Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Improve stranding efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

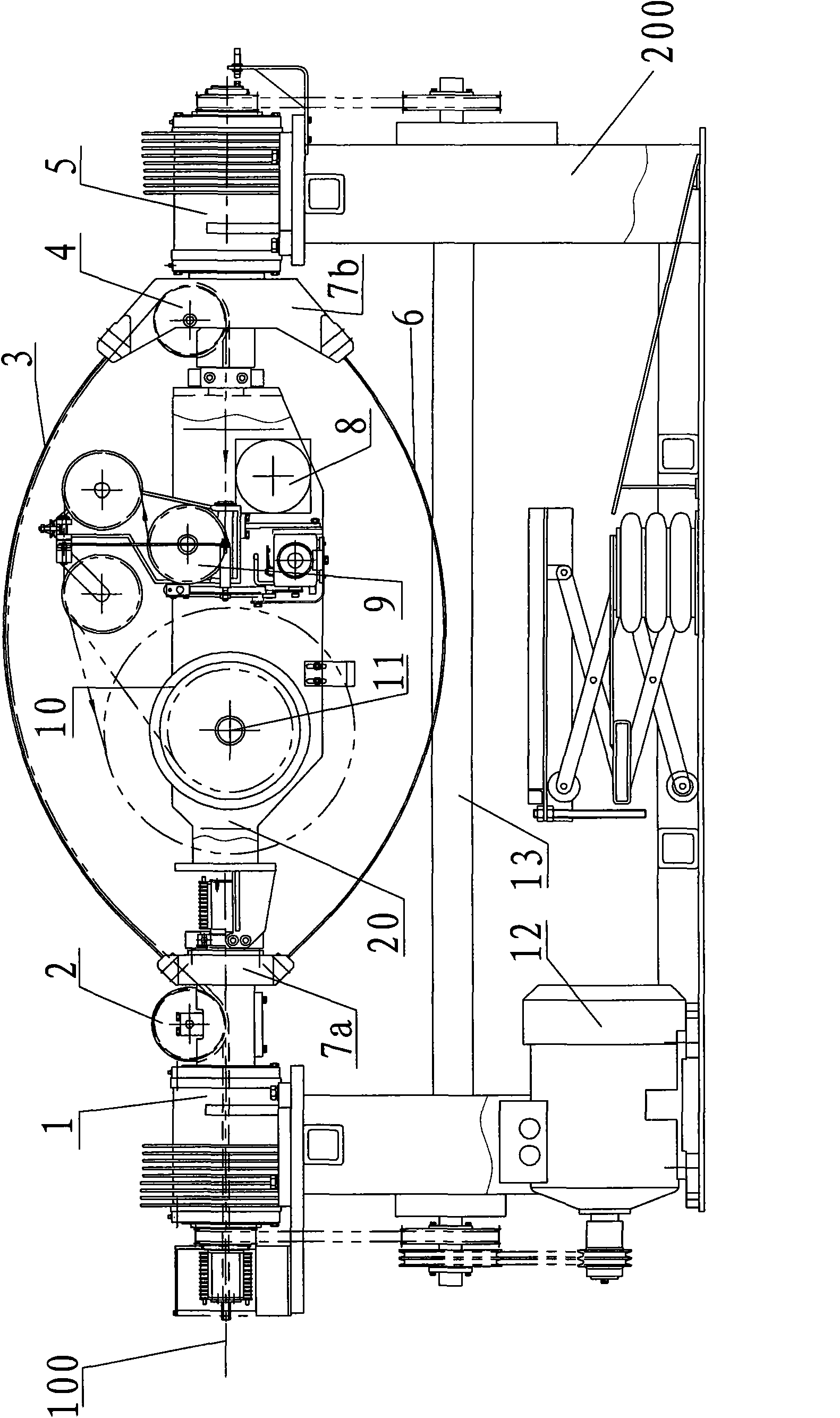

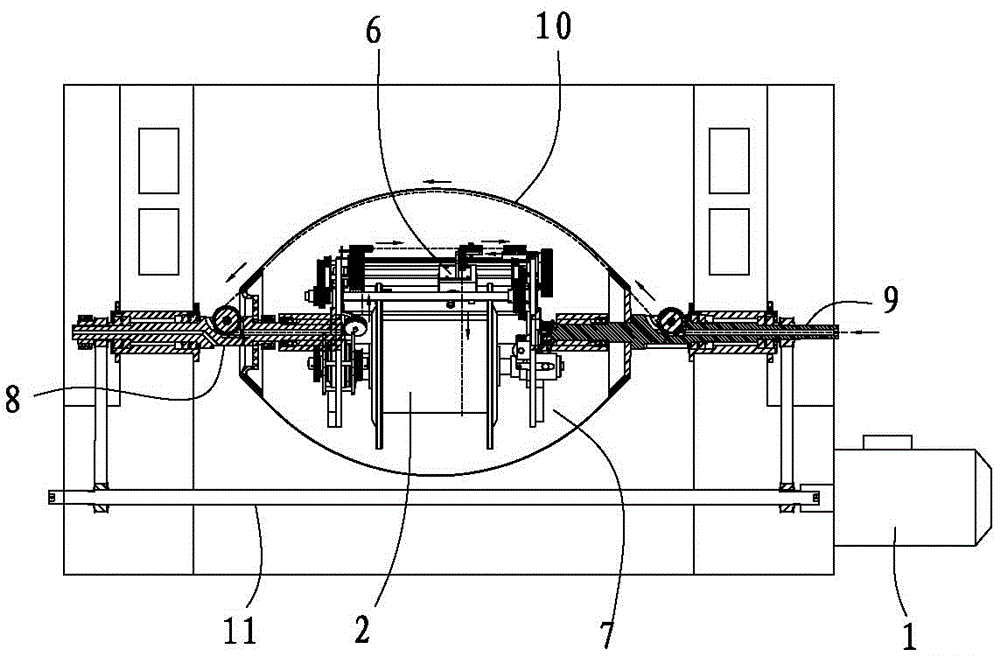

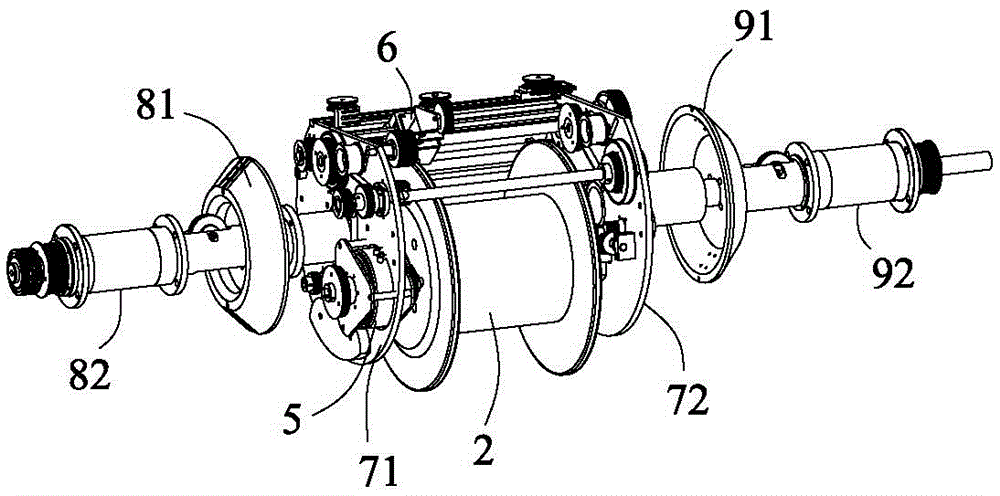

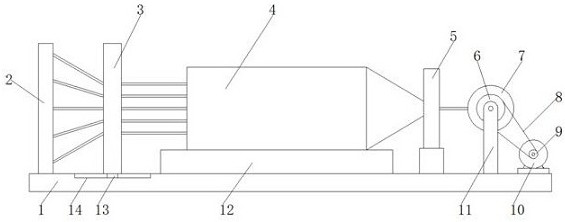

Four-pitch wire twisting machine capable of realizing continuous production

InactiveCN101599323AImprove stranding efficiencySmall sizeCable/conductor manufactureTextile cablesElectrical conductorFuselage

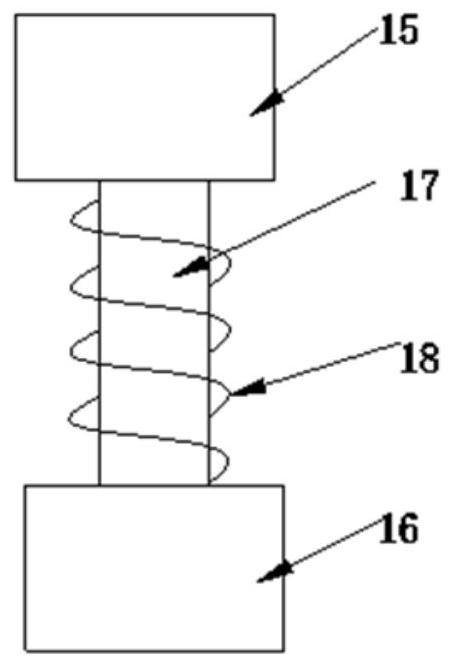

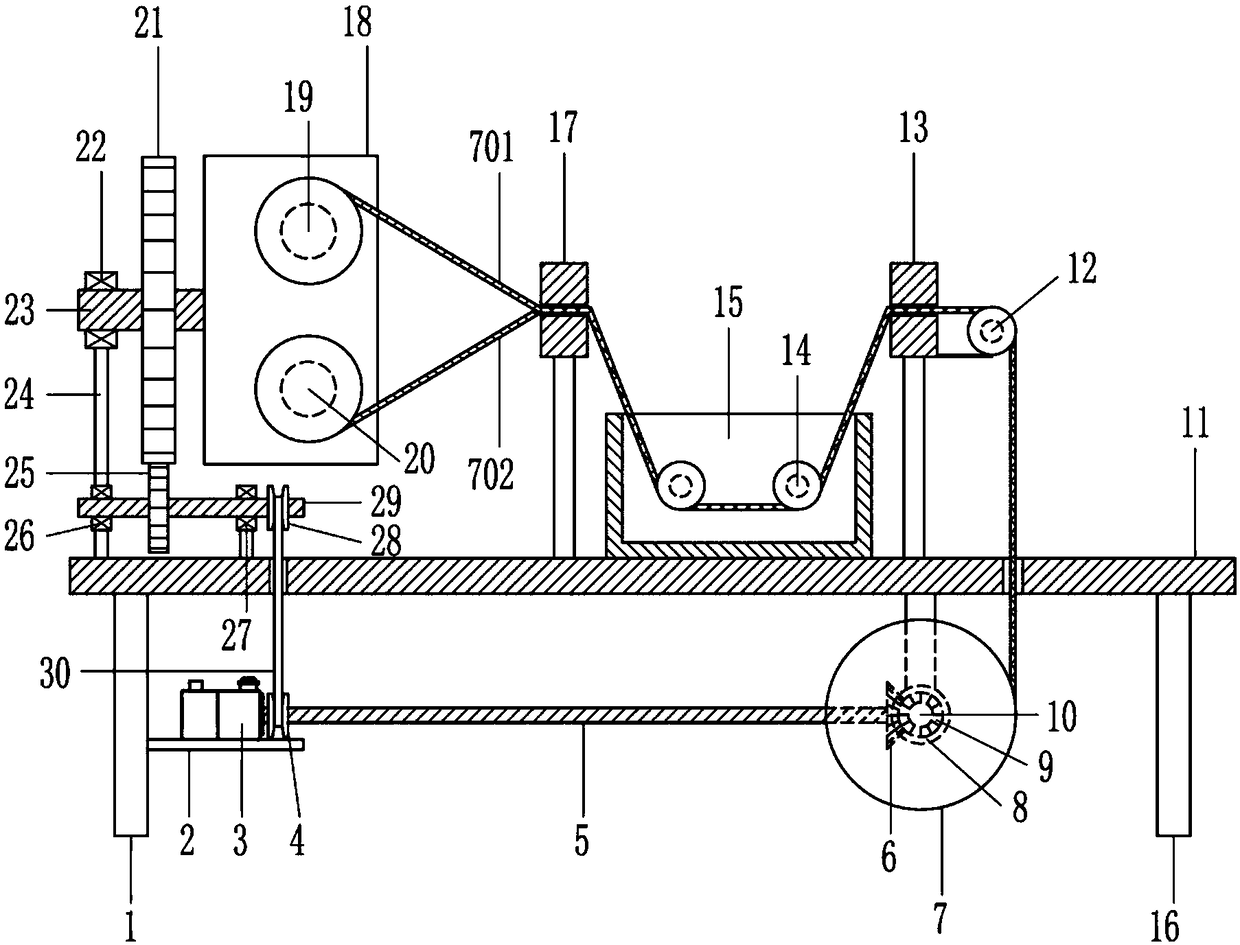

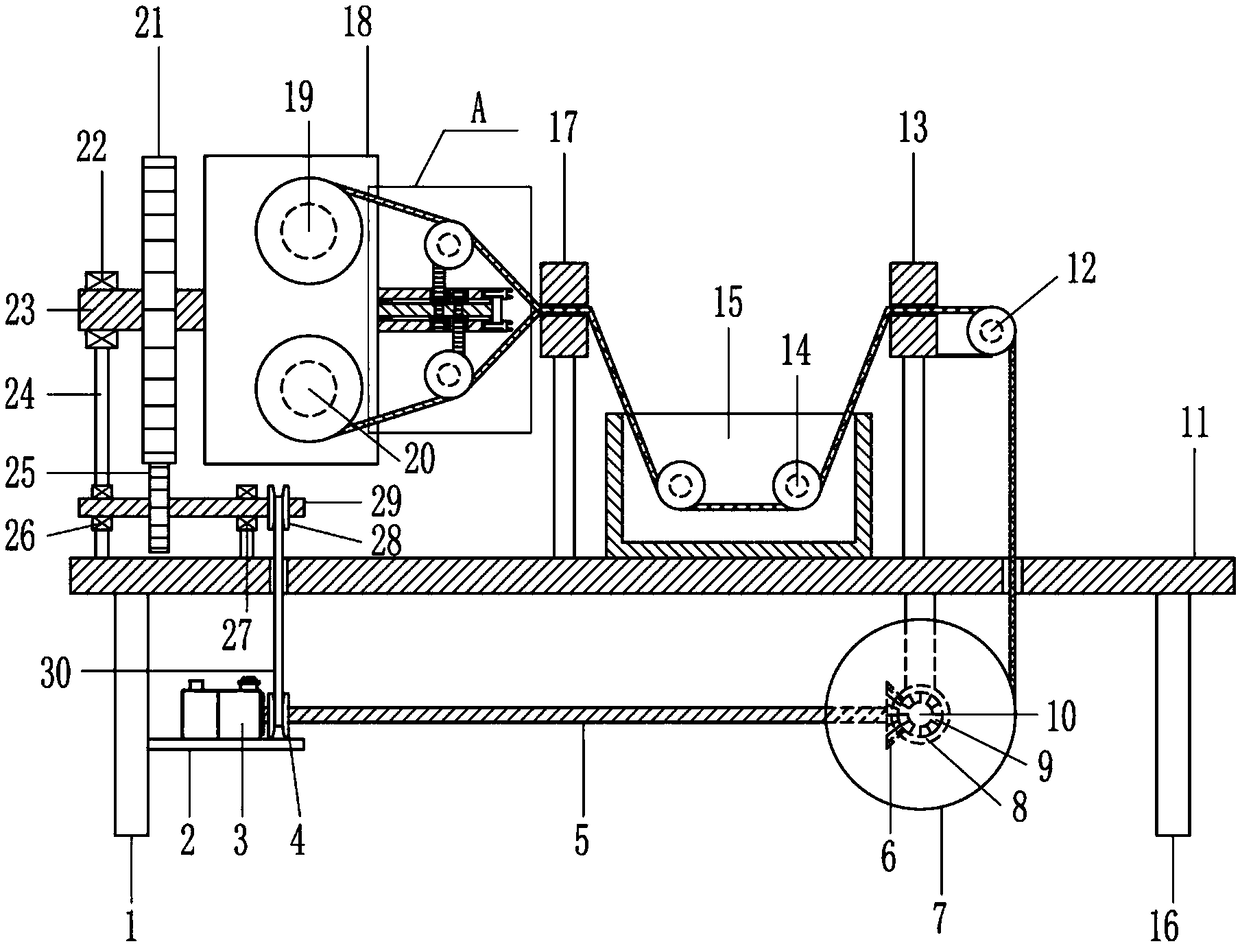

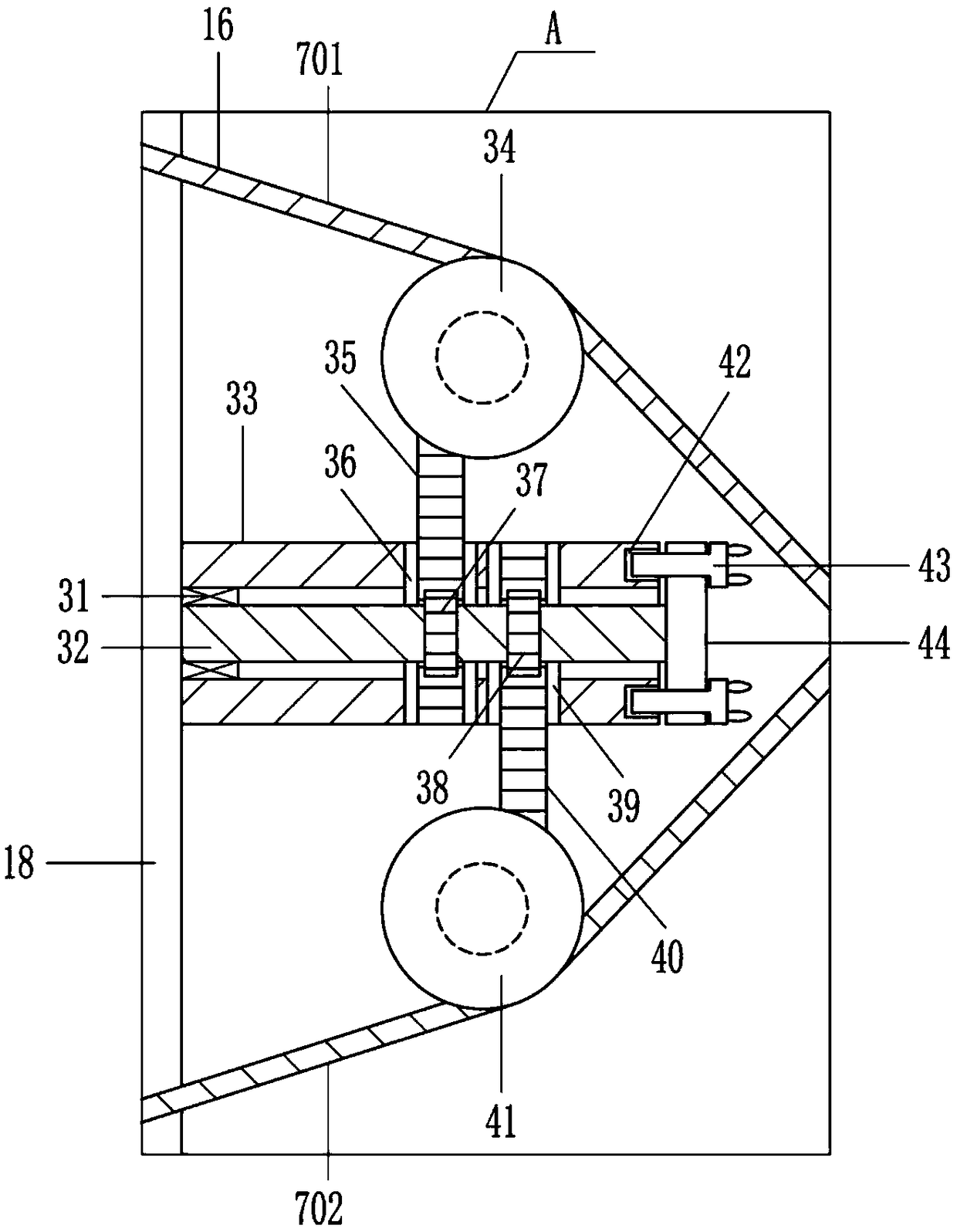

The invention discloses a four-pitch wire twisting machine capable of realizing continuous production, comprising a machine body, a driving mechanism, a cradle, a wire-in main shaft, a wire-out main shaft, two twisting bow brackets, a pair of twisting bows, a first wire twisting guide wheel, a second wire twisting guide wheel and a traction device, wherein the pair of twisting bows are respectively used as a wire-in twisting bow and a wire-out twisting bow, that is, a counter weight twisting bow of the prior art is used as the wire-out twisting bow so as to ensure a core wire passes through the two twisting bows to realize four-pitch wire twisting; meanwhile, in order to ensure the core wire can walk along the wire-out twisting bow, a wire-out guide wheel, a third wire twisting guide wheel and a fourth wire twisting guide wheel are additionally arranged, so as to ensure multistrand conductors or core wires in the twisting machine first enter from the wire-in main shaft and finally exit from the wire-out main shaft by passing through the first wire twisting guide wheel, the wire-in twisting bow, the second twisting wire guide wheel, the traction device, the wire-out guide wheel, the third wire twisting guide wheel, the wire-out twisting bow and the fourth wire twisting guide wheel. The wire twisting machine is high in efficiency and low in loss, can realize continuous production, and can be used as a single machine or be used for united machine production.

Owner:向继光

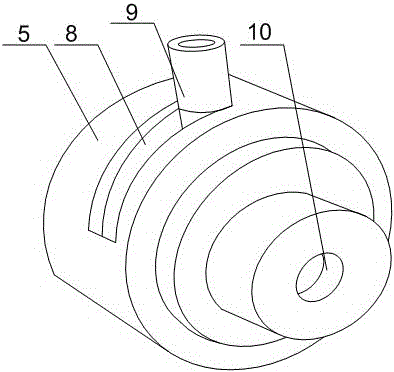

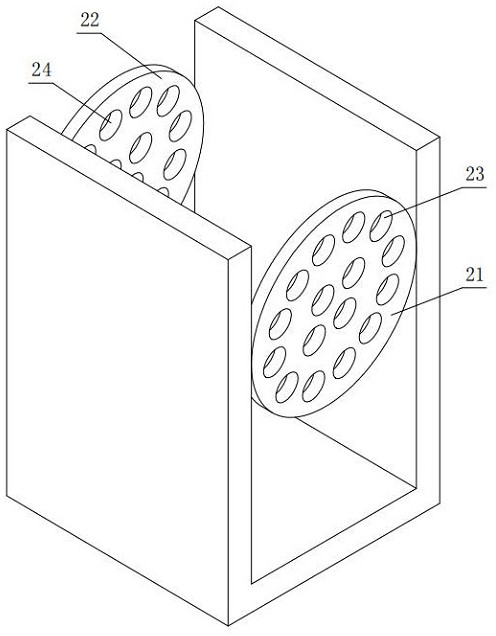

Line passing device of high-speed stranding machine

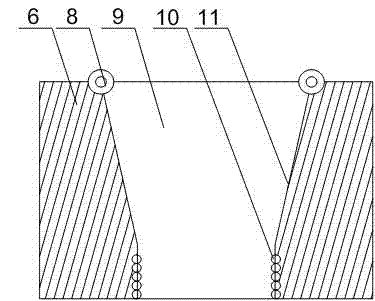

ActiveCN104851526AReduce wearReduce mutual wearCable/conductor manufactureCircular coneAgricultural engineering

The present invention discloses a line passing device of a high-speed stranding machine. The line passing device comprises a bracket, and a distributor plate and a reserved plate which are fixed on the bracket in turn along a copper line incoming direction, wherein a plurality of line passing holes are disposed in the distributor plate and the reserved plate, a line entering device is fixed in the axis of the reserved plate, two connecting rods are arranged in a sliding manner at the bracket, free ends of the two connecting rods are connected with each other through an adjusting ring, a line entering hole is disposed in the adjusting ring, an inner circular conical surface is arranged at the upper part of the line entering hole, a plurality of roll balls are arranged at the lower part of the line entering hole, and the adjusting ring is arranged in a sliding manner on the bracket through the connecting rods, that is, the position of the adjusting ring can be adjusted in a sliding manner according to the diameter of an actual copper line, thereby reducing abrasion between the copper lines and the line entering hole and between the inlet of the stranding machine.

Owner:CHENGDU XINGDA OF COPPER CO LTD

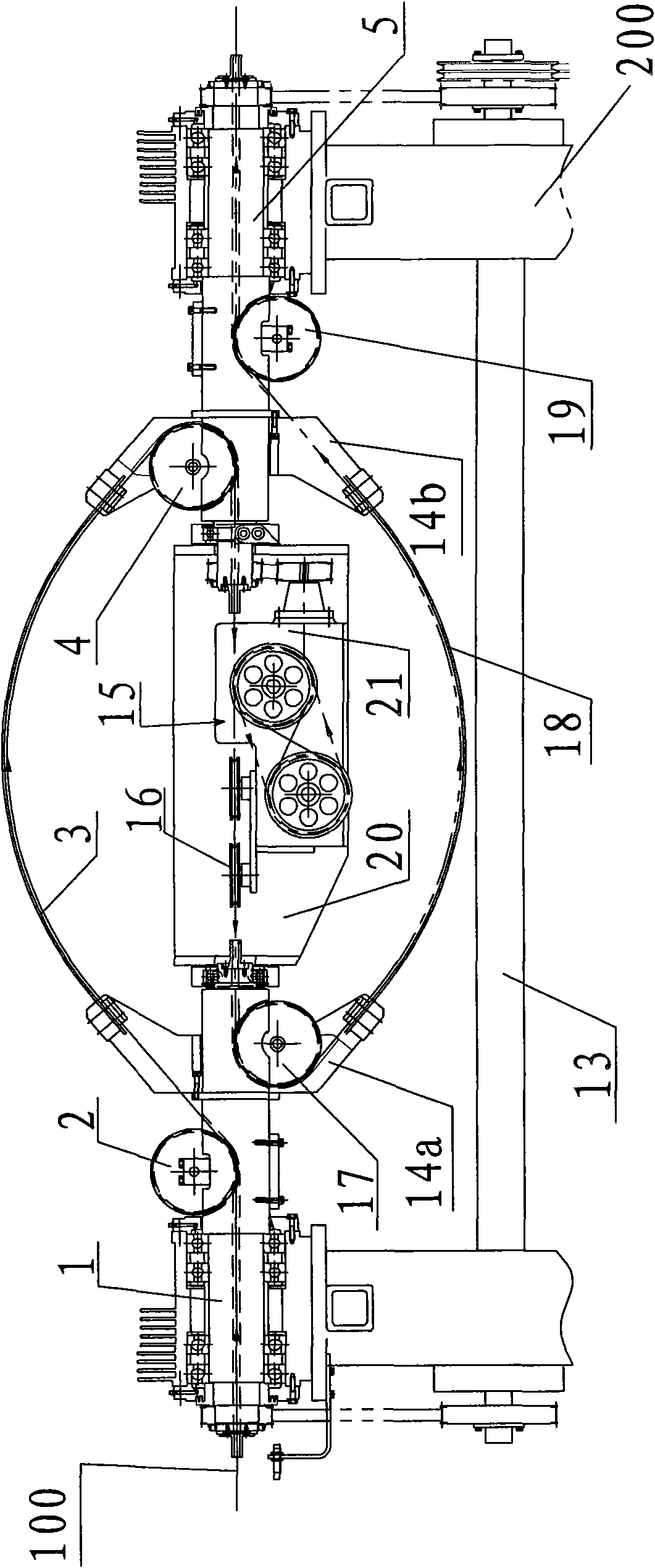

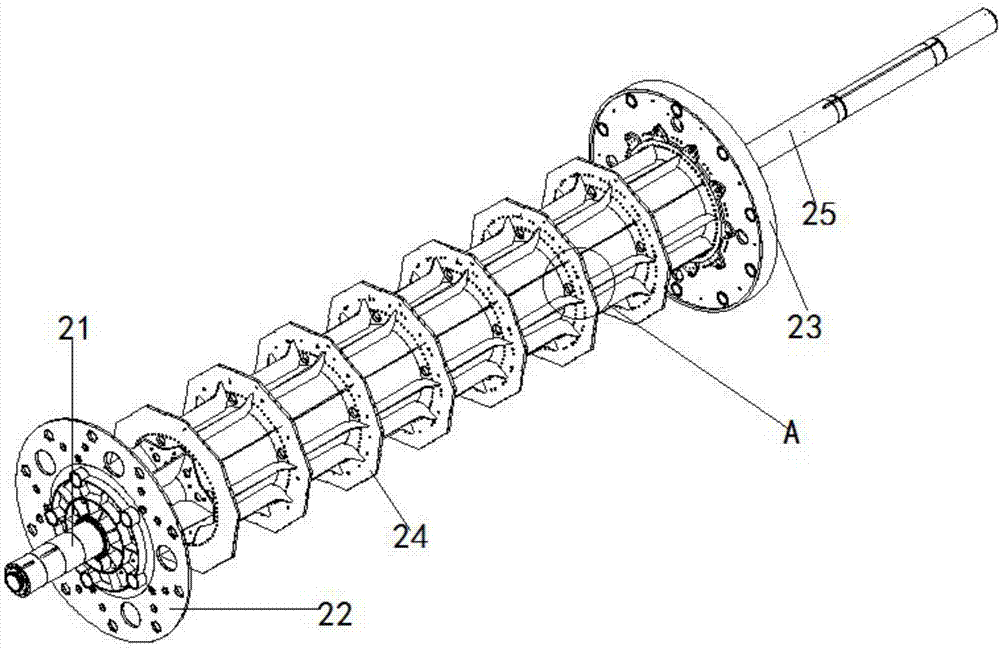

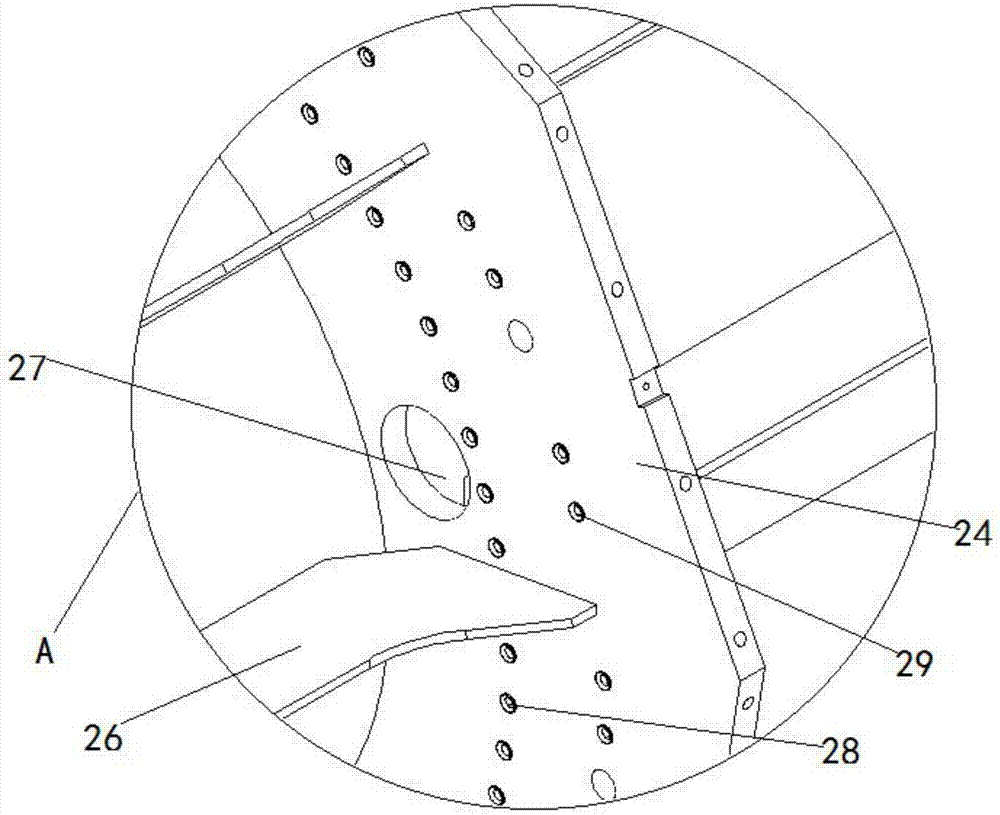

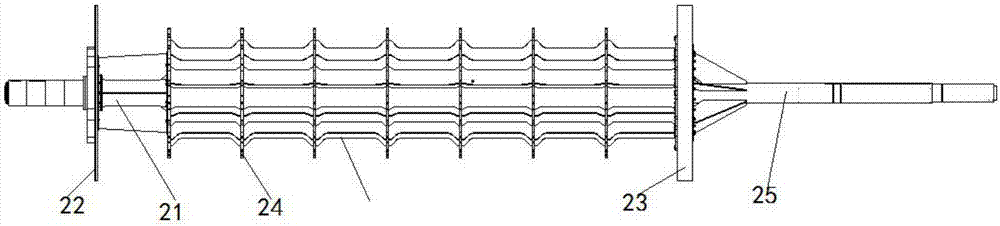

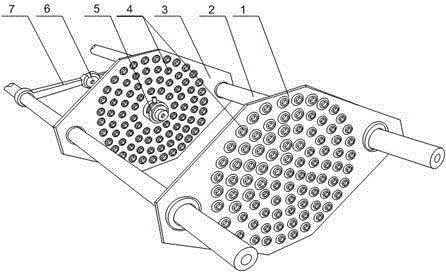

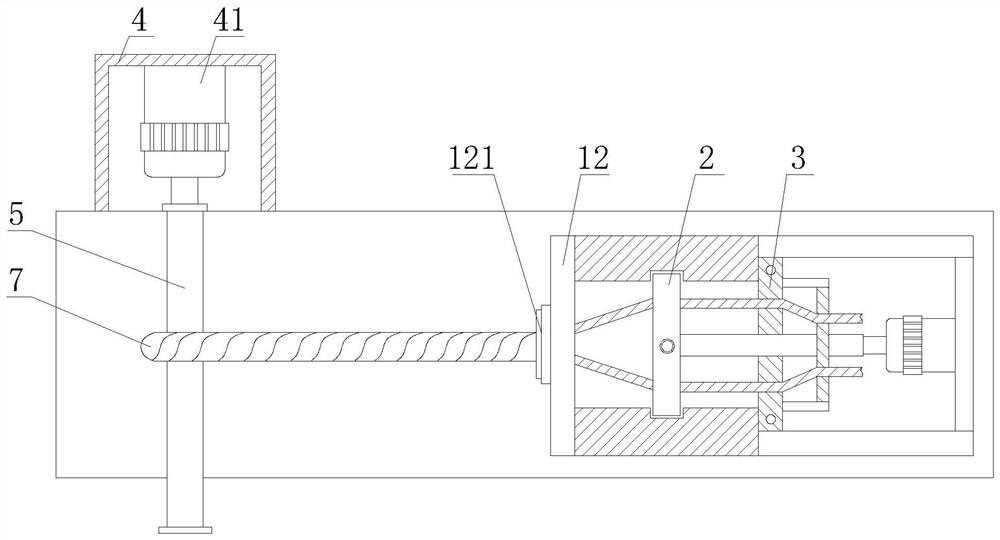

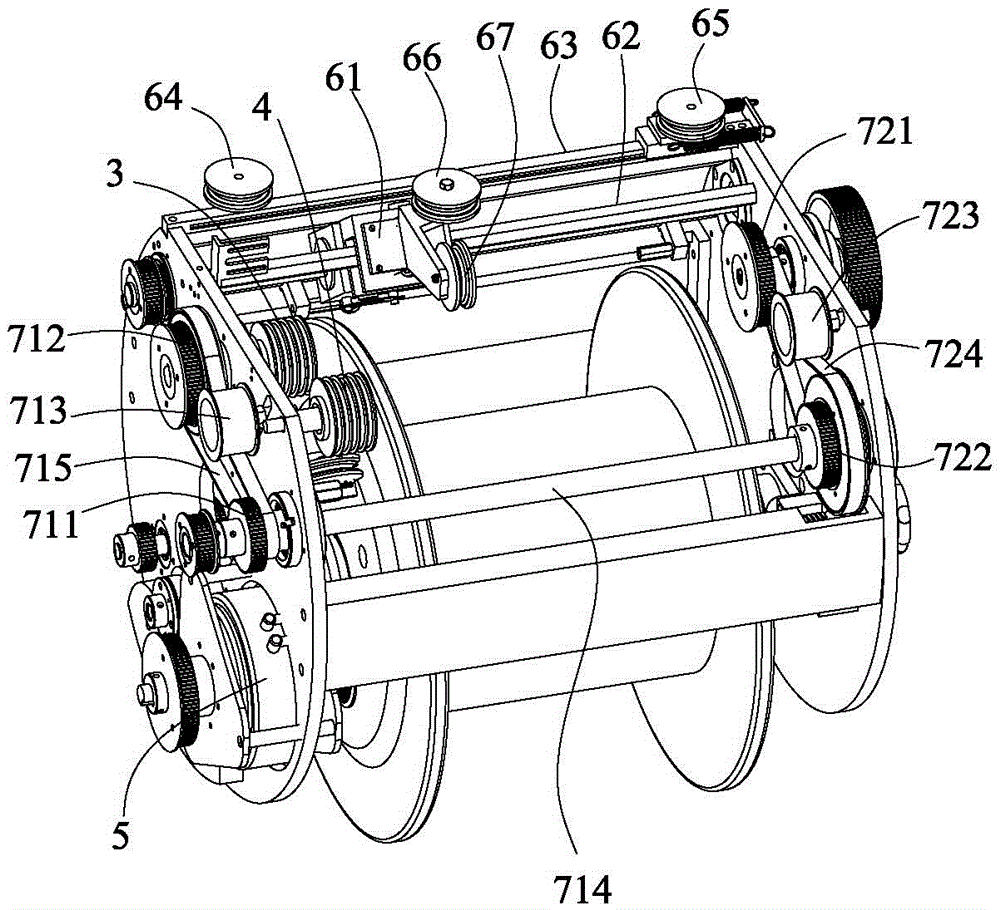

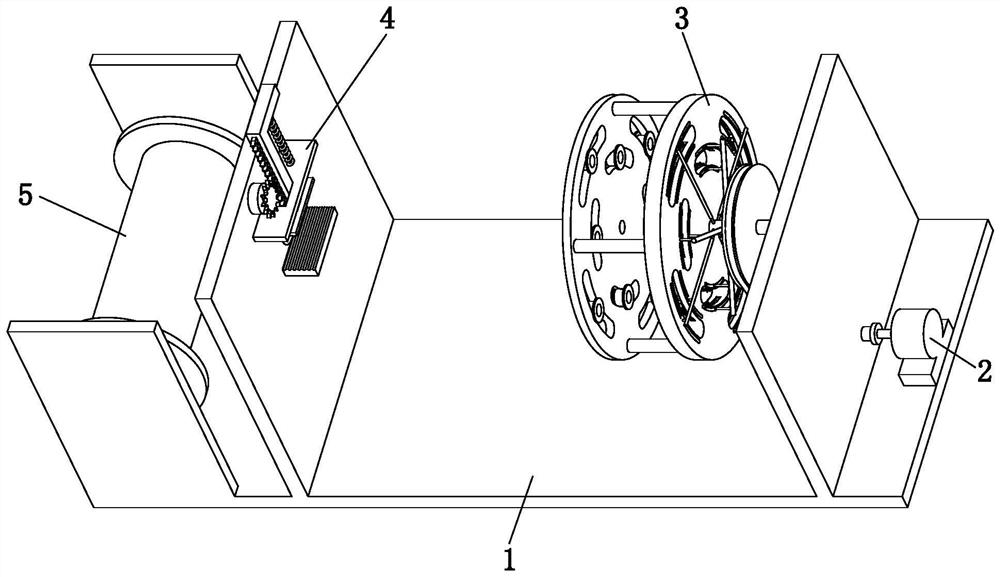

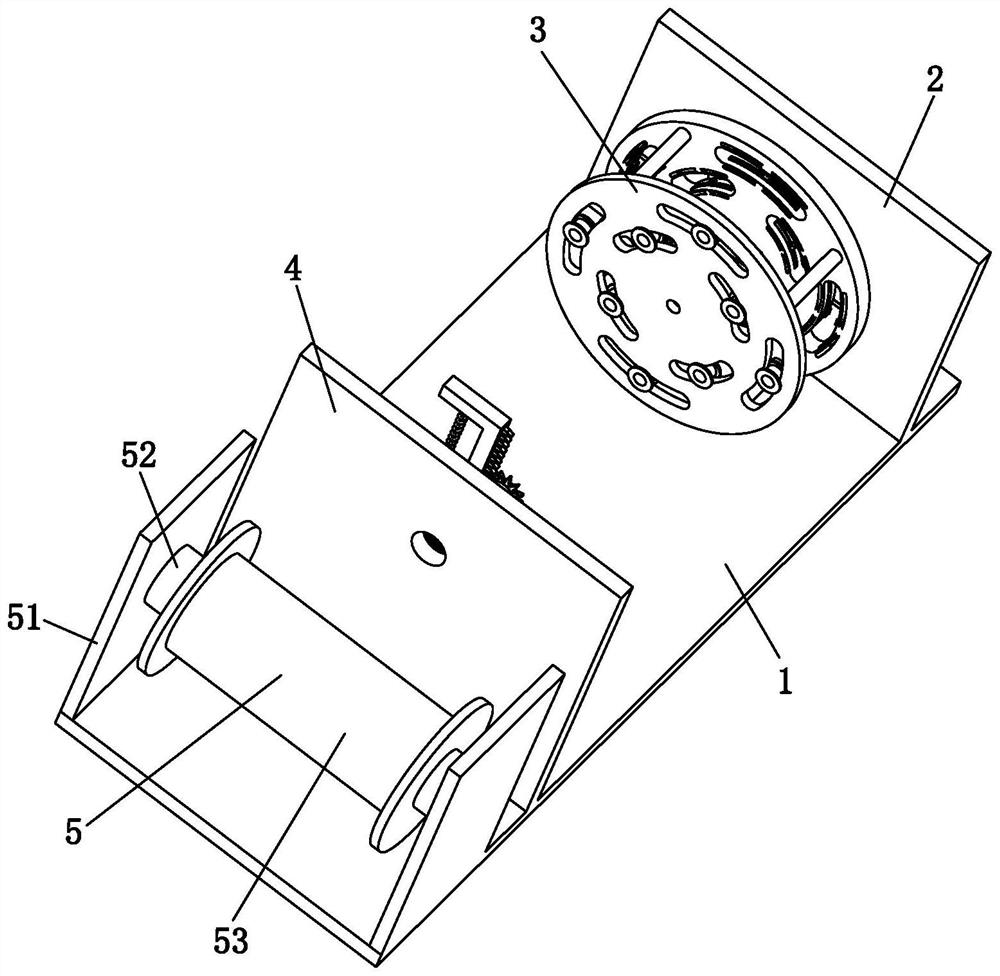

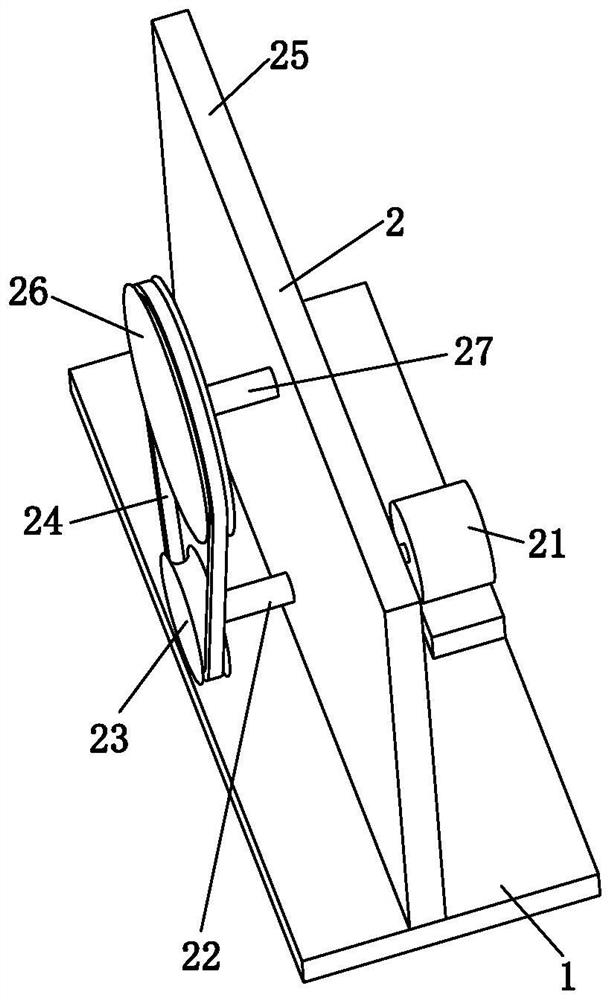

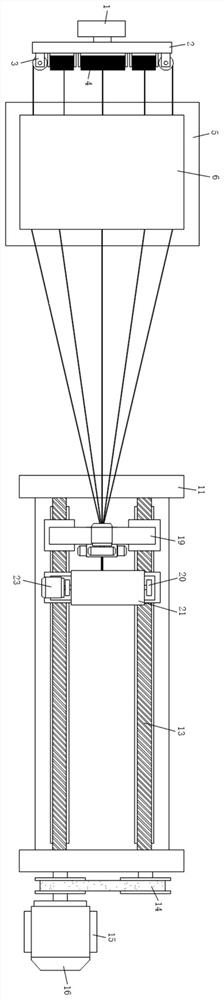

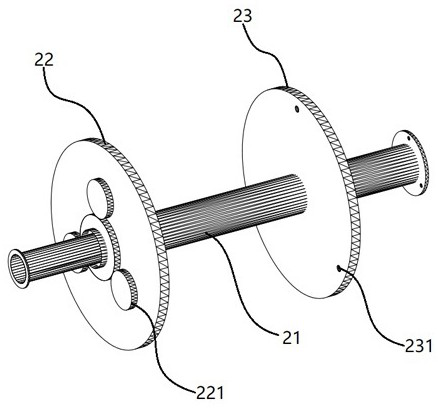

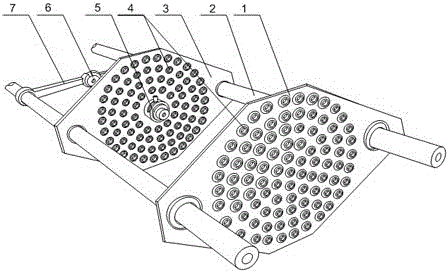

Novel multi-winch cage stranding machine

ActiveCN107275010AChange the shortcomings of insufficient quantityImprove stranding efficiencyCable/conductor manufactureEngineeringUltimate tensile strength

The invention discloses a novel multi-winch cage stranding machine including a spindle assembly. The spindle assembly includes a spindle. A rotating disc is mounted at the input end of the spindle. The output end of the spindle is coaxially connected with a pre-twisting shaft through a pre-twisting disc. A plurality of winches are equidistantly distributed along the axial direction between the rotating disc and the pre-twisting disc. Connecting plates are uniformly distributed along the circumferential direction between adjacent winches. A first wire hole group, a second wire hole group and a third wire hole group are arranged sequentially along the radius direction on the surface of each winch. Through clever design of the spindle, the rotating disc and the pre-twisting disc, the shortcoming that the traditional stranding machine has insufficient winches is changed. The novel multi-winch cage stranding machine has a simple and compact structure, and is of higher stranding efficiency. Tight, solid and reliable stranding is ensured. High mechanical strength is achieved. The novel multi-winch cage stranding machine has good economic and promotion values.

Owner:HEFEI SMARTER TECH GROUP CORP

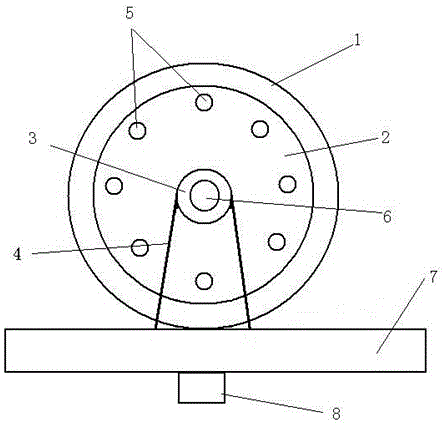

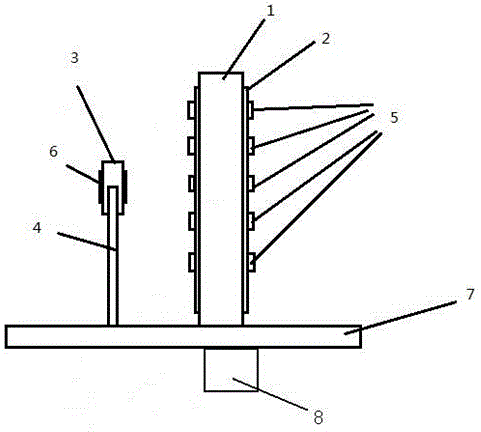

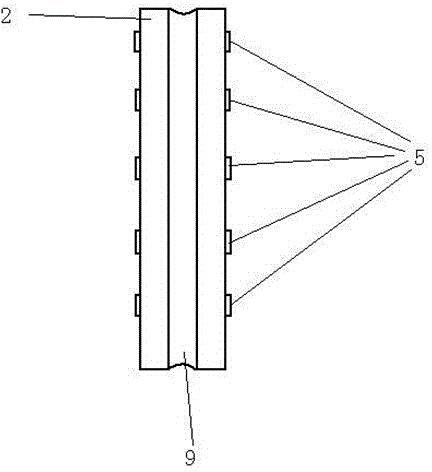

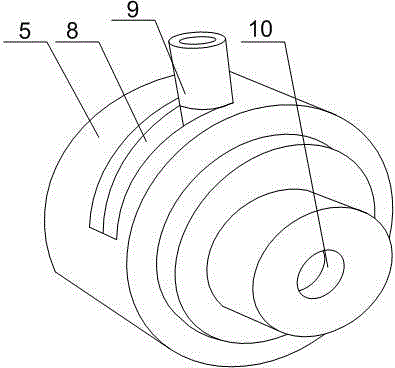

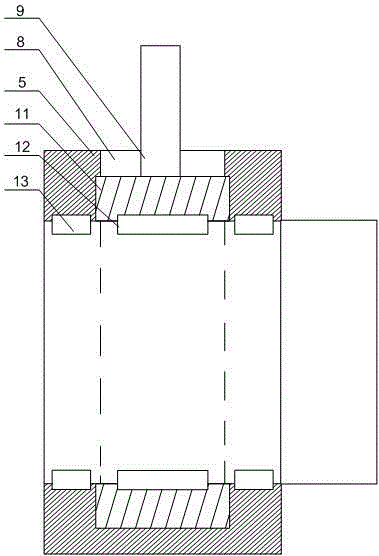

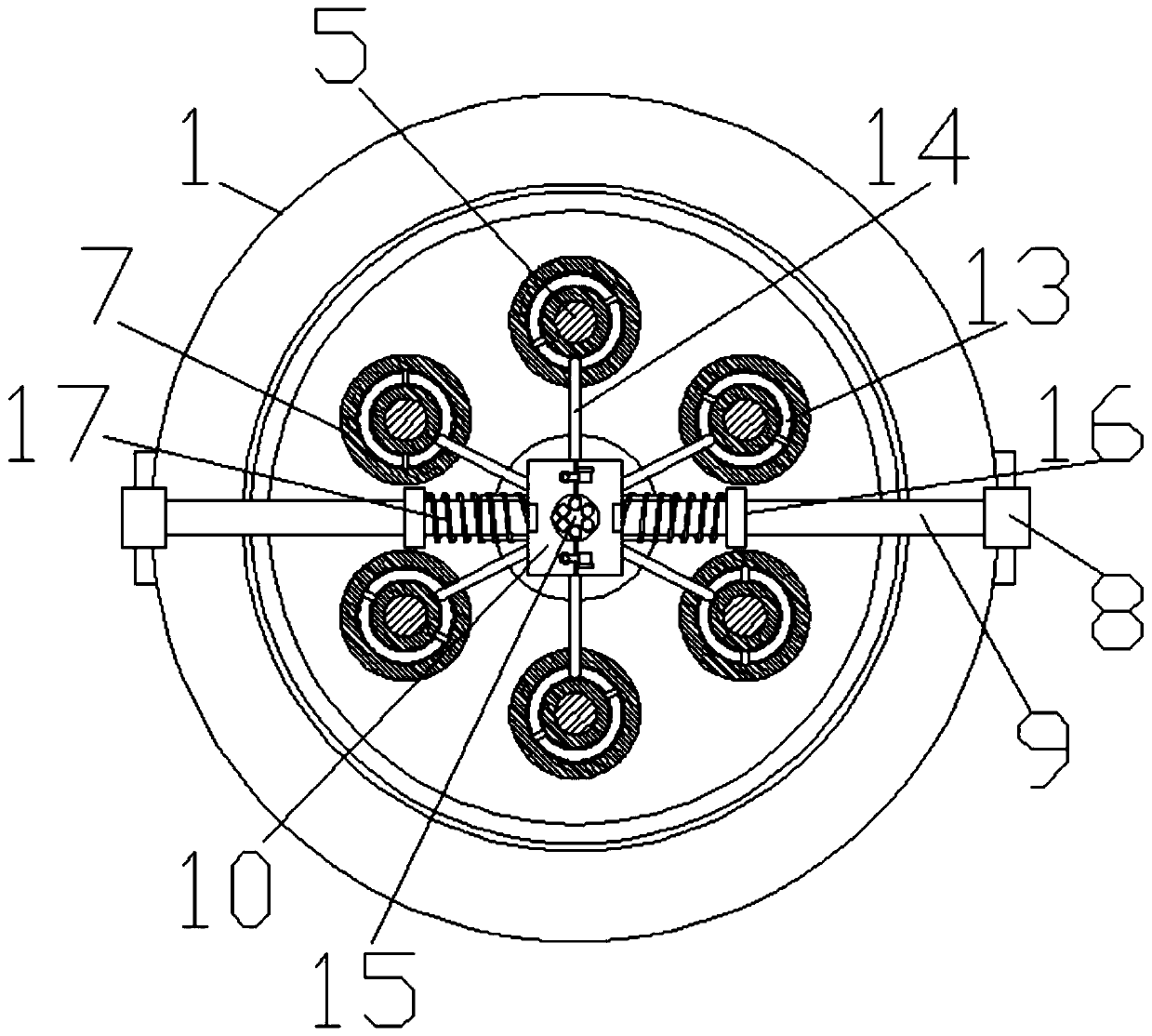

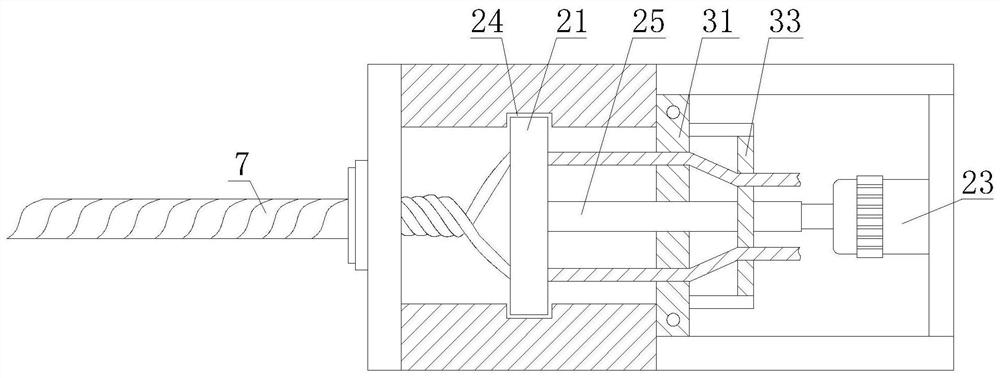

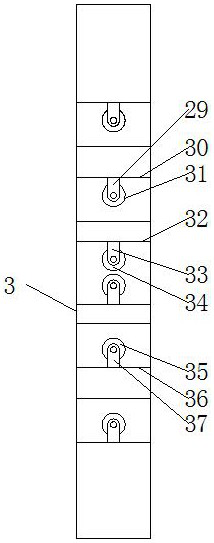

Cable line stranding device

The present invention discloses a cable line stranding device. The cable line stranding device comprises a circular bearing sleeve (1), a disc (2), a line-outgoing coil (3), a line-outgoing coil support (4), a support platform (7) and a motor (8). The motor (8) is located at the lower portion of the support platform (7), and the disc is embedded in the circular bearing sleeve (1); and the circular bearing sleeve (1) is vertically disposed at the upper surface of the support platform (7), and the line-outgoing coil (3) is installed at the top end of the line-outgoing coil support (4) and is in parallel with the disc (2). According to the invention, a motor is configured to drive the rotation of a disc, single lines shunted to each disc hole are stranded, so that the softness and the integrity of cable lines are improved, the wires may be uniformly and rapidly stranded together and the production processing efficiency and the quality of the cable lines are improved.

Owner:程友根

High-speed branching device of stranding machine

ActiveCN104900342AImprove efficiencyReduce mutual wearCable/conductor manufactureCopper wireConical surface

The invention discloses a high-speed branching device of a stranding machine. The branching device comprises a carriage, a branching plate and a reserved plate, wherein the branching plate and the reserved plate are successively fixed on the carriage along the copper wire inlet direction, each of the branching plate and the reserved plate is provided with wire through holes, a wire inlet unit is fixed at the axial center of the reserved plate, and the carriage is provided with two connecting rods in a sliding manner. The moving ends of the two connecting rods are connected with each other via an adjusting loop, a wire inlet is formed in the adjusting loop, the upper portion of the wire inlet is provided with an inner conical surface, and the lower portion of the wire inlet is provided with balls. The inner wall of the wire inlet unit is rotatably provided with an adjusting ring whose internal diameter is the same with that of the wire inlet unit, an arc chute is formed in the outer wall of the wire inlet unit, and a push rod is connected with the adjusting ring by penetrating the arc chute. The adjusting loop is slidably arranged on the carriage via the connecting rod, thus, the adjusting loop can be slid according to the practical diameter of copper wires, and wearing between the copper wires and the wire inlet as well as an upper inlet of the twisting machine can be reduced.

Owner:重庆星达铜业有限公司

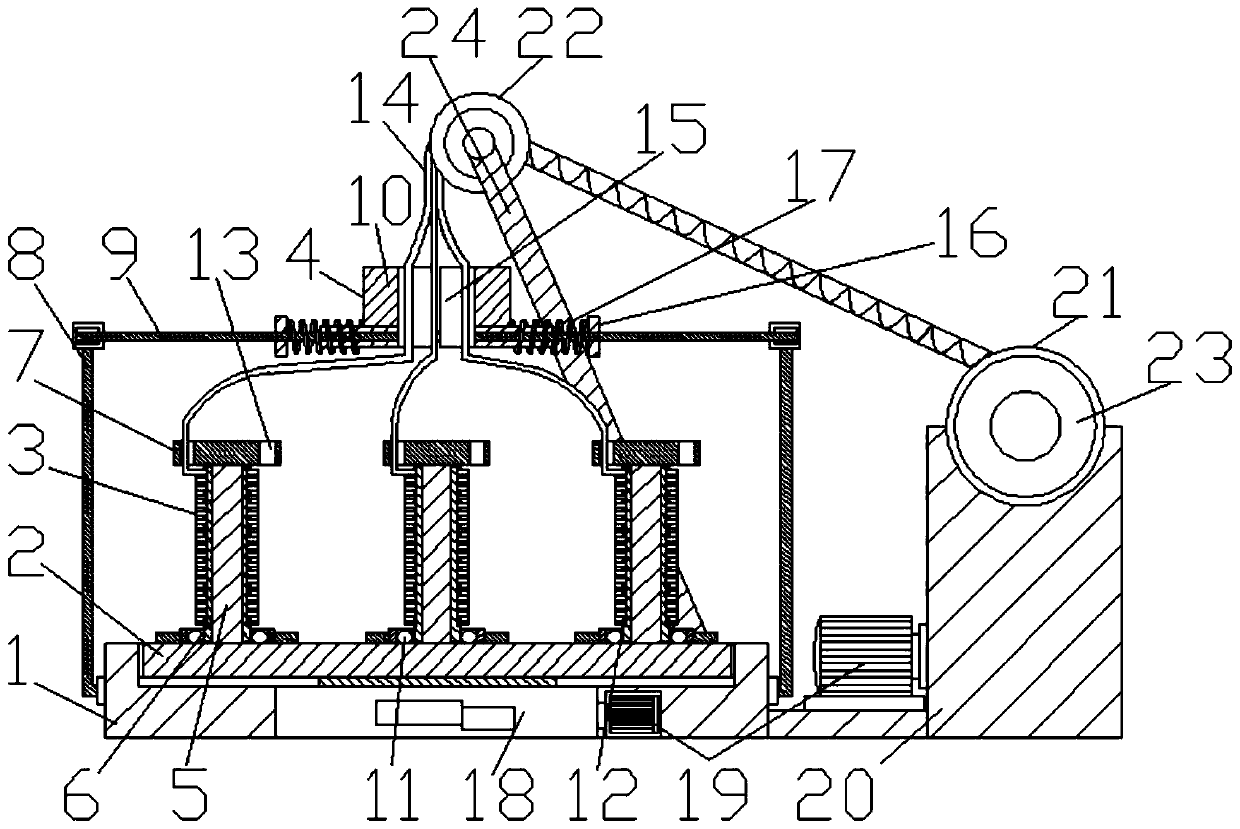

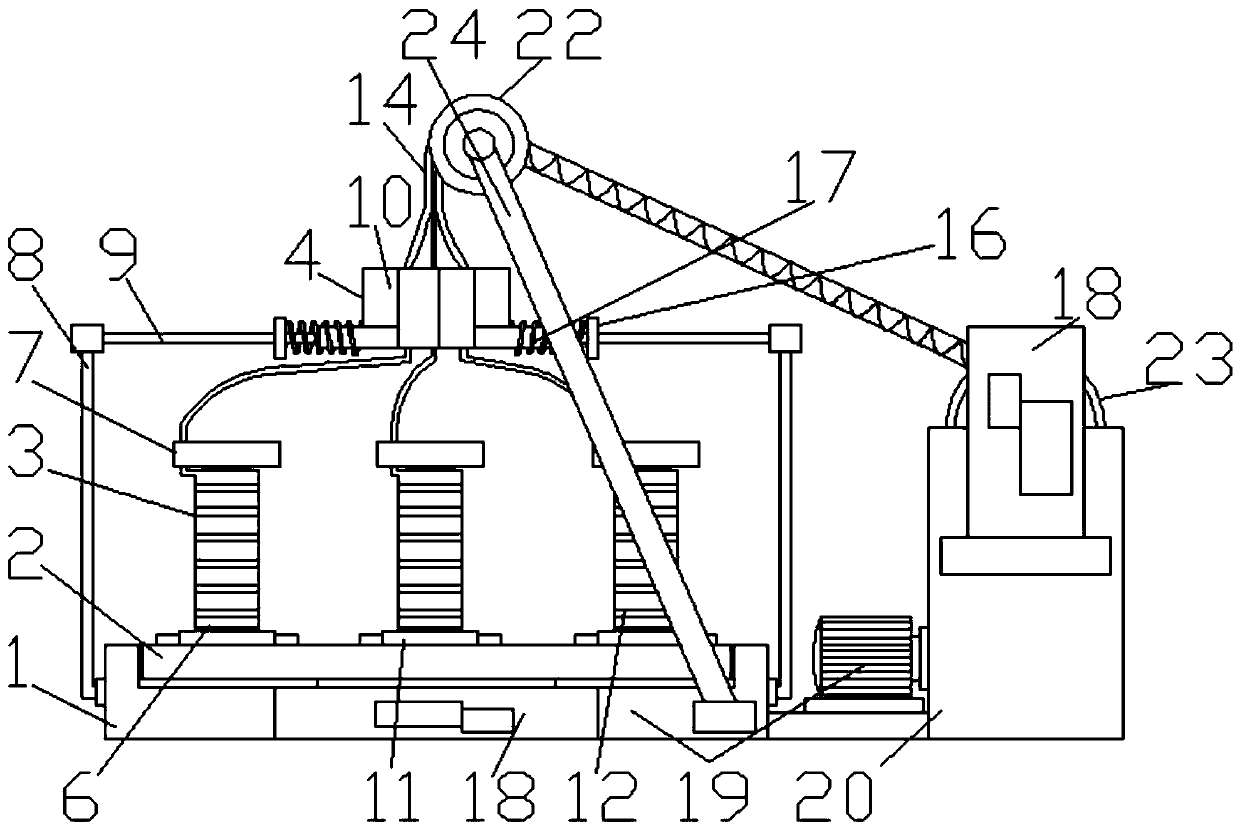

Automatic stranding machine for marine waterproof cable production

InactiveCN110767385ARealize the twisted functionEasy to transportCable/conductor manufactureMarine engineeringStructural engineering

The invention discloses an automatic stranding machine for marine waterproof cable production, which comprises a support base, take-up devices, a gathering device and a conveying device, wherein a rotating disc is arranged in the middle of the top end of the support base, the take-up device is arranged above the top end, and the left and right end surfaces of the support base are rotationally connected with the bottom end of the gathering device respectively. Through rotation between the rotating disc and the support base, the multiple take-up devices integrally rotate along with the rotation,a single-strand cable stranding function is achieved, and the structure is simple, flexible and ingenious; besides, the collecting quality is enhanced through the gathering device; a vertical rod anda transverse rod can rotate in respective space planes and the adaptability is high; multiple strands of cables are adjusted and gathered through a pressing spring and a gathering block, wire stranding is facilitated, friction damages to the cable and reduction of the quality safety during the wire stranding process are prevented, and finally, an automatic stranding production function is achieved through a take-up wheel, and good stranding quality guarantee is achieved.

Owner:安徽华上电缆科技有限公司

Stranding device for cable and implementation method thereof

InactiveCN111883315AImprove fixation efficiencyPrevent disengagementCable/conductor manufactureEngineeringStructural engineering

The invention discloses a stranding device for a cable and an implementation method thereof, and belongs to the technical field of cable stranding devices. The stranding device comprises a workbench plate, a stranding support is fixed at the upper end of the workbench plate, the front end of the stranding support is connected with a fixing plate, a wire outlet hole is formed in the fixing plate, and a stranding assembly is arranged in the stranding support; and a wire guiding device is arranged at the rear end of the stranding assembly. According to the stranding device for the cable and the implementation method of the stranding device, stranding of multiple strands of wires is facilitated, the stranding efficiency is improved, the fixing efficiency of the multiple strands of wires is improved, disengagement is avoided, the sealing ring pad is arranged on the inner wall, friction between the sealing ring pad and the wires is increased, the wires are straightened in the stranding process, and a dredging effect is achieved; double dredging is carried out on the wire by arranging the wire disc and the wire ring, the dredging efficiency is improved, knotting is prevented, the space issaved, the collected cable is convenient for post-processing, and the next collection is not influenced.

Owner:安徽和光电气设备有限公司

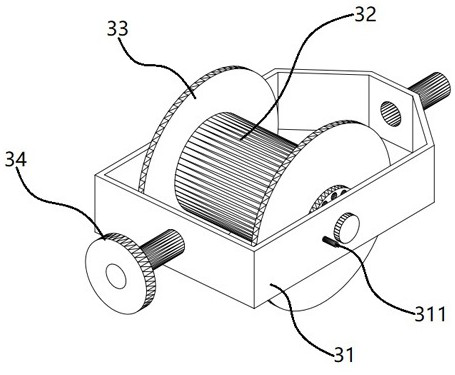

Stranding machine and wire retreating device thereof

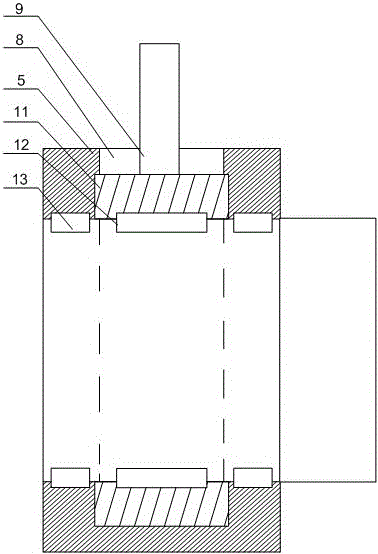

The invention discloses a stranding machine and a wire retreating device thereof. The wire retreating device comprises a revolving and supporting device, a bobbin loader which is rotatably arranged on the revolving and supporting device, a first driving device which drives the bobbin loader to rotate and a second driving device which is arranged on the bobbin of the bobbin loader and drives the bobbin to rotate. The rotating axis of the bobbin loader is perpendicular to that of the bobbin. With application of the arrangement, the problem of low stranding efficiency of the stranding machine can be effectively improved by the wire retreating device of the stranding machine.

Owner:HEFEI SMARTER TECH GROUP CORP

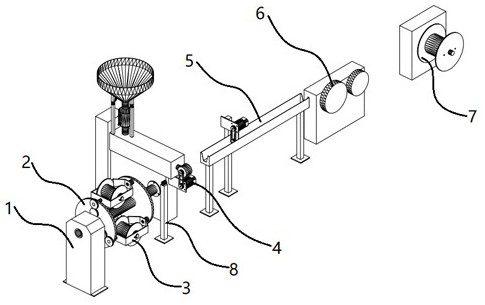

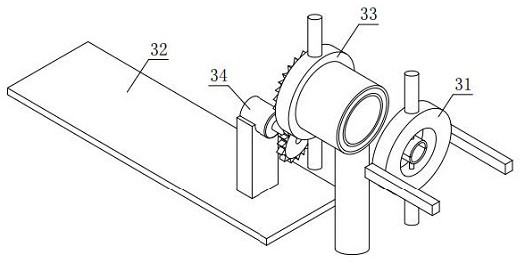

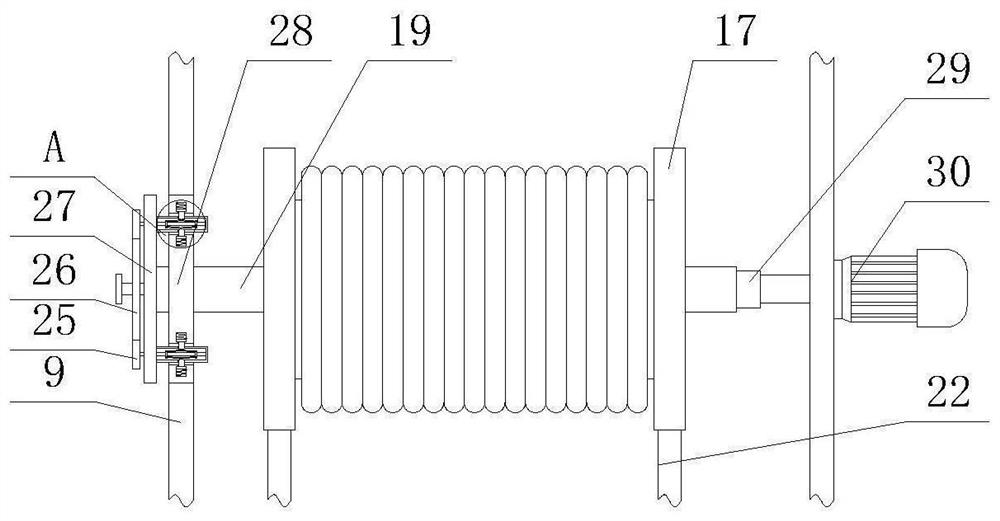

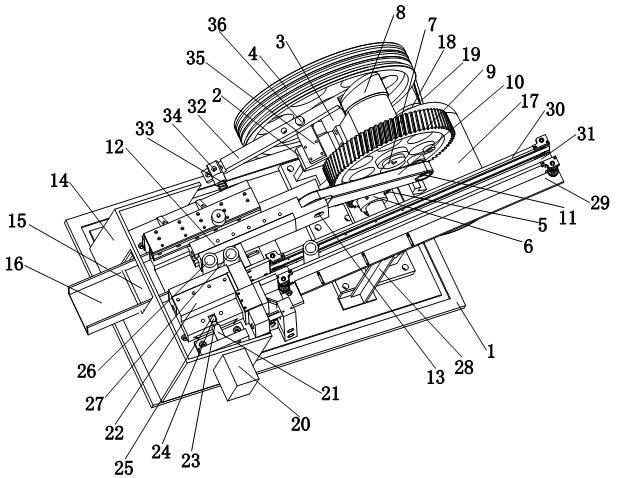

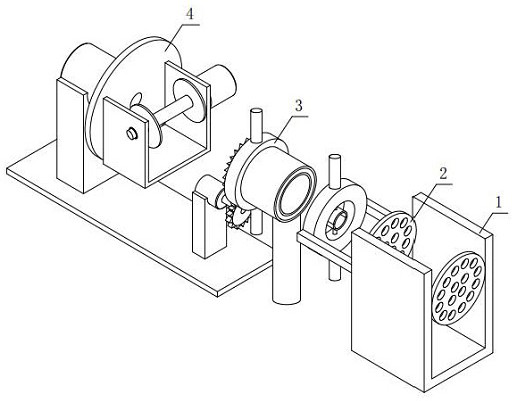

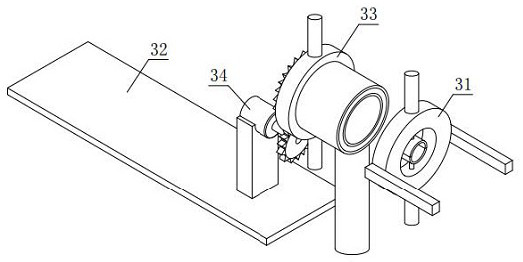

Automatic High Speed Stranding Machine

InactiveCN104376931BIngenious designImprove job stabilityCable/conductor manufactureGear wheelEngineering

The invention discloses an automatic high-speed stranding machine which comprises a high-rotation-speed servo motor, a spool, a variable leading wheel, a fixed leading wheel, a magnetic powder clutch, a flat cable mechanism, a spool seat, a left threading rotary shaft and a right threading rotary shaft. The left threading rotary shaft and the right threading rotary shaft are symmetrically disposed on two sides of the spool seat. The automatic high-speed stranding machine has the advantages that the machine is ingenious in design, component structure and layout are optimized reasonably, the high-rotation-speed servo motor and a high-precision bearing block are used, stranding efficiency is increased greatly, the highest rotation speed can reach 2500 turn / minute, and high work stability and good stranding quality are achieved; traditional gear transmission is replaced by belt pulley transmission, the structure is effectively simplified while simple and convenient operation is achieved, when the stranding distance needs to be adjusted, an operator only needs to select the belt pulley with corresponding tooth number in A-group, B-group, C-group and D-group belt pulleys to match with the required stranding distance, fast adjusting, flexible matching, wide stranding distance adjusting range, time saving and labor saving are achieved, a large amount of time and manpower is saved effectively, and the machine is wide in application range and beneficial to widely popularization and application.

Owner:DONGGUAN NEW ENSHIANG MACHINERY ENTERPRISE

High-strength steel strand producing, manufacturing and stranding processing machine

InactiveCN113279274AImprove stranding qualityAvoid entanglementRope making machinesStructural engineeringManufacturing engineering

The invention relates to a high-strength steel strand producing, manufacturing and stranding processing machine. The high-strength steel strand producing, manufacturing and stranding processing machine comprises a bottom plate, a driving device, a stranding device, a clamping device and a winding device. The stranding processing machine can solve the following problems in the stranding process of steel wires: a, the number of wire harnesses of the steel wires is relatively large, traditional stranding equipment cannot position, install and guide steel wire coils easily, so that the phenomenon that the steel wires are wound easily in the stranding process is caused, consequently, the stranding is blocked or the stranding quality is relatively poor, and the stranded steel strands cannot be put into use; and b, the mounting positions of the steel wire coils are mostly fixed, so that when different strands of steel wires are stranded and adjusted, the mounting positions of the steel wire coils cannot be changed, the included angles between the stranded steel wires are not uniform, the polymerization degree of the stranded steel strands is relatively poor, and the overall performance of the steel strands is reduced.

Owner:武亮

Tubular stranding machine for cable processing

InactiveCN112885533AQuality assuranceReasonable designCable/conductor manufactureStructural engineeringElectric cables

A tubular stranding machine for cable processing disclosed by the present invention comprises a mounting base, one side of the upper end of the mounting base is fixedly connected with a pay-off reel, a mounting block is fixed at the extension position of one end of the pay-off reel, a pay-off roller is rotatably connected between the two mounting blocks in the same group, one side of the mounting base is provided with a mounting rack, and the mounting rack is provided with a pay-off roller. A straightening block is fixed to the top face of the mounting frame, a cylindrical hole is formed in the extension portion of the end, close to the mounting base, of the straightening block, heating pieces are fixed to the inner wall of the cylindrical hole, a rectangular groove is further formed in the extension position of the other end of the straightening block and communicates with the cylindrical hole, and straightening rollers are rotationally connected to the inner walls of the front side and the rear side of the rectangular groove. Fixing seats are further arranged on the sides, away from the mounting base, of the mounting frames, and supporting plates are further fixedly connected to the lower ends of the two fixing seats. The stranding machine is reasonable in design, stable in device operation and high in stranding efficiency, and cable raw materials are straightened before stranding, so that the quality of cable stranding is well guaranteed.

Owner:安徽维尔特仪表线缆有限公司

A high-speed stranding machine wire passing device

The present invention discloses a line passing device of a high-speed stranding machine. The line passing device comprises a bracket, and a distributor plate and a reserved plate which are fixed on the bracket in turn along a copper line incoming direction, wherein a plurality of line passing holes are disposed in the distributor plate and the reserved plate, a line entering device is fixed in the axis of the reserved plate, two connecting rods are arranged in a sliding manner at the bracket, free ends of the two connecting rods are connected with each other through an adjusting ring, a line entering hole is disposed in the adjusting ring, an inner circular conical surface is arranged at the upper part of the line entering hole, a plurality of roll balls are arranged at the lower part of the line entering hole, and the adjusting ring is arranged in a sliding manner on the bracket through the connecting rods, that is, the position of the adjusting ring can be adjusted in a sliding manner according to the diameter of an actual copper line, thereby reducing abrasion between the copper lines and the line entering hole and between the inlet of the stranding machine.

Owner:CHENGDU XINGDA OF COPPER CO LTD

Insulated cable production stranding equipment

PendingCN114566330AImprove efficiencySupport wellInsulating conductors/cablesWire segmentStructural engineering

Owner:HUZHOU VOCATIONAL & TECH COLLEGE (HUZHOU RADIO & TELEVISION UNIV) (HUZHOU COMMUNITY UNIV)

A stranding device for composite cable production and its use method

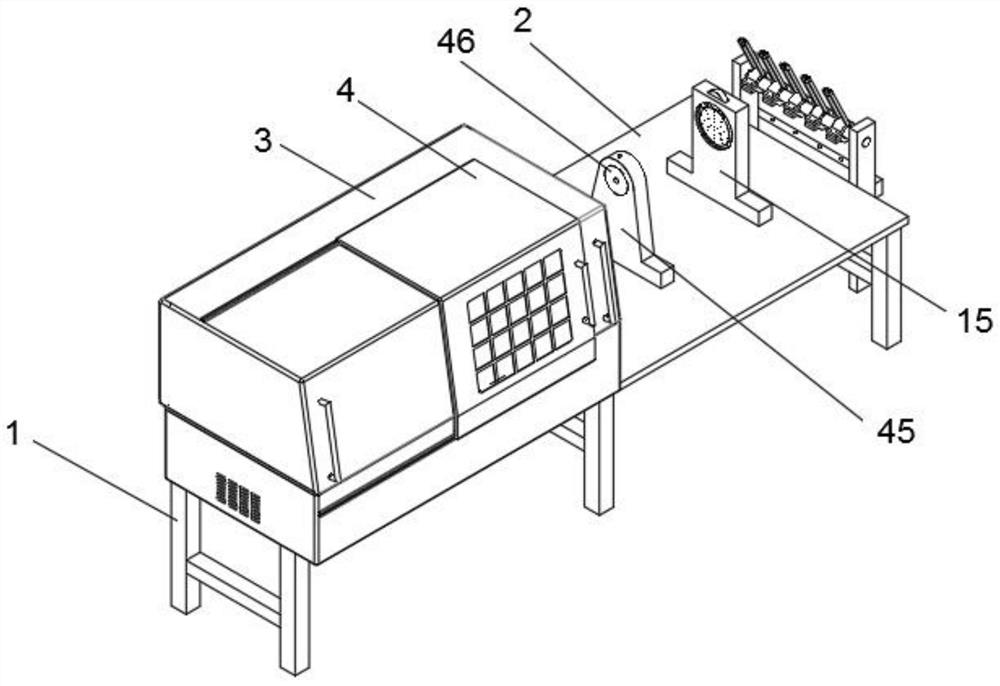

ActiveCN108695026BImprove stranding efficiencyProtective winding operationCable/conductor manufacturePower switchingStructural engineering

The invention discloses a wire stranding device for composite cable production, which comprises a wire strander, a control device, a conveying device, a wire stranding device and a gathering device, wherein the front side of the shell of the wire strander is provided with the control device; the upper side of the shell of the wire strander is provided with the conveying device; one side of the conveying device is provided with the wire stranding device; one side of the wire stranding device is provided with the gathering device; and the control device comprises a console, a circuit board, a control chip, a power switch, a digital keyboard, a keyboard control chip, a display screen, a display driver chip, a loudspeaker and an audio control chip. The wire stranding device for composite cableproduction and the use method have the beneficial effects that fully-automatic wire stranding operation can be carried out on the composite cable, wire stranding adopts a wire stranding frame for rotating operation, protection wire winding operation is carried out on the composite cable after wire stranding is completed, and fully-automatic gathering operation can be carried out on the cable after wire stranding is completed.

Owner:福建鼎力电缆科技有限公司

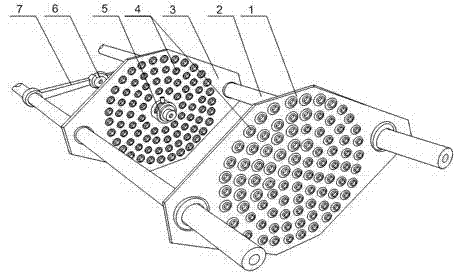

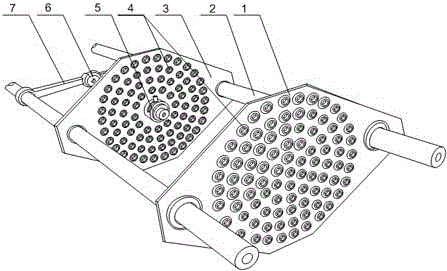

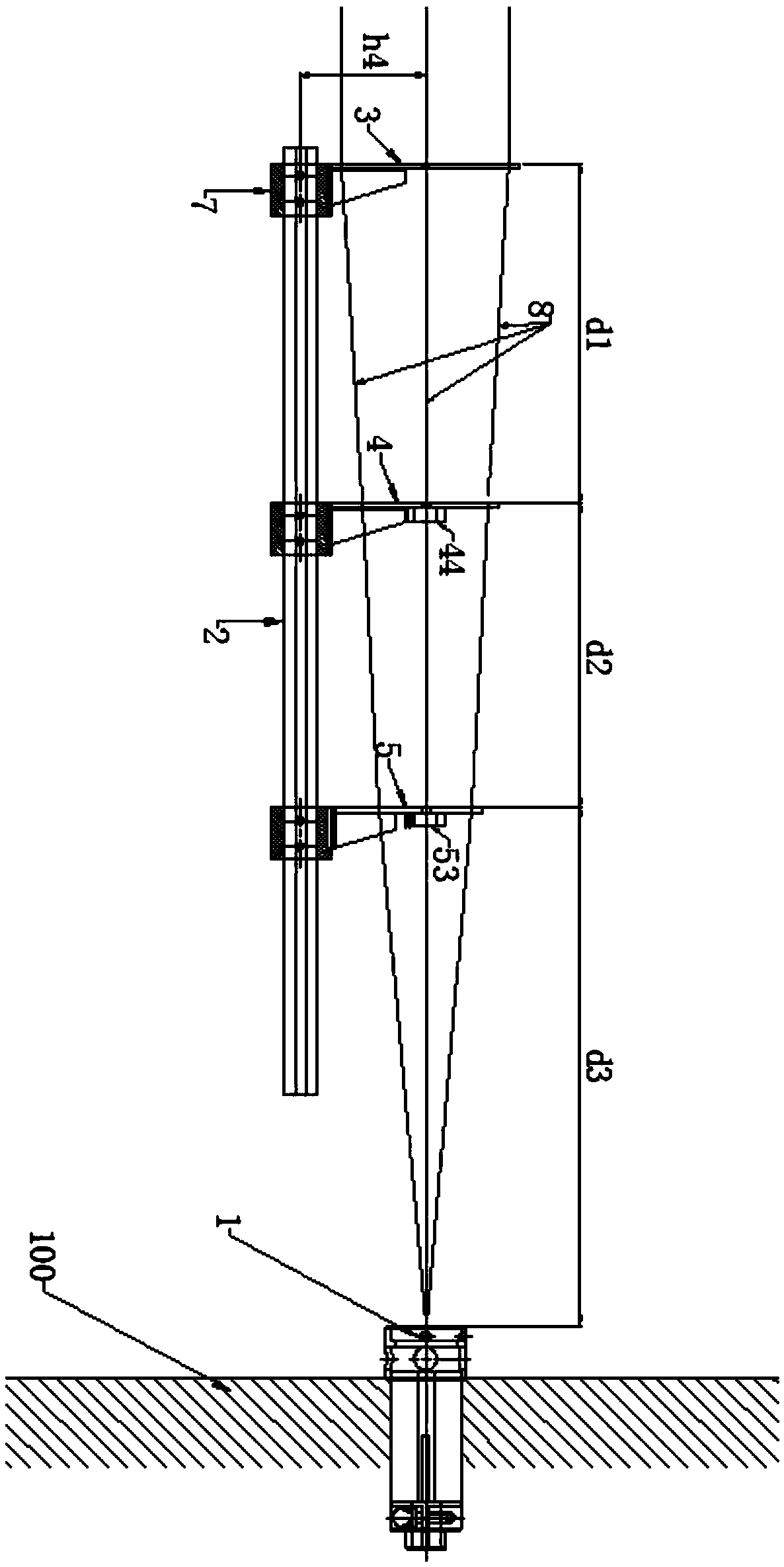

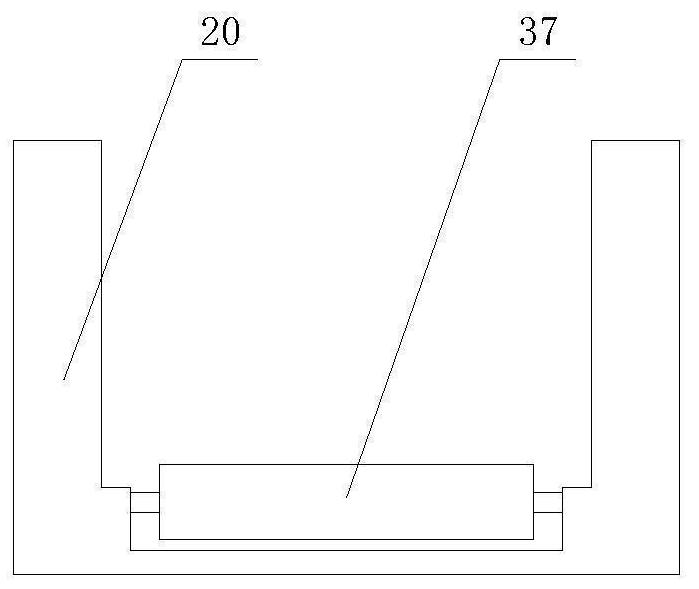

Stranded wire passing system and twisted wire passing method of high speed stranding machine

ActiveCN107221391BImprove yieldNot easy to wearCable/conductor manufactureElectrical conductorCopper wire

The present invention discloses a wire-stranding and wire-crossing system of a high-speed wire-stranding machine. The wire-stranding and wire-crossing system comprises a fixed link and distributor plates fixed on the fixed link, the distributor plates comprises a first distributor plate, a second distributor plate and a third distributor plate along the wire-stranding and wire-crossing direction, the centers of the distributor plates and the center of an eye model at a main shaft end are located on the same straight line, wire-crossing holes configured to allow wire materials to pass through are distributed on the distributor plates, the center of the second distributor plate is provided with a second middle eye model, and the center of the third distributor plate is provided with a third middle eye model; and the diameter of the first distributor plate is larger than the diameter of the second distributor plate, and the diameter of the second distributor plate is larger than the diameter of the third distributor plate. The arrangement mode of the wire-crossing holes of the distributor plates are improved to improve the introduction angles of the wire materials so as to reduce the resistance, allow the wire materials not to be stretched and deformed and improve the yield; the wire-crossing holes of the distributor plates are not easy to be worn, and the service life is prolonged; and moreover, the wire-stranding and wire-crossing method is simple and easy to enforce, the prepared products are not easy to deform, and the wire-stranding and wire-crossing method is specially suitable for stranding preparation of conductor wires such as copper wires and the like.

Owner:昆山金源光电科技有限公司

Wire winch device for steel wire rope production and implementation method thereof

ActiveCN113512894AQuality improvementGuaranteed efficiencyRope making machinesManufacturing engineeringWire rope

The invention discloses a wire winch device for steel wire rope production and an implementation method thereof, and belongs to the technical field of steel wire rope wire winches. The wire winch device for steel wire rope production comprises a mounting seat frame, wherein a dredging device is arranged in the mounting seat frame, and a clamping and stranding assembly connected with the mounting seat frame is arranged behind the dredging device; a winding assembly is arranged at the rear ends of the clamping and stranding assembly and the dredging device. According to the wire winch device for steel wire rope production and the implementation method thereof, the wire quality is improved, the influence of wire bending on the stranding quality is reduced, the wire stranding efficiency is effectively guaranteed, the steel wire rope quality is improved, a winch assembly can conveniently conduct stranding, the stranding stability is improved, the situation that a wire body shakes is prevented, and wire displacement is reduced; the next wire set is subjected to stranding, the stranding efficiency is improved, the winch assembly has the same rotation frequency, the situation that a steel wire rope loosens after being stranded is prevented, the winding efficiency is improved, the compactness of the steel wire rope is guaranteed, and the quality of the wound steel wire rope is improved.

Owner:南通市一帆钢绳有限公司

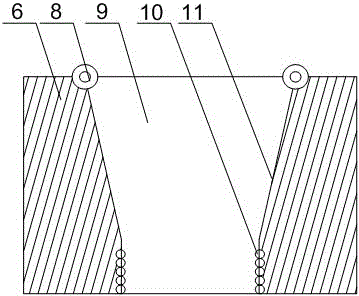

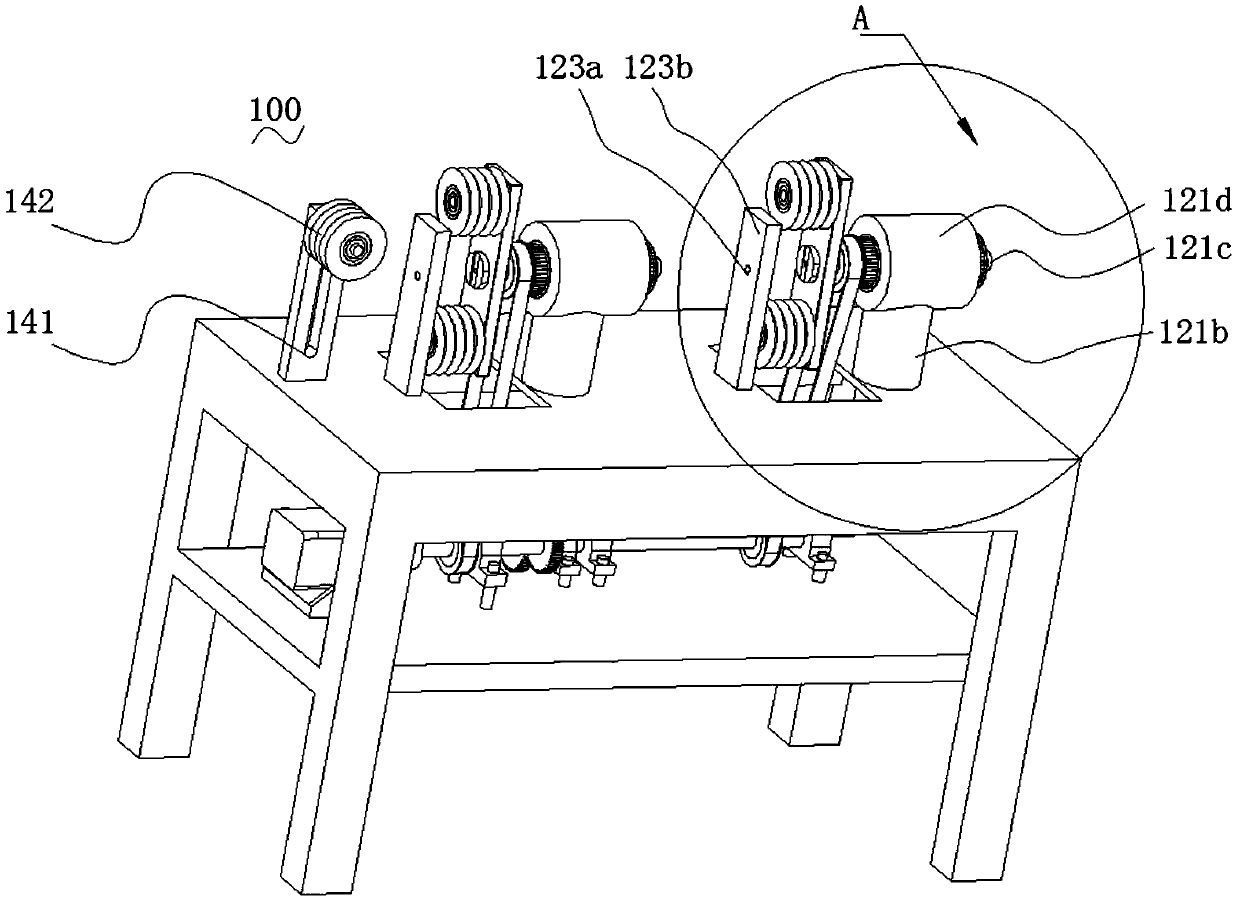

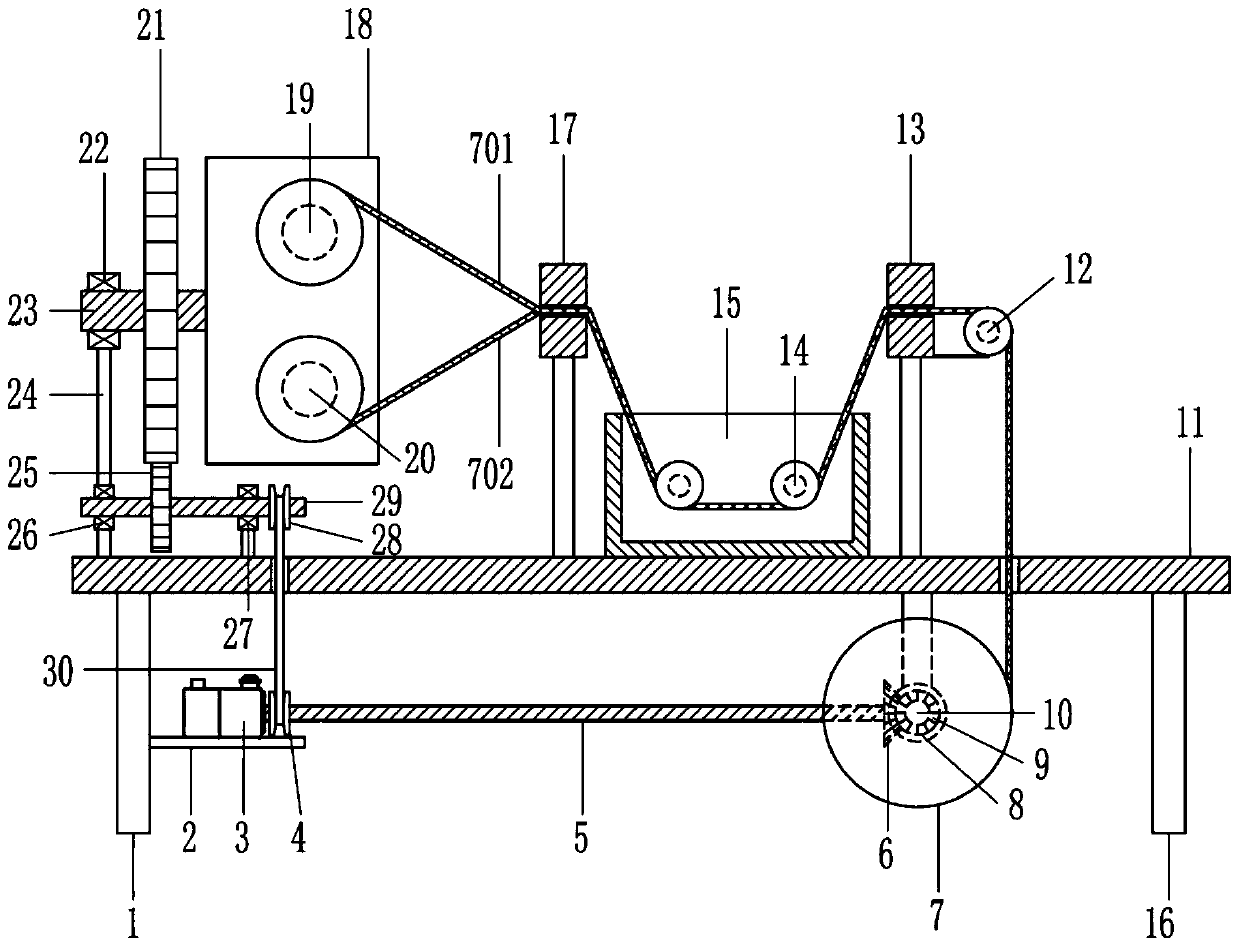

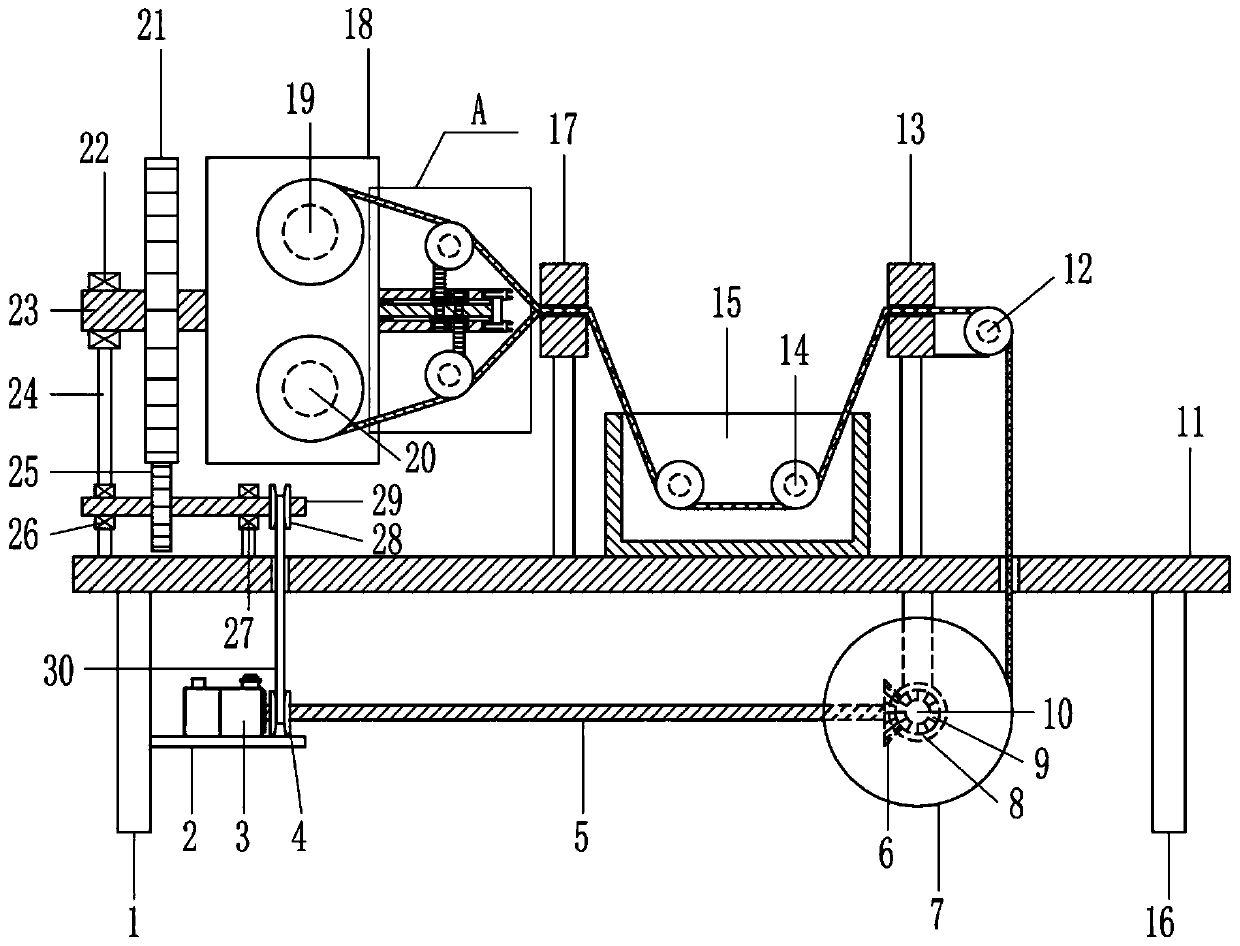

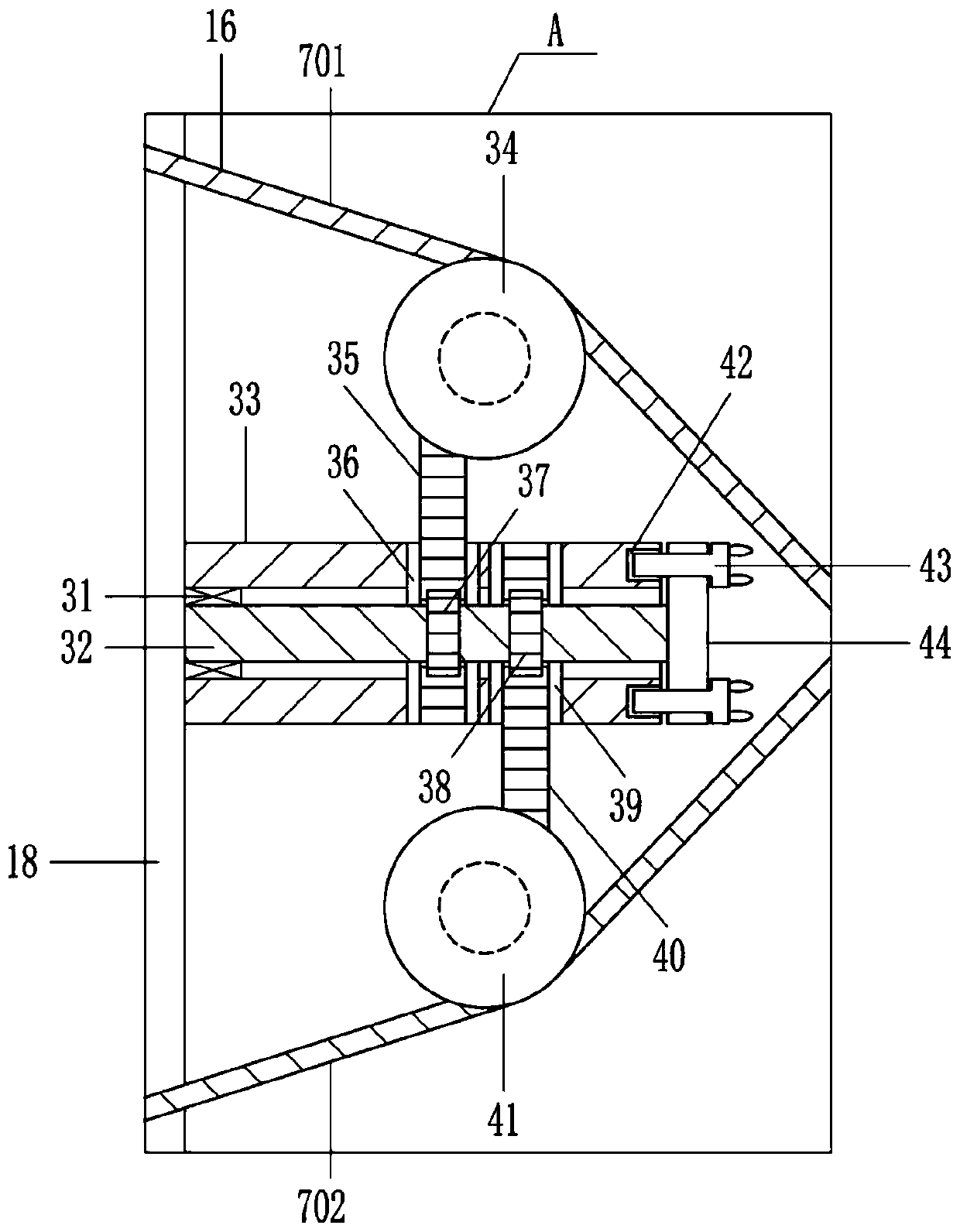

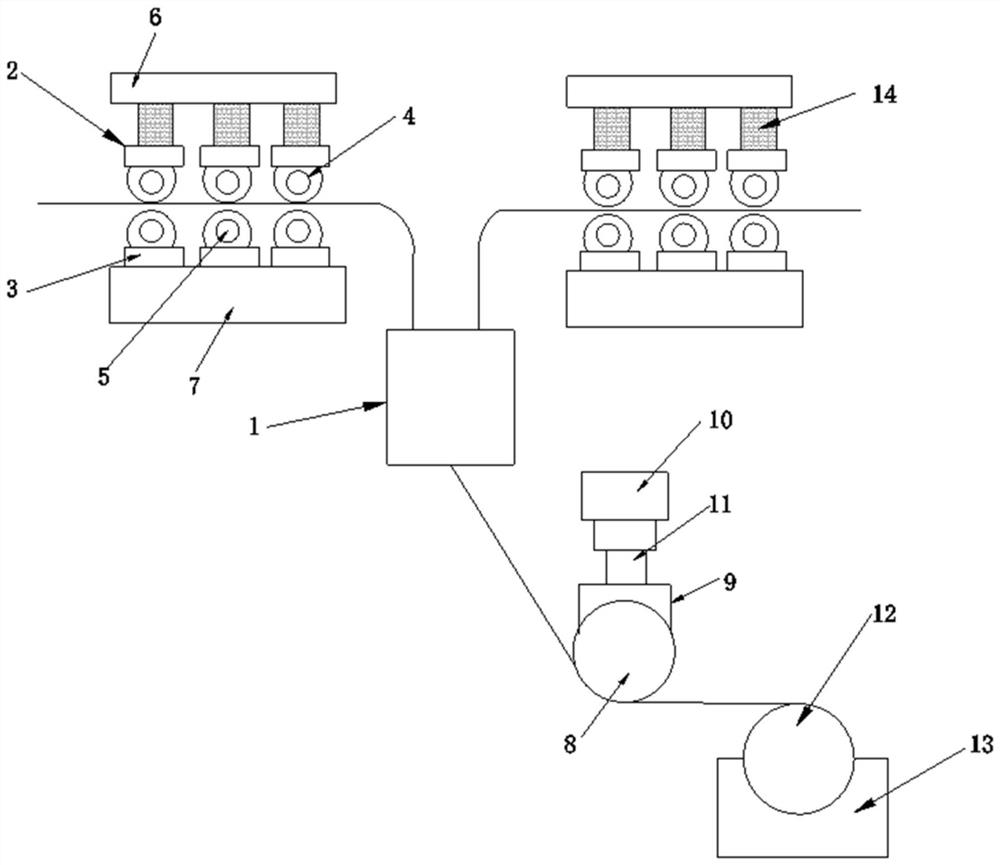

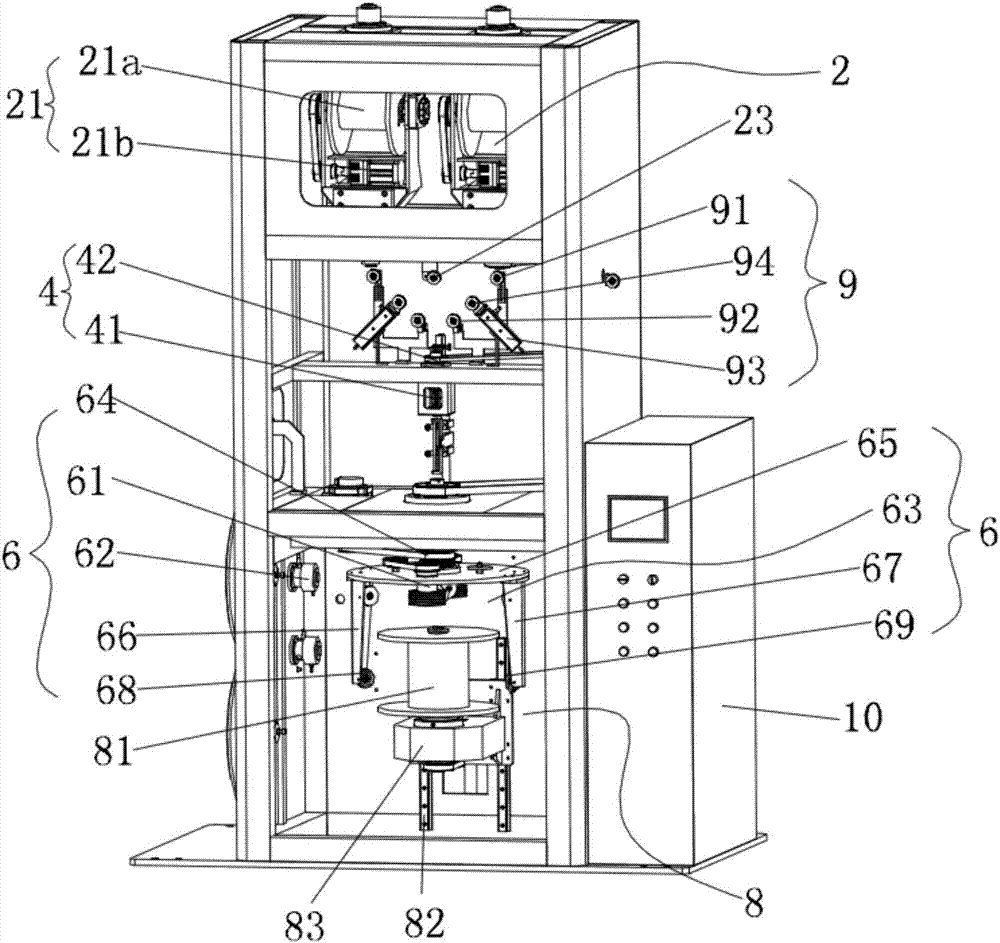

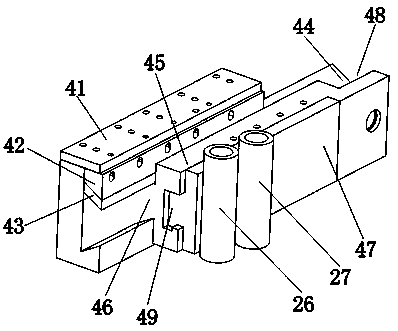

High quality cable production system

ActiveCN107481804BAvoid spreadingWon't call backApparatus for feeding conductors/cablesInsulating conductors/cablesEngineeringSmall footprint

The invention relates to the field of wire twisting machines, in particular to a high-quality cable production system. The system comprises a wire twisting machine which comprises a wire twisting platform, multiple wire twisting mechanisms installed on the wire twisting platform and a power mechanism which is installed below the wire twisting platform and used for providing power for the wire twisting mechanisms, and the wire twisting directions of the two adjacent wire twisting mechanisms are opposite; each wire twisting mechanism comprises a wire inlet unit used for wire incoming, a twisting unit connected to the output end of the wire inlet unit and a wire passing unit which is arranged parallel to the wire inlet unit and located on the side, deviating from the wire inlet unit, of the twisting unit for wire passing after twisting; a wire inlet hole is formed in each wire inlet unit, a wire outlet hole is formed in the portion, corresponding to each wire inlet hole, of the corresponding twisting unit, a wire passing hole is formed in the portion, corresponding to each wire outlet hole, of the corresponding wire passing unit, and wire inlet holes, the wire outlet holes and the wire passing holes are located on a straight line. The wire twisting machine is high in production efficiency, good in wire twisting quality and small in occupied area.

Owner:东莞市卡源电子有限公司

High-speed stranding machine splitter

The invention discloses a high-speed branching device of a stranding machine. The branching device comprises a carriage, a branching plate and a reserved plate, wherein the branching plate and the reserved plate are successively fixed on the carriage along the copper wire inlet direction, each of the branching plate and the reserved plate is provided with wire through holes, a wire inlet unit is fixed at the axial center of the reserved plate, and the carriage is provided with two connecting rods in a sliding manner. The moving ends of the two connecting rods are connected with each other via an adjusting loop, a wire inlet is formed in the adjusting loop, the upper portion of the wire inlet is provided with an inner conical surface, and the lower portion of the wire inlet is provided with balls. The inner wall of the wire inlet unit is rotatably provided with an adjusting ring whose internal diameter is the same with that of the wire inlet unit, an arc chute is formed in the outer wall of the wire inlet unit, and a push rod is connected with the adjusting ring by penetrating the arc chute. The adjusting loop is slidably arranged on the carriage via the connecting rod, thus, the adjusting loop can be slid according to the practical diameter of copper wires, and wearing between the copper wires and the wire inlet as well as an upper inlet of the twisting machine can be reduced.

Owner:重庆星达铜业有限公司

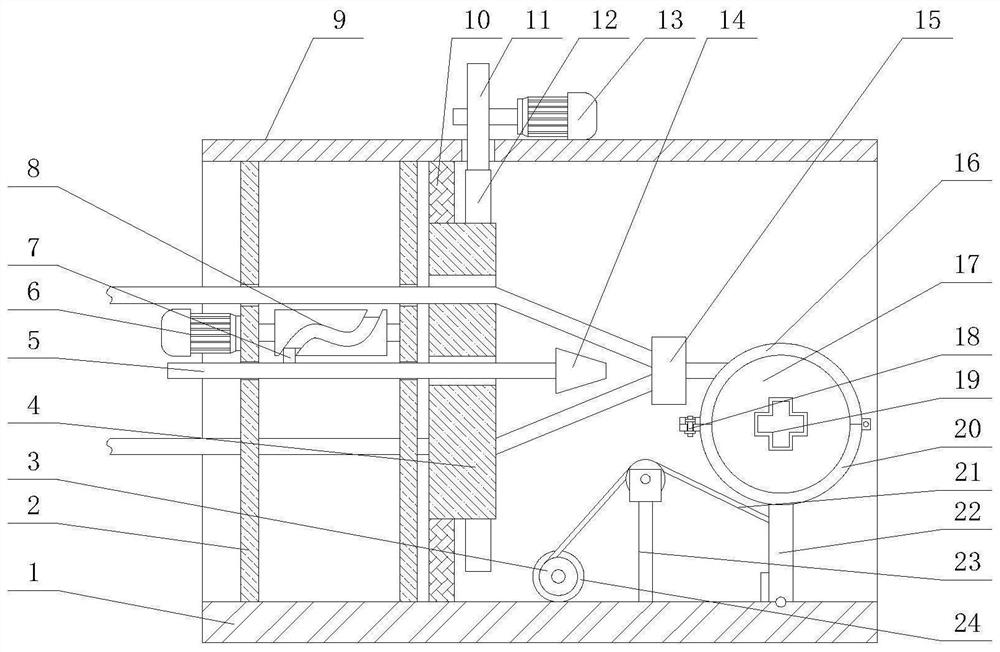

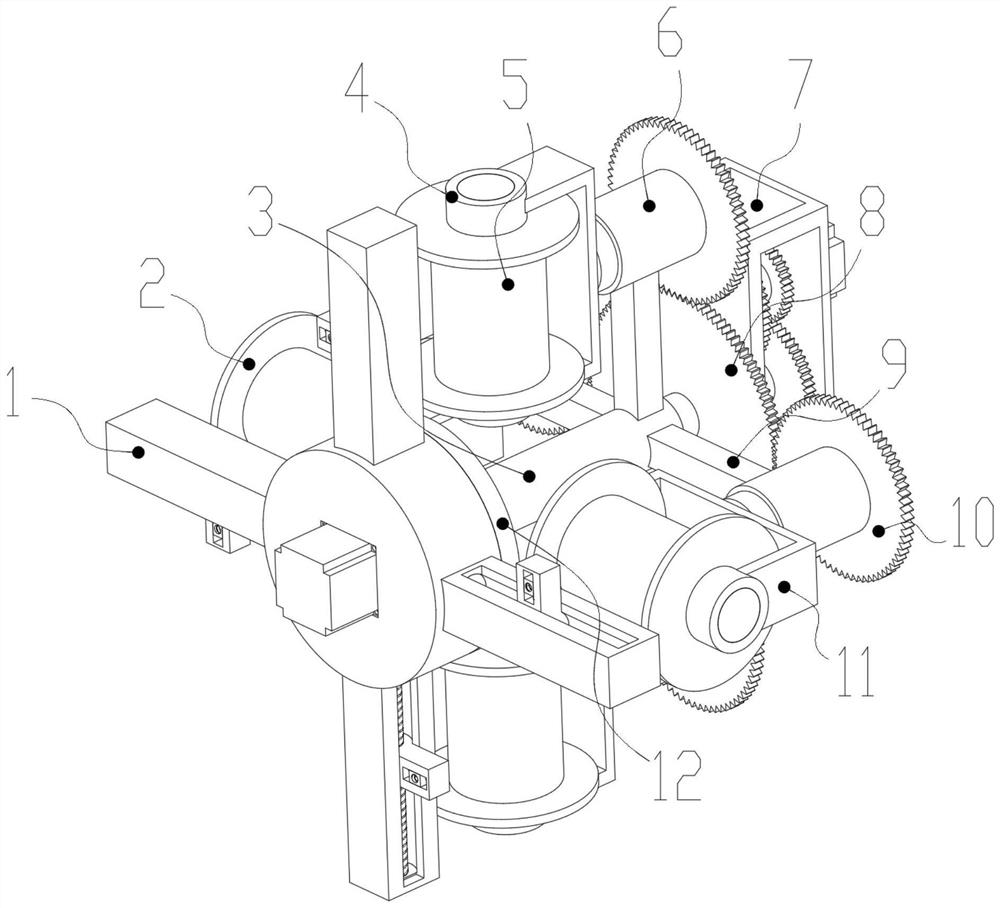

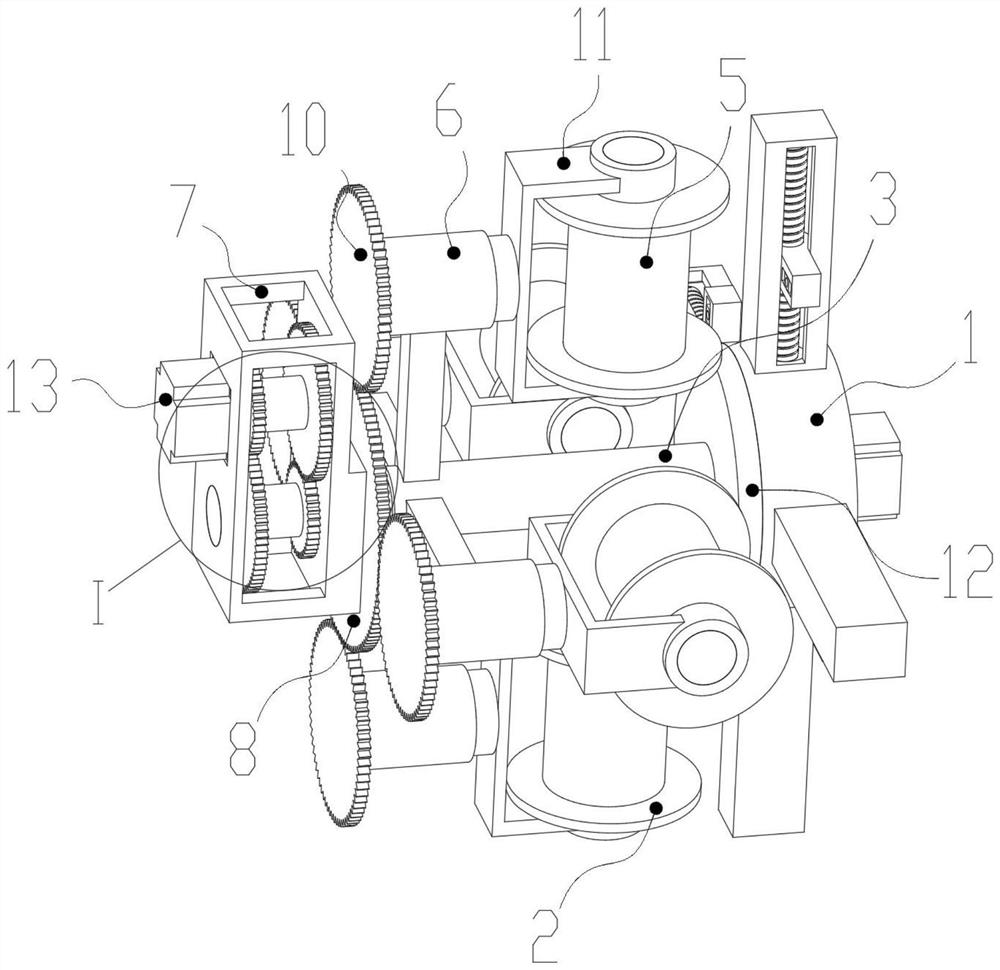

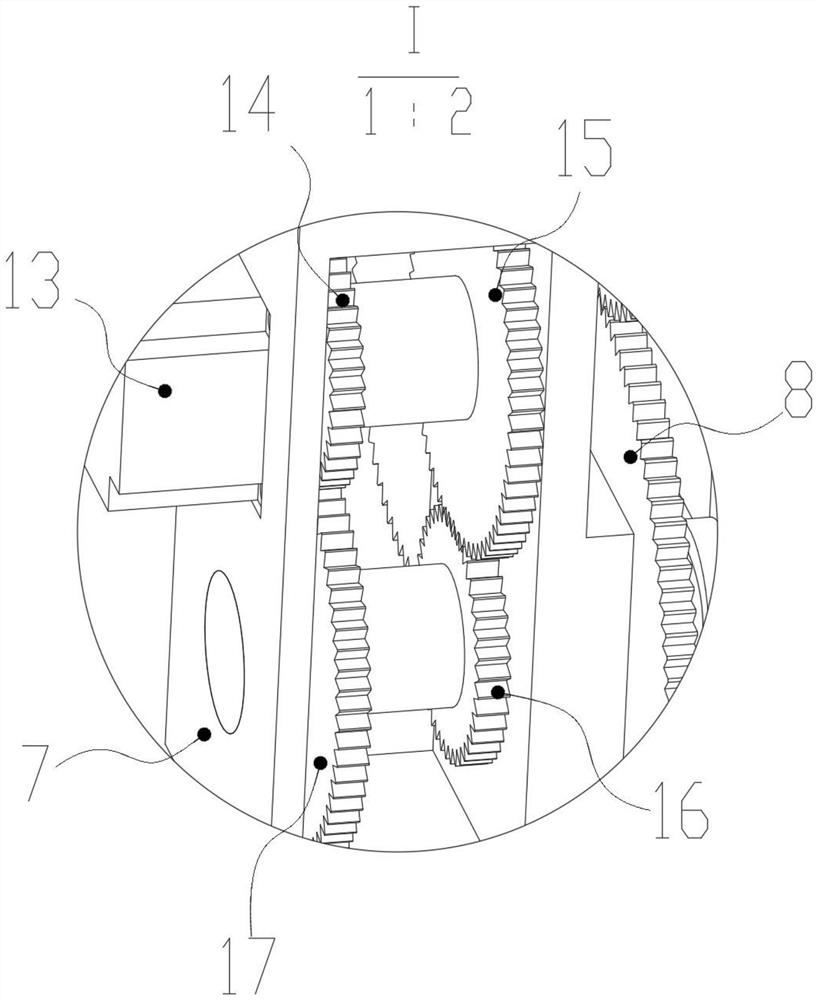

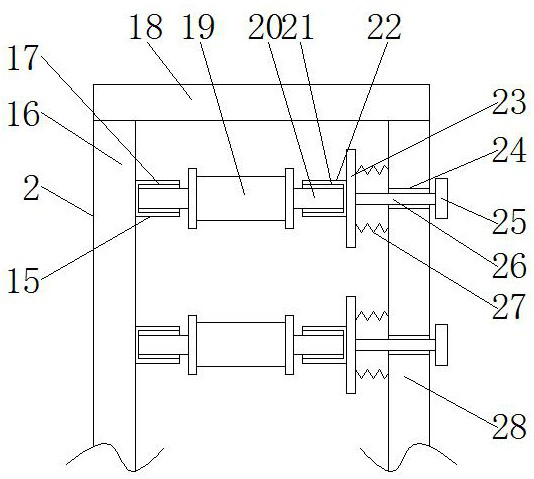

A high-safety wire stranding machine

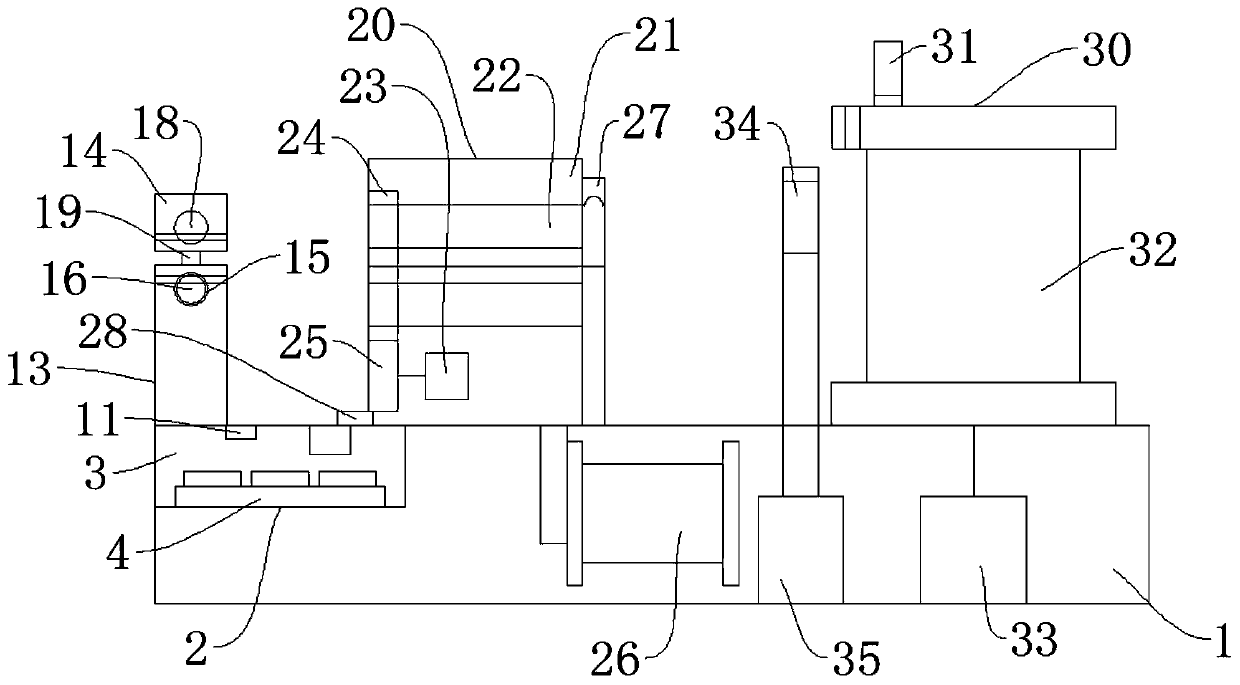

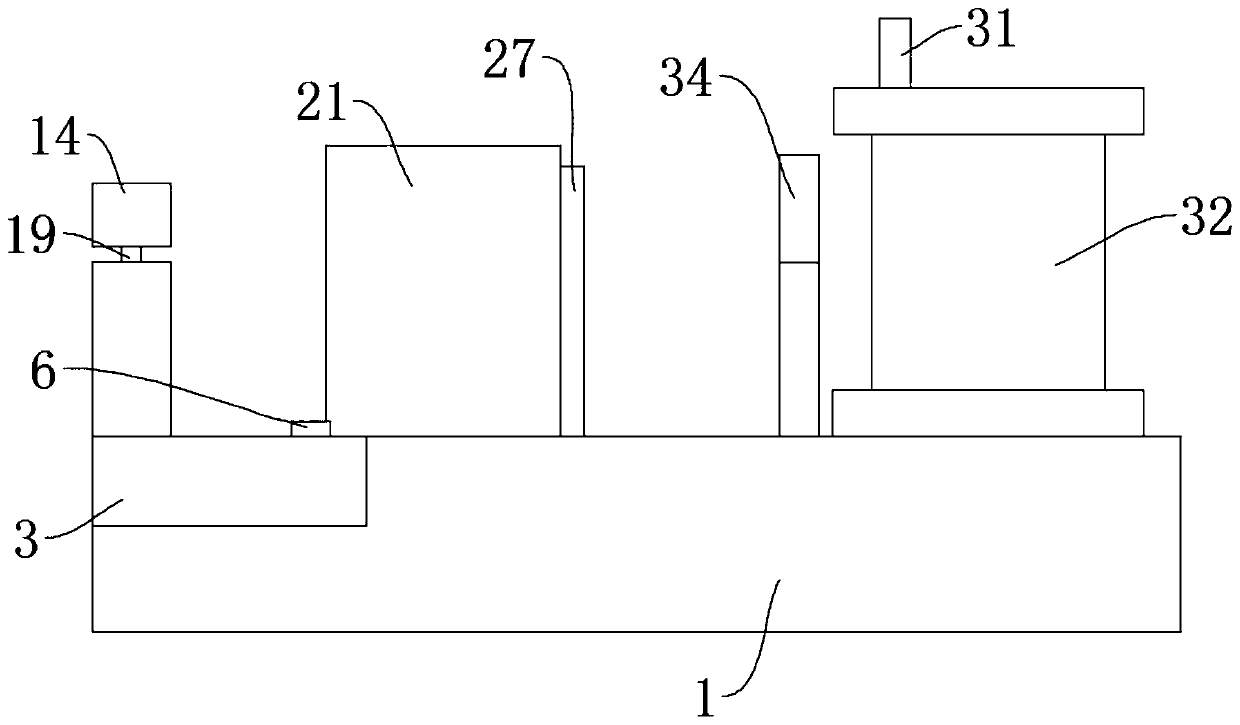

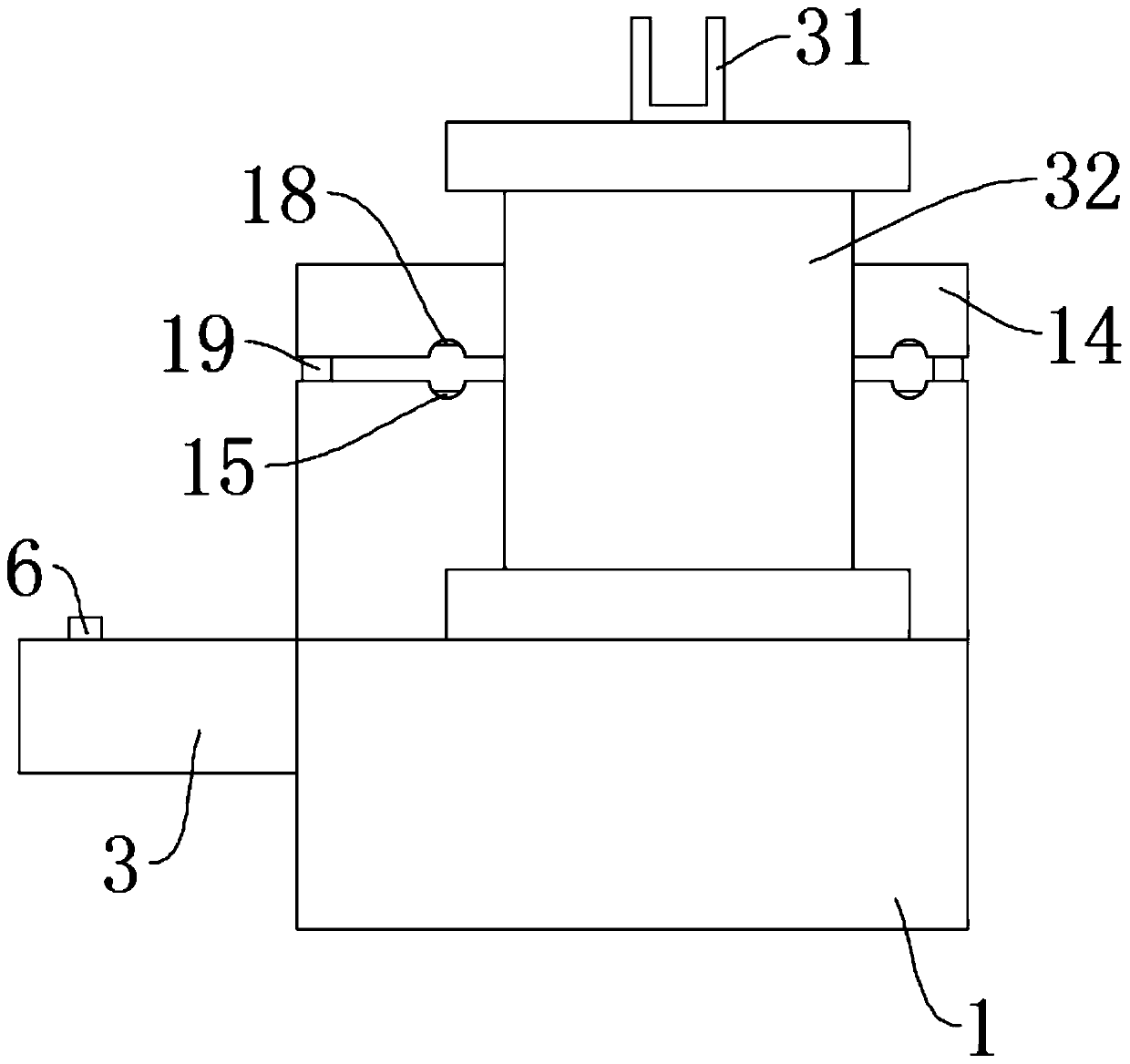

ActiveCN108711474BEasy to cleanImprove stranding efficiencyCable/conductor manufactureSafety wireBobbin

The present invention relates to the field of wire manufacturing, and specifically to a high-security wire stranding machine. The technical problem to be solved by the present invention is to providea high-security wire stranding machine with high stranding efficiency and easy cleaning of impurities. The high-security wire stranding machine comprises a first pillar, a first fixed plate, a drivingmotor, a first transmission wheel, a first rotating shaft, a first bevel gear, a first bobbin, a first bearing seat, a second bevel gear, a second rotating shaft, a table plate, a first guide wheel,a wiping block, a second guiding wheel, a cleaning tank, a second pillar, a guide frame, a mounting plate, a second bobbin, a third bobbin, a circular gear, a second bearing seat, a third rotating shaft, a second fixed plate, a second circular gear, a third bearing seat, a fourth bearing seat, a second transmission wheel, a fourth rotating shaft, a transmission belt and the like. The high-securitywire stranding machine in the invention achieves the effects of high stranding efficiency and easy cleaning of impurities.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

A high-performance ultra-flexible transmission line for aerospace

ActiveCN112233858BReduce labor intensitySaves twisting timeApparatus for feeding conductors/cablesElectrical conductorSilver plate

The invention discloses a high-performance ultra-flexible transmission line for aerospace, which comprises a conductor, an inner insulating layer and an outer insulating layer. It is made of twisted silver soft copper thin wires. The twisting device of the high-performance ultra-flexible transmission line for aerospace includes a chassis and a lifting plate. By setting the lifting plate and the telescopic hydraulic rod, the telescopic hydraulic rod is used to drive the lifting plate up or down. Movement, so as to carry the winding bobbin, reduce the labor intensity of manual handling, save the twisting time, and improve the efficiency of twisting, by setting the torsion spring and the thread take-up lever, and rotating between the thread take-up levers arranged in parallel Install the take-up wheel to control the tension of the silver-plated annealed copper wire, avoid the phenomenon of knotting or breaking the wire caused by the inconsistent pay-off speed of the pay-off wheel, improve the quality of the twisted wire, and the setting of the cycloid block can make the conductor evenly arranged. Clothed on the surface of the bobbin to enhance the aesthetics.

Owner:ANHUI HUAYU CABLE GRP

Double-wire-end copper-tin alloy stranding device

InactiveCN111799042ANovel structural designFor quick twistCable/conductor manufactureEngineeringStructural engineering

The invention discloses a double-wire-end copper-tin alloy wire stranding device. The device comprises a first wire guiding assembly, a second wire guiding assembly, a wire stranding cylinder and a winding assembly, wherein the first wire guiding assembly and the second wire guiding assembly are symmetrically arranged on the two sides of the wire stranding cylinder, the winding assembly is installed on one side of the wire stranding cylinder, and the tensioning wheel assembly is arranged between the wire stranding cylinder and the winding assembly. The double-wire-end copper-tin alloy wire stranding device is novel in structural design, can achieve quick double-wire stranding, can conduct wire stranding on wire ends with different thicknesses, and improves the wire stranding efficiency.

Owner:常宁市隆源铜业有限公司

High-security wire stranding machine

ActiveCN108711474AEasy to cleanImprove stranding efficiencyCable/conductor manufactureBobbinTransmission belt

The present invention relates to the field of wire manufacturing, and specifically to a high-security wire stranding machine. The technical problem to be solved by the present invention is to providea high-security wire stranding machine with high stranding efficiency and easy cleaning of impurities. The high-security wire stranding machine comprises a first pillar, a first fixed plate, a drivingmotor, a first transmission wheel, a first rotating shaft, a first bevel gear, a first bobbin, a first bearing seat, a second bevel gear, a second rotating shaft, a table plate, a first guide wheel,a wiping block, a second guiding wheel, a cleaning tank, a second pillar, a guide frame, a mounting plate, a second bobbin, a third bobbin, a circular gear, a second bearing seat, a third rotating shaft, a second fixed plate, a second circular gear, a third bearing seat, a fourth bearing seat, a second transmission wheel, a fourth rotating shaft, a transmission belt and the like. The high-securitywire stranding machine in the invention achieves the effects of high stranding efficiency and easy cleaning of impurities.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

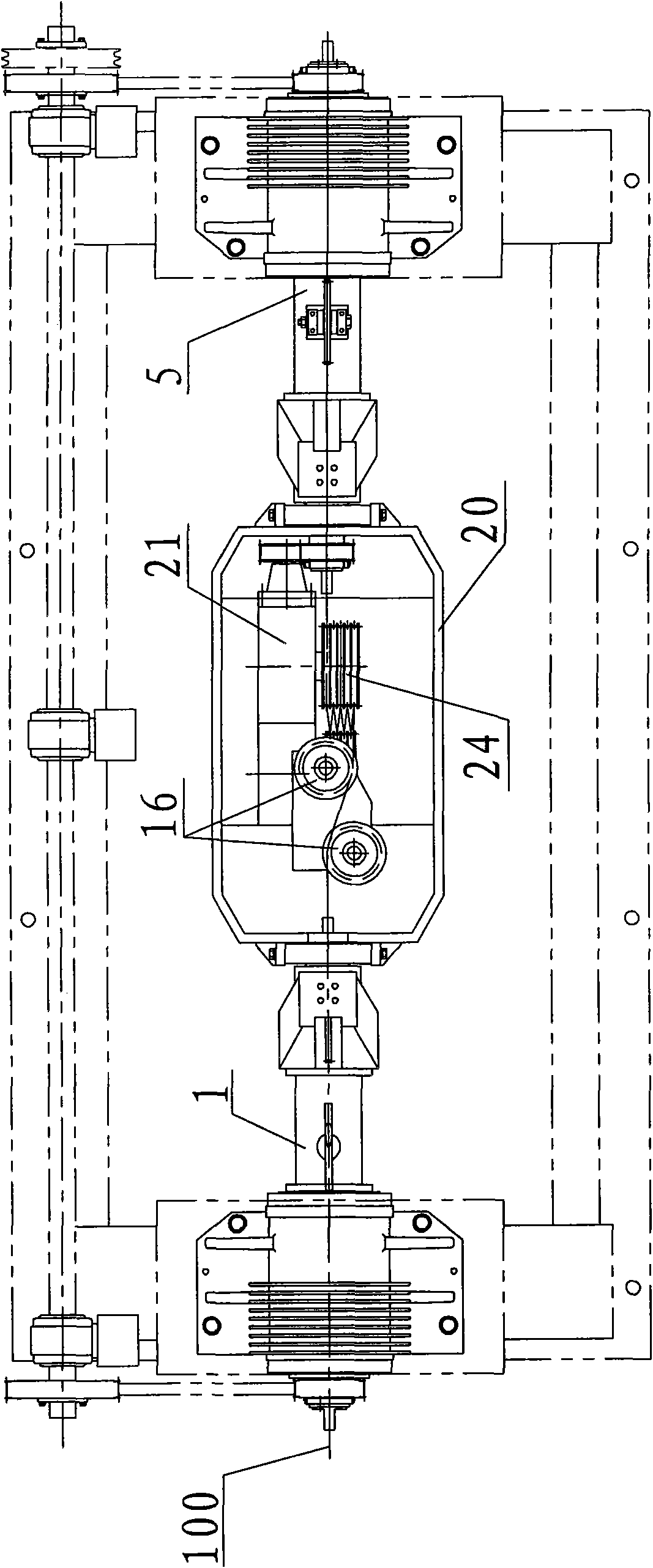

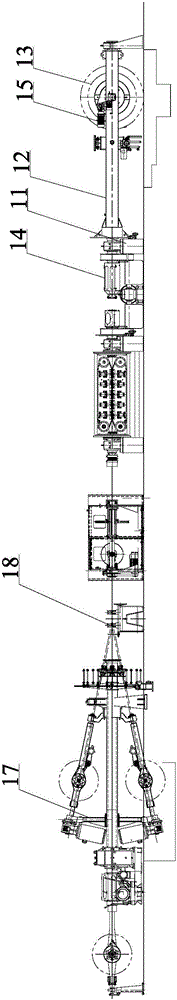

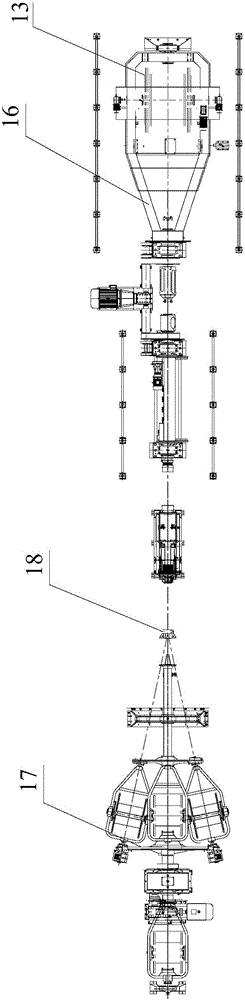

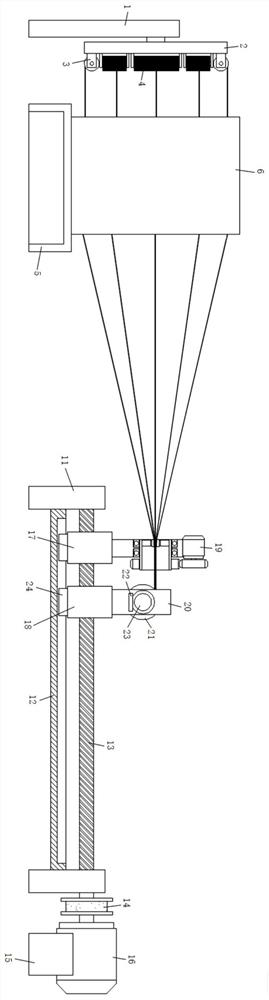

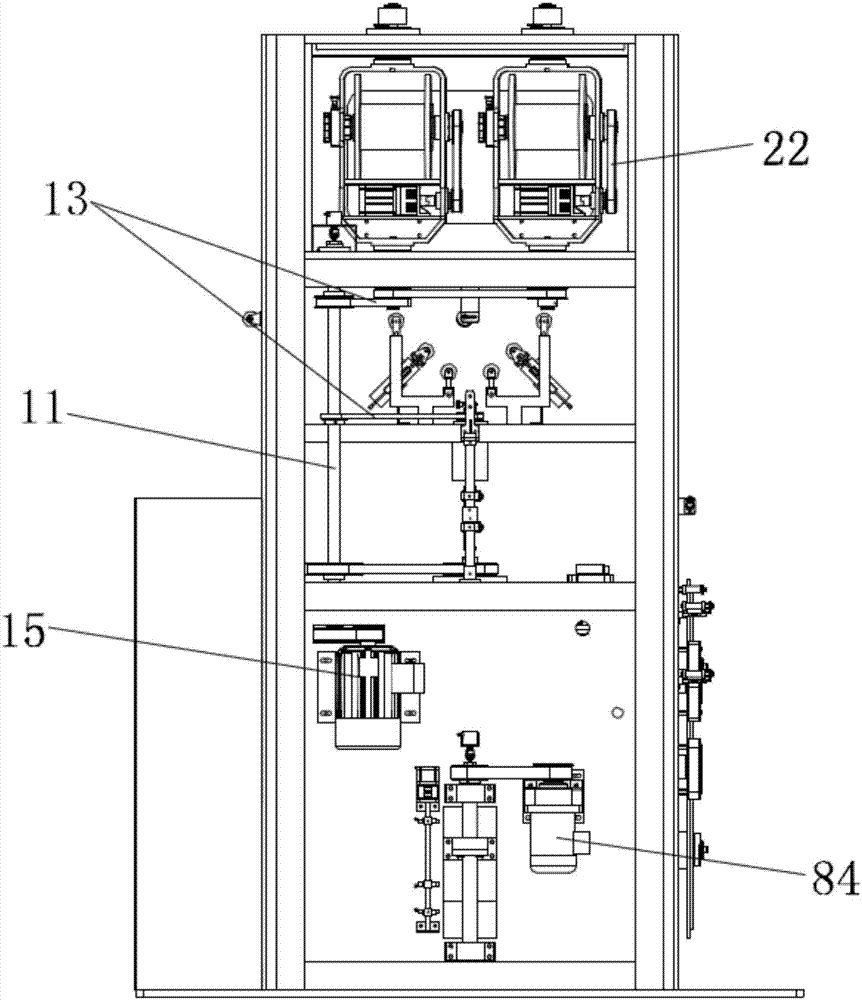

Vertical backfiring single stranding machine

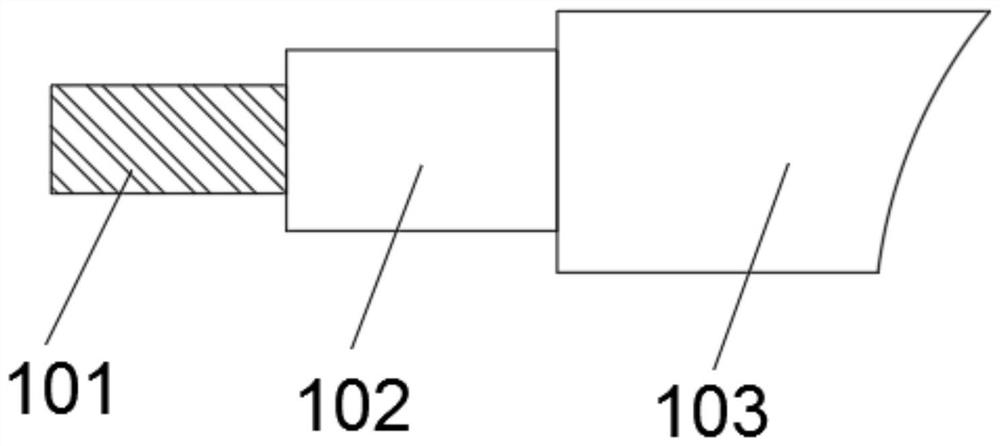

ActiveCN106057372BCompact structureSmall footprintCable/conductor manufactureElectrical conductorCrystal structure

The invention provides a vertical back burning single twist machine which is a vertical standing machine and comprises a back burning back twist device, a pre-twist device, a lead leading device and a wire retreating device which are arranged in the vertical standing machine from the top to the bottom in turn. The back burning back twist device, comprises a back scroll and a first rotator. The pre-twist device comprises a wire twist module group and a second rotator. The lead leading device comprises a first shaft, a second shaft, a cantilever component and a third rotator. The first rotator, the second rotator and the third rotator synchronously rotate through a spindle and a transmission system. According to the vertical back burning single twist machine, arrangement of the vertical standing machine is adopted, configuration of all parts is optimized and then the structure is compact so that space occupation of the whole machine can be greatly reduced in comparison with the convenient horizontally arranged single twist machine, and relocation and installation are facilitated; meanwhile, the three rotators synchronously rotate so that signal core wires are enabled to be constantly in the tensioning state in the process of wire feeding and twisting without damaging the crystal structure of the conductor surface, and thus transmission loss and delay difference of the cabled wires can be reduced.

Owner:SUZHOU CHAOLONG MACHINERY

Stranding device for prestressed steel strand production and processing

ActiveCN113846499AGuaranteed compactnessAvoid loose situationsRope making machinesGear wheelElectric machine

The invention discloses a stranding device for prestressed steel strand production and processing. The stranding device for prestressed steel strand production and processing comprises a base, a vertical plate, a pull rope winding wheel, a stranding disc, a sliding rod, a third stepping motor, a guide rod, a cylindrical cam, a U-shaped mounting plate, a supporting plate, a second driving gear, a driven gear ring, a second stepping motor, a circular-truncated-cone-shaped pressing base, a guide plate, an upper arc-shaped base, a steel strand winding barrel, a limiting pin, a cross-shaped rod, a lower arc-shaped base, a pull rope, a supporting rod, a fixed pulley, a double-shaft motor, a driven gear, a first driving gear, a mounting disc, a rotating disc, a clamping block, a first stepping motor, a limiting cylinder, a left-right rotating lead screw, a driving seat, a connecting rod, a limiting column, a mounting groove and a rotating roller. According to the stranding device for prestressed steel strand production and processing provided by the invention, through mutual cooperation of the stranding disc, the cylindrical cam, the sliding rod, the circular-truncated-cone-shaped pressing base, the guide rod, the guide plate and the gear ring, the stranding position of a steel strand can be better and repeatedly extruded when the steel strand is stranded, so that the stranding compactness of the steel strand is guaranteed, and the stranding efficiency is greatly improved.

Owner:安徽通利预应力科技有限公司

Tightness-adjustable stranding mechanism for industrial production

The invention discloses a tightness-adjustable stranding mechanism for industrial production. The stranding mechanism comprises an adjusting mechanism, a limiting baffle plate, a supporting shaft, a limiting lantern ring, a winding wheel, a limiting clamping sleeve, a supporting seat, a transmission gear, a guide supporting plate, a positioning gear, a connecting bracket, a mounting bottom plate, a fixed motor, a connecting gear, a fixed gear, a supporting gear and a clamping gear, wherein the fixed motor used for transmission is fixedly connected to the outer end face of the supporting base in a manner of being close to the middle. By arranging the adjusting mechanism, when the tension degree of a wire is adjusted, a connecting motor can drive four sets of threaded shafts to rotate at the same time through connecting teeth in a gear rotating disc, and then the threaded shafts can drive a positioning sliding plate to conduct centrifugal or centripetal movement through threaded clamping sleeves, so that the distance between the external wire and an external winding roller can be increased or decreased, the tension degree of the wire rod during stranding is effectively improved, and the quality of subsequent stranding is improved.

Owner:重庆市春鹏预应力钢绞线有限公司

A twisting machine for cable manufacturing

ActiveCN111863355BAvoid random placementEasy to manageCable/conductor manufactureStructural engineeringElectric cables

The invention provides a stranding machine for cable manufacturing, which relates to the field of electrical machinery and includes a base, the left side of the top of the base is fixedly connected with a pay-off device, and the right side of the pay-off device is provided with a guide device , the bottom of the guide device is fixedly connected with a slider, the top of the base is provided with a chute, the base is slidably connected with the slider through the chute, and the top of the base is located on the right side of the guide device An installation base is fixedly connected, and the top of the installation base is fixedly connected with a twisted wire barrel. The stranding machine used for cable manufacturing, through the arrangement of the pay-off device, by pulling the pull handle on one side of the second fixing frame, each pay-off cylinder that needs to be used can be fixed on the corresponding first limit cylinder and Between the second limit cylinders, the operation is simple, can effectively avoid random placement of various cables, effectively facilitates staff management, can also reduce floor space, is convenient and simple to use, and has good use effects.

Owner:宁波欣博通信科技有限公司

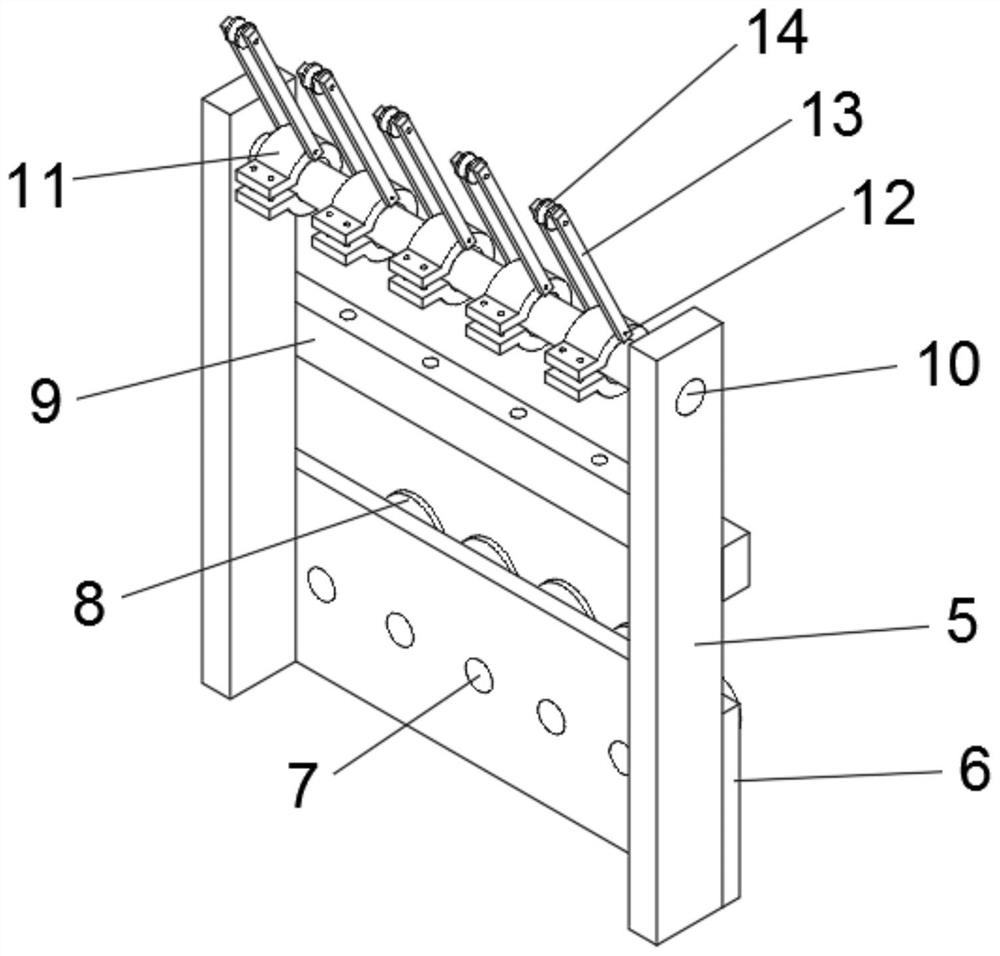

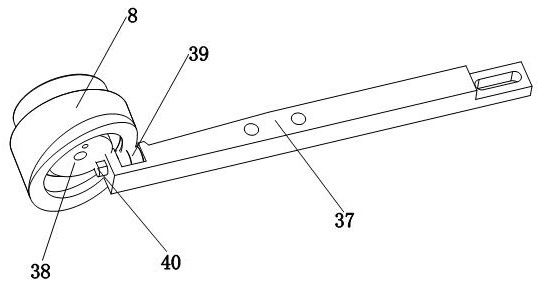

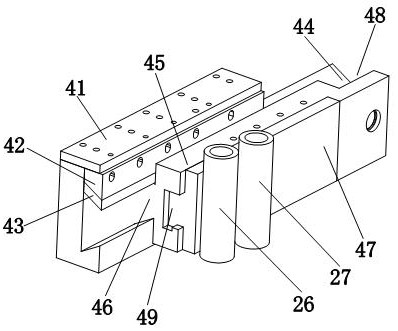

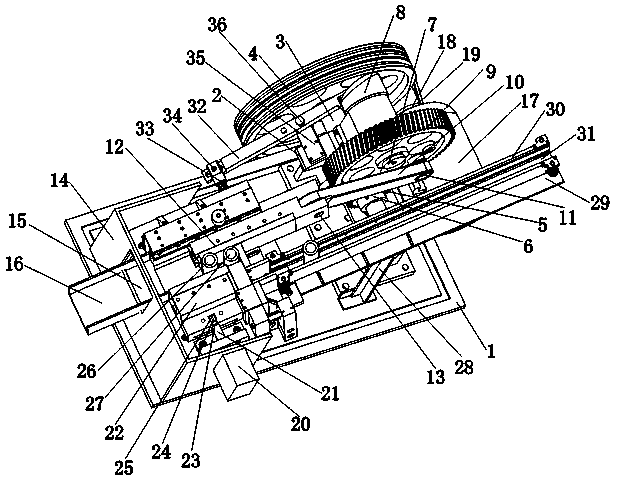

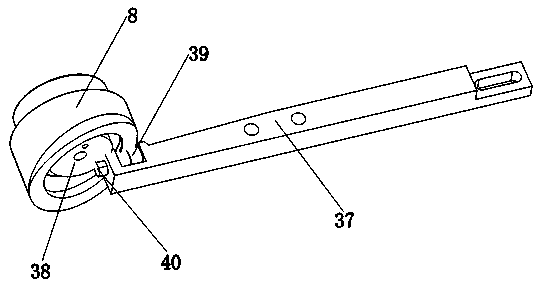

A single-wire core progressive conveying device for a stranding machine

ActiveCN111477411BEasy twisting operationImprove efficiencyCable/conductor manufactureRotational axisDrive wheel

The invention relates to a single-wire core progressive conveying device for a stranding machine. The other end of the shaft is provided with a transmission wheel, the upper part of the positioning seat is provided with a rotating shaft, one end of the rotating shaft is provided with a rotating wheel, the other end of the rotating shaft is a free end, and the rotating wheel meshes with the driving wheel; the rotating wheel is connected with a swing arm, One end of the swing arm is connected with the outer part of the rotating wheel, and the other end of the swing arm is provided with a progressive conveying mechanism; a drive motor is provided on the frame, and a drive wheel is set on the outer peripheral surface of the drive shaft of the drive motor, and the drive wheel and the driving wheel It is connected by a driving belt; a positioning shell is provided on the frame. The present invention is convenient for multiple single-wire cores to be transported forward step by step, and facilitates the twisting operation of multiple single-wire cores by a stranding machine; the efficiency of the stranding is greatly improved.

Owner:林杨

Single-wire core progressive conveying device for stranding machine

ActiveCN111477411AEasy twisting operationImprove efficiencyCable/conductor manufactureRotational axisDrive wheel

The invention relates to a single-wire core progressive conveying device for a stranding machine. The device comprises a rack; a positioning base is arranged on the rack; a driving shaft is arranged on the lower portion of the positioning base; a driver is arranged at one end of the driving shaft, and a transmission wheel is arranged at the other end of the driving shaft; a rotating shaft is arranged on the upper portion of the positioning base; a rotating wheel is arranged at one end of the rotating shaft, and the other end of the rotating shaft is a free end; the rotating wheel and the driving wheel are meshed; the rotating wheel is connected with a swing arm; one end of the swing arm is connected with the outer side part of the rotating wheel, and the other end of the swing arm is provided with a progressive conveying mechanism; a driving motor is arranged on the rack; the peripheral surface of a driving shaft of the driving motor is sleeved with a driving wheel, and the driving wheel is connected with the driver through a driving belt; a positioning shell is arranged on the rack. According to the invention, forward progressive conveying of a plurality of single-wire wire coresis facilitated; stranding operation of the plurality of single-wire wire cores by the stranding machine is facilitated; and the stranding efficiency is greatly improved.

Owner:林杨

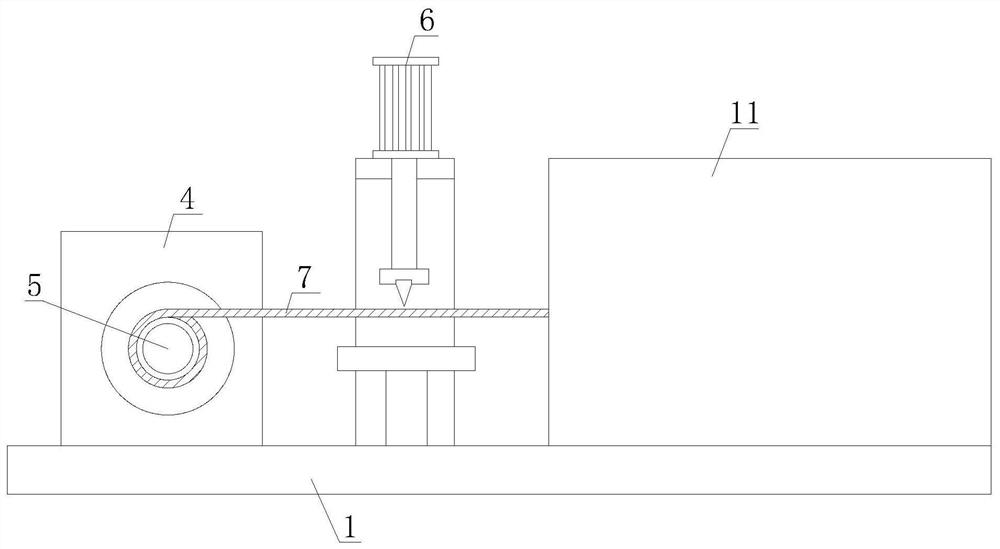

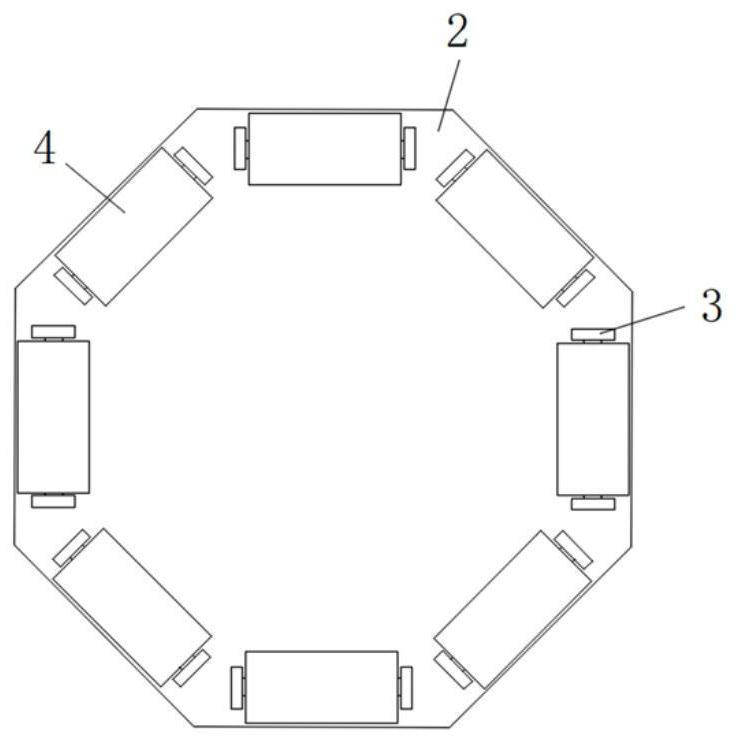

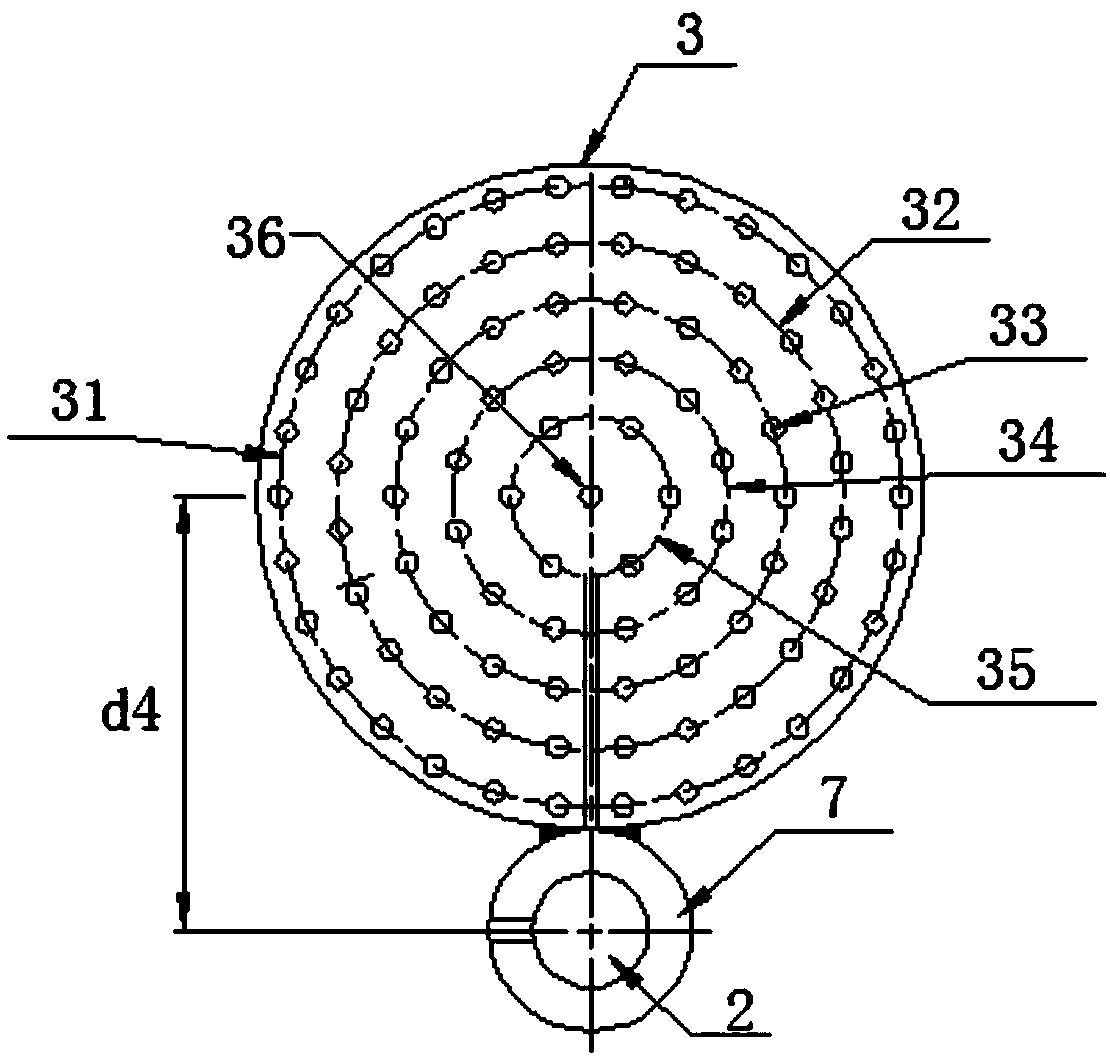

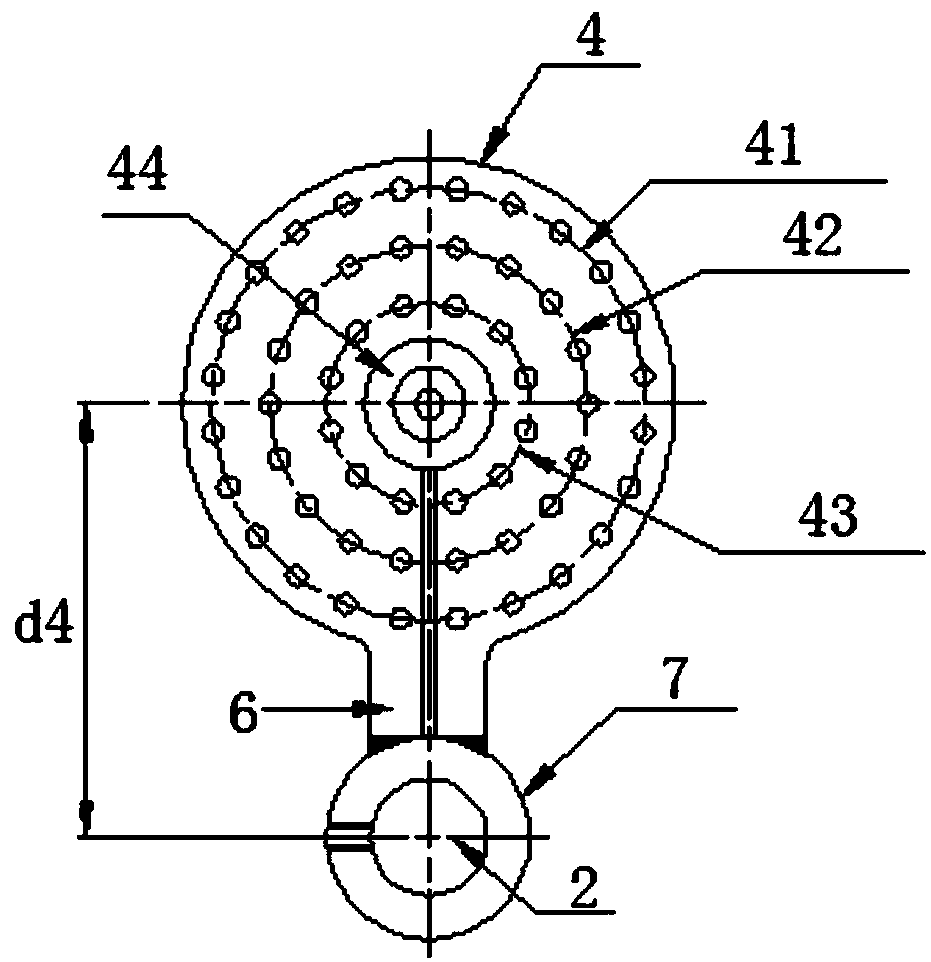

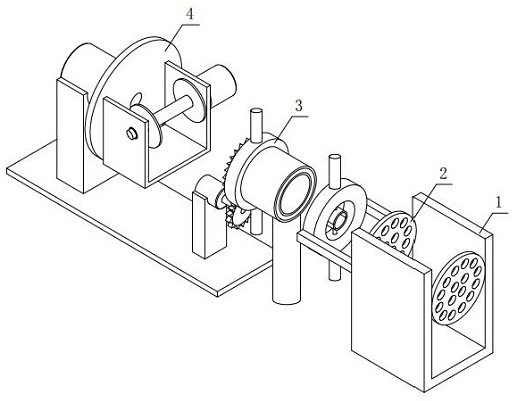

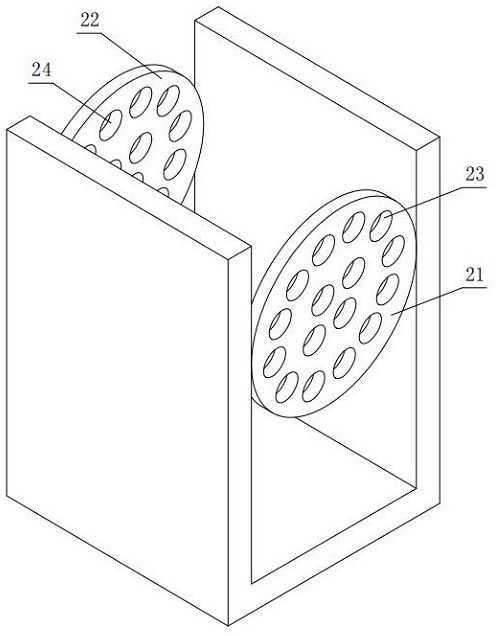

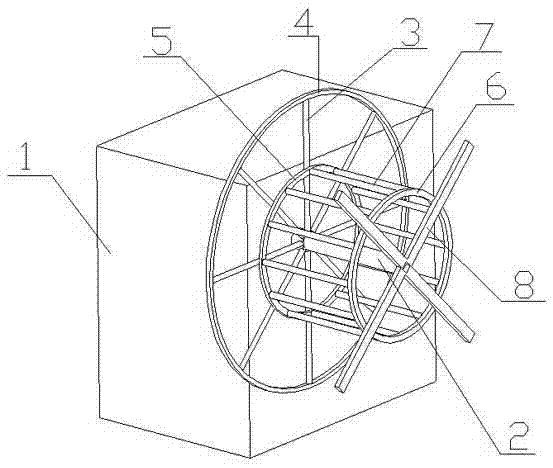

Pipeline winding device used in plastic pipe production workshop

InactiveCN106865337AClean environmentImprove stranding efficiencyFilament handlingMotor driveEngineering

A wire stranding device used in a plastic pipe production workshop, which consists of a motor box (1), a motor, a central shaft (2), a set of inner gear rods (3), a reinforcing ring (4), and an inner stranding coil (5 ), diplomatic coil (6), one group of twisted wire rods (7) and one group of outer gear rods (8). The advantages of the present invention are: using the device to collect scattered pipelines, the process of stranding can be automatically completed by driving the central shaft through the motor, saving time and effort, improving the efficiency of stranding, using a low-power motor to drive and automatically adjusting the speed, so that The environment of the whole production workshop is more tidy.

Owner:付安丽

A kind of wire winch device for wire rope production and its implementation method

ActiveCN113512894BQuality improvementGuaranteed stranding efficiencyRope making machinesEngineeringWinch

The invention discloses a wire winch device for steel wire rope production and an implementation method thereof, belonging to the technical field of wire rope winches, comprising a mounting frame, a dredging device is arranged inside the mounting frame, and a mounting seat is arranged behind the dredging device The clamping strand assembly connected with the frame, the rear end of the clamping strand assembly and the dredging device is provided with a winding assembly. The invention discloses a wire winch device for steel wire rope production and its implementation method, which can improve the quality of the wire, reduce the bending of the wire and affect the quality of the twisted wire, effectively ensure the efficiency of the twisted wire, improve the quality of the steel wire rope, facilitate the winch assembly to twist the wire, and improve the quality of the twisted wire. The stability of the wire can prevent the wire body from shaking, reduce the displacement of the wire, and twist the next section of the wire group to improve the efficiency of the wire. Compactness, improve the quality of the wire rope after winding.

Owner:南通市一帆钢绳有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com