Stranded wire passing system and twisted wire passing method of high speed stranding machine

A wire stranding machine and wire stranding technology, applied in the field of wire stranding machines, can solve problems such as unreasonable spacing and arrangement of distribution boards, easy wear and tear of wire passing holes of distribution boards, and easy stretching and thinning of wires, etc., to achieve Easy to implement, not easy to stretch and deform, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

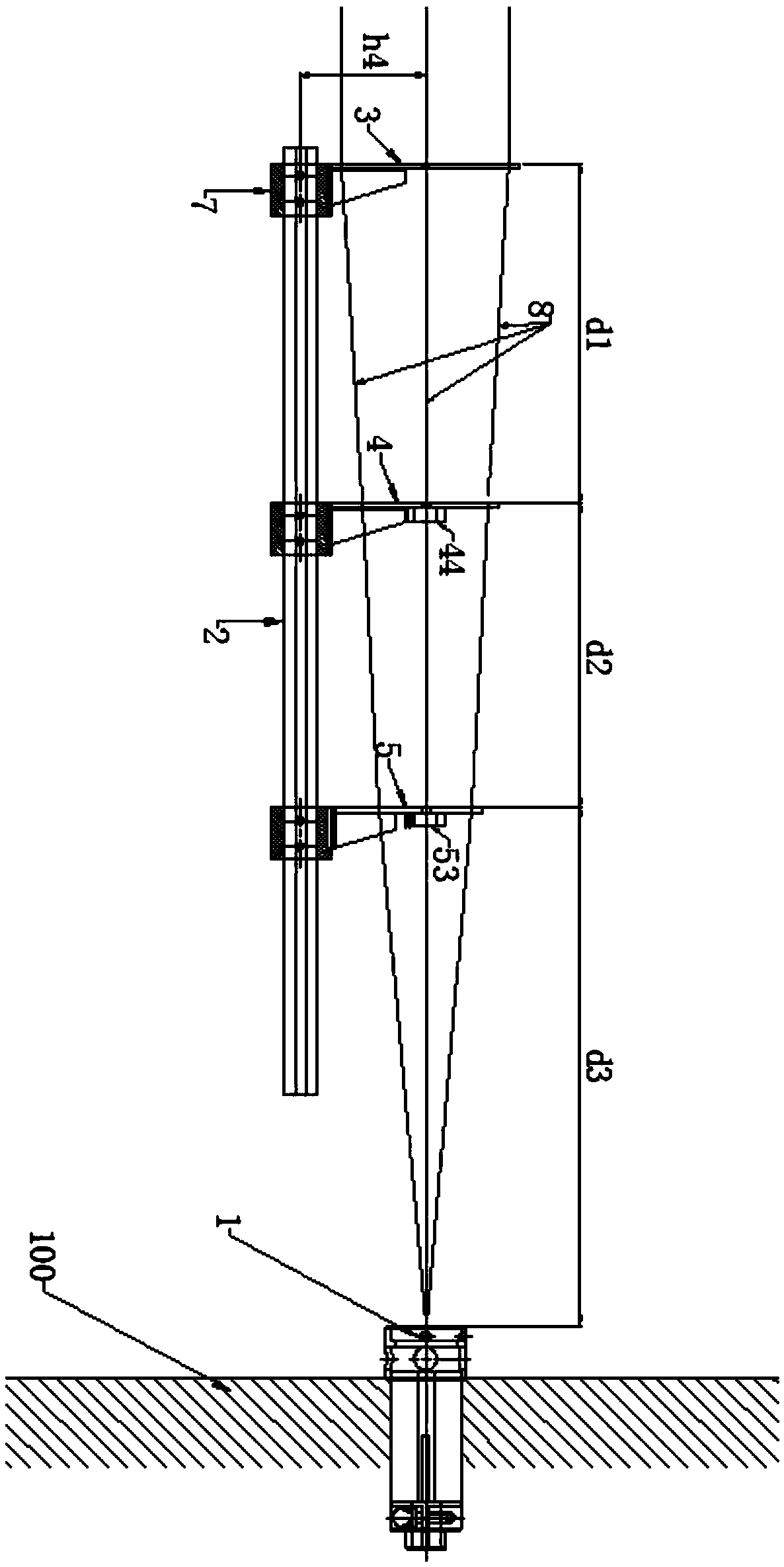

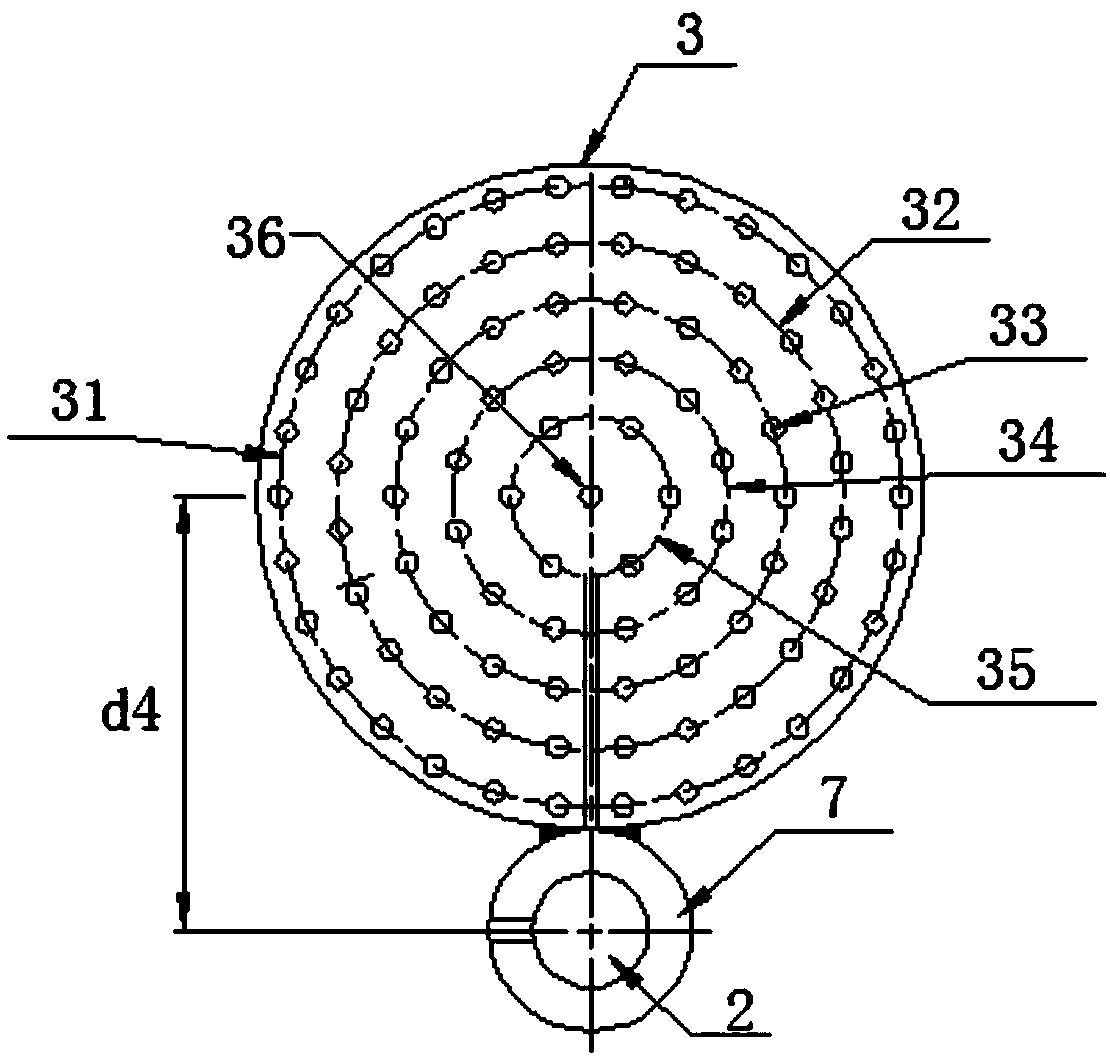

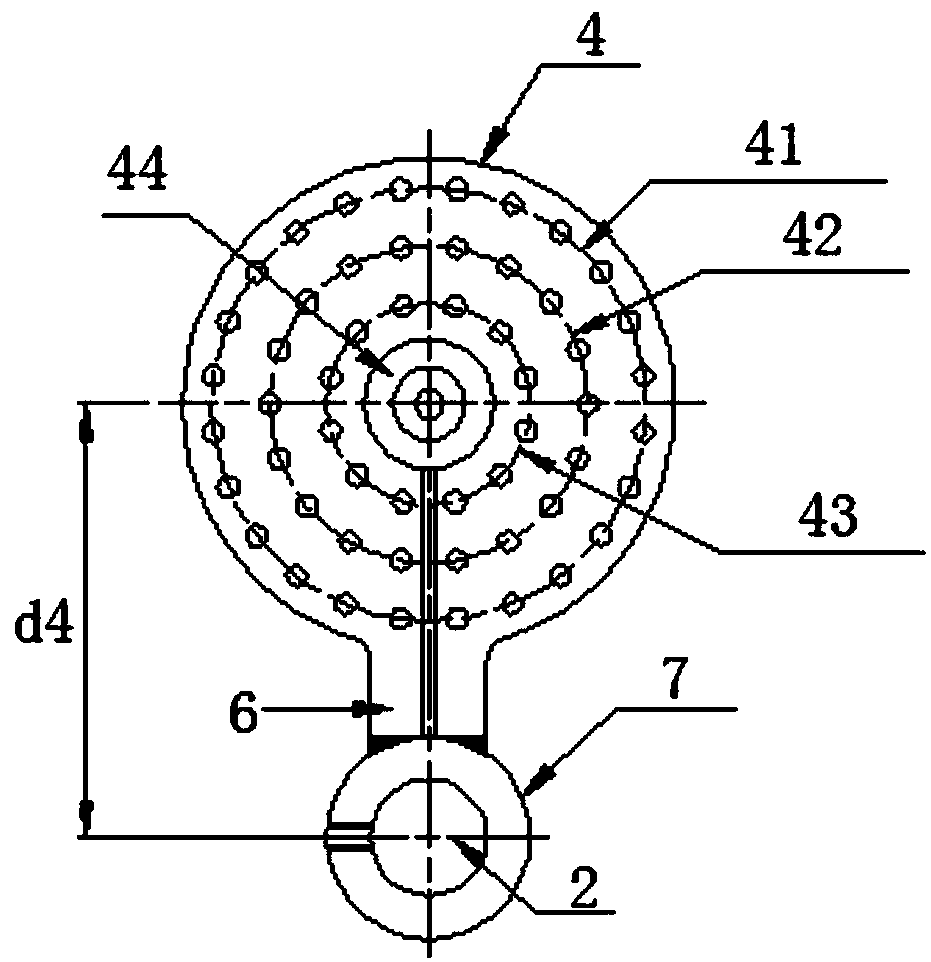

[0038] Embodiment: a kind of twisted wire passing system of high-speed twisting machine, such as Figure 1 to Figure 4As shown, the main shaft end eye mold 1 including the stranding machine 100 includes a fixed rod 2 and a distribution board fixed on the fixed rod. It is the first distribution board 3, the second distribution board 4 and the third distribution board 5, the lower end of each of the distribution boards is fixed on the fixed rod, and the second distribution board and the third distribution board The lower end of the line board is extended to form a height compensation section 6, the height of the height compensation section of the third line board is greater than the height of the height compensation plate of the second line board, the centers of all the line boards and the The center of the eye mold at the main shaft end is located on the same straight line, and each of the branch boards is covered with passing holes for the wire 8 to pass through, and the cente...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com