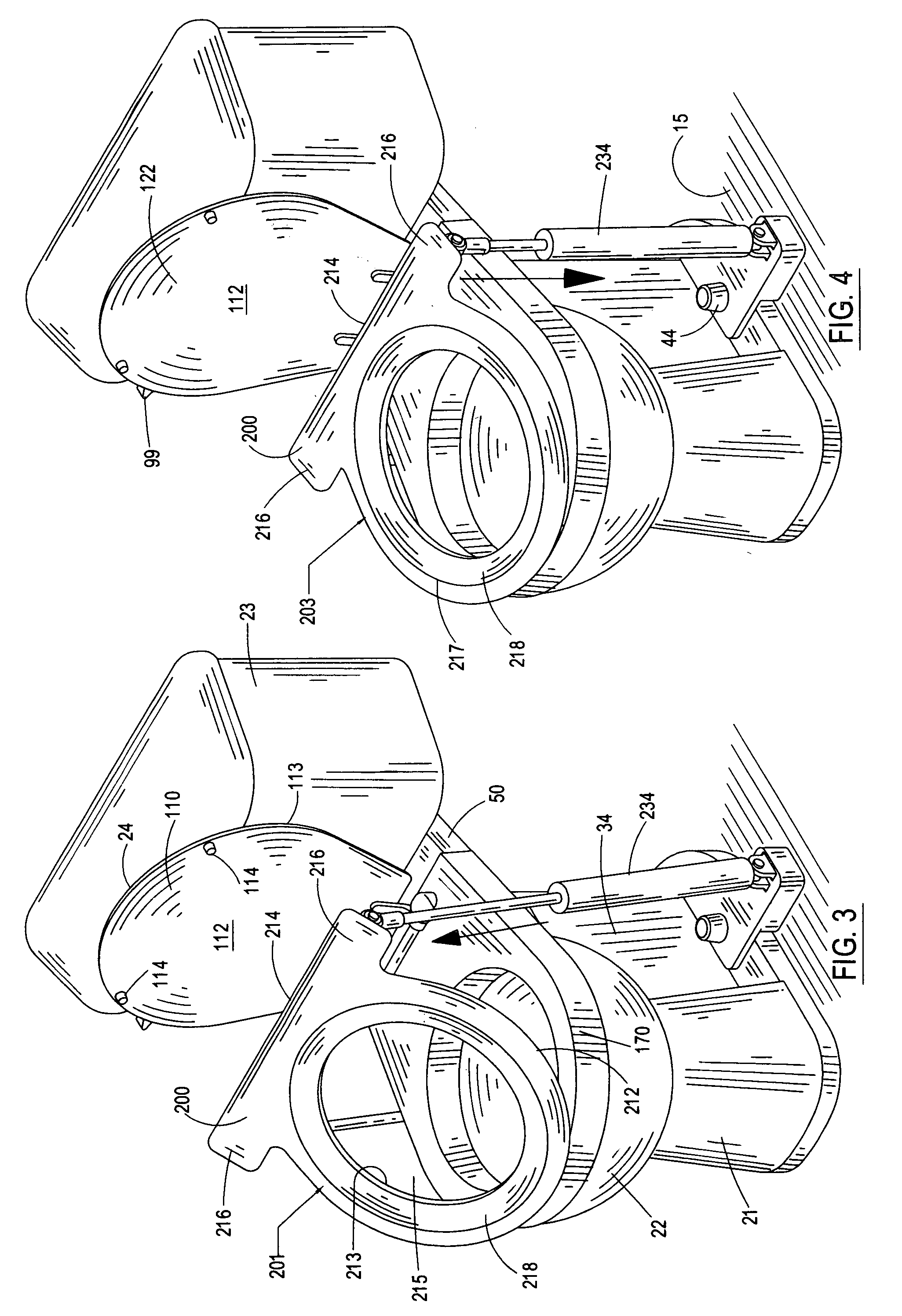

Waste minimizing carousel-style dispenser

A dispenser for rolled absorbent web material is disclosed. A carriage is rotatable between at least two orientations. The carriage includes a first roll holder, which holds a first roll of absorbent web material in a primary position when the carriage is in a first orientation and in a secondary position when the carriage is in a second orientation, and a second roll holder, which holds a second roll of absorbent web material in the secondary position when the carriage is in the first orientation and in the primary position when the carriage is in the second orientation. A roll sensor senses the amount of absorbent web material remaining on the roll in the primary position. A feed mechanism dispenses absorbent web material from at least one of the rolls. A transfer mechanism feeds absorbent web material from the roll in the secondary position into the feed mechanism when the absorbent web material on the roll in the primary position is nearly depleted.

Owner:GPCP IP HLDG LLC

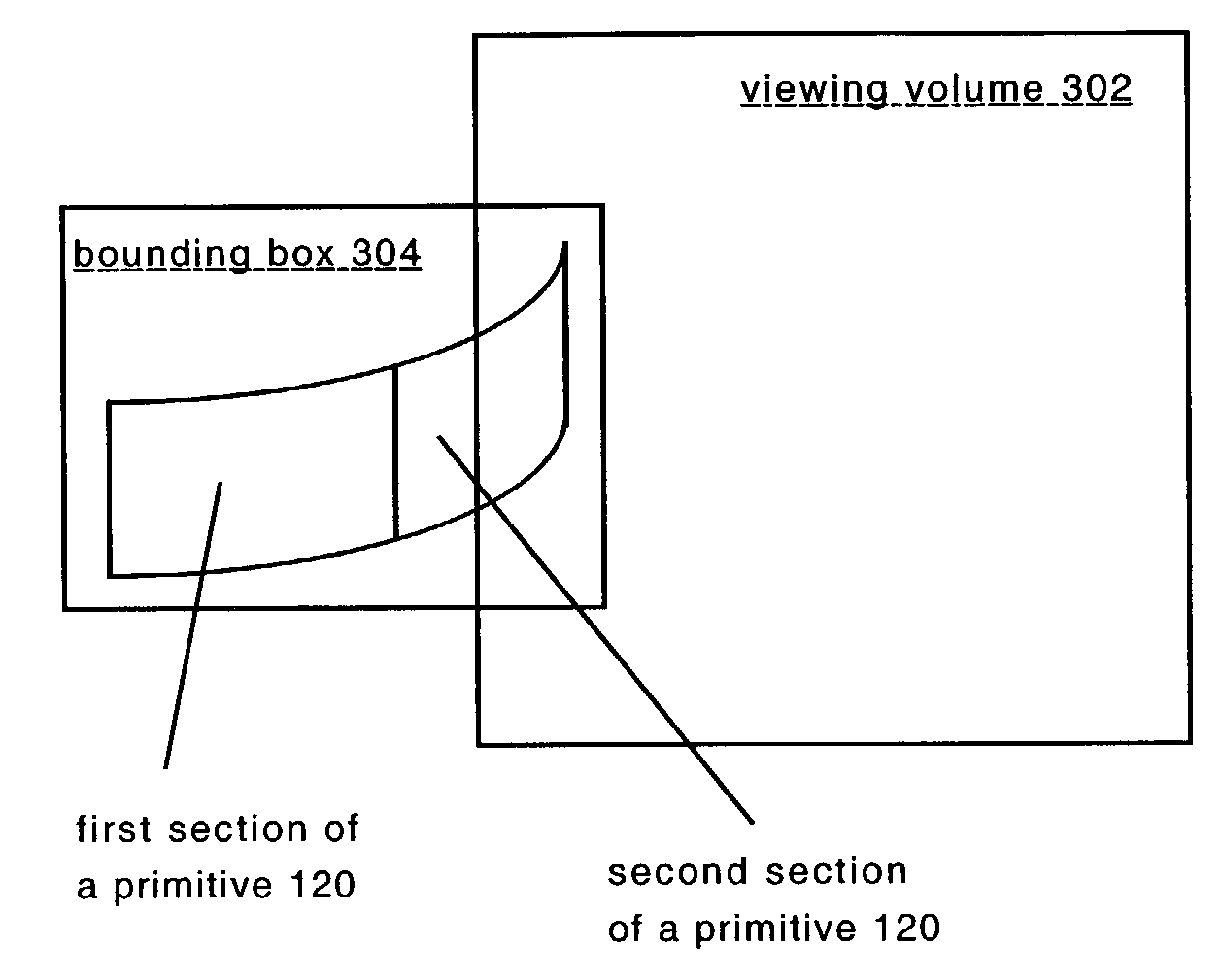

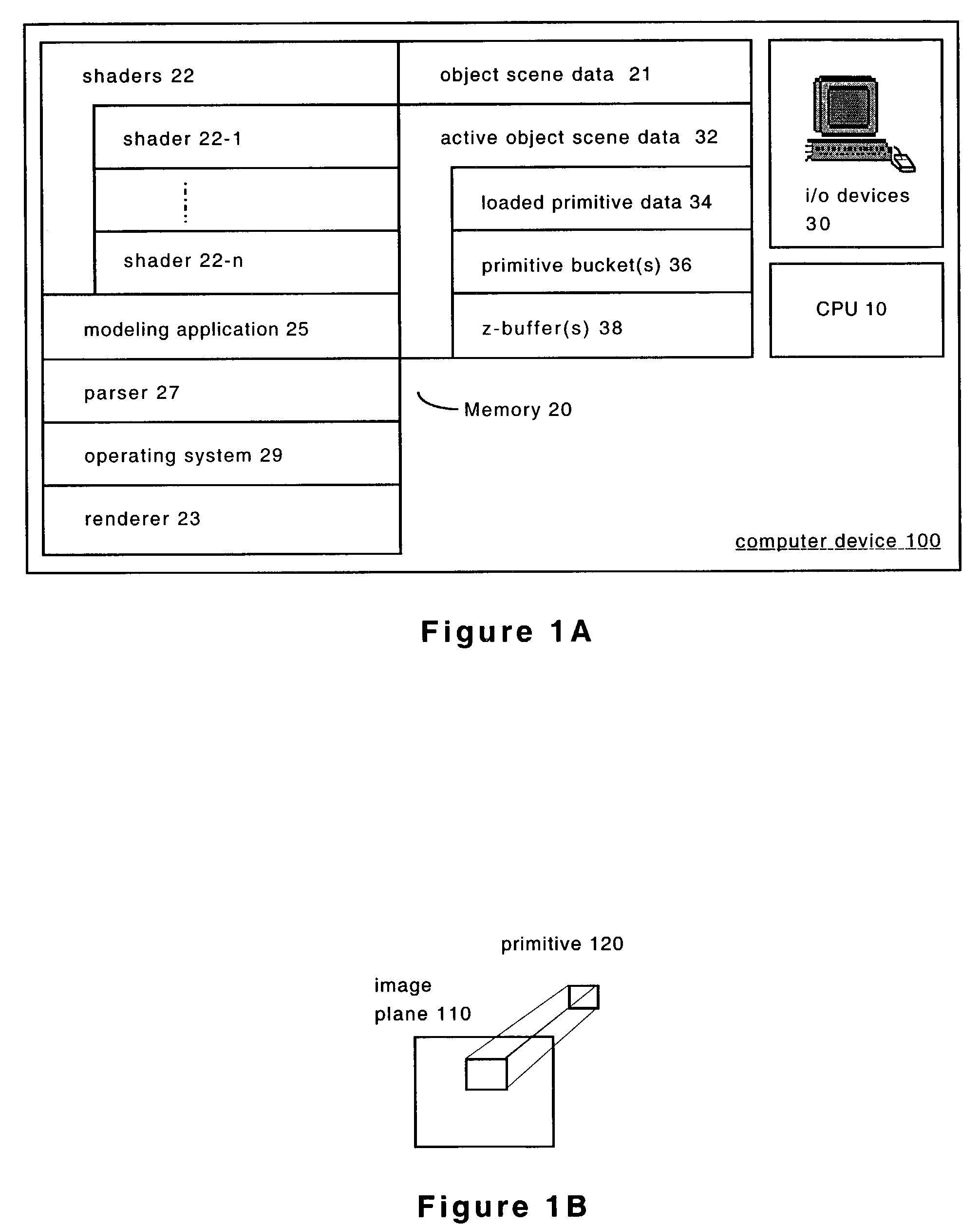

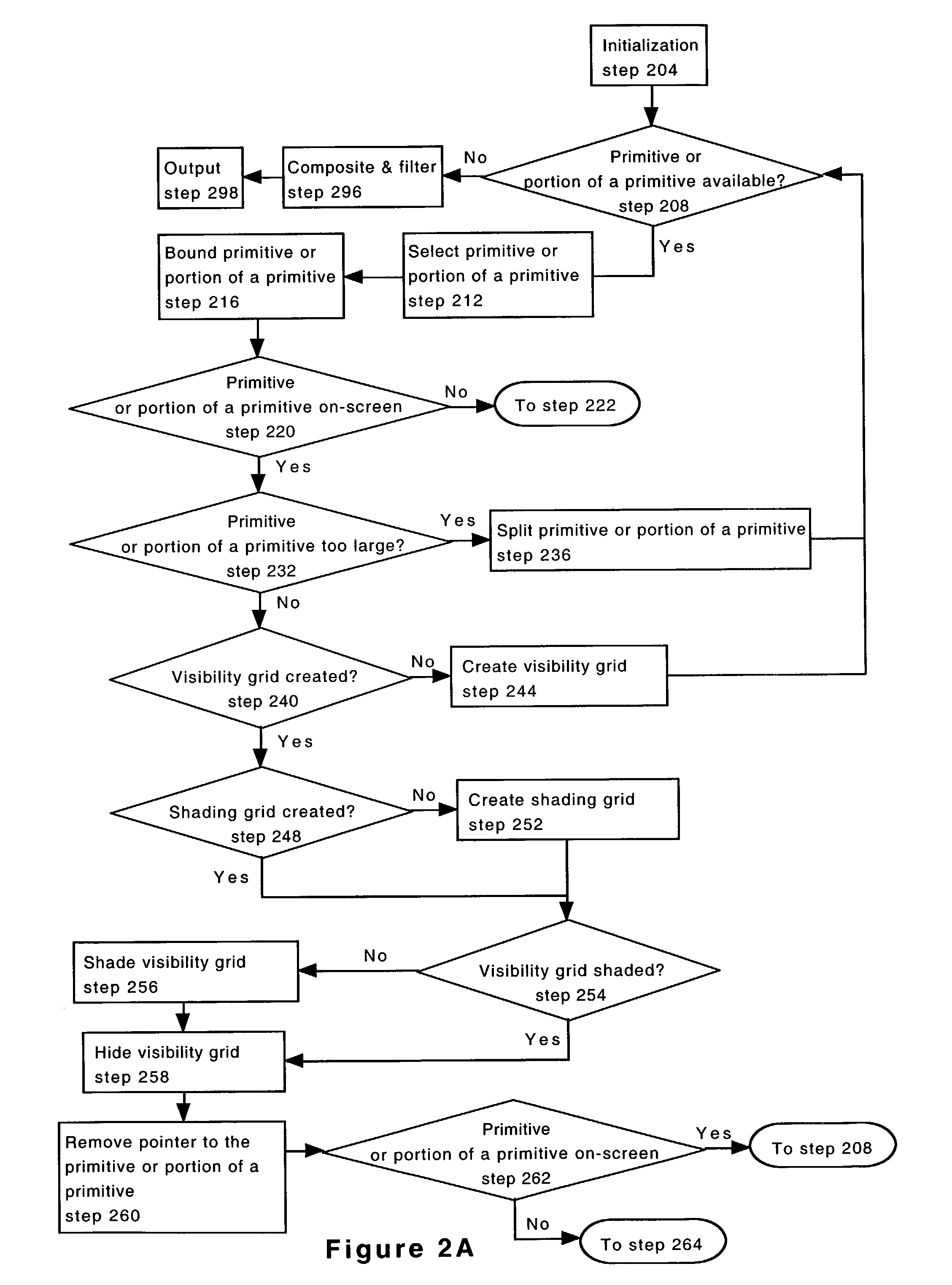

System and method of using multiple representations per object in computer graphics

InactiveUS7009608B2Resolution be relatively coarseCathode-ray tube indicatorsCamera body detailsGraphicsImage resolution

Owner:NVIDIA CORP

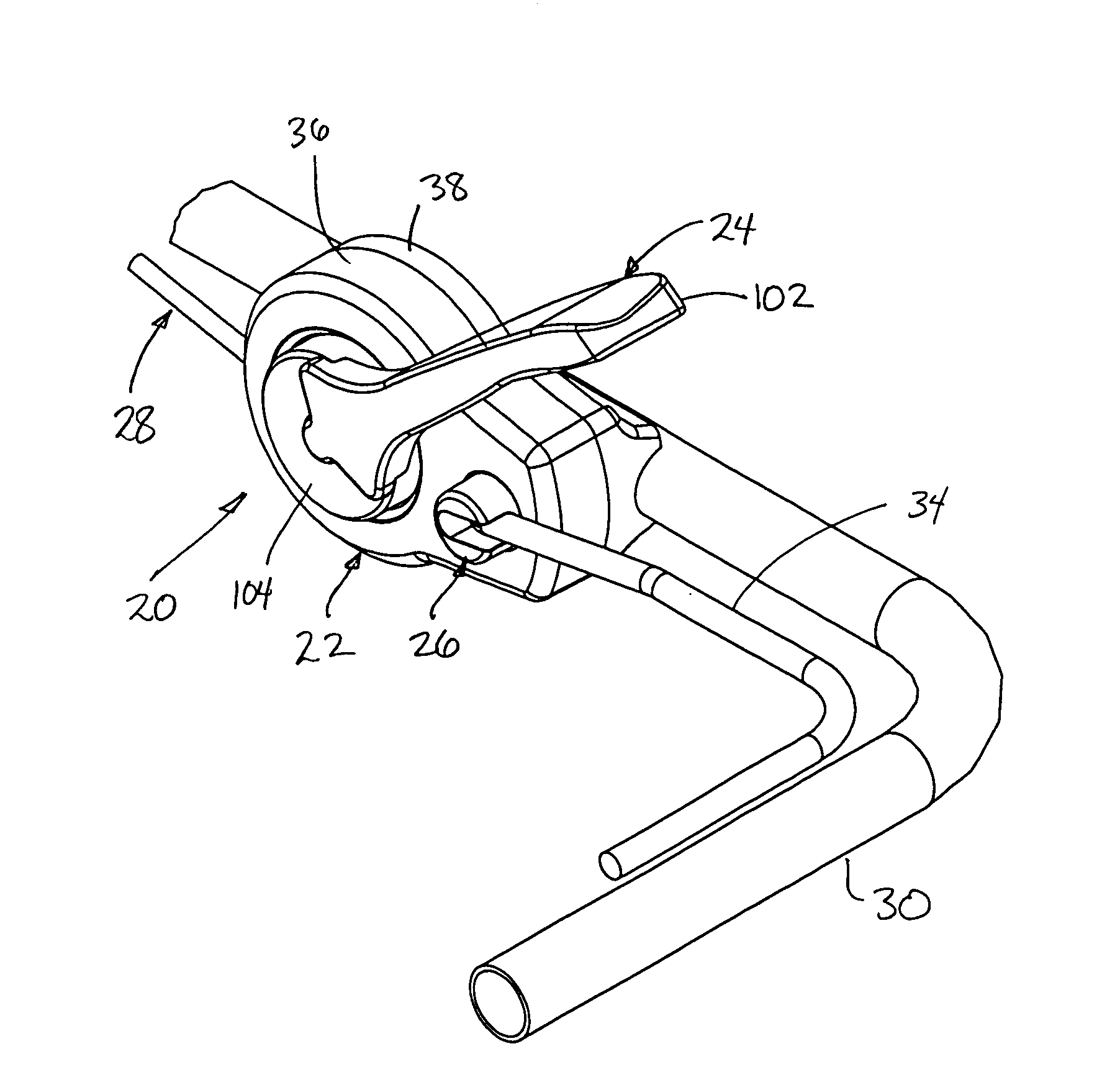

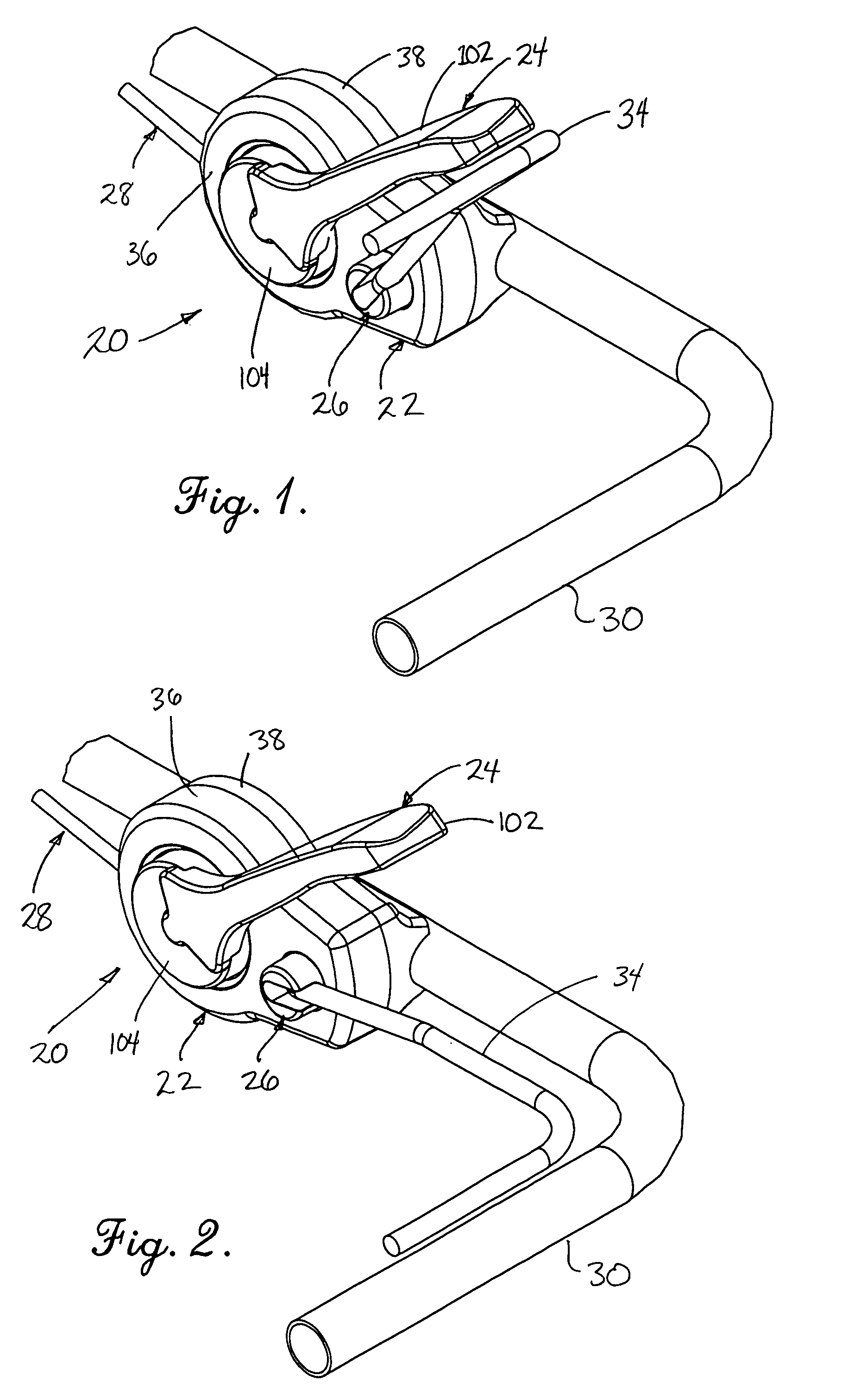

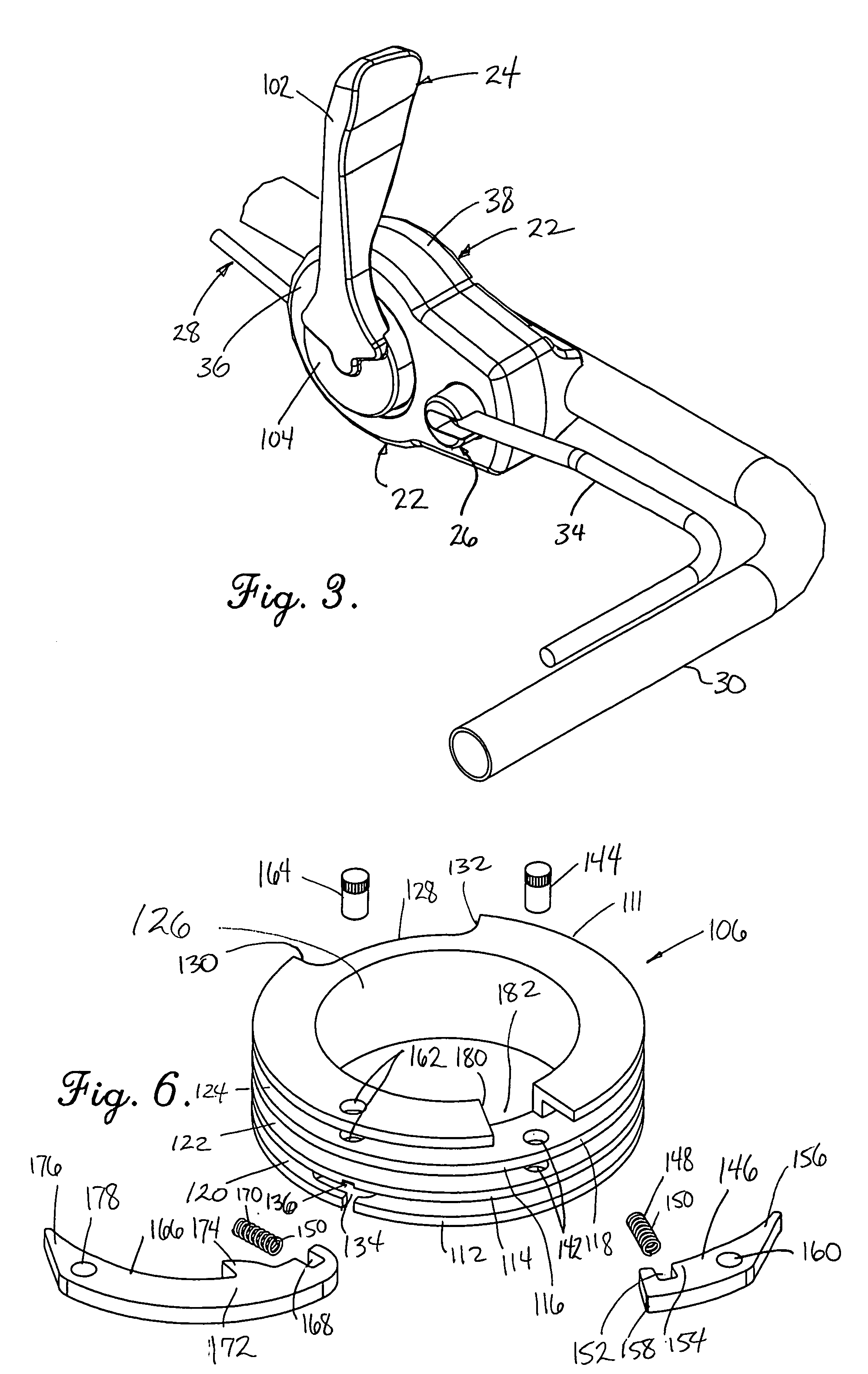

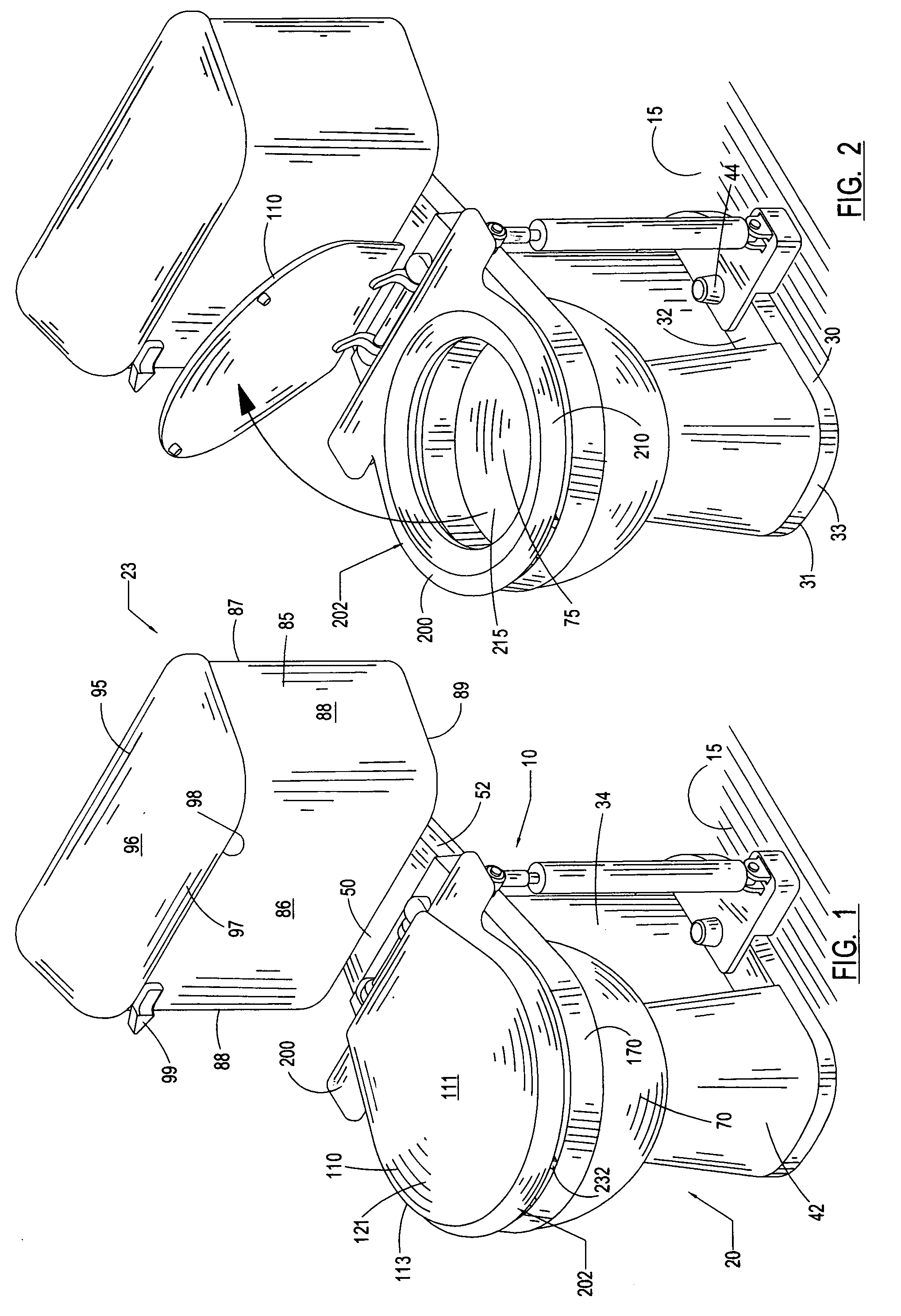

Apparatus for two-motion cable engagement

ActiveUS7591126B2Less-expensive to constructLess-expensive to assembleMowersEngineeringElectric cables

A method and apparatus for two motion cable engagement includes a housing adapted for attachment to a tubular member such as a handlebar or the like of a walk-behind lawnmower, a lever assembly pivotably mounted to the housing, and a socket operatively connectable to the lever assembly and actuatable by a deadman handle. The lever assembly preferably includes a lever, a hub connected to the lever, and a pivotable member which is selectively pivotably driven by the hub. When the socket is pivoted by the deadman handle from a primary position to an engaged position, movement of the lever from an initial position to an advanced position produces pivoting of the pivotable member and a control cable attached thereto. With the socket remaining in the engaged position, the lever may be permitted to return to the initial position, and the pivotable member remains advanced and held by the socket, keeping the control cable in the actuated condition until the deadman handle is released, whereupon tension on the control cable causes the pivotal member returned to its initial position and permits the control cable to extend and deactivate a controllable mechanism to which it is attached.

Owner:WESCON CONTROLS

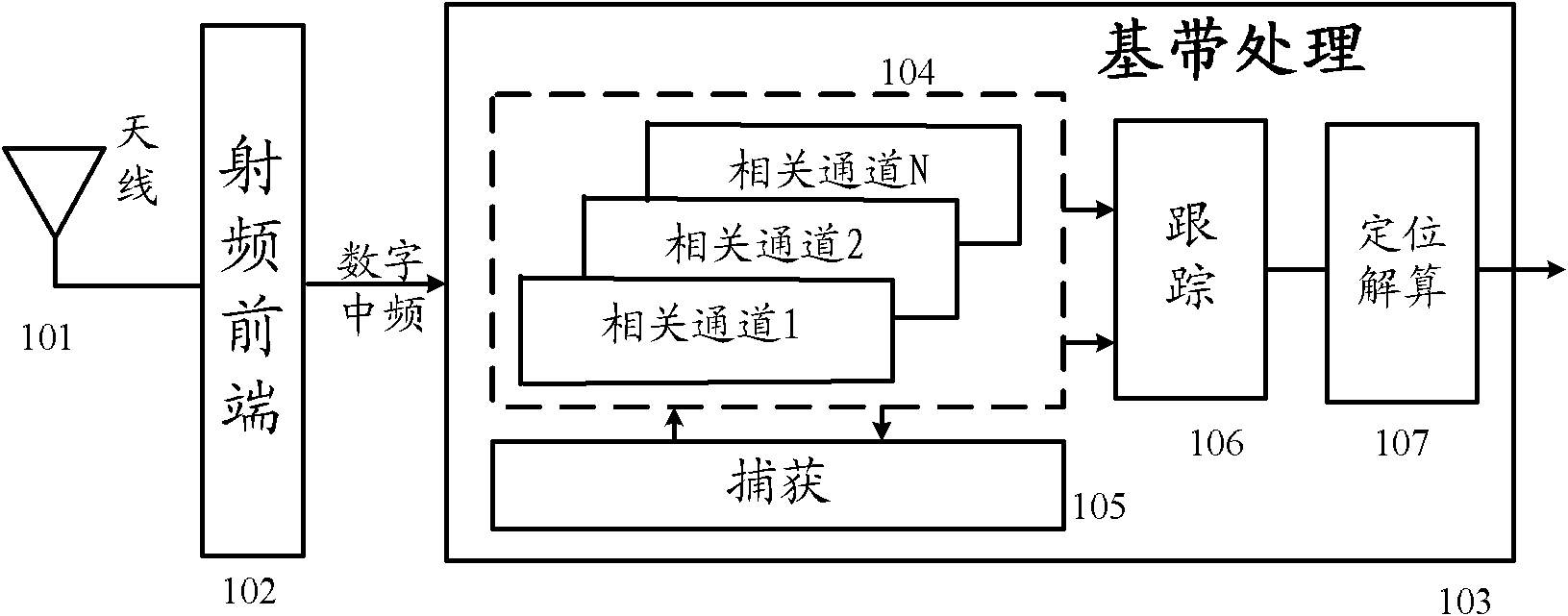

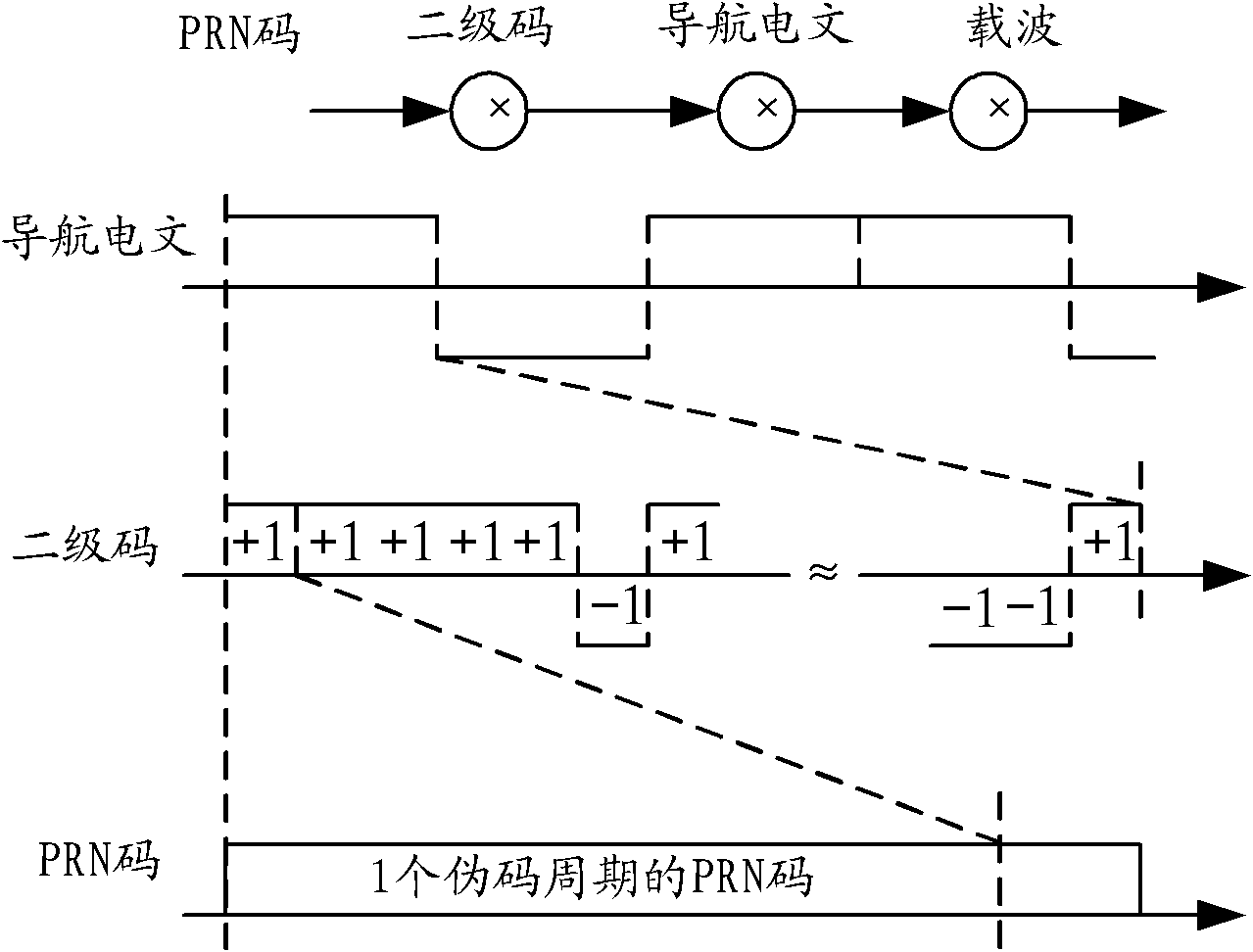

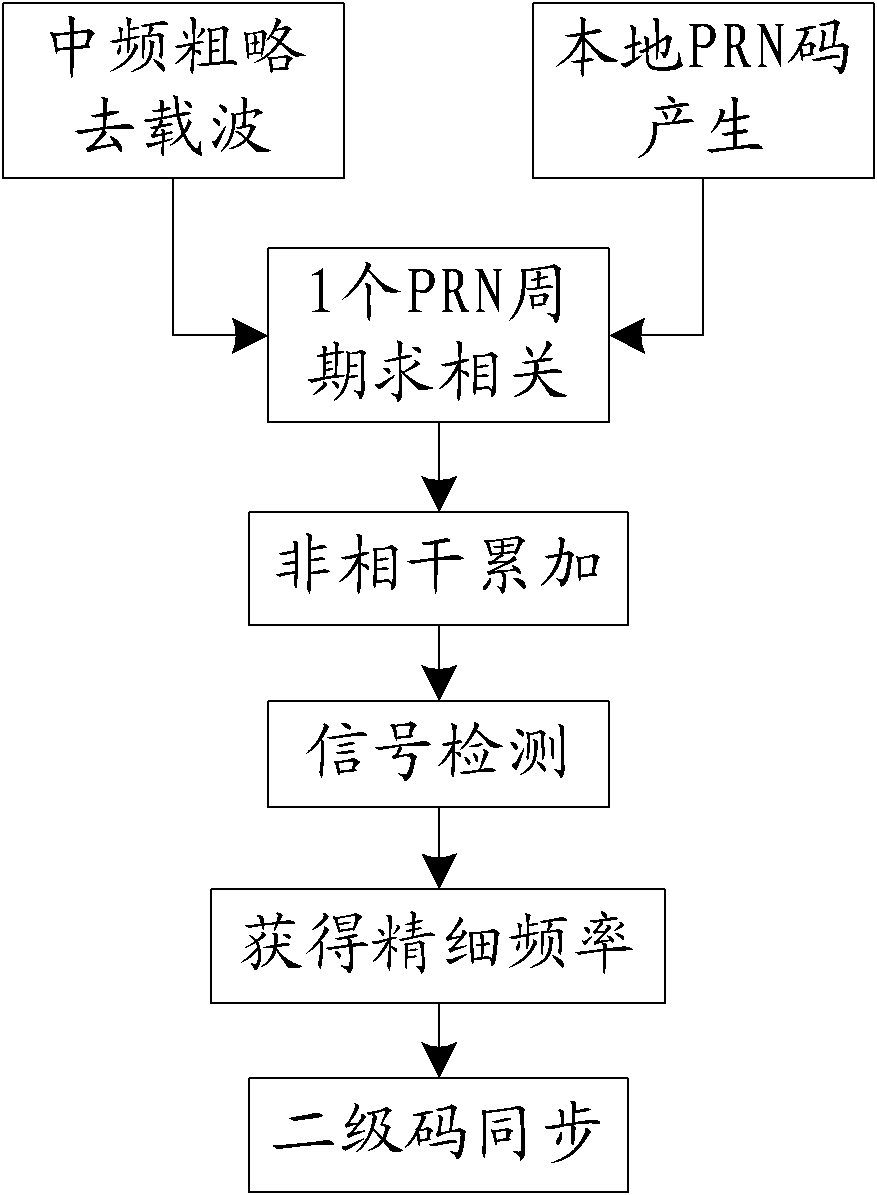

Rapid associated acquisition device and method thereof

InactiveCN102759739AFast joint captureSmall amount of calculationSatellite radio beaconingFast Fourier transformPrior information

The embodiment of the invention provides a rapid associated acquisition device, comprising an intermediate frequency carrier removing module, a code generator, a sampling module, a register module, a matching filter, a relevant result memorizer, a secondary code stripping module, a data processing module and a signal detection unit. On the other aspect, the embodiment of the invention provides a rapid associated acquisition method. In the technical scheme provided by the invention, rapid associated acquisition to the secondary code-containing GNSS (Global Navigation Satellite System) signal is provided through the matching filter technology and the FFT (Fast Fourier Transform) technology, thus, the aim of associated acquisition of satellite pseudo code primary position and secondary code primary position is realized; and the carrier frequency can be searched in parallel, the limit of the frequency offset sensitivity of the secondary code to the searching step size when performing pseudo code and secondary code associated acquisition is solved, the calculated quantity is reduced greatly, and the acquisition speed is improved, so that the device and the method provided by the invention are not only suitable for weak signal reacquisition with prior information, but also suitable for cold start high sensitivity acquisition.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

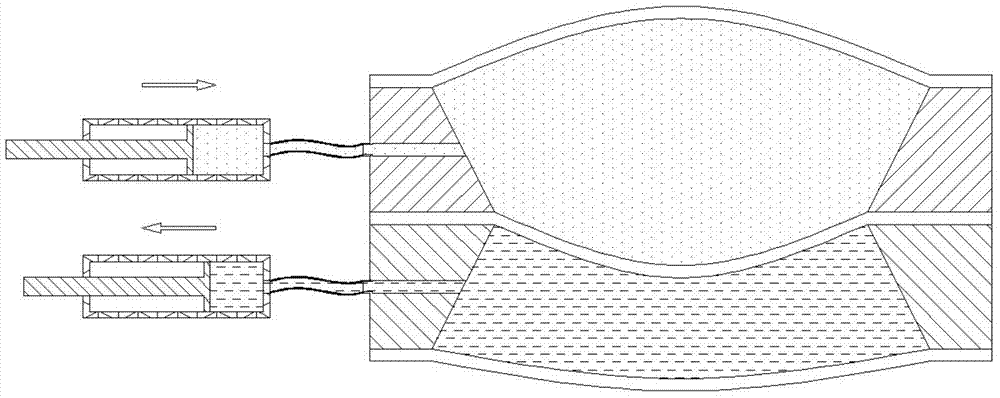

Multiple port fluid control valves

A fluid control valve is disclosed which, with a single valve, can manipulate flow between a saline supply, a contrast supply, a waste dump and a catheter. The control valve includes three primary positions including a contrast position where the valve provides communication between an injector and a contrast supply while isolating the saline supply and catheter. The valve also can be moved to a saline / waste position where the valve provides communication between the injector and the saline supply and / or the waste dump while isolating the contrast supply and catheter. The valve also can be moved to an injection position where the valve provides communication between the injector and the catheter. A single valve provides all three functions. The valve also may provide communication between a pressure transducer and catheter during the saline loading, waste dumping and contrast loading functions. The valve also provides protection or isolation of the pressure transducer during injection procedures.

Owner:MEDLINE INDUSTRIES

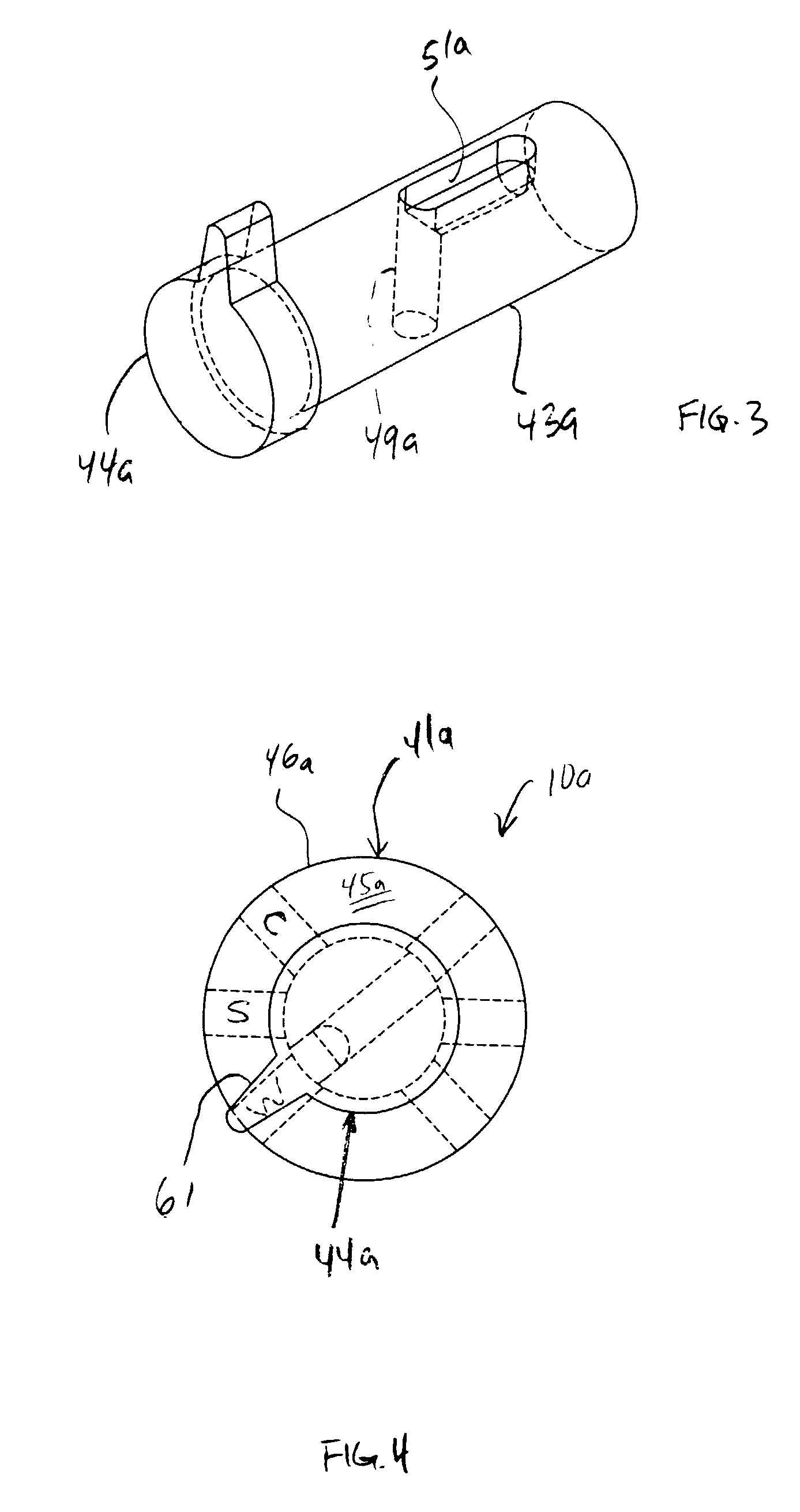

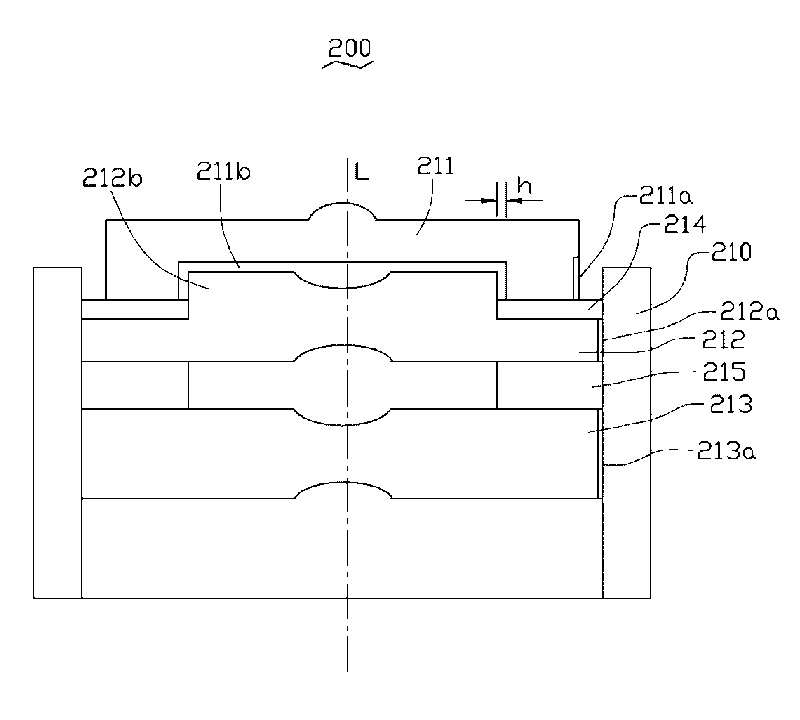

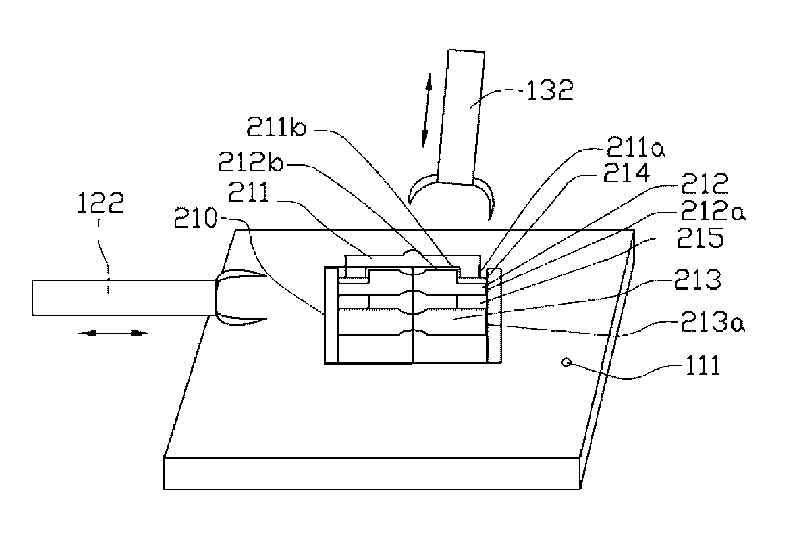

Assembling and testing device and method thereof

InactiveCN101726986AImprove the efficiency of eccentric adjustmentTesting optical propertiesPhotographyCamera lensOptical axis

The invention provides an assembling and testing device, comprising a movement mechanism, an image sensor and a controller; the assembling and testing device is used for assembling and testing multiple lens modules; the inner part of the lens module is orderly provided with a first lens and a second lens from the object side to the image side; the second lens is fixed in the lens module and the first lens can move opposite to the second lens in the radial direction; the controller comprises a locating module for controlling the movement mechanism to radially move the first lens to a position as a primary position, an acquiring module for acquiring the image sensed by the image sensor, an adjusting module for controlling the movement mechanism to move the first lens and enable the first lens to be not eccentric relative to the optical axis of the lens module according to the image, a memory module for recording the movement process of the movement mechanism, a control module for controlling the movement mechanism to move the first lens of an other lens module according to the recorded moving process of the movement mechanism. The assembling and testing device provided by invention adjusts the eccentricity according to the record, thus saving time; in addition, the invention also provides an assembling and testing method.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

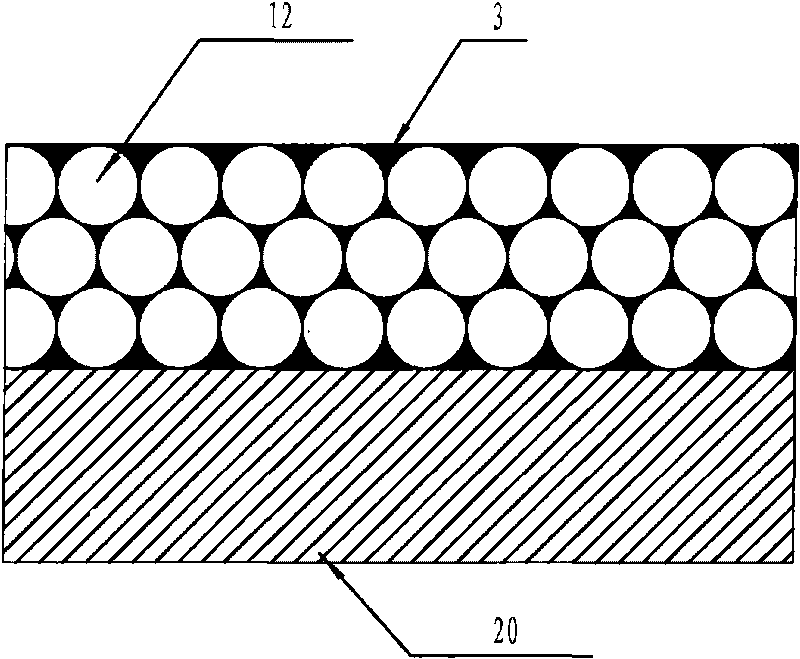

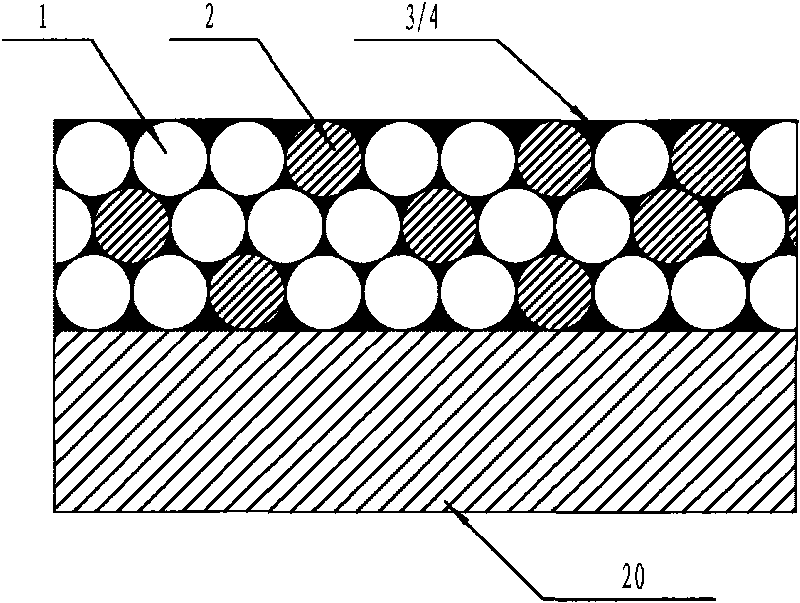

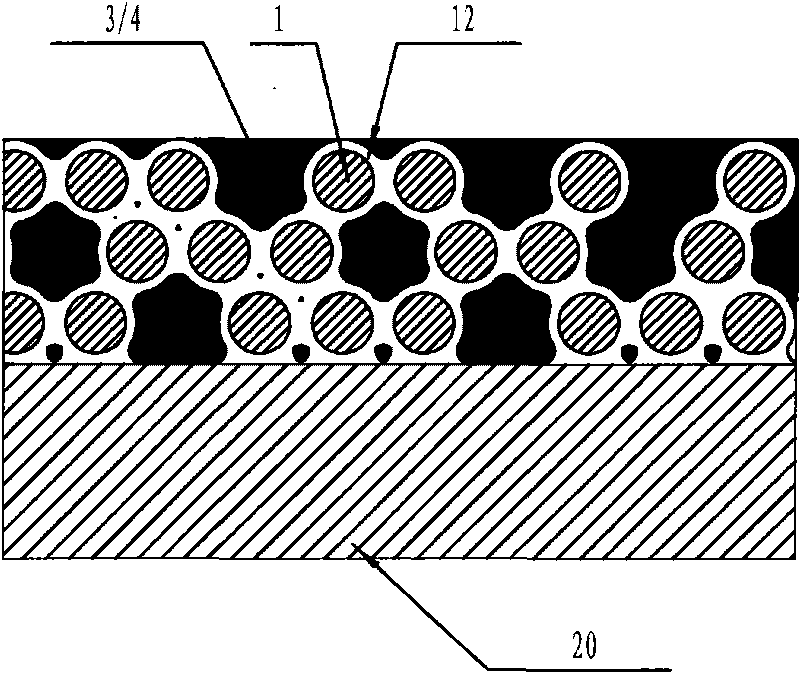

Manufacturing method of bimetal self-lubricating bearing material

ActiveCN101704104AHigh graphite contentGood self-lubricating performanceBearing componentsMaterials scienceHydraulic turbines

The invention relates to a manufacturing method of a bimetal self-lubricating bearing material, which comprises the following steps of: mixing powder, namely uniformly mixing a certain proportion of mixed pure metal powder of Cu, Sn and Pb and graphite powder in an amount which is 5 to 10 percent of the total mass of the mixed pure metal powder in a blender mixer; coating the mixed powder on a steel plate, a stainless steel plate or a bronze sheet and performing secondary sintering, namely performing instant liquid-phase sintering at the temperature higher than the melting point of the Sn powder and lower than the sintering temperature of a copper alloy, wherein limited connection is formed between the Cu powder, a solid solution is formed between the tin and the copper, the Pb powder is distributed between copper and tin solid solution crystal boundaries or dendritic crystal net cells in a form of single Pb particles, the primary positions of the Sn powder and Pb powder are vacant, and the graphite is distributed at the positions; performing the secondary sintering according to the sintering temperature of the copper alloy; and manufacturing the bimetal self-lubricating bearing material by precisely rolling and annealing. The product has stable and reliable performance and is widely applied to machinery industry, such as a hydraulic turbine guide vane bearing, a hydraulic metal structure and metallurgical equipment.

Owner:DALIAN SANHUAN COMPOSITE MATERIAL TECH DEV

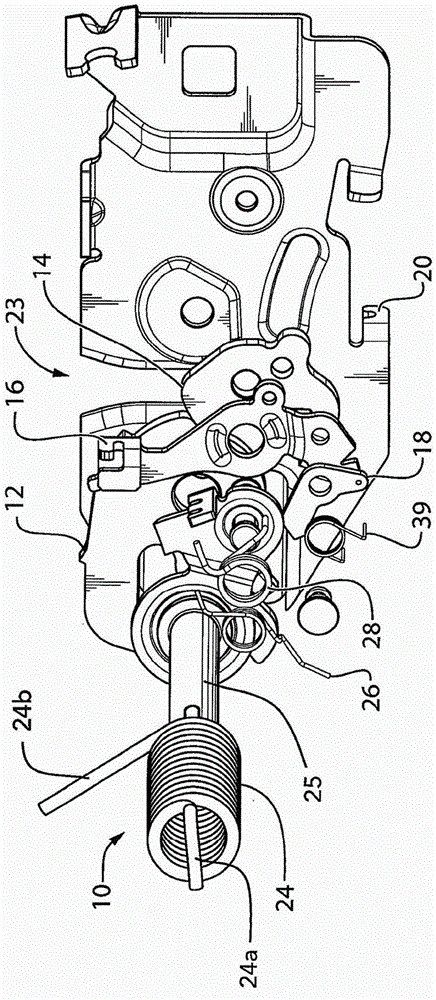

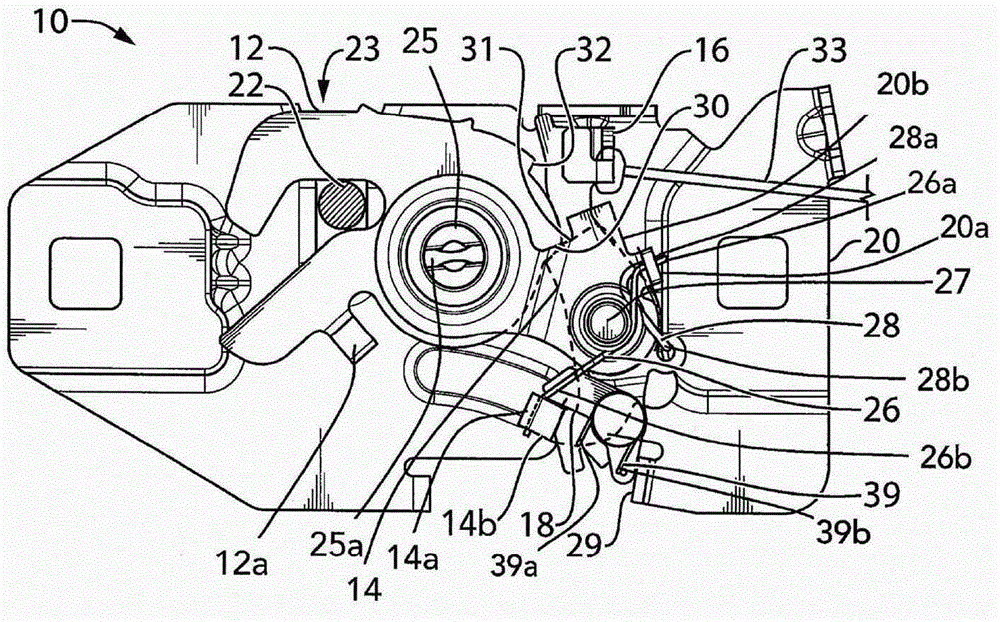

Latch with double pull for closure panel

A latch described herein comprises a ratchet movable between a primary closed position, a secondary closed position and an open position. The ratchet is biased towards the open position for facilitating travel of a striker in a fishmouth of the latch to the secondary closed position. The latch includes a pawl movable between a primary locking position, a secondary locking position and an unlocking position. The pawl is biased towards the primary locking position and has a pawl locking surface for holding the ratchet in the primary closed position and the secondary closed position. The latch includes a lift lever biased towards the open position for moving the striker in the fishmouth away from the secondary closed position and towards the open position when the pawl is in the unlocking position. The striker is further from the primary position when in the open position compared to the secondary closed position.

Owner:MAGNA CLOSURES INC

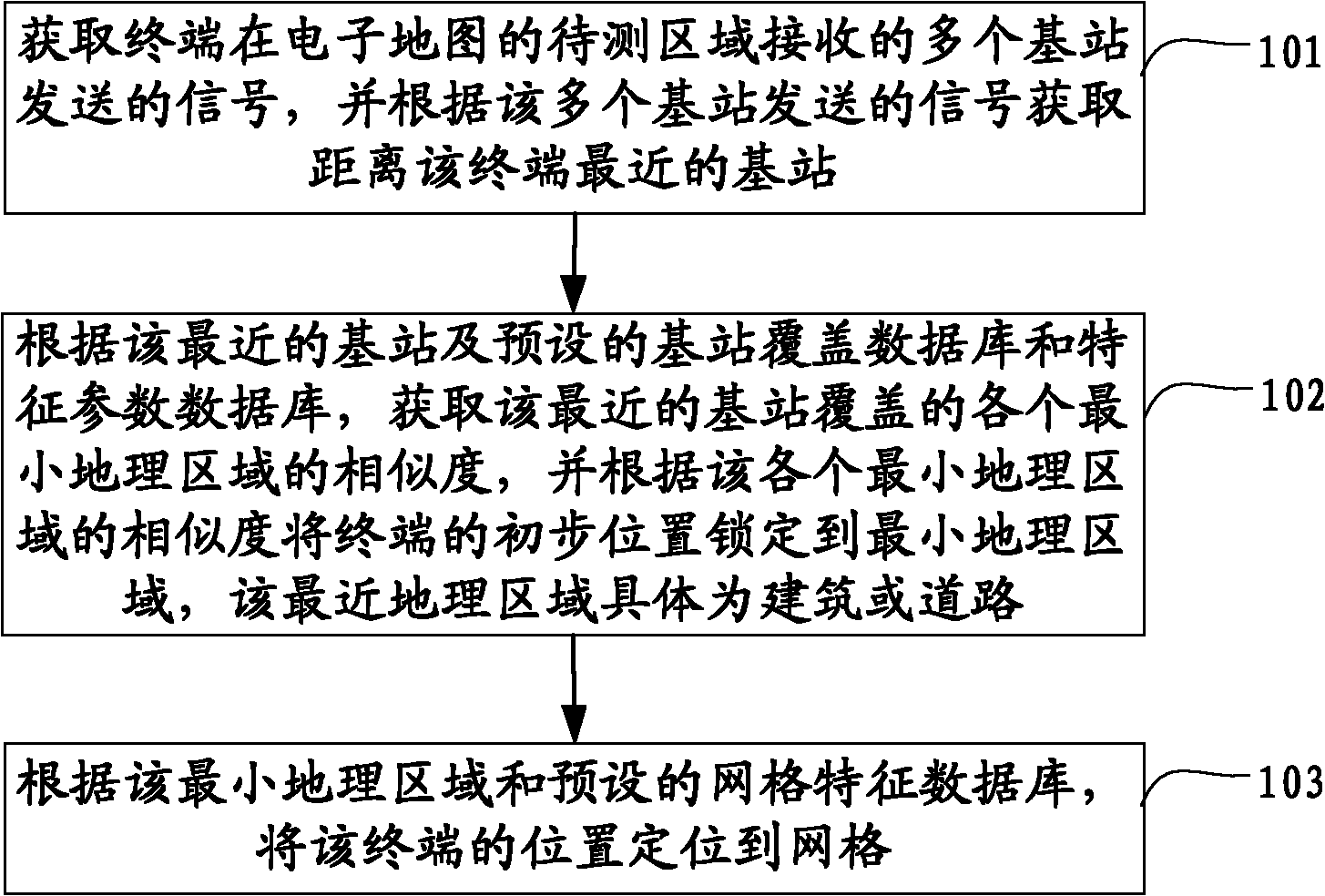

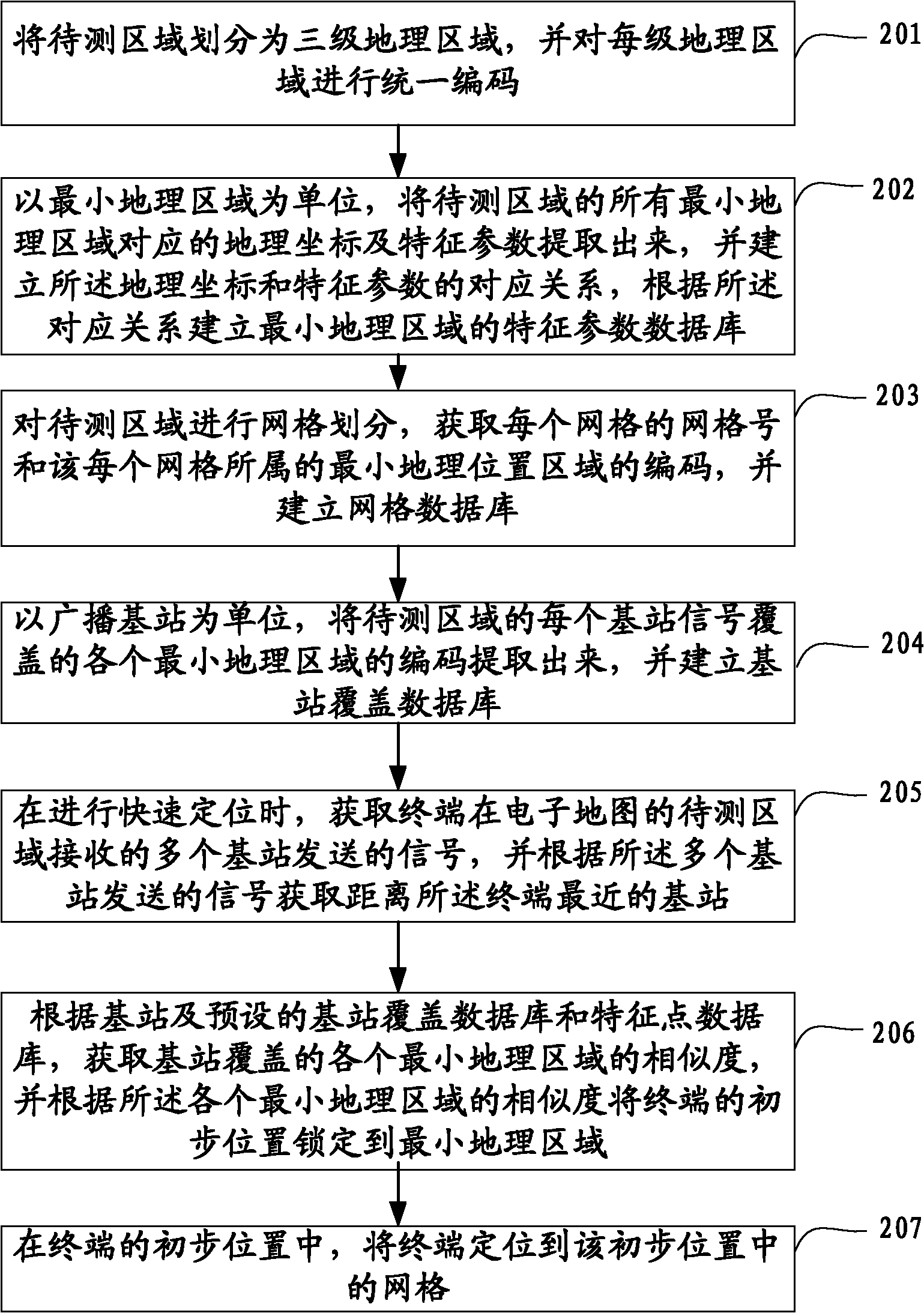

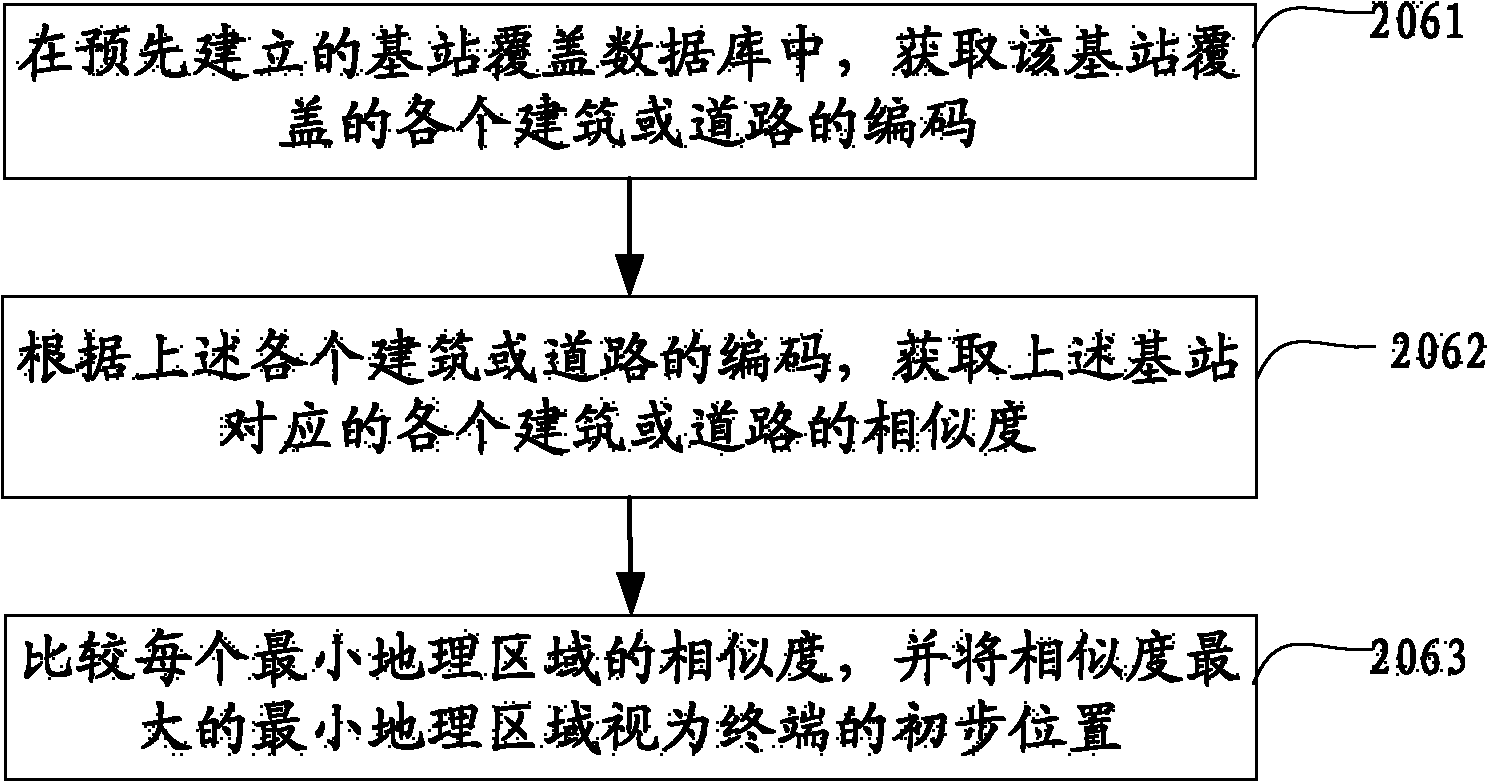

Quick positioning method and device

ActiveCN102209384AReduce computing costRapid positioningWireless communicationComputer scienceElectronic map

The invention discloses a quick positioning method and device, which belong to the field of navigation. The method comprises the following steps of: acquiring signals, which are transmitted by a plurality of base stations, received by a terminal at an area to be measured of an electronic map, and acquiring the base station which is nearest to the terminal according to the signals transmitted by the base stations; acquiring the similarity of all minimum geographic areas covered by the nearest base station according to the nearest base station and preset base station coverage database and characteristic parameter database, and locking the primary position of the terminal to the minimum geographic area according to the similarity of all the minimum geographic areas, wherein the minimum geographic area is specifically a building or a road; and positioning the position of the terminal to a grid according to the minimum geographic areas and a preset grid characteristic database. In the invention, the positioning is performed by taking the base station as a starting point, so that the positioning range is quickly reduced; and the positioning is performed by using a grid concept after the area is primarily positioned, so that the positioning efficiency is increased.

Owner:BEIJING UNIV OF POSTS & TELECOMM +1

Support apparatus

A support apparatus for use with an appliance, the apparatus having a substantially rigid support member adapted to be engaged by a human being for access to the appliance; an assembly mounting the support member on the appliance for movement through a range of positions between a primary position and a secondary position elevated from the primary position; and a mechanism for moving the support member between the primary position and the secondary position to move the human being engaged therewith between the primary position and the secondary position.

Owner:NUGENT PAUL J

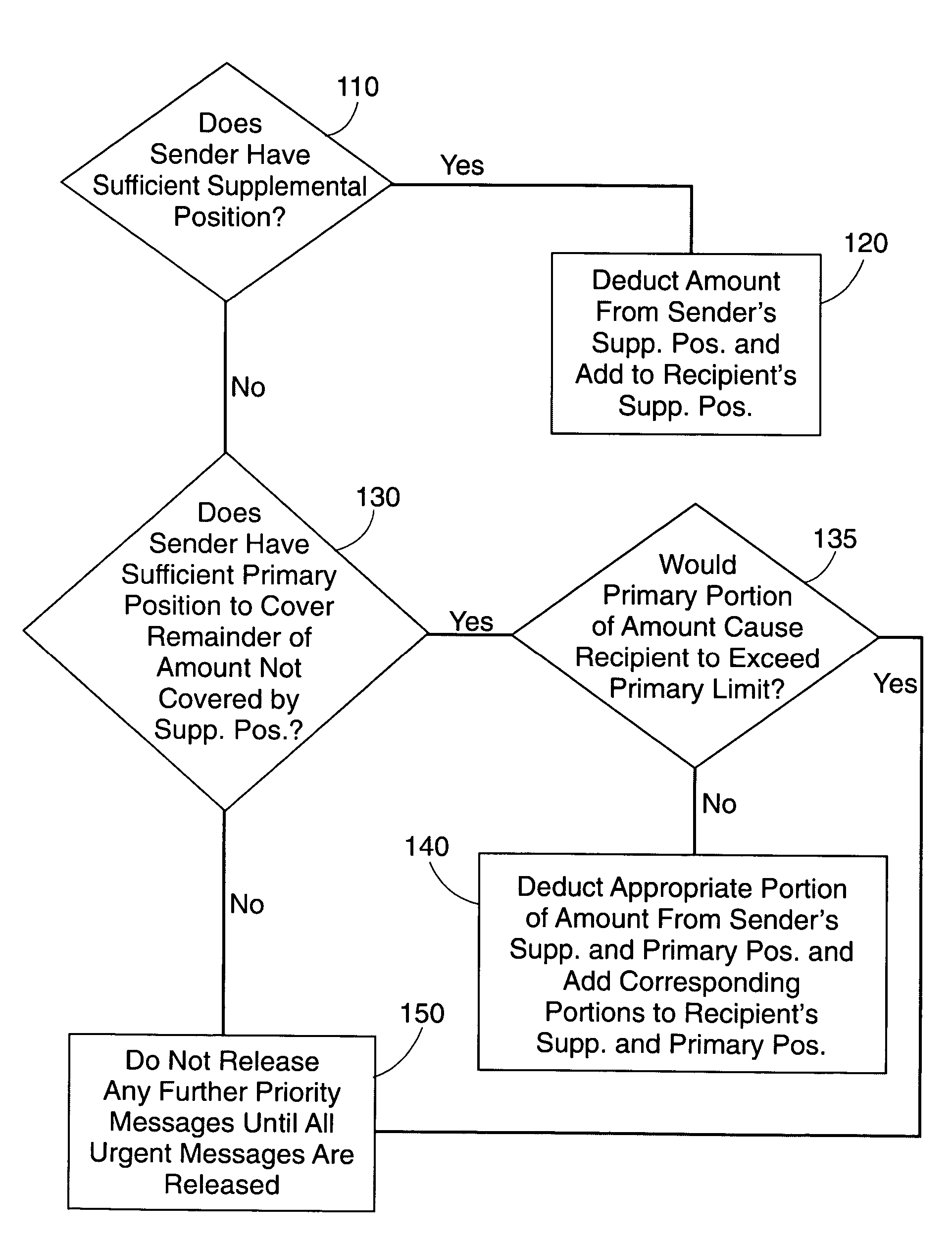

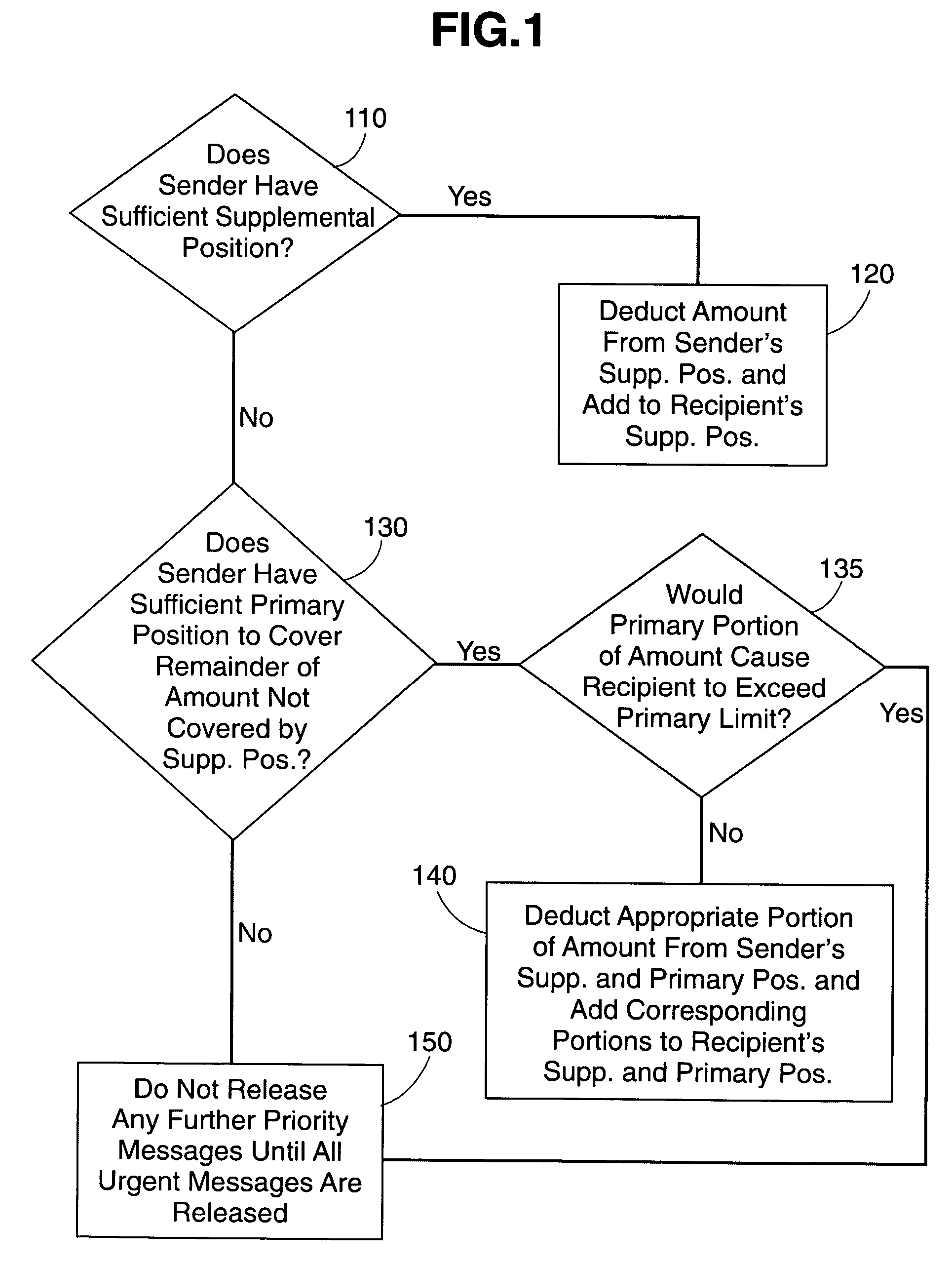

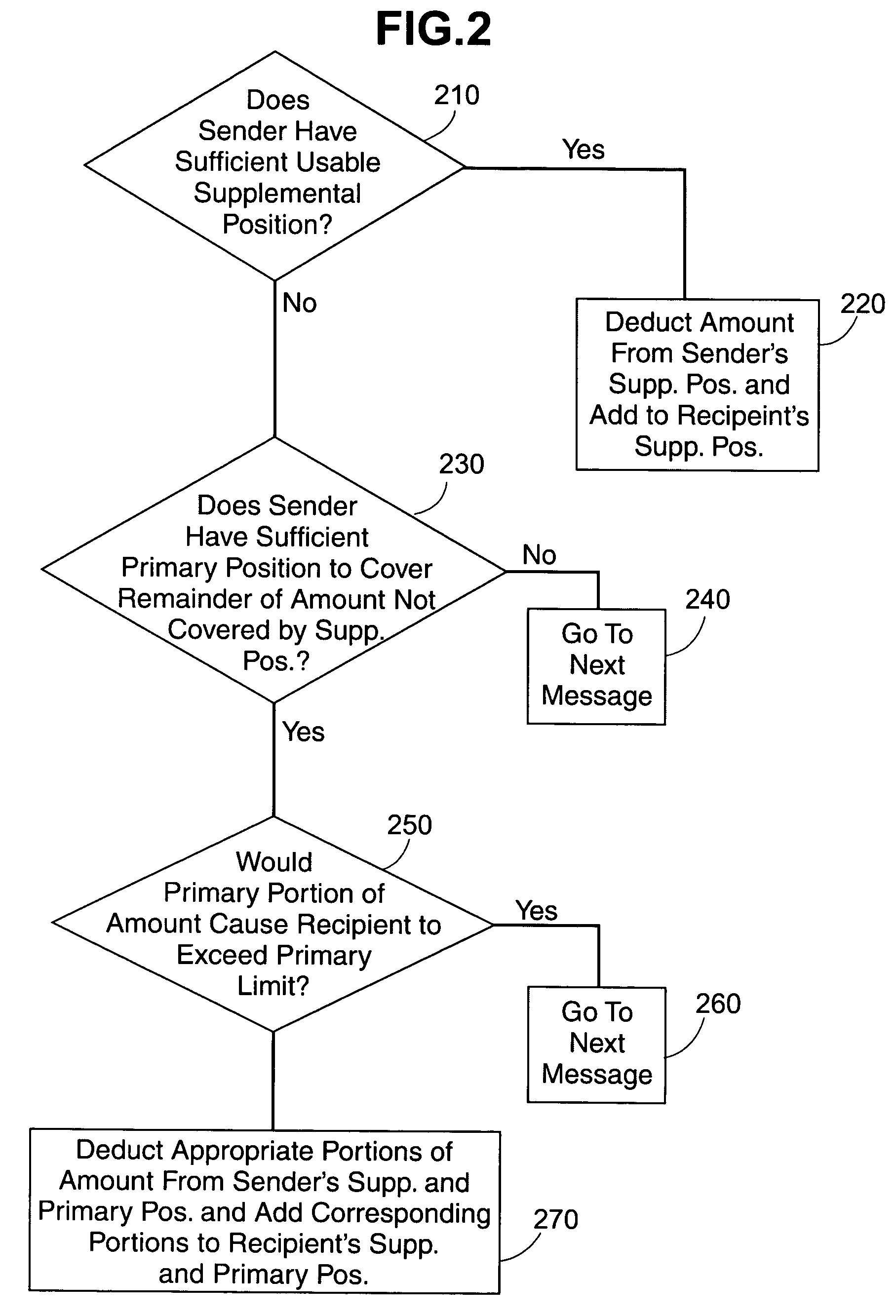

System and method for intraday netting payment finality with supplemental funding

A system and method are disclosed for continuous intraday final settlement of payment orders among a plurality of participants, each participant having facilities configured to electronically send and receive the payment orders in the form of payment messages. Primary positions, corresponding to balances in a prefunded balance account, are stored. Supplemental positions, corresponding to balances in the prefunded balance account, are stored. Payment messages are received from sending participants. A selected payment message is released, such that the sending participant's supplemental position is decreased by the payment amount and the receiving participant's supplemental position is increased by the payment amount, if it is determined that: (i) the sending participant's supplemental position, after subtraction of the payment amount, is greater than or equal to the predetermined minimum for the sending participant's supplemental position, and (ii) the receiving participant's supplemental position, after addition of the payment amount, is less than or equal to the predetermined maximum for the receiving participant's supplemental position.

Owner:THE CLEARING HOUSE PAYMENTS

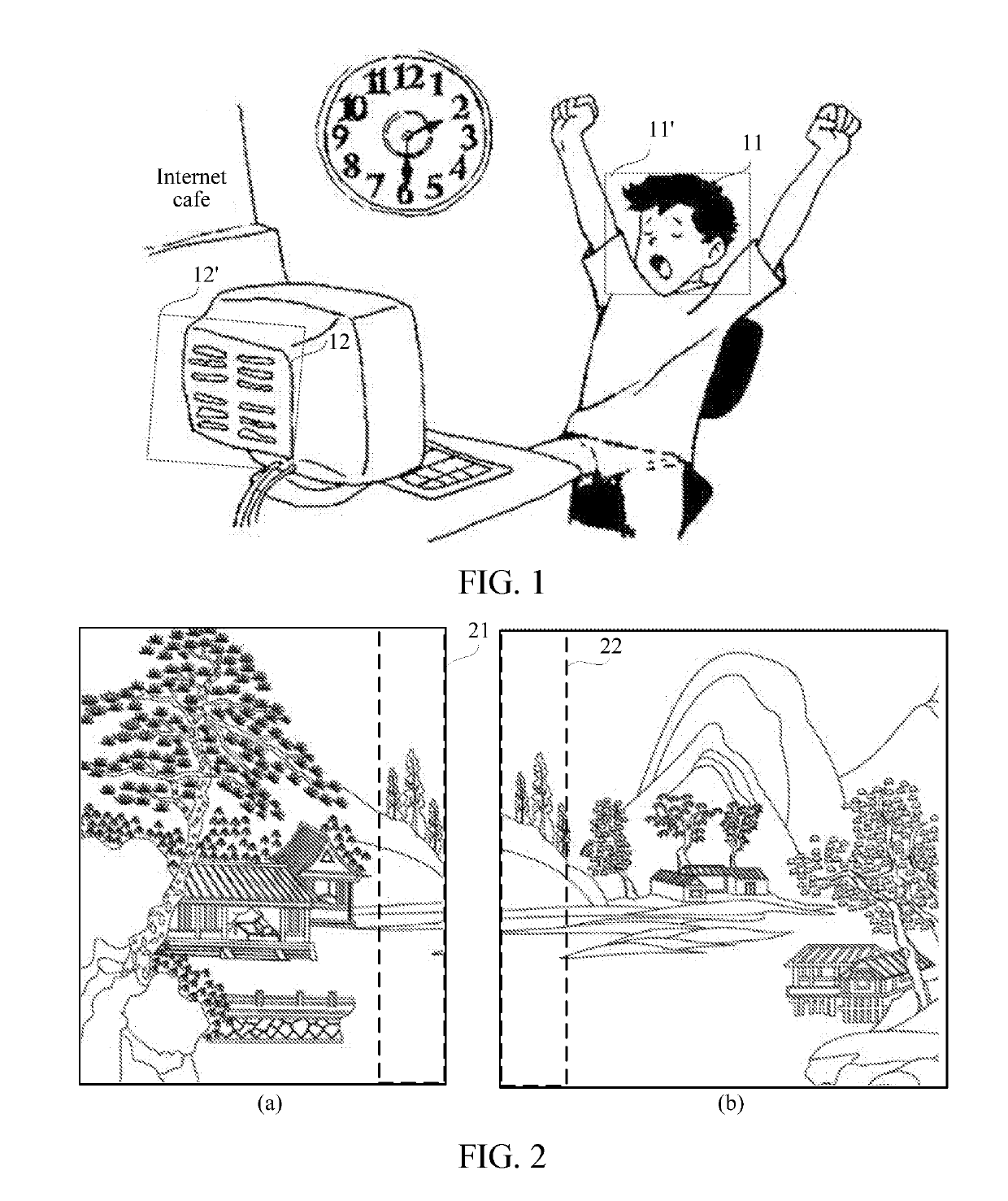

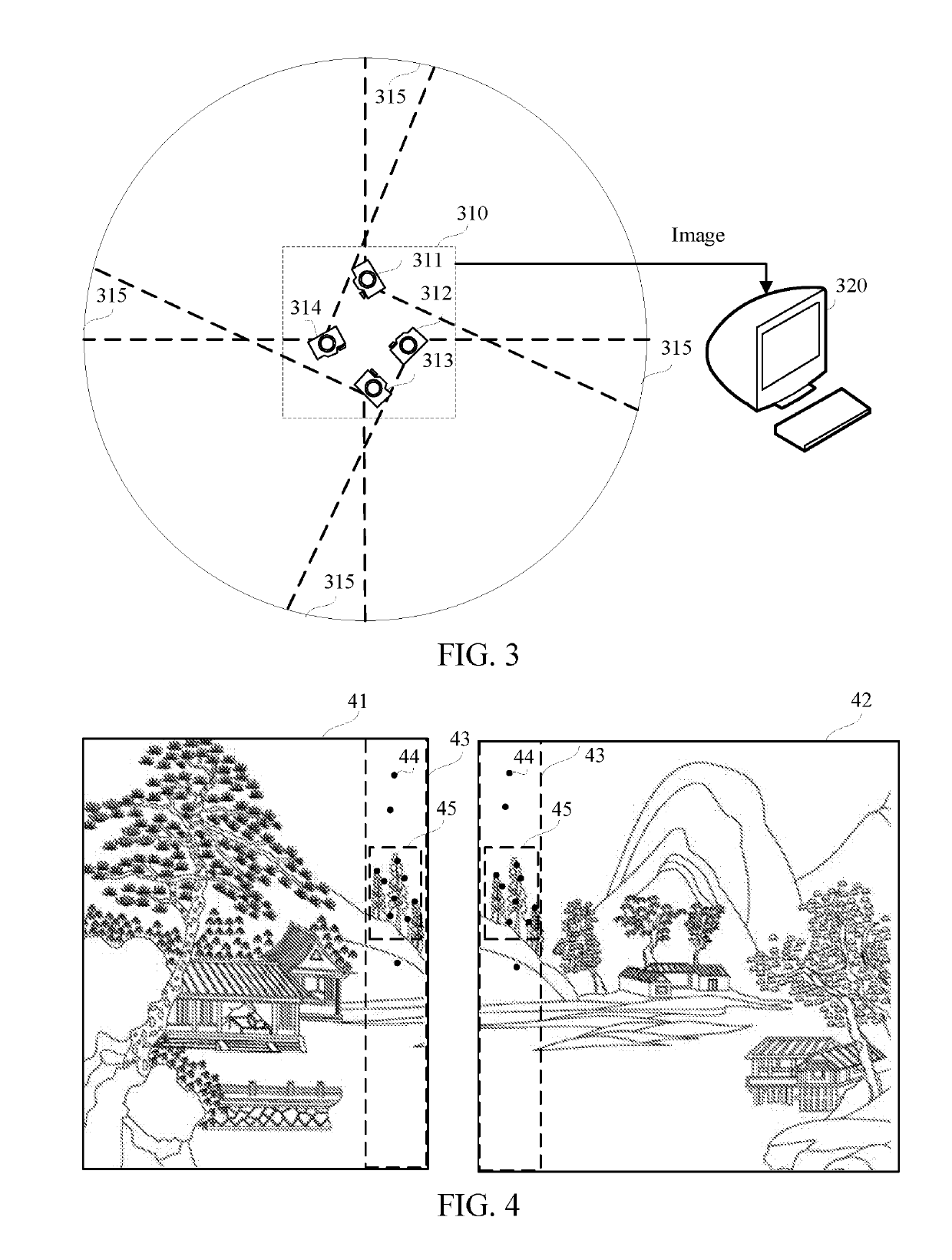

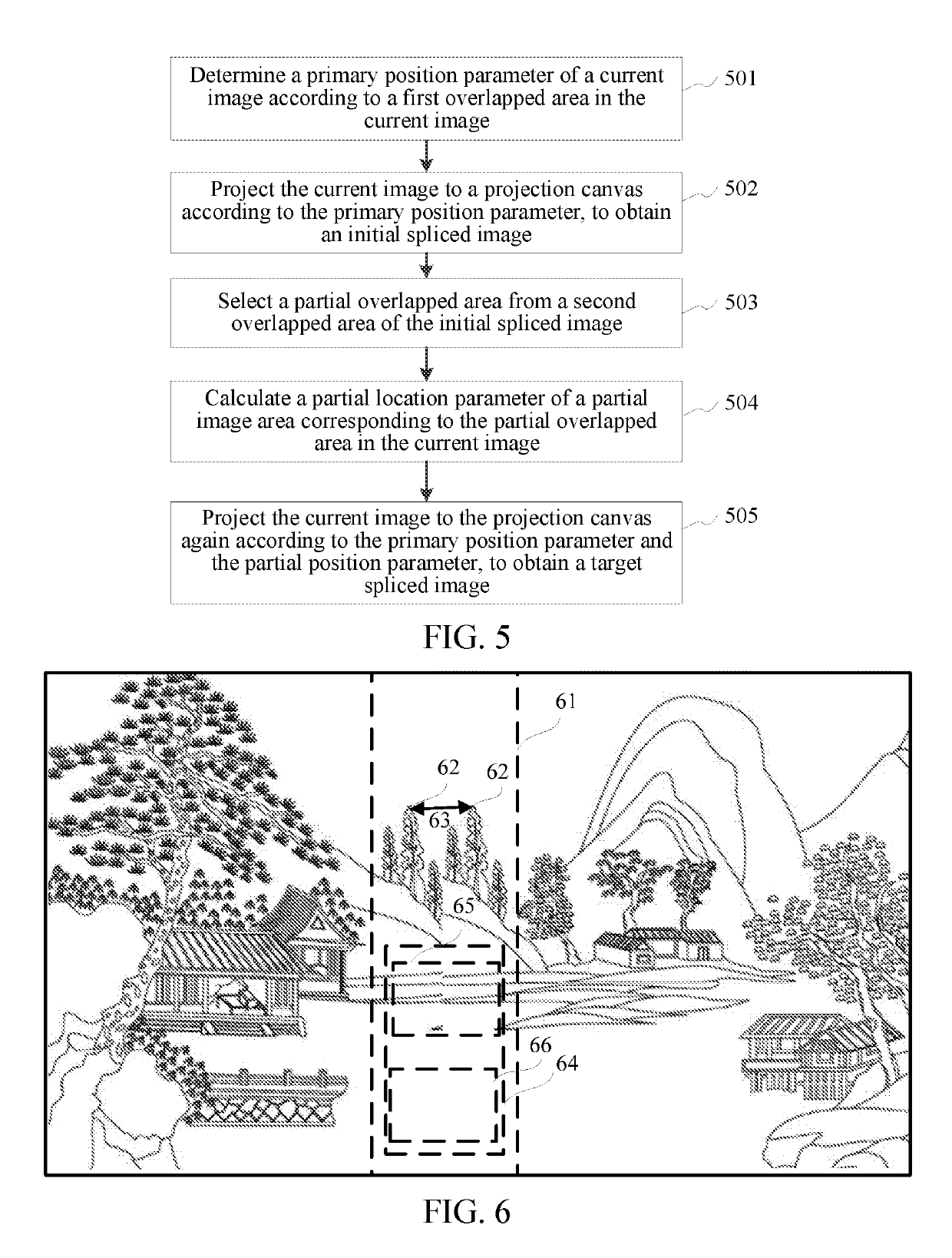

Image splicing method, apparatus, terminal, and storage medium

ActiveUS20190251663A1Good splicing effectImage analysisGeometric image transformationComputer terminalComputer vision

Embodiments of this application disclose an image splicing method and apparatus, a terminal, and a storage medium thereof. The image splicing method includes determining a primary position parameter of a current image according to a first overlapped region in the current image; and projecting the current image to a projection canvas according to the primary position parameter to obtain an initial spliced image, the initial spliced image being obtained by splicing the current image and the neighboring image. The method further includes selecting a partially overlapped region from a second overlapped region of the initial spliced image; calculating a partial position parameter of a partial image region corresponding to the partially overlapped region in the current image; and projecting the current image to the projection canvas again according to the primary position parameter and the partial position parameter, to obtain a target spliced image.

Owner:TENCENT TECH (SHENZHEN) CO LTD

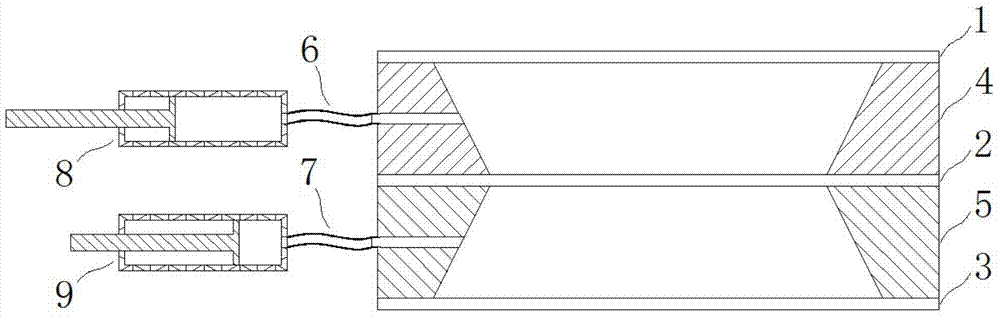

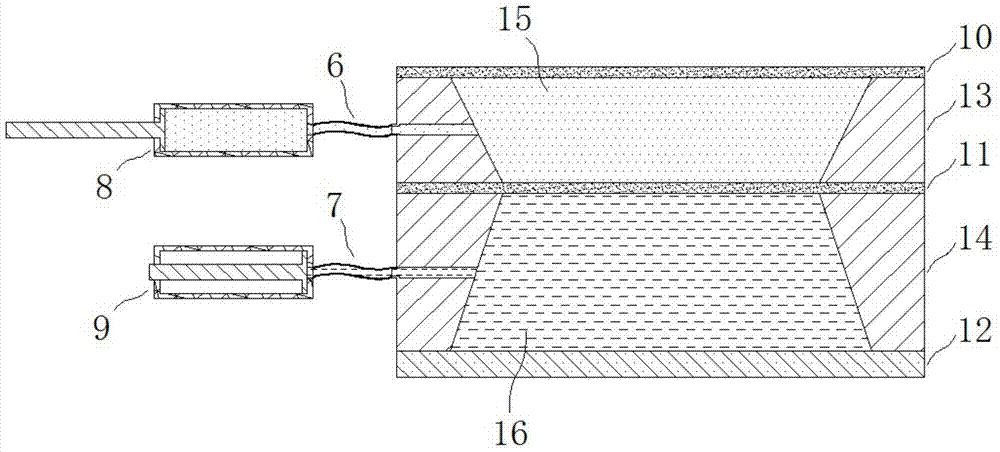

Human-eye-crystalline-lens adjustment imitating liquid zoom lens and aberration correction method of human-eye-crystalline-lens adjustment imitating liquid zoom lens

The invention discloses a human-eye-crystalline-lens adjustment imitating liquid zoom lens and an aberration correction method of the human-eye-crystalline-lens adjustment imitating liquid zoom lens. A first circular ring is installed between a first round transparent film and a second round transparent film to form a plus lens containing cavity, a second circular ring is installed between the second round transparent film and a third round transparent film to form a minus lens containing cavity, a rodless cavity of a first plunger device is communicated with the plus lens containing cavity through a first hose, a rodless cavity of a second plunger device is communicated with the minus lens containing cavity through a second hose, and the two containing cavities are both filled with transparent liquid to form a plus lens and a minus lens. According to the human-eye-crystalline-lens adjustment imitating liquid zoom lens, continuous zooming within a design-required zoom range can be achieved, primary position chromatic aberration, primary spherical aberration and primary sinusoidal aberration can be further corrected at the same time, and therefore imaging is complete. The human-eye-crystalline-lens adjustment imitating liquid zoom lens is simple in structure, small in size, light in weight, stable in optical axis, continuous in zooming, high in response speed and accuracy, convenient to operate, easy to manufacture, low in cost and capable of being widely applied to various modern imaging systems.

Owner:ZHEJIANG UNIV

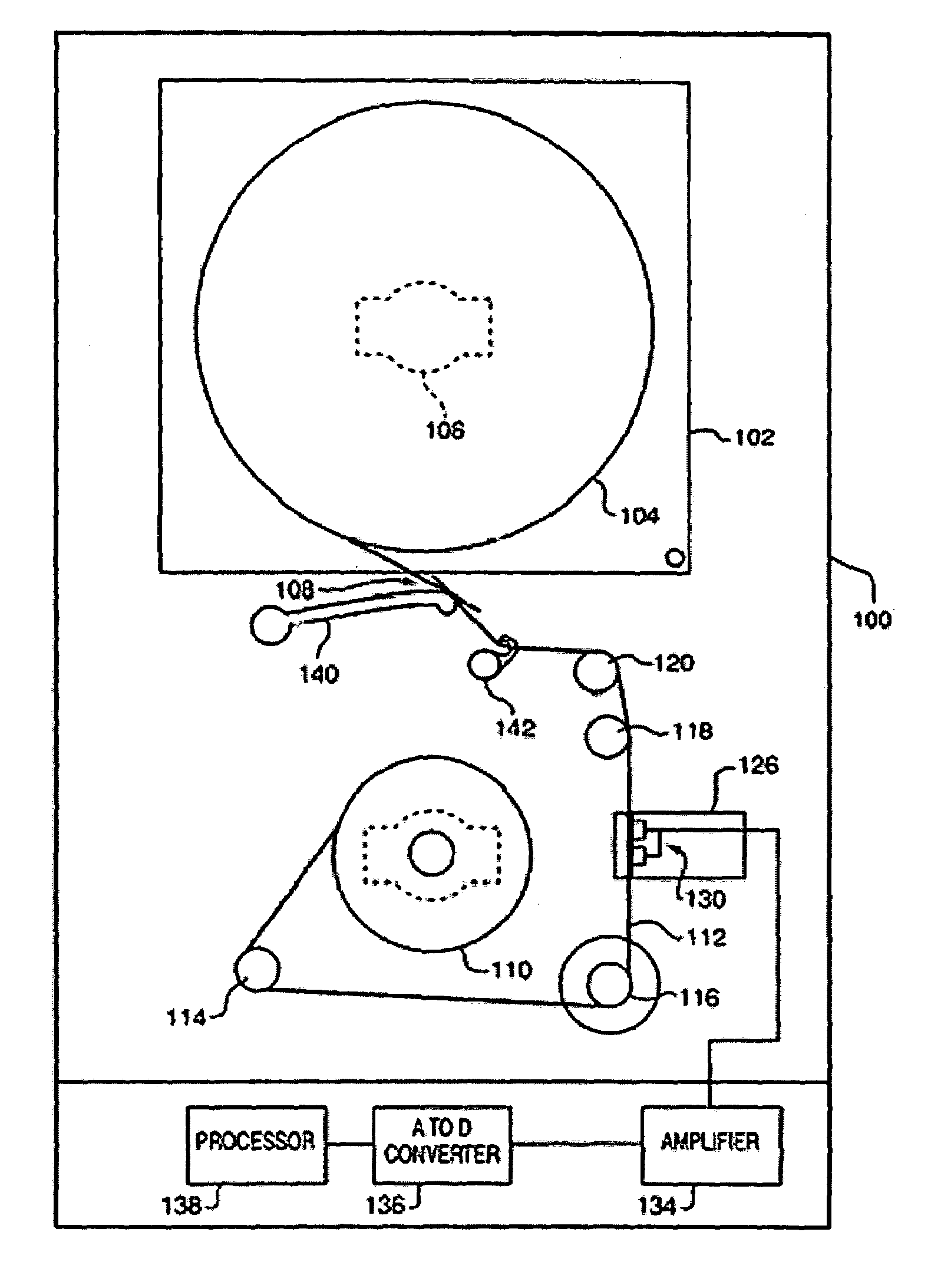

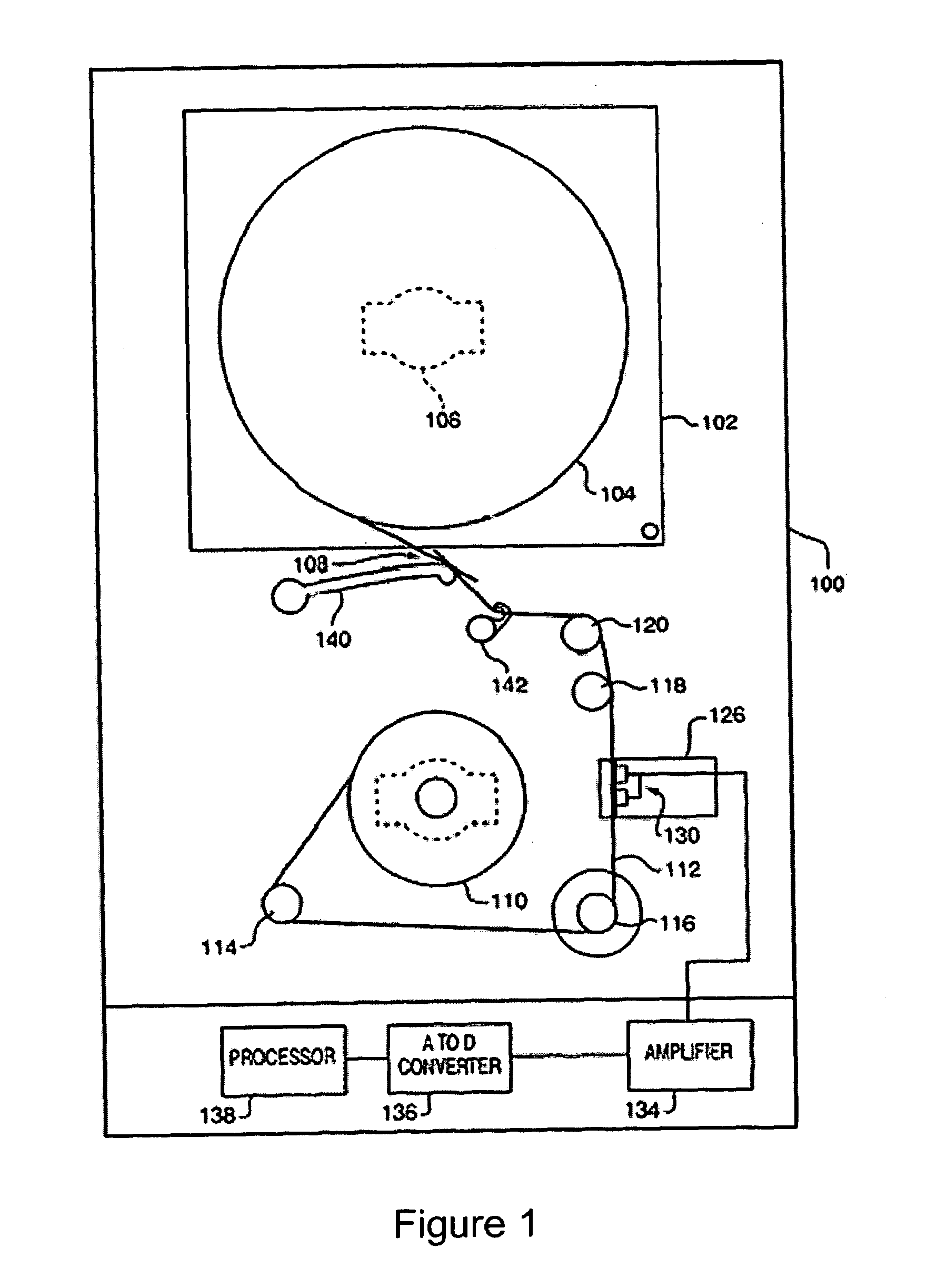

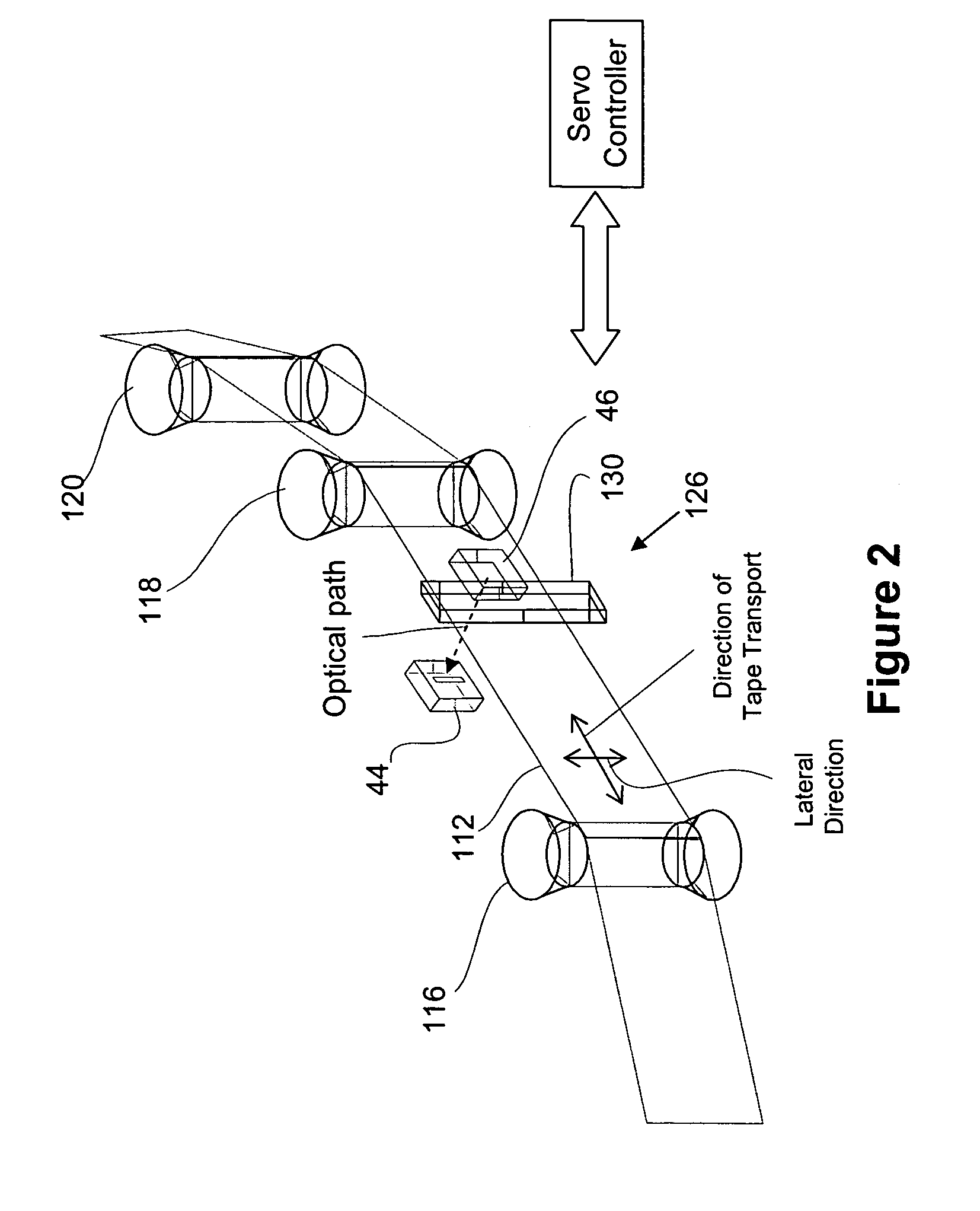

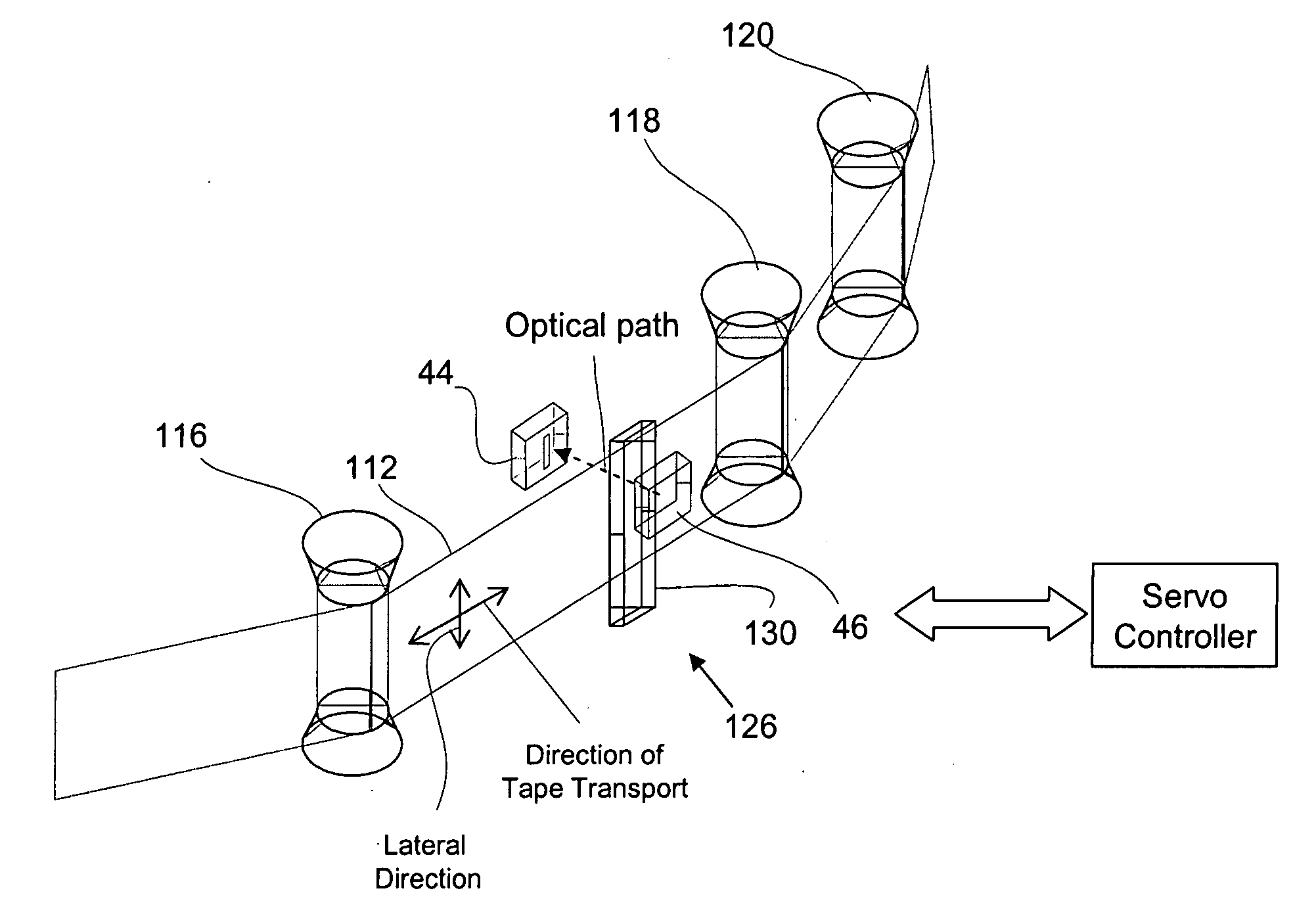

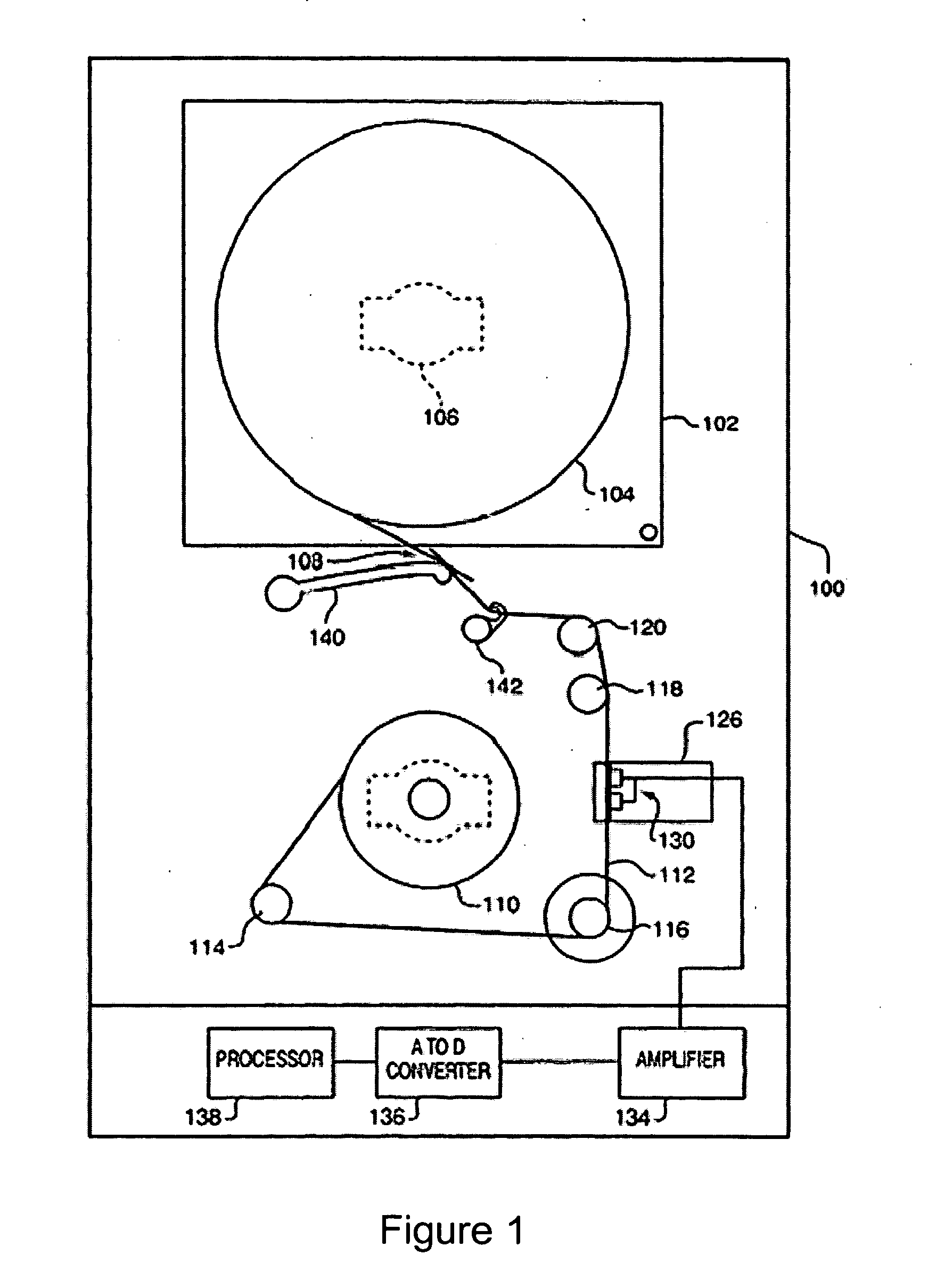

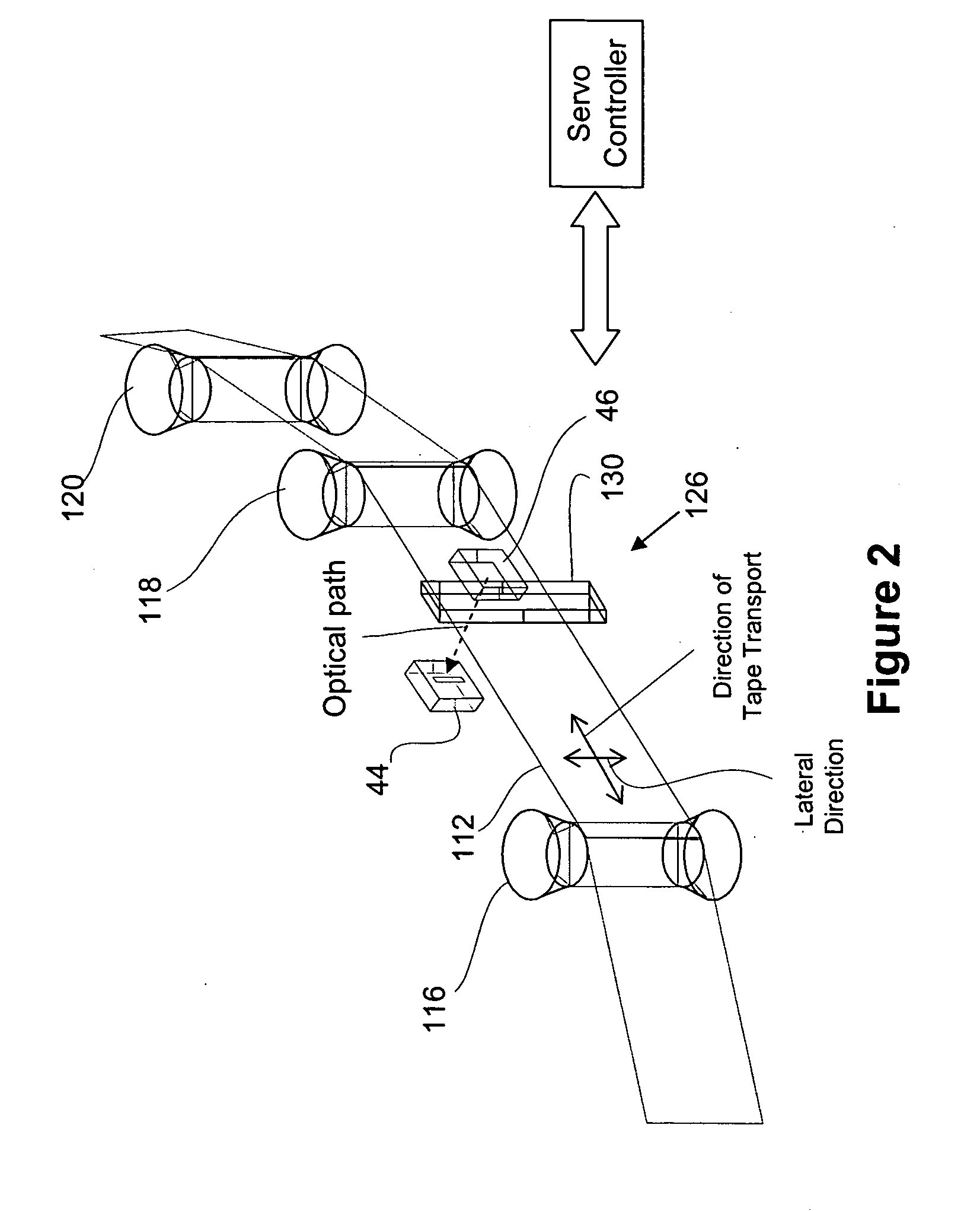

Dual source tracking servo systems and associated methods

InactiveUS7184233B2Alignment for track following on tapesRecord information storageMagnetic storageTransducer

In one example, a dual source tracking servo system includes a head assembly having a data transducer, a primary position detector for sensing the position of a magnetically stored data track, and a secondary position detector for sensing the position of a fixed reference associated with a magnetic storage medium. A controller is configured for adjusting the position of the head assembly in response to a weighted average of the sensed position of the magnetically stored data track and the fixed reference, wherein the position of the magnetically stored data track is weighted more than the position of the fixed reference. The primary position detector may include one or more dedicated servo read elements associated with the head assembly and the secondary position detector may include a magnetic or optical sensor. The fixed reference may include a tape edge or servo track.

Owner:QUANTUM CORP

Dual source tracking servo systems and associated methods

InactiveUS20050270687A1Alignment for track following on tapesRecord information storageMagnetic storageMagnetic tape

In one example, a dual source tracking servo system includes a head assembly having a data transducer, a primary position detector for sensing the position of a magnetically stored data track, and a secondary position detector for sensing the position of a fixed reference associated with a magnetic storage medium. A controller is configured for adjusting the position of the head assembly in response to a weighted average of the sensed position of the magnetically stored data track and the fixed reference, wherein the position of the magnetically stored data track is weighted more than the position of the fixed reference. The primary position detector may include one or more dedicated servo read elements associated with the head assembly and the secondary position detector may include a magnetic or optical sensor. The fixed reference may include a tape edge or servo track.

Owner:QUANTUM CORP

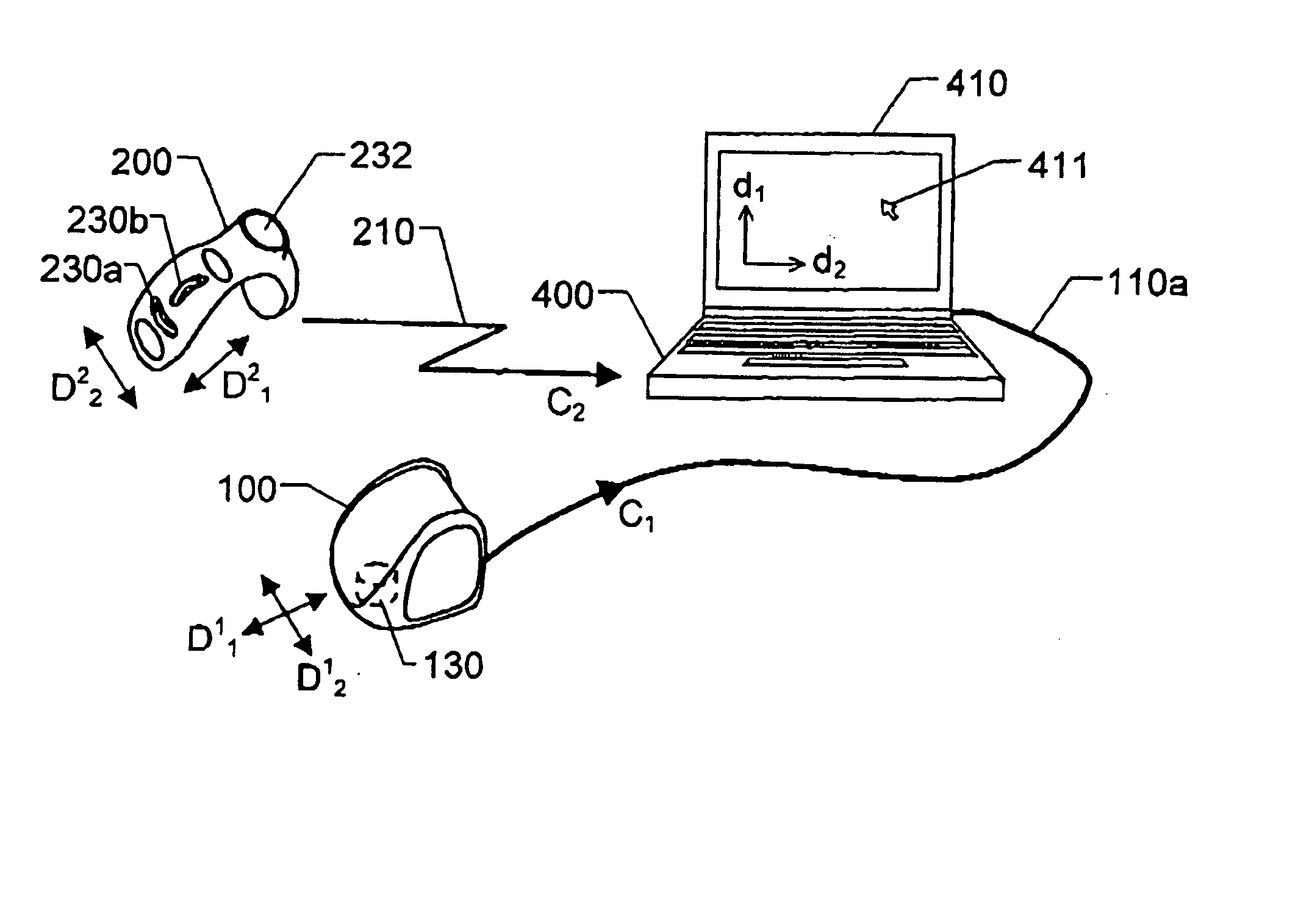

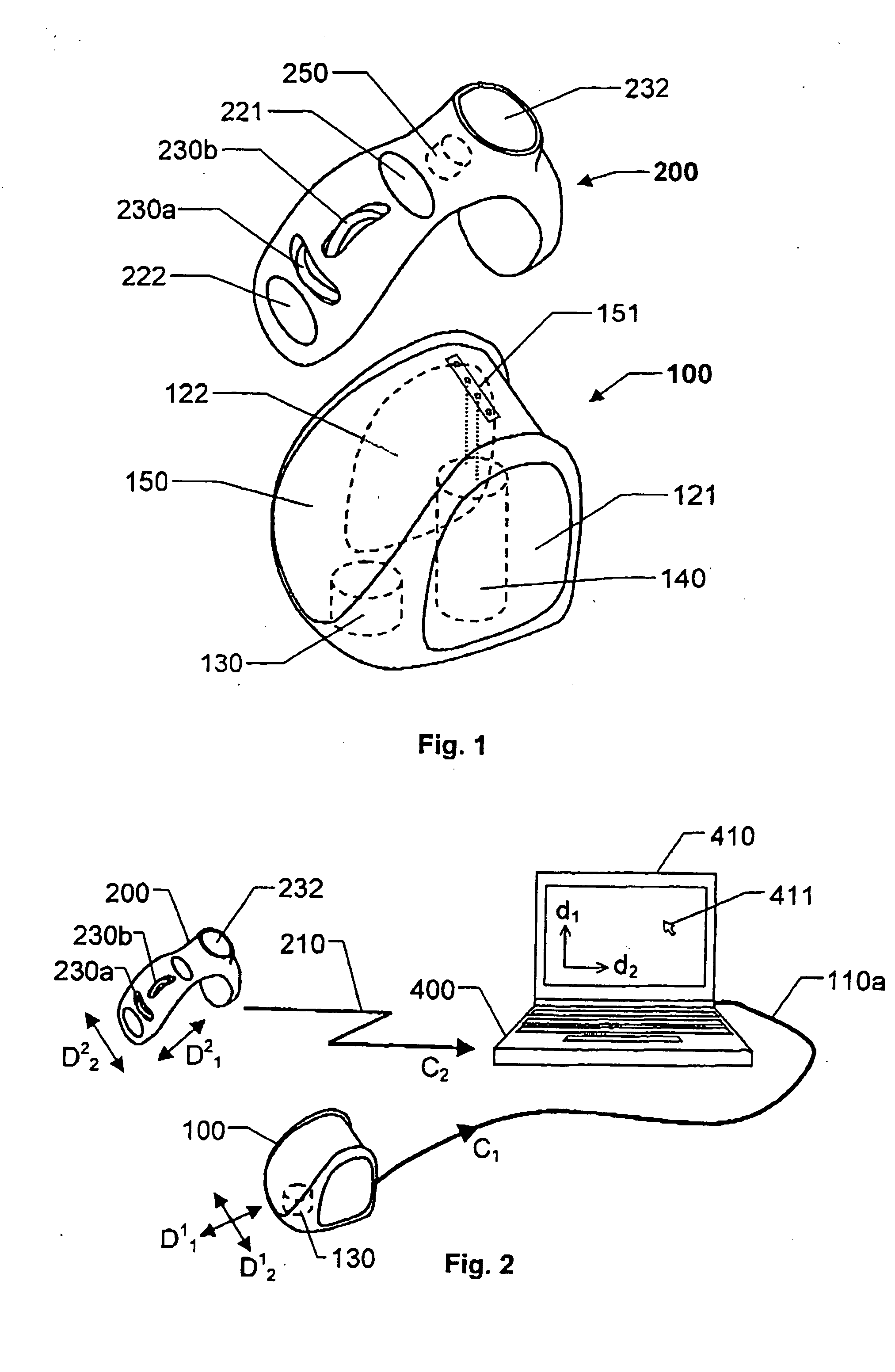

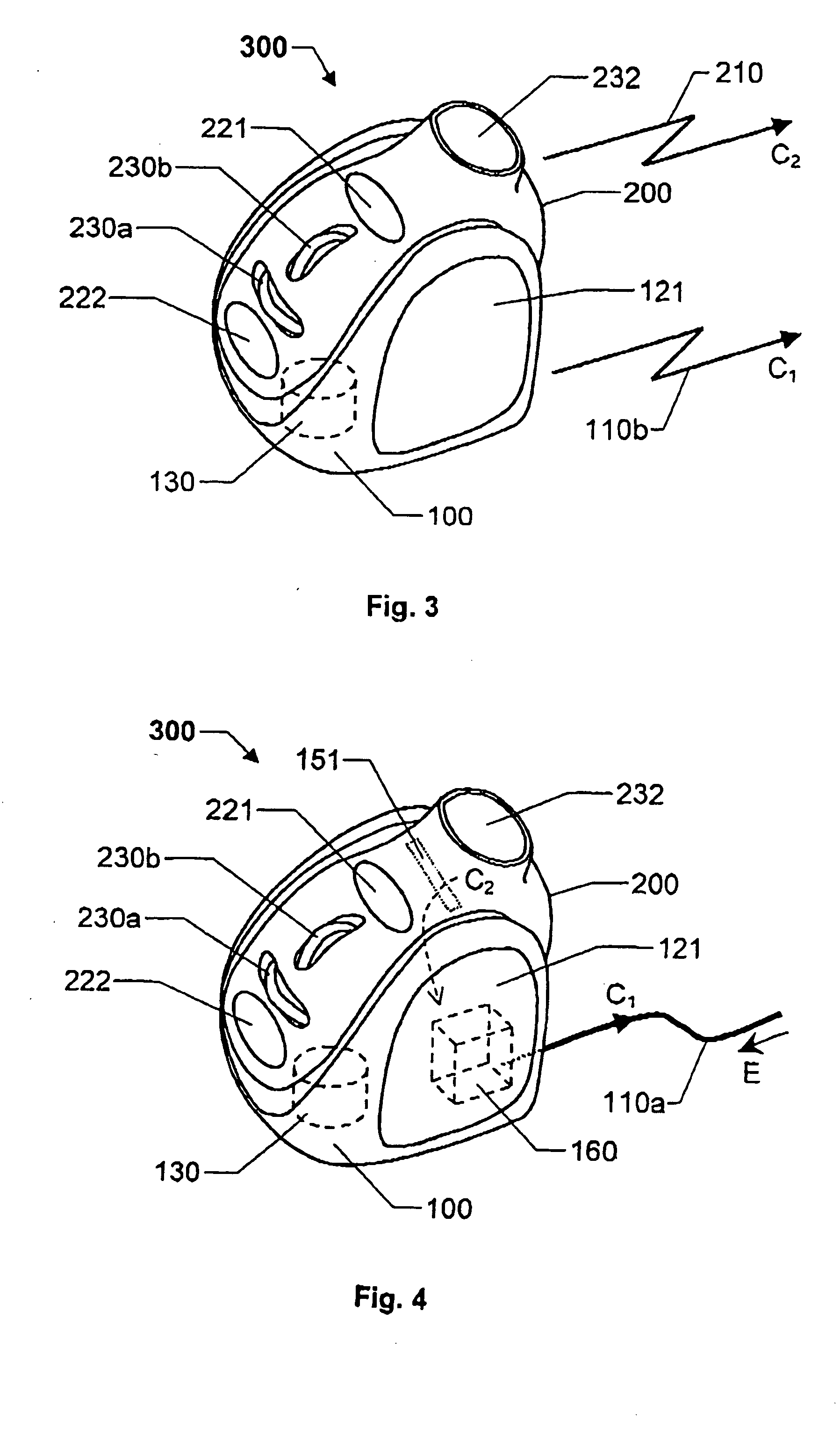

Pointing device

InactiveUS20050052416A1Reduce decreaseCathode-ray tube indicatorsInput/output processes for data processingUser inputInput control

A primary pointing device controls the position of a cursor on a digital screen by means of primary position commands (C1). The primary position commands (C1) are generated by relative movement (D11; D12) between the primary pointing device and a substantially flat external surface, such as a tabletop or mouse pad. The primary pointing device is adapted to dock with a secondary pointing device, which may also control the position of the cursor on the digital screen. Bearing registering user input controls in the secondary pointing device generate secondary position commands (C2), which are fed to the digital processor for causing the cursor to move on the digital screen. Furthermore, the primary pointing device is adapted to dock with the secondary pointing device.

Owner:DIGITYPER

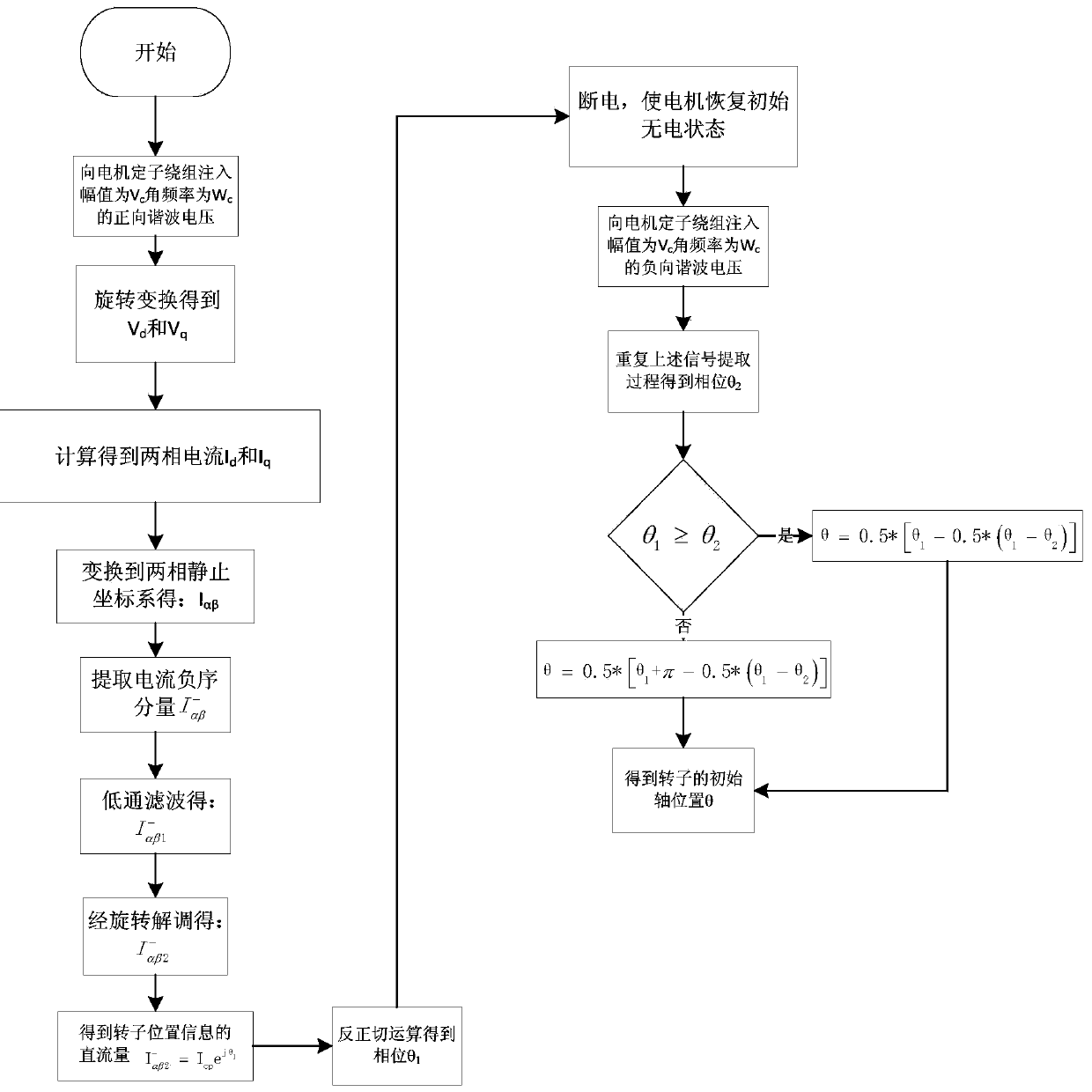

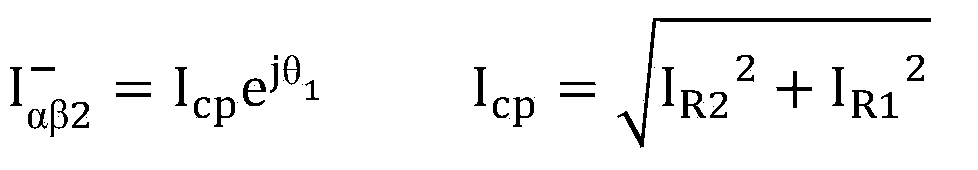

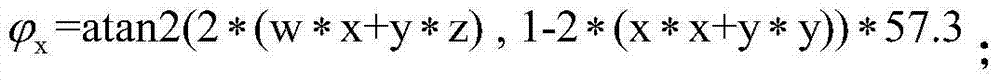

Positive and negative sequence harmonic injection-based motor rotor primary position estimation method

ActiveCN103701395AAccurate estimateAccurate measurementElectronic commutation motor controlVector control systemsTime delaysEstimation methods

The invention discloses a positive and negative sequence harmonic injection-based motor rotor primary position estimation method. The method improves the estimation angel error generated when a traditional rotary high-frequency injection method is used for estimating a d axis position. A stator resistor and a nonlinear feature of an inverter dead zone are comprised, and influences of line time delay and filter delay on the rotor primary position are analyzed, so the primary d axis position of a rotor can be more accurately, faster and more stably estimated; the polarity of magnetic pole of a permanent magnet is distinguished by a magnetic saturation effect on the d axis through estimation, and finally the accurate rotor primary angle is obtained. The positive and negative sequence harmonic injection-based motor primary position estimation method is easy to realize, has very strong antijamming capacity, and can more accurately, faster and more stably measure the primary position of the rotor.

Owner:杭州兆鼎科技实业有限公司

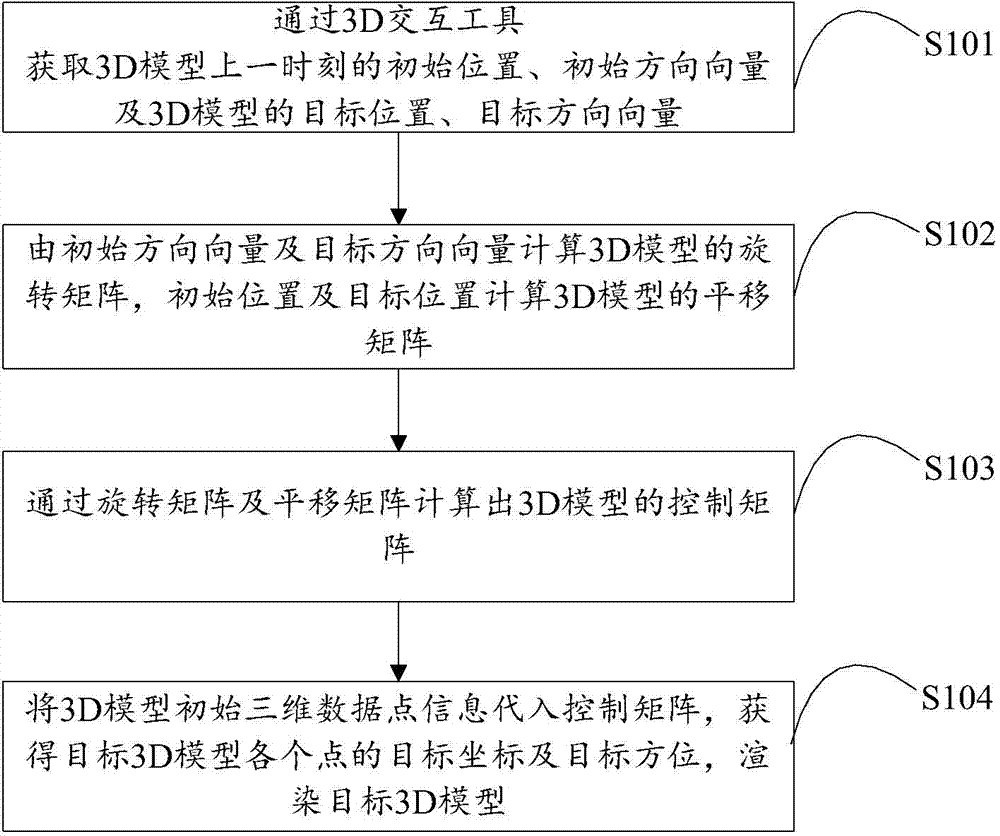

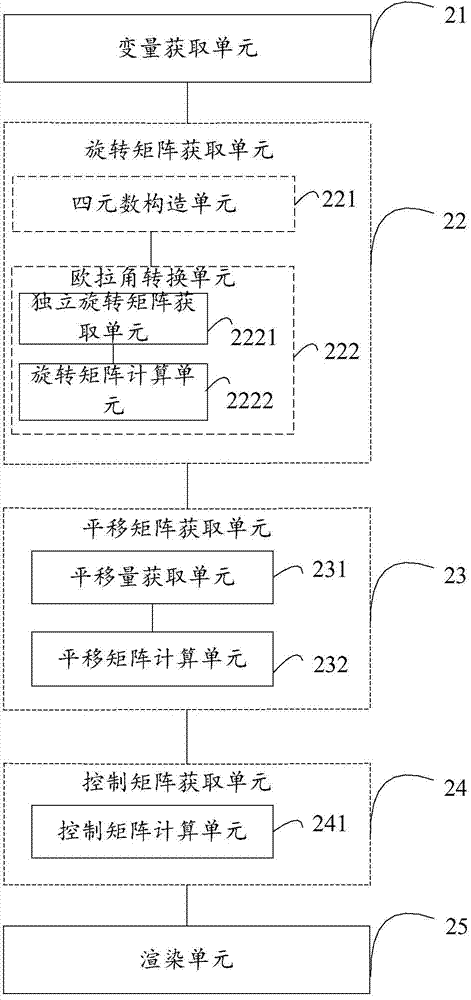

Method and device of rendering 3D (three dimensional) model in any orientation

InactiveCN103810746AGood conditionImprove the speed of determining the orientation of 3D models in real time3D-image renderingImaging processingComputer graphics (images)

The invention is applicable to the field of image processing, and provides with a method and a device of rendering a 3D (three dimensional) model in any orientation. The method comprises the steps of obtaining the primary position and the primary direction vector of the last moment of the 3D model and the target position and the target direction vector of the 3D model through a 3D interactive tool; calculating the rotary matrix of the 3D matrix through the primary direction vector and the target direction vector, and calculating the translation matrix of the 3D model through the primary position and the target position; calculating the control matrix of the 3D model through the rotary matrix and the translation matrix; substituting the primary 3D data point information of the 3D model into the control matrix to obtain the target coordinates and target directions of all points of the 3D model, and rendering the target 3D model. Any 3D model which accords with a control requirement can be rendered, so that the method is applicable to the real-time rendering of any 3D model, the speed of determining the position of the 3D model can be improved in real time, and the state of controlling the 3D model can be effectively improved.

Owner:TCL CORPORATION

System and method for automatically judging subvolume surface quality grade

ActiveCN102628812ARealize online monitoringThe detection process is fastOptically investigating flaws/contaminationLocation detectionStatistical analysis

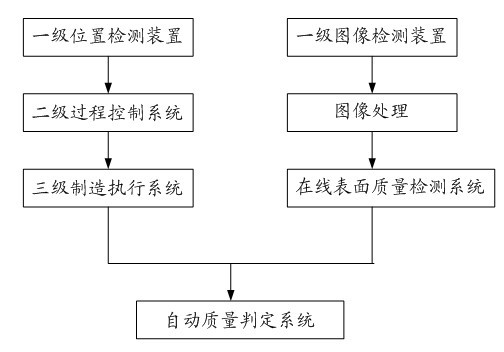

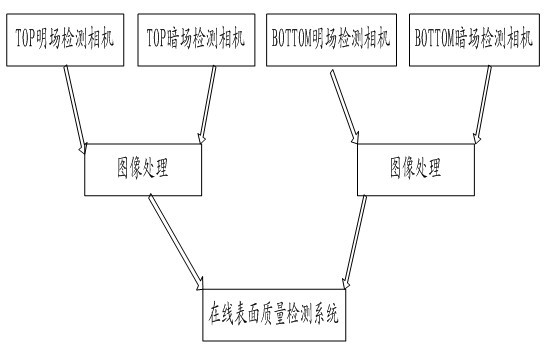

The invention discloses a system and a method for automatically judging subvolume surface quality grade. The system comprises a primary position detection device, a secondary process control system, a tertiary manufacturing execution system, a primary image detection device, an on-line surface quality detection system and an automatic quality judgment system, wherein the primary position detection device is connected with the secondary process control system through a data interface; the secondary process control system is connected with the tertiary manufacturing execution system through a data interface; the primary image detection device is connected with the on-line surface quality detection system through a data interface; and the automatic quality judgment system is connected with the tertiary manufacturing execution system and the on-line surface quality detection system respectively through data interfaces. The system can automatically monitor the surface quality of the finished product steel coil, has high detection speed and high accuracy, can accurately judge the quality of each subvolume of the primary volume, and can also perform statistical analysis on the whole quality of the subvolume.

Owner:SHOUGANG CORPORATION

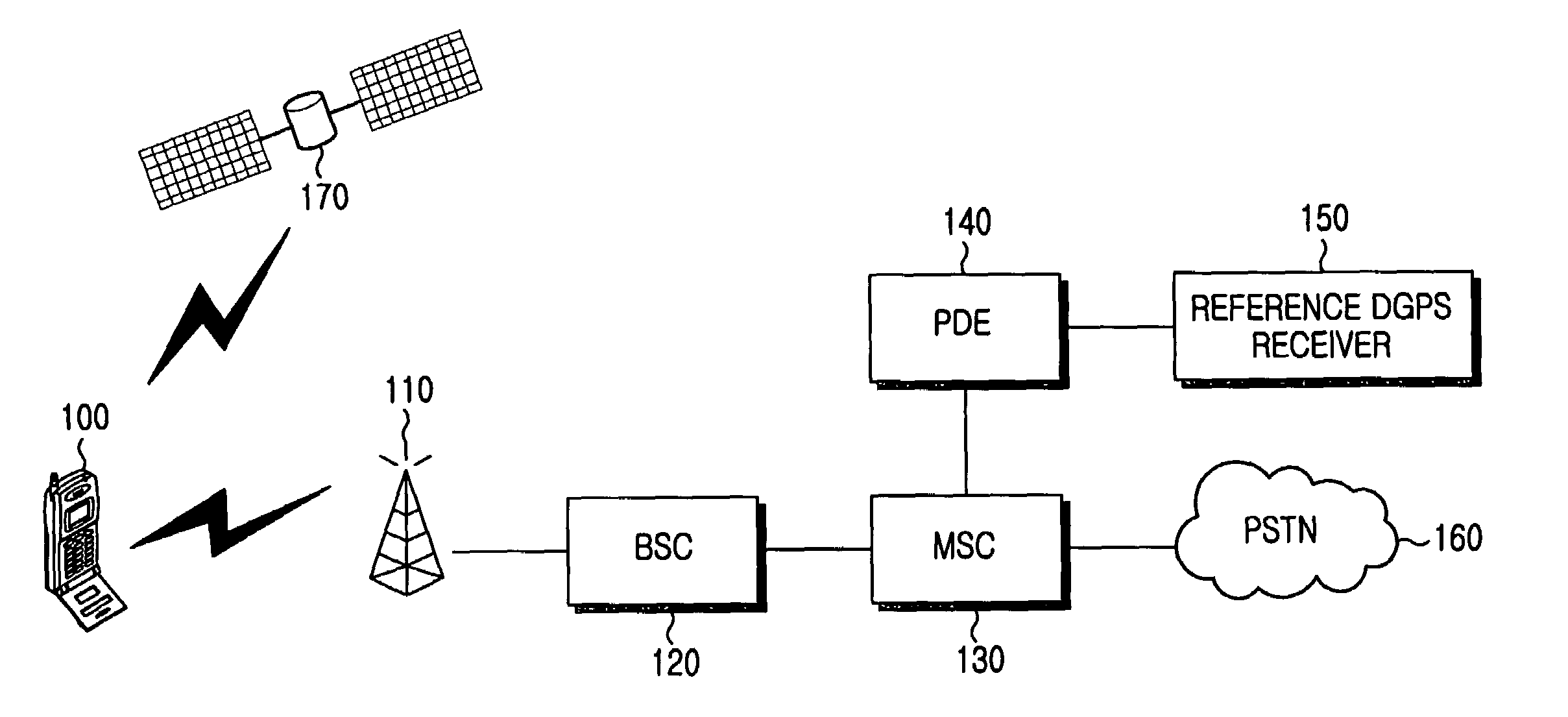

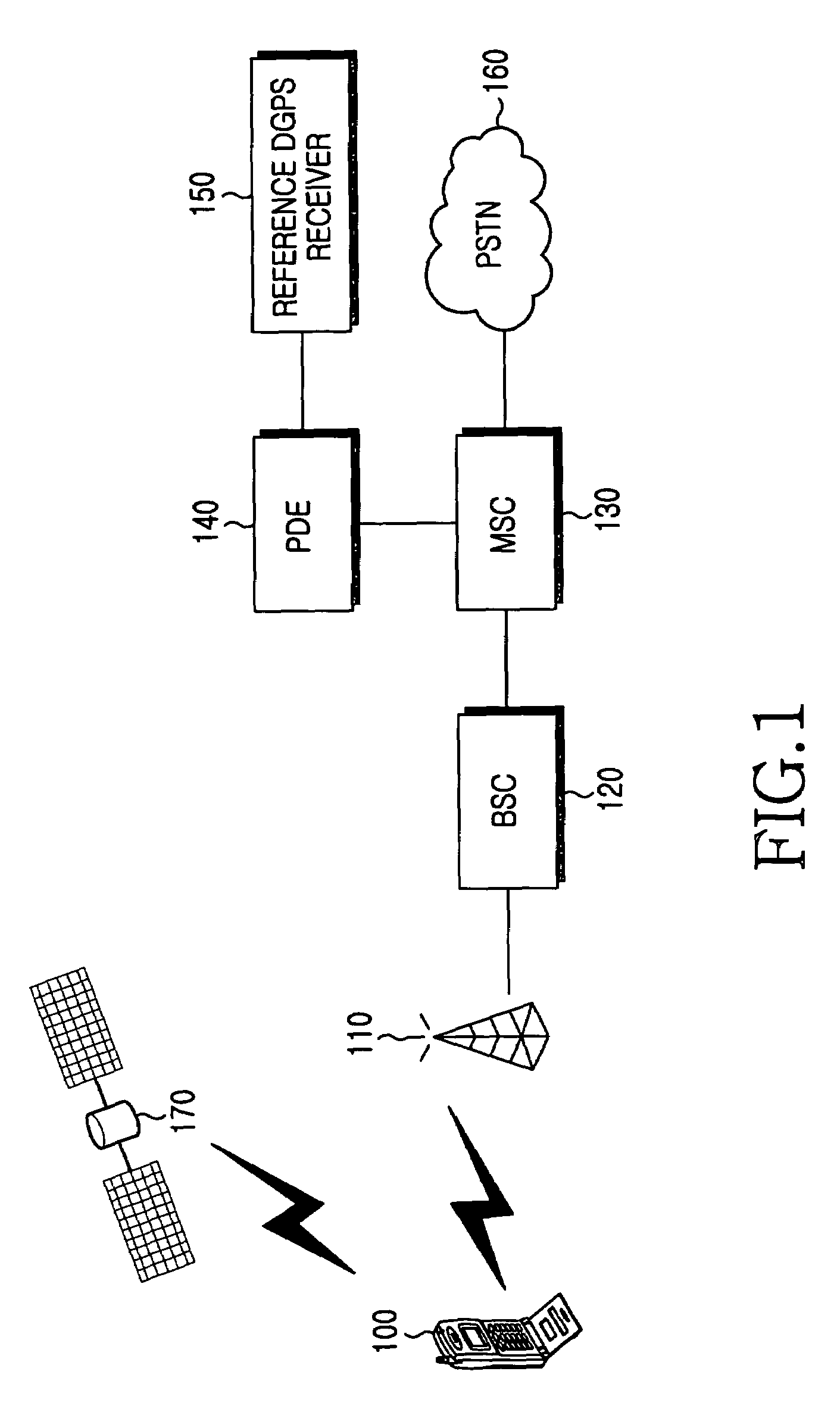

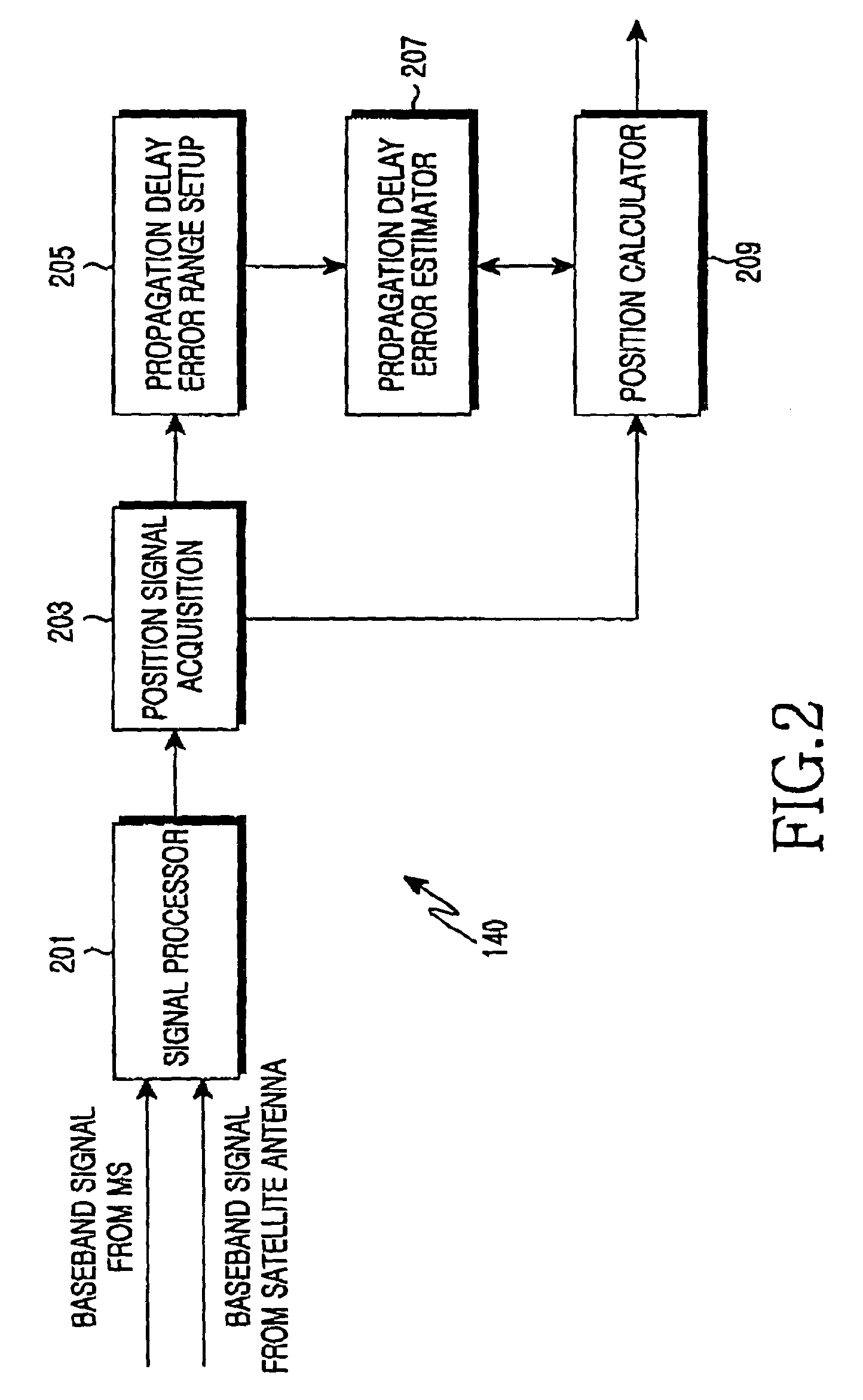

Apparatus and method for determining position information of a mobile station

InactiveUS7203501B2Reduce positioning errorsBeacon systems using radio wavesPosition fixationPropagation delayMobile communication systems

An apparatus and method for determining position information of a mobile station (MS). The apparatus directly estimates a propagation delay error by measuring a signal strength of a propagation signal for use in a mobile communication system, and reduces a MS position error. The apparatus reduces the MS position error by either combining the propagation signal for the mobile communication system with a GPS signal or using only the propagation signal. The apparatus receives Mobile Station (MS) position acquisition signals from the mobile communication system in order to estimate position information of the MS. The position signal acquisition unit receives the MS position acquisition signals, acquires a position signal from the received MS position acquisition signal, and outputs an acquired position signal. The primary position calculator calculates a primary position using the acquired position signal received from the position signal acquisition unit. The propagation delay error range setup unit determines a propagation delay error range using the acquired position signal. The propagation delay error estimator estimates a propagation delay error using the determined propagation delay error range and the primary position. The position calculator calculates a secondary position using the propagation delay error estimation value received and the calculated primary position.

Owner:SAMSUNG ELECTRONICS CO LTD

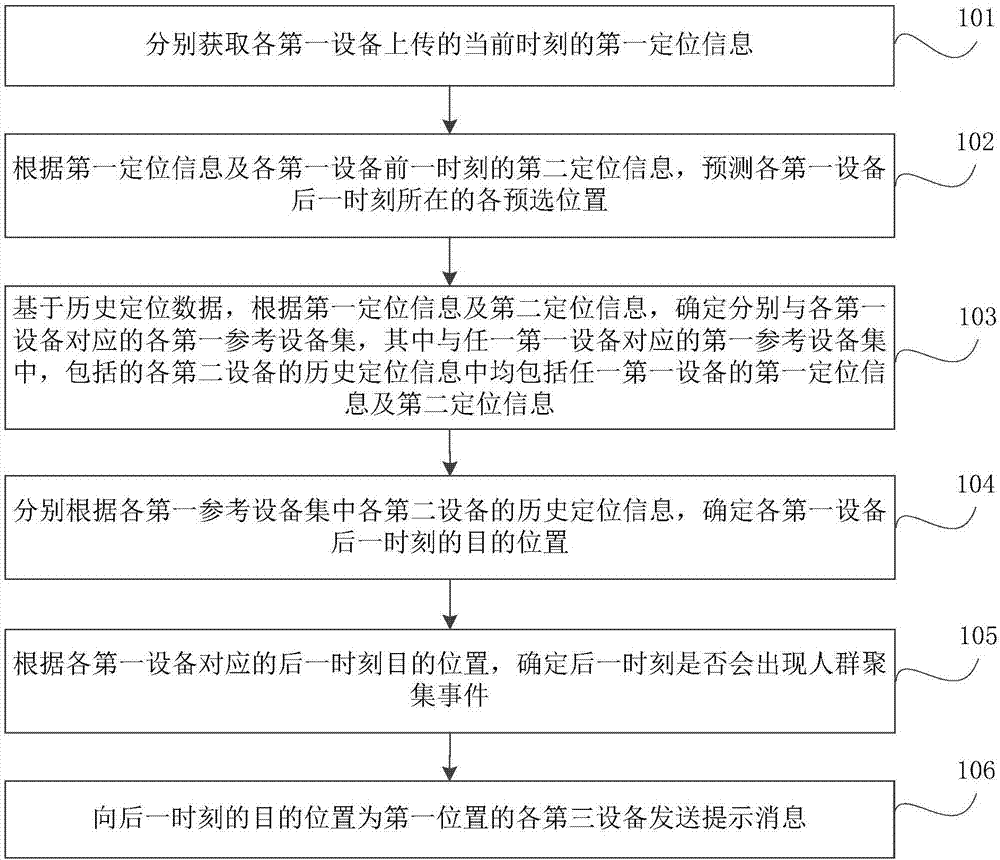

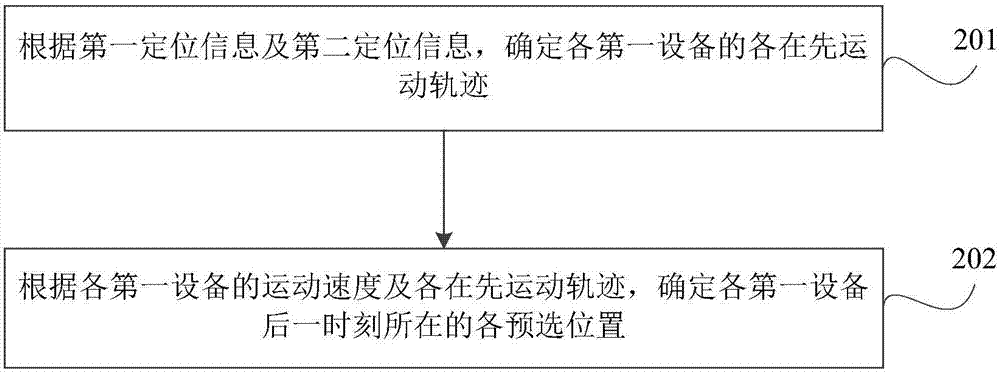

Gathering event prediction method and device and apparatus

The invention discloses a gathering event prediction method and device and an apparatus. The method comprises the following steps of: respectively first positioning information, at the current moment,uploading by each first apparatus; predicting a primary position, at the next moment, of each apparatus according to the first positioning information and second positioning information, at the lastmoment, of each first apparatus; determining a first reference apparatus set corresponding to each first apparatus according to the first positioning information and the second positioning informationon the basis of history positioning data; determining a target position, at the next moment, of each apparatus according to history positioning information of each second apparatus in each first reference apparatus set; and determining whether a crowd gathering event occurs at the next moment or not according to the target position, at the next moment, of each first apparatus. The method is capable of correctly predicting gathering events via relatively low cost, so that conditions are provided for solving the potential safety hazards caused by crowd gathering events.

Owner:NEUSOFT CORP

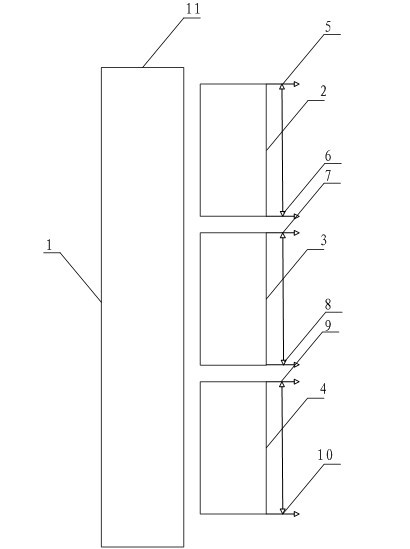

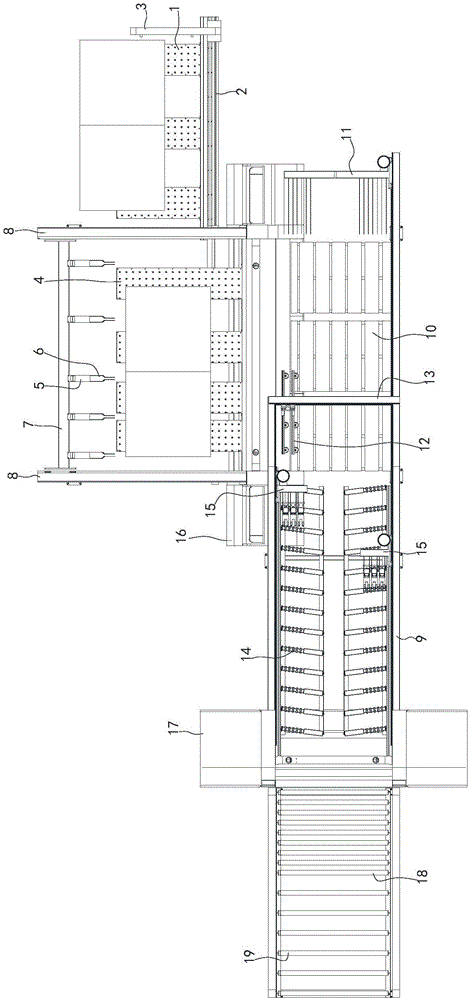

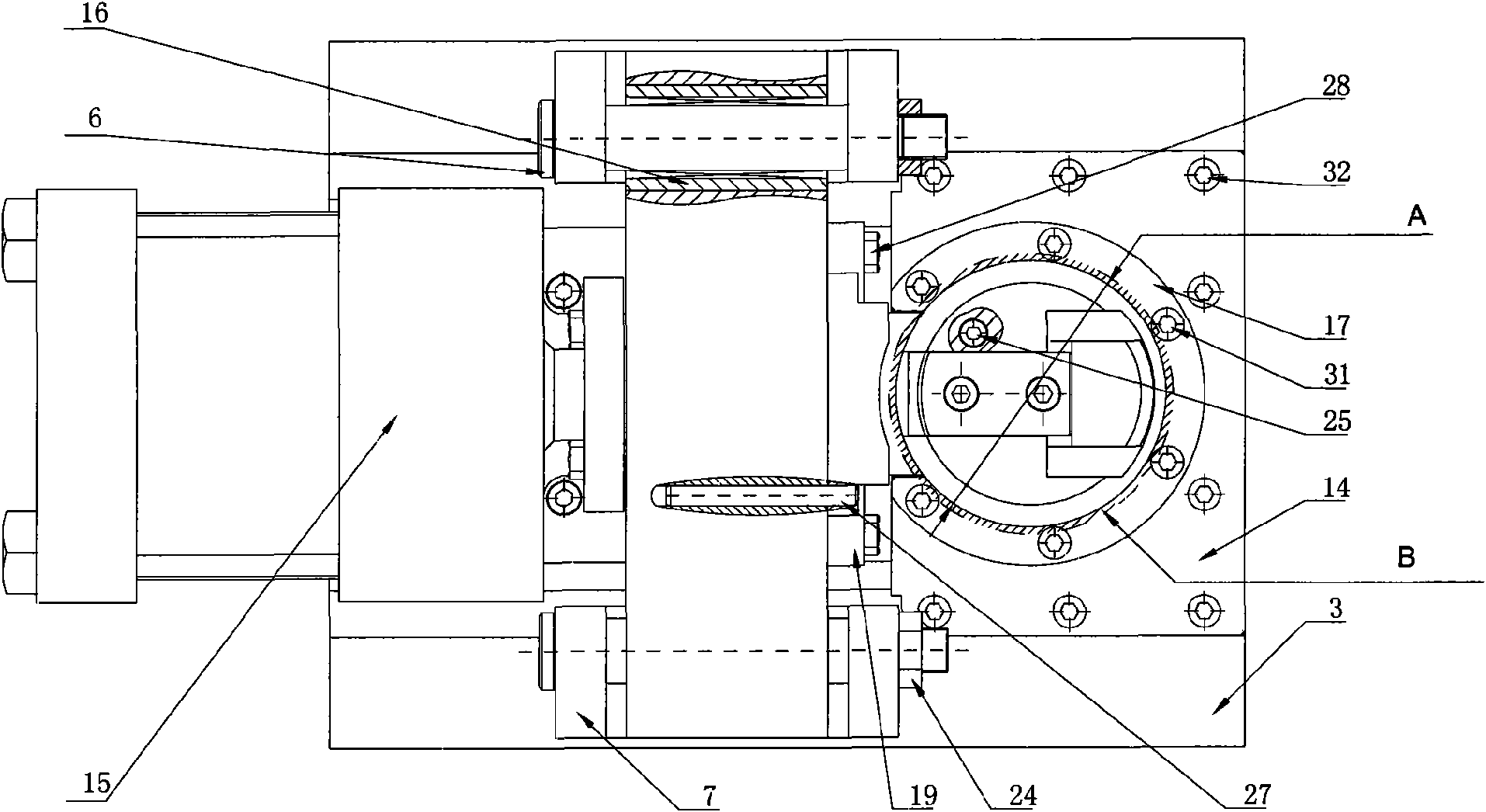

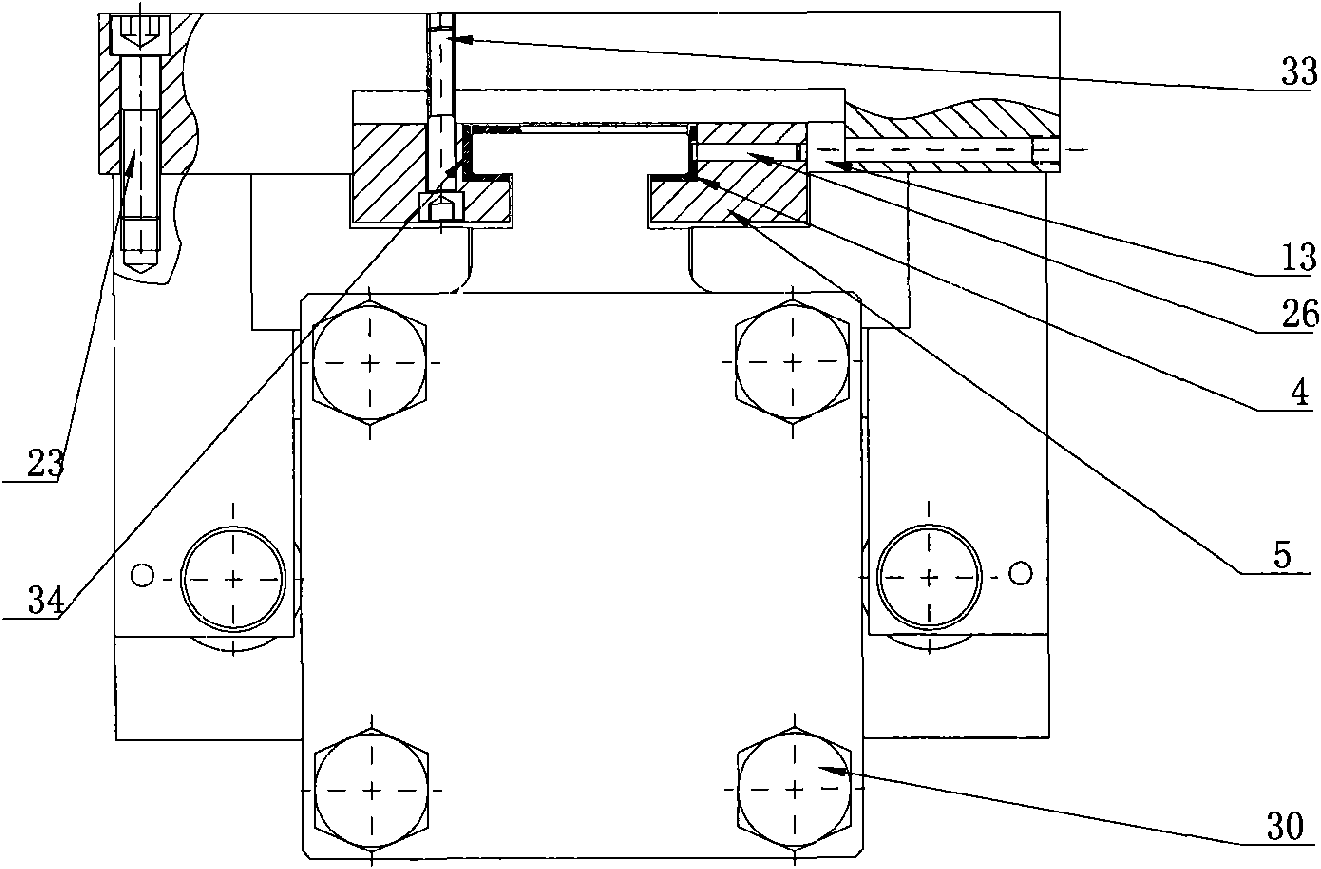

Longitudinal and transverse saw cutting device

ActiveCN106003253ARealize continuous automatic productionIncrease productivityFeeding devicesLoading equipmentEngineeringMachining

The invention provides a longitudinal and transverse saw cutting device comprising a transverse cutting mechanism and a longitudinal cutting mechanism. The feeding end of the transverse cutting mechanism communicates with a feeding mechanism; a plate material is supplied to the transverse cutting mechanism through the feeding mechanism; the transverse cutting mechanism performs transverse saw cutting treatment on the plate material; a conveying mechanism is arranged between the transverse cutting mechanism and the longitudinal cutting mechanism; the discharging end of the transverse cutting mechanism communicates with the feeding end of the longitudinal cutting mechanism through the conveying mechanism; the plate material subjected to the transverse saw cutting treatment of the transverse cutting mechanism enters the longitudinal cutting mechanism and is subjected to longitudinal saw cutting treatment through the longitudinal cutting mechanism; the feeding mechanism comprises a primary position material supporting platform and a secondary position material supporting platform; the primary position material supporting platform communicates with a feeding device which supplies the plate material to the primary position material supporting platform; the secondary position material supporting platform communicates with the primary position material supporting platform which transfers the plate material to the secondary position material supporting platform; and the primary position material supporting platform comprises a set of primary position supporting plates, and the secondary position material supporting platform comprises a set of secondary position supporting plates. The device adopts a door sleeve plate as a main machining object and is reasonable in structure, high in production efficiency and high in machining precision.

Owner:MENGTIAN HOUSEHOLD GRP CO LTD

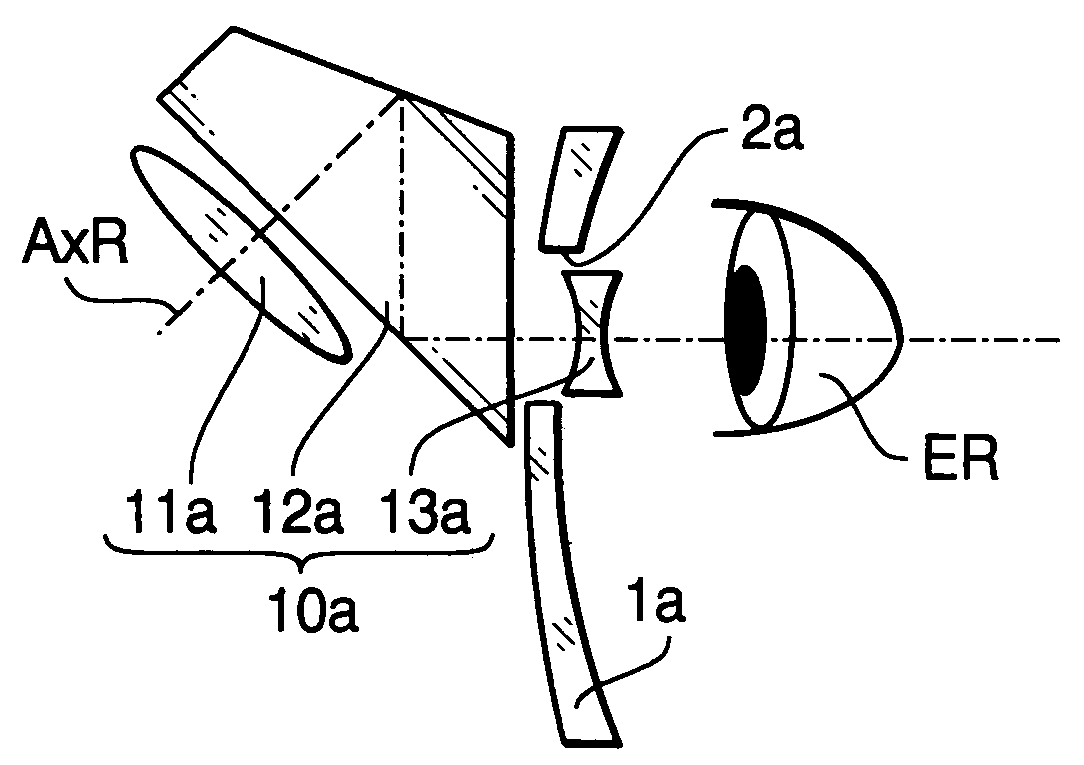

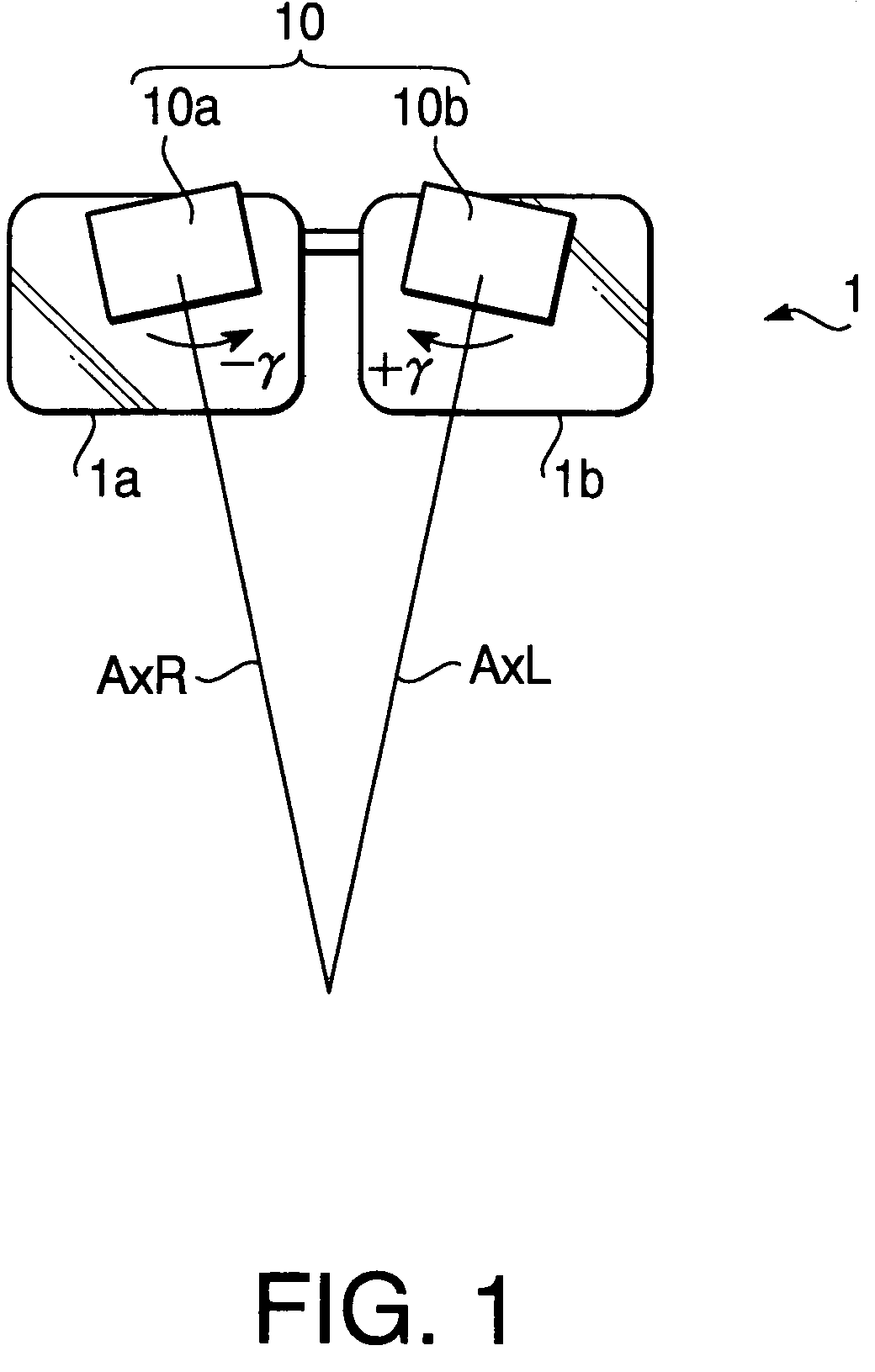

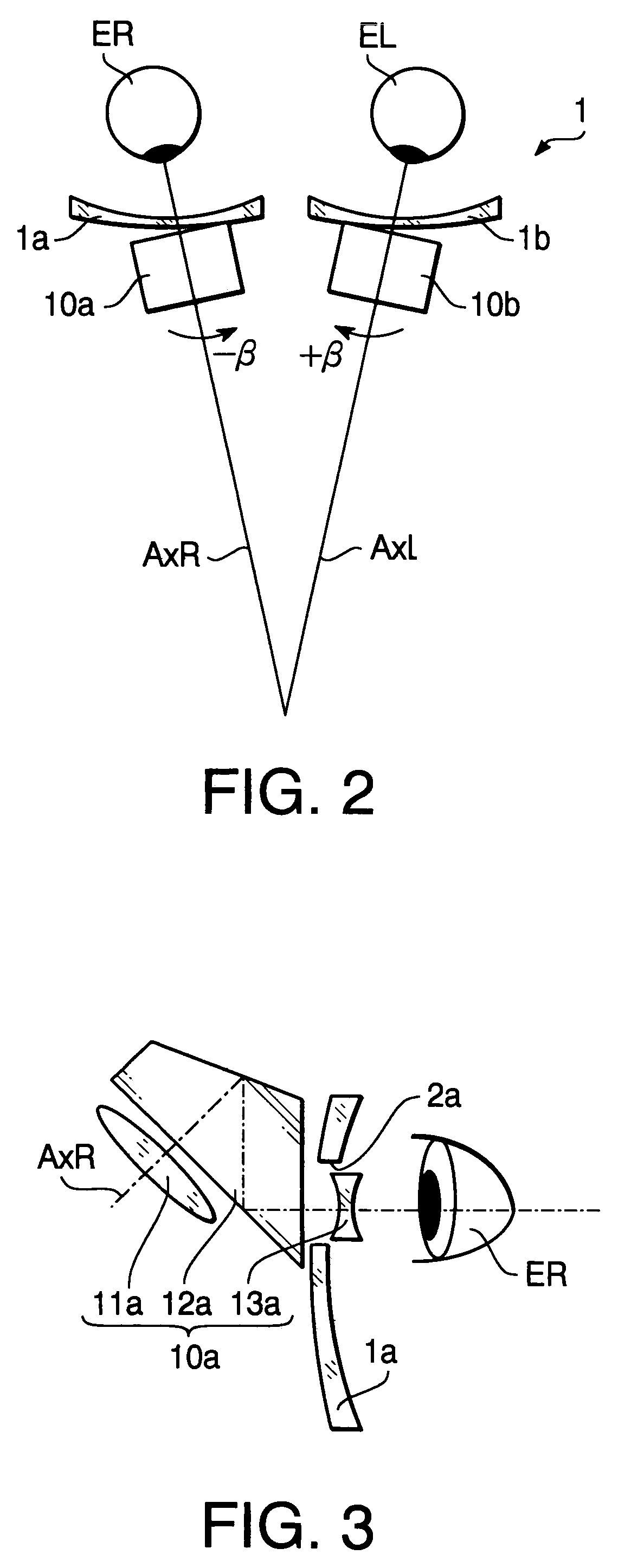

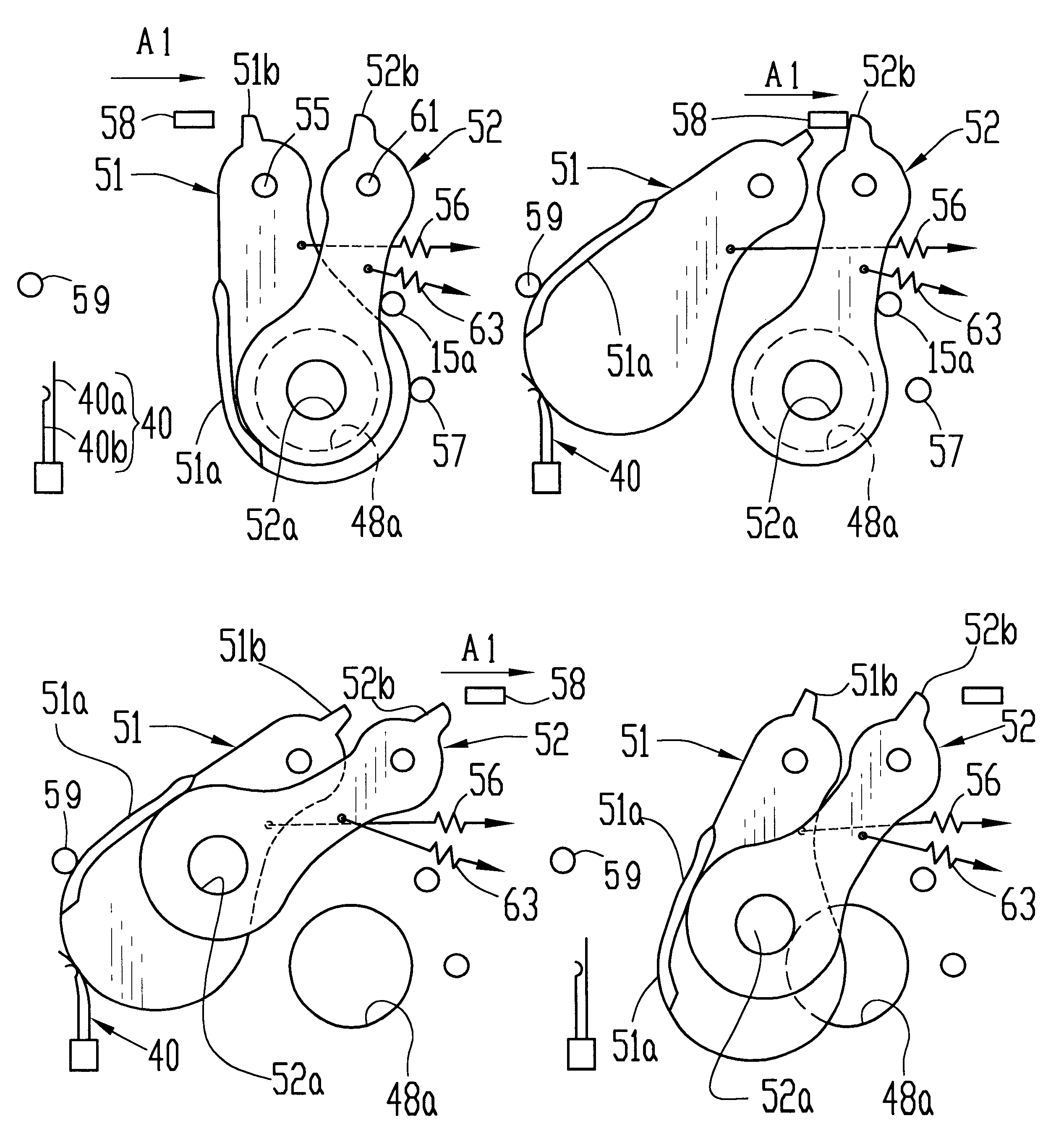

Binocular magnifying glasses

ActiveUS7242522B2Reduce the burden onAccurate inclinationCooking vesselsBeverage vesselsMagnifying glassComputer science

An adjustment method includes rotating a pair of magnifying glasses in directions opposite to each other using γ-rotation, and correcting inclination of an image, caused by the γ-rotation, by rotating the pair of magnifying glasses in directions opposite to each other using the β-rotation, given that rotation about each of axes XL and XR, which respectively correspond to visual axes of left and right eyes when an object distance is infinite in a condition of a primary position, is represented by the γ-rotation, and that rotation about each of axis YL and YR, which are respectively perpendicular to the axes XL and XR and are also perpendicular to a z-axis which perpendicularly intersects with the axis XL at a position of a deflector for the left eye and the axis XR at a position of the deflector for the right eye, is represented by the β-rotation.

Owner:ASAHI KOGAKU KOGYO KK

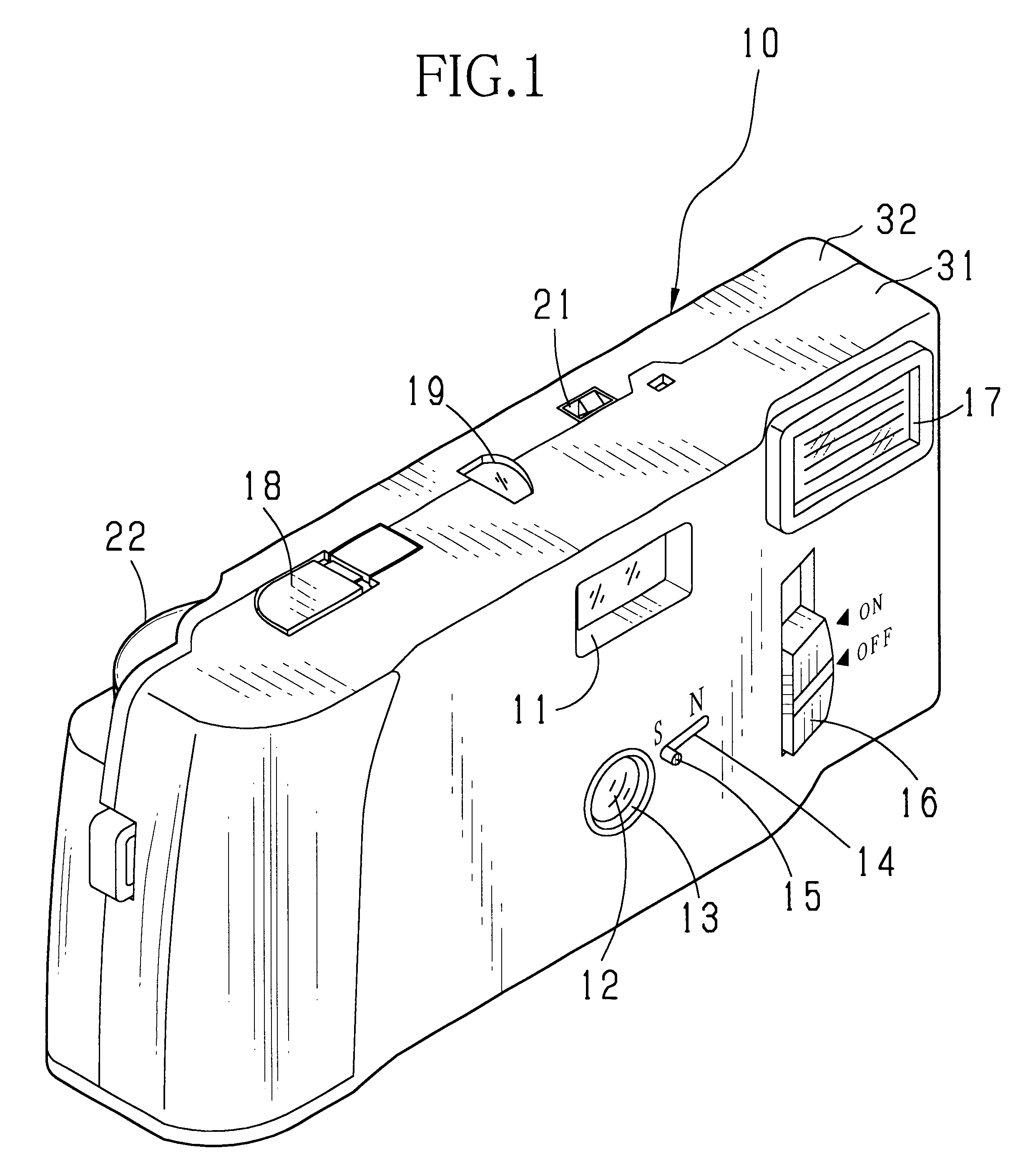

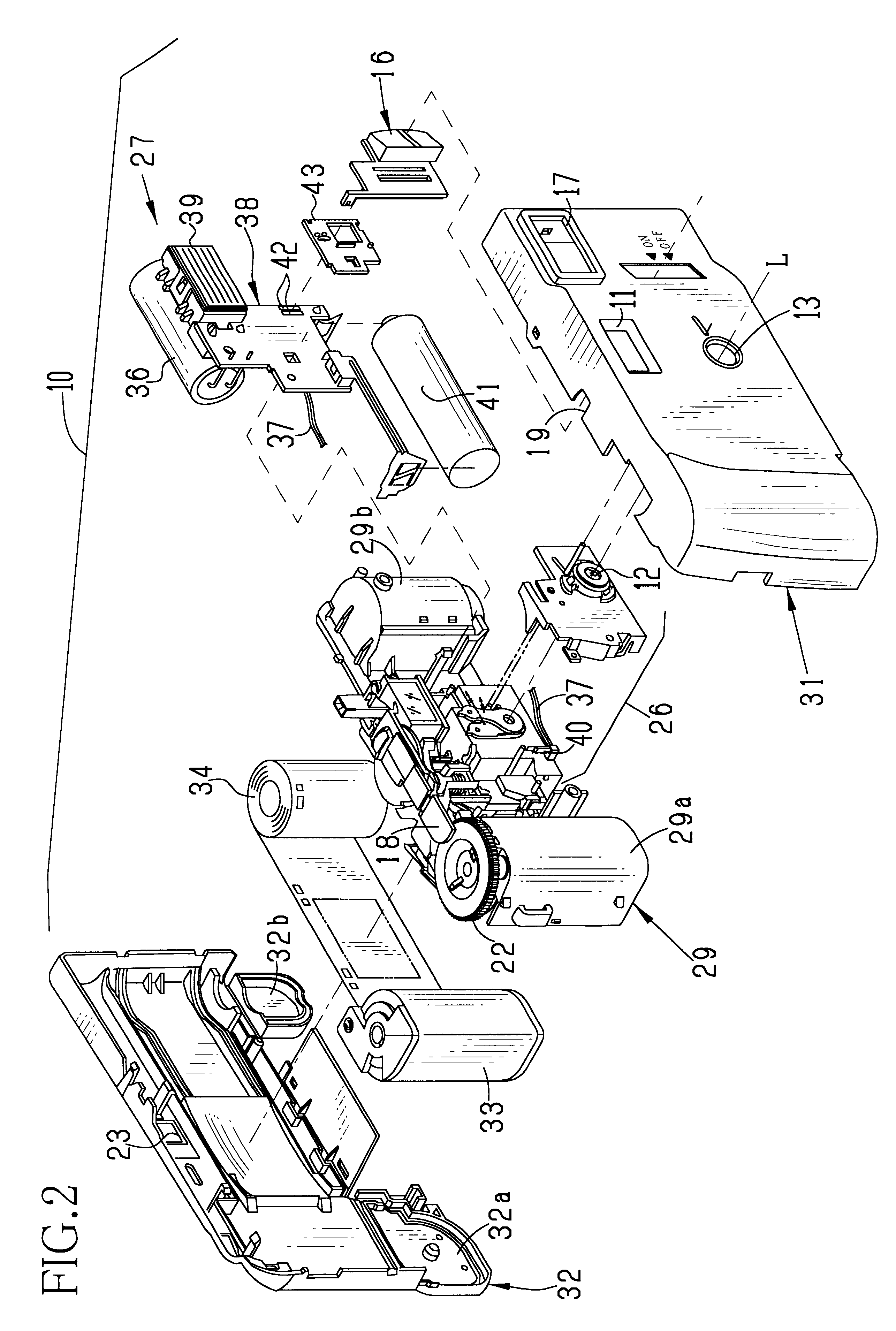

Shutter device of camera

A shutter device includes a shutter blade for opening and closing a shutter opening and a stop plate having a small stop of a shutter opening. While the small stop is disposed on the shutter opening, the shutter blade swings from a primary position responding to operation of shutter release. After the shutter blade leaves the shutter opening, a flashlight is emitted. Thereafter, the stop plate swings sequentially such that the shutter opening may entirely appear, and then the shutter blade swing back to the primary position with covering the small stop.

Owner:FUJIFILM HLDG CORP +1

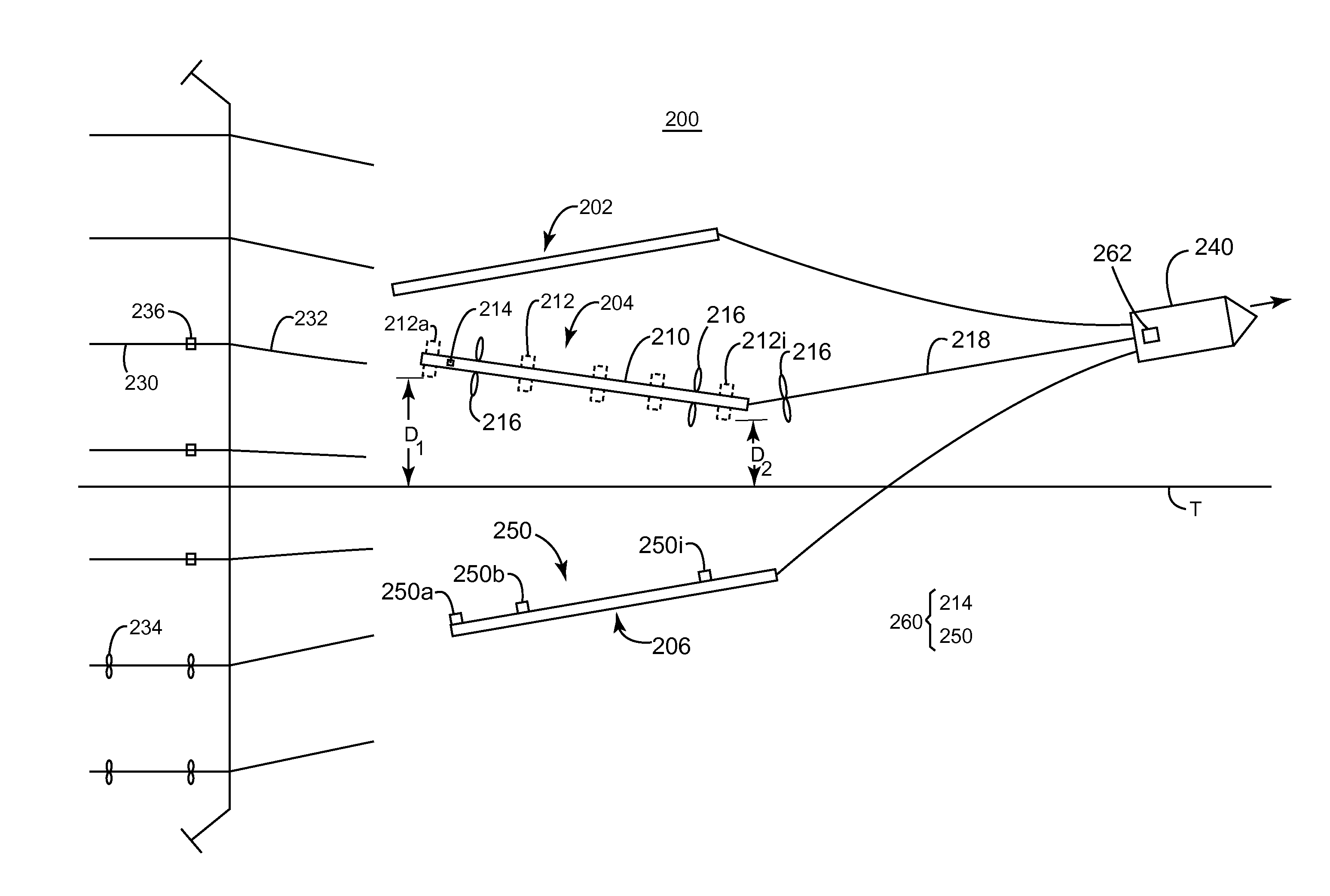

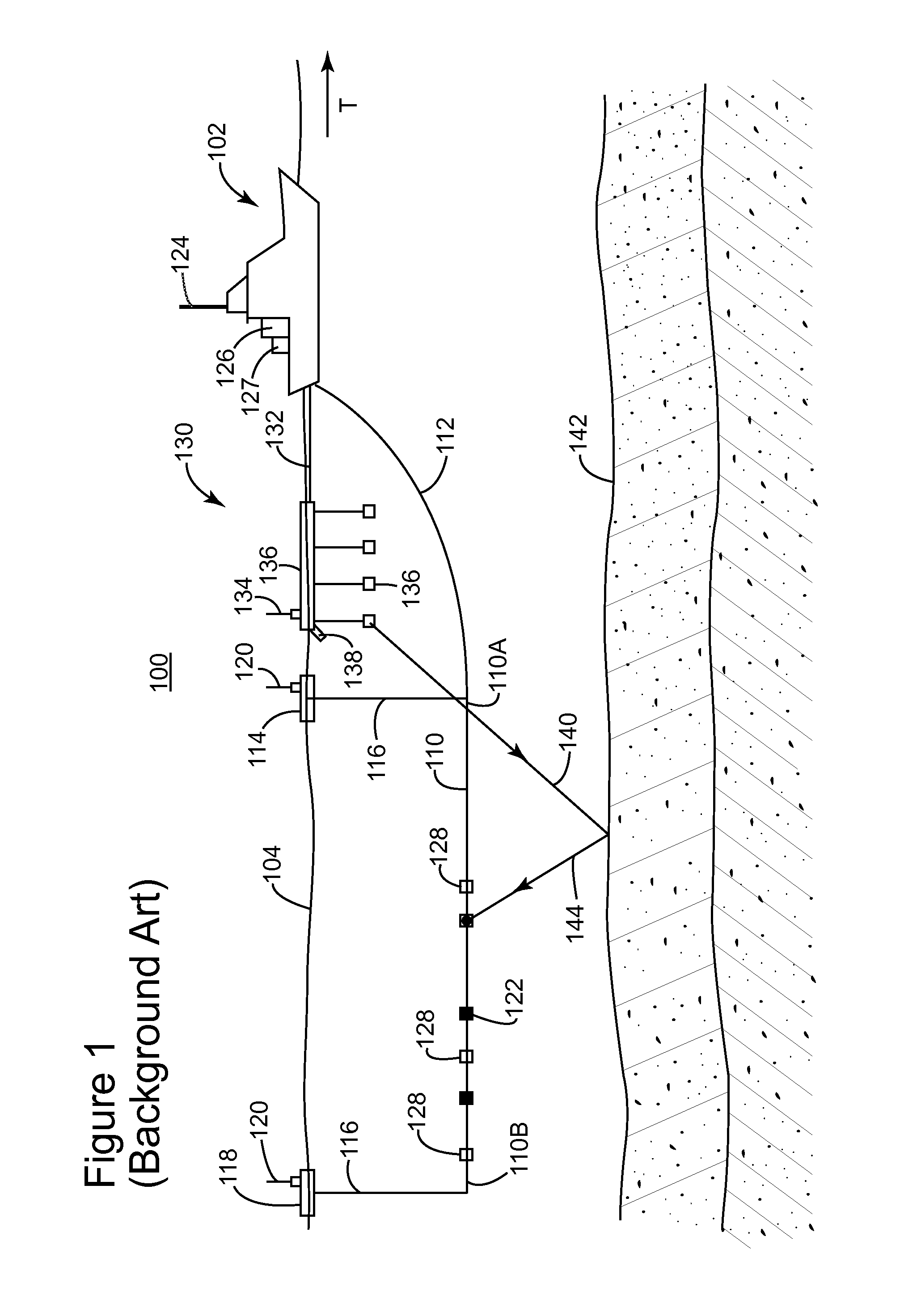

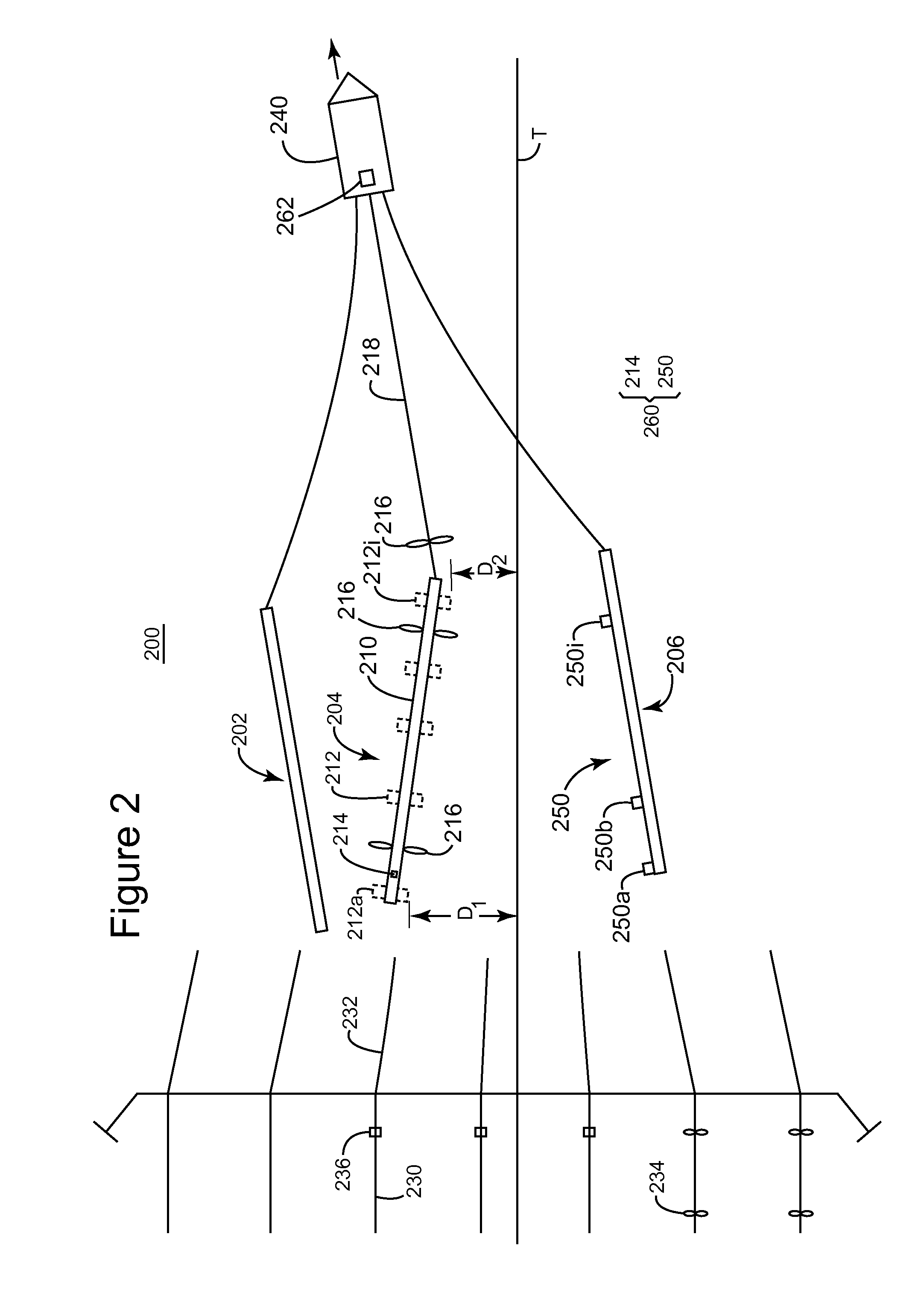

System and method for locating and positioning seismic source

InactiveUS20140241123A1Seismology for water-covered areasAcoustic wave reradiationTransceiverSeismic survey

A source array generates seismic waves in water during a marine seismic survey. The source array includes a first sub-array including plural source elements; plural acoustic transceivers distributed along the first sub-array; a positioning system; a primary position control device configured to control a position of the first sub-array; and a secondary position control system configured to adjust a depth of the first sub-array.

Owner:CGG SERVICES SA

Stamping method for numerical control stamping machine tool

InactiveCN101623731AImprove stabilityAvoid easy deformationPerforating toolsMetal-working feeding devicesNumerical controlEngineering

The invention discloses a stamping method for a numerical control stamping machine tool, and relates to stamping technology. In the stamping method provided by the invention, a die stamping device on the used numerical control stamping machine tool is provided with a fixed piece which is arranged telescopically. When a workpiece is stamped, the fixed piece is fixed to the side of the current stamping position of the workpiece; and after the current station stamping is finished, the fixed piece retracts to the primary position. The dimension stability of the workpiece can be ensured by adopting the stamping method of the invention. The stamping method for the numerical control stamping machine tool can continuously form waist holes with different heights on the workpiece so as to improve the working efficiency.

Owner:上海运通工程机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com