A twisting machine for cable manufacturing

A cable manufacturing and stranding machine technology, applied in the field of stranding machines, can solve the problems of cable position deviation, inconvenient unified management, large floor space, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

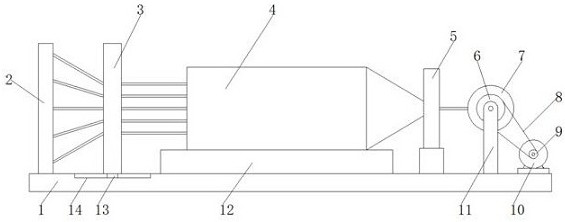

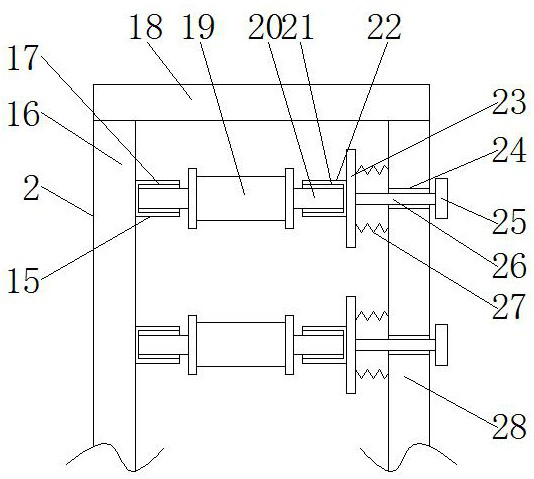

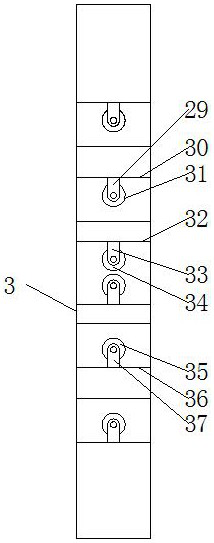

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0022] Embodiments of the present invention provide a stranding machine for cable manufacturing, such as Figure 1-3 As shown, including base 1, the left side of base 1 top is fixedly connected with pay-off device 2, the right side of pay-off device 2 is provided with guide device 3, and the bottom of guide device 3 is fixedly connected with slider 13, base The top of 1 is provided with a chute 14, the base 1 is slidably connected with the slider 13 through the chute 14, the top of the base 1 is fixedly connected with the installation base 12 on the right side of the guide device 3, and the top of the installation base 12 is fixedly connected There is a twisted wire drum 4, the right side of the twisted wire drum 4 is provided with an outlet turntable 5, the top of the base 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com