Four-pitch wire twisting machine capable of realizing continuous production

A stranding machine and stranding technology, which is applied in the field of stranding and cabling equipment, can solve the problems of reduced stranding efficiency, increased energy consumption, and inability to produce on-line, so as to reduce production costs, increase economic benefits, and improve stranding efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

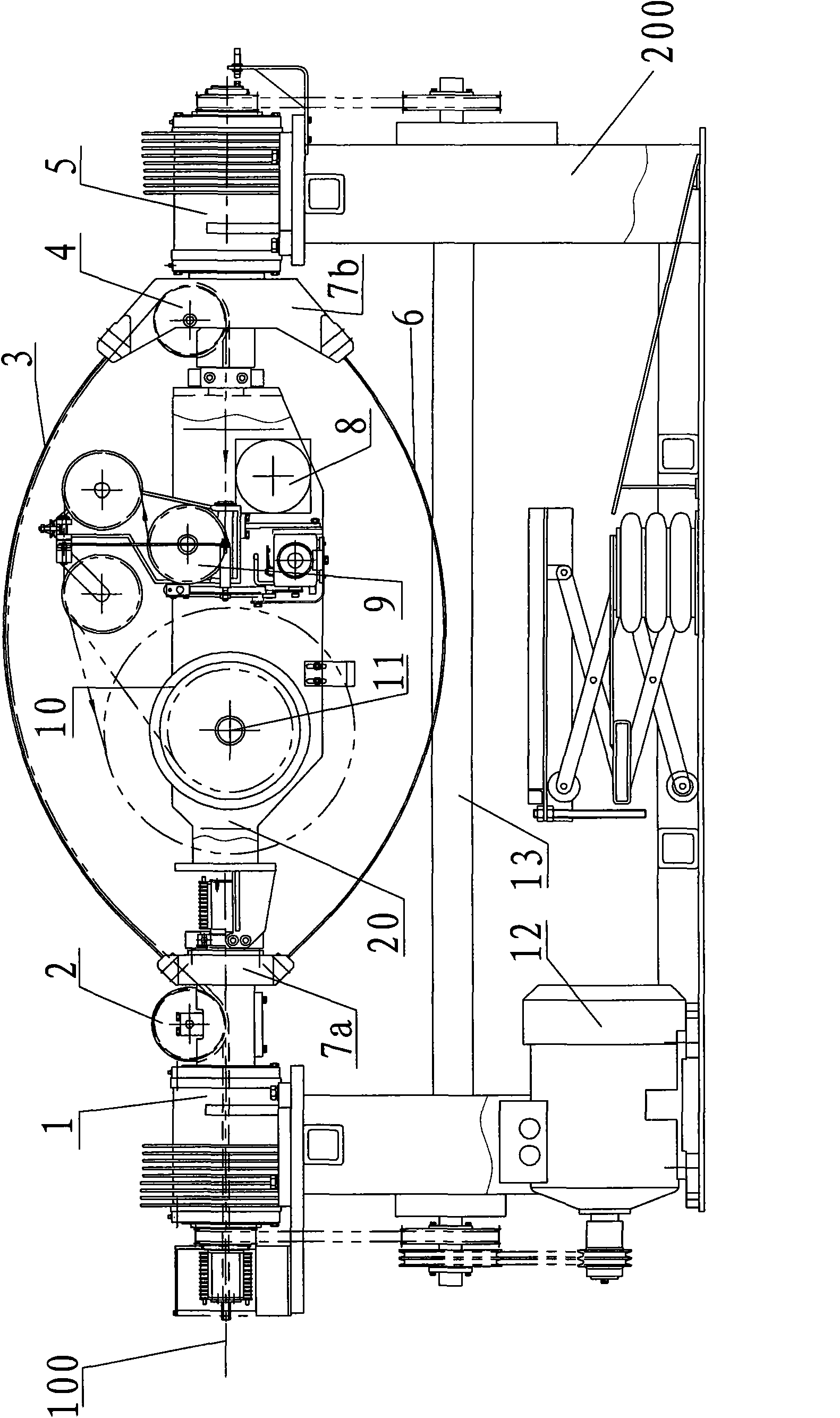

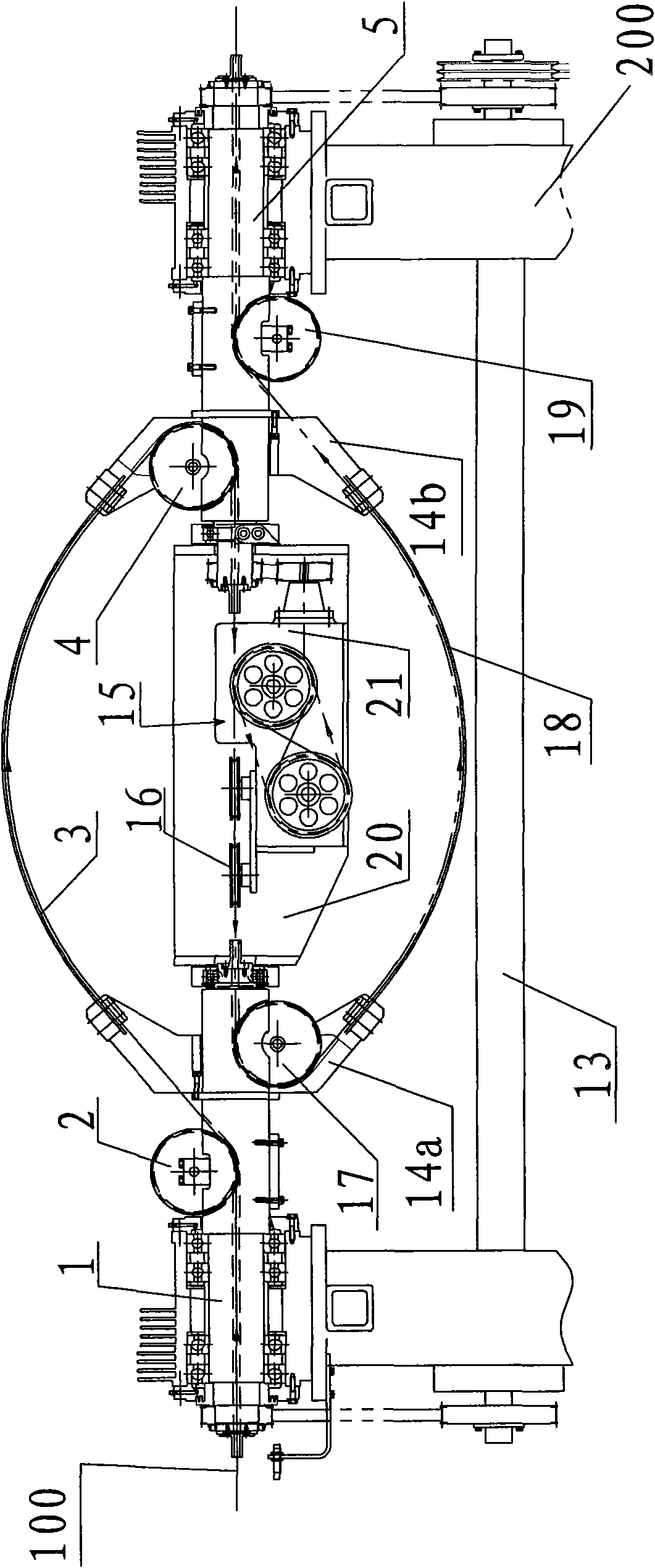

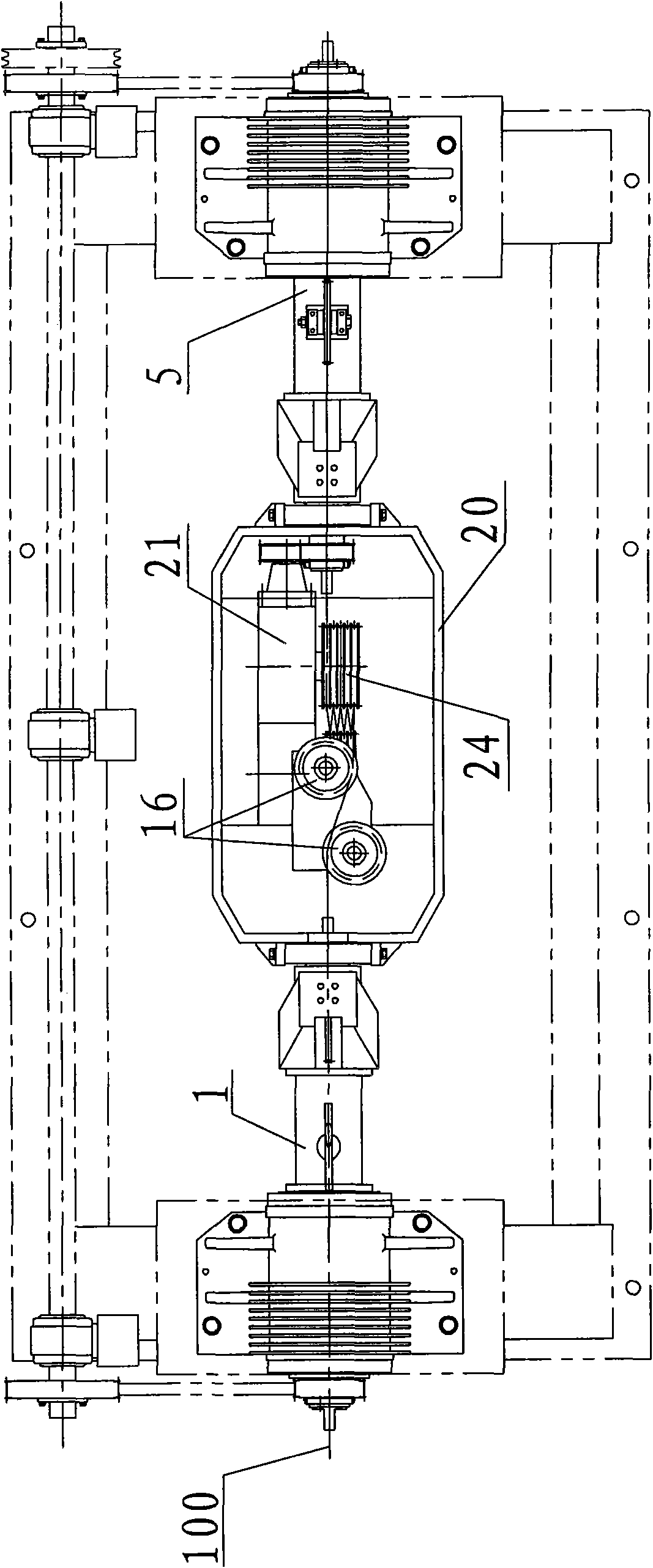

[0040] like Figure 2 to Figure 4 A four-pitch stranding machine that can realize continuous production is shown, which includes a fuselage 200, a drive mechanism, a cradle 20, an incoming wire spindle 1, an outgoing wire spindle 5, two twisting bow supports, a pair of twisting bows, The first strand guide wheel 2, the second strand guide wheel 4 and the traction device, wherein the drive mechanism is made of a motor and a transmission shaft 13, and the transmission shaft 13 is installed on the fuselage, which is connected with the motor by a transmission belt, and is driven by the motor. It is driven to rotate, and the incoming line main shaft 1 and the outgoing line main shaft 5 are respectively connected to the transmission shaft 13 through the synchronous belt, and the transmission shaft 13 drives the two to rotate synchronously. At the ends of the wire spindle and the outlet spindle, a pair of twisted bows are symmetrically arranged on the two twisted bow supports, and th...

Embodiment 2

[0048] Embodiment two of the four-pitch stranding machine of the present invention is as Figure 5 As shown, the difference from Embodiment 1 is that it is also equipped with a take-up and discharge device, which is located outside the twisting mechanism of the four-pitch twisting machine, and the conductor or core wire 100 is drawn from the fourth strand guide wheel 19 After being exported, it directly enters the wire take-up device to wind up the conductor or core wire 100. The wire take-up device includes a tension frame 25, a wire arrangement mechanism 26 and a wire take-up device 27. The tension frame 25 is equipped with a plurality of height-adjustable wire take-up devices. The tension wheel 25a with different speeds varies slightly. The wire arranging mechanism 26 is provided with a polished rod or a screw rod for arranging the wires. The wire take-up device 27 is equipped with a take-up spool 27a. , after passing through the cable arrangement mechanism, it is wound on ...

Embodiment 3

[0050] Embodiment three of the four-pitch stranding machine of the present invention is as Image 6 As shown, different from Embodiment 2, this embodiment does not have a take-up device, that is, the whole stranding machine does not have a take-up spool, and the twisted cable passes through the storage wheel of the storage rack or the tension frame 25 or The tension wheel 25a is then directly transported to the extruder 28 for an extrusion process to realize continuous production. Because there is no need to be provided with a take-up spool in this embodiment, manpower, spools, and waste wire ends can be saved, the production cost of electric wires and cables can be reduced, and economic benefits can be increased.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com