A high-safety wire stranding machine

A safe, twisting machine technology, applied in the manufacture of circuits, electrical components, cables/conductors, etc., can solve problems such as low efficiency, easy residual impurities, and influence of wire energization efficiency, and achieve high stranding efficiency and easy cleaning of impurities , Improve the effect of stranding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

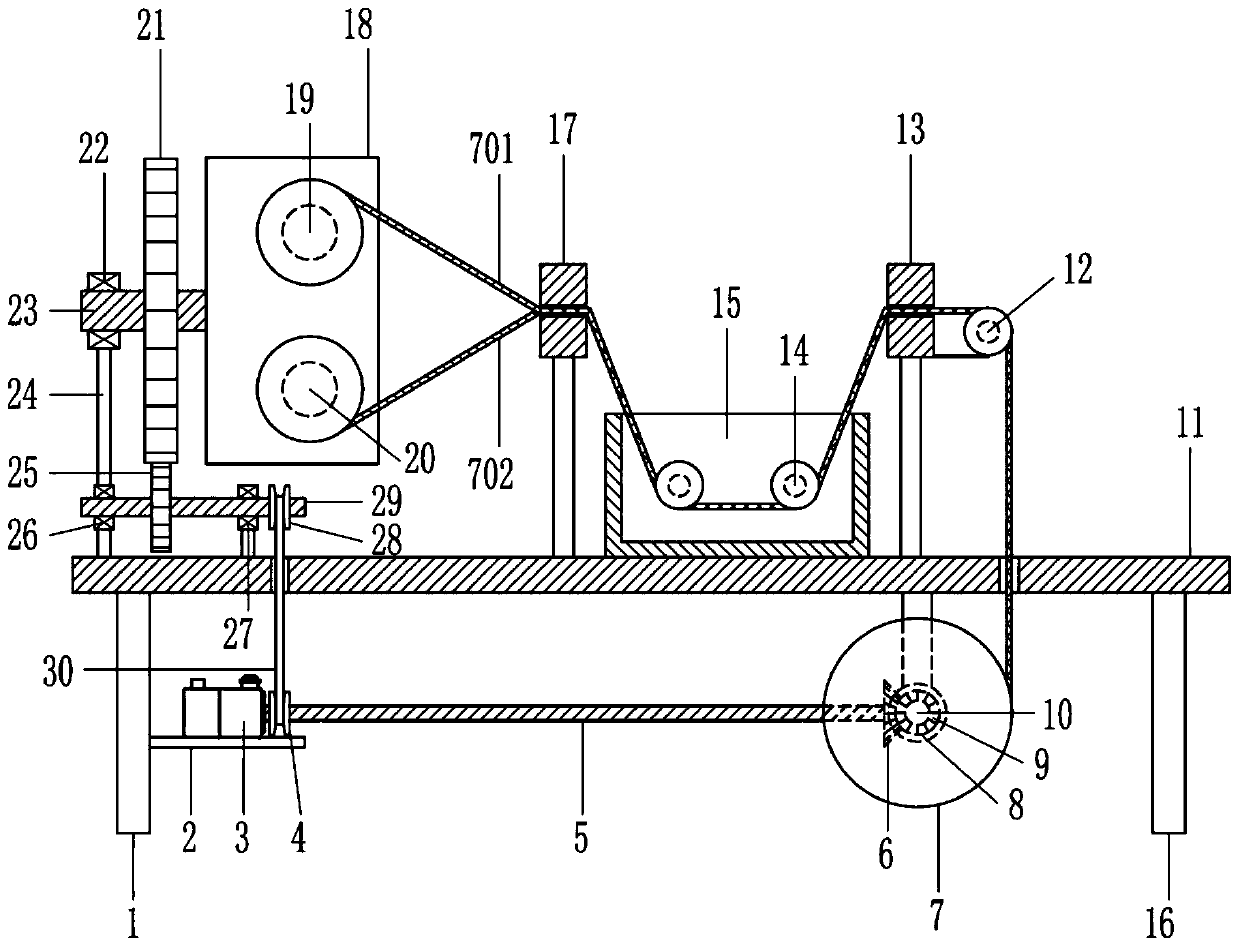

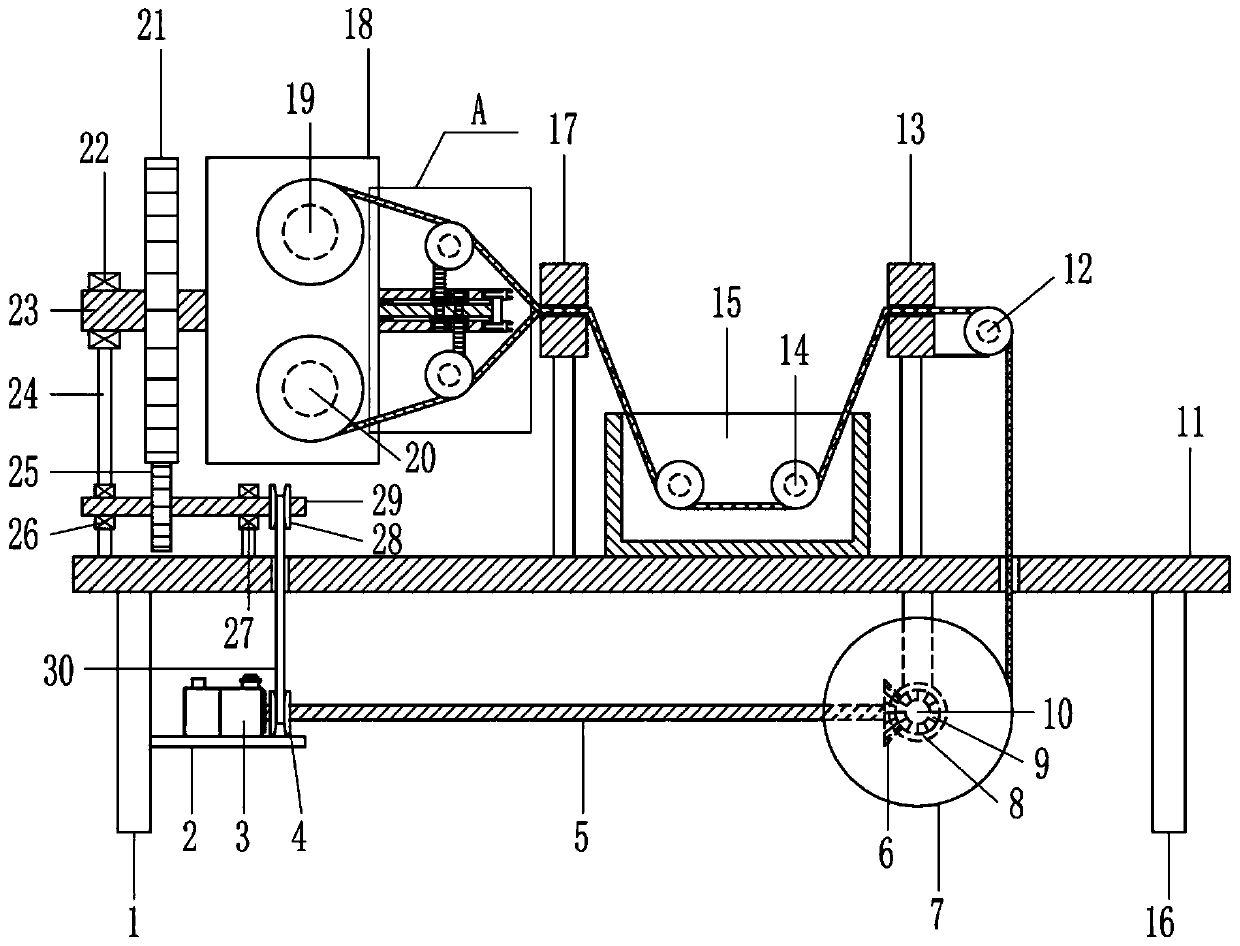

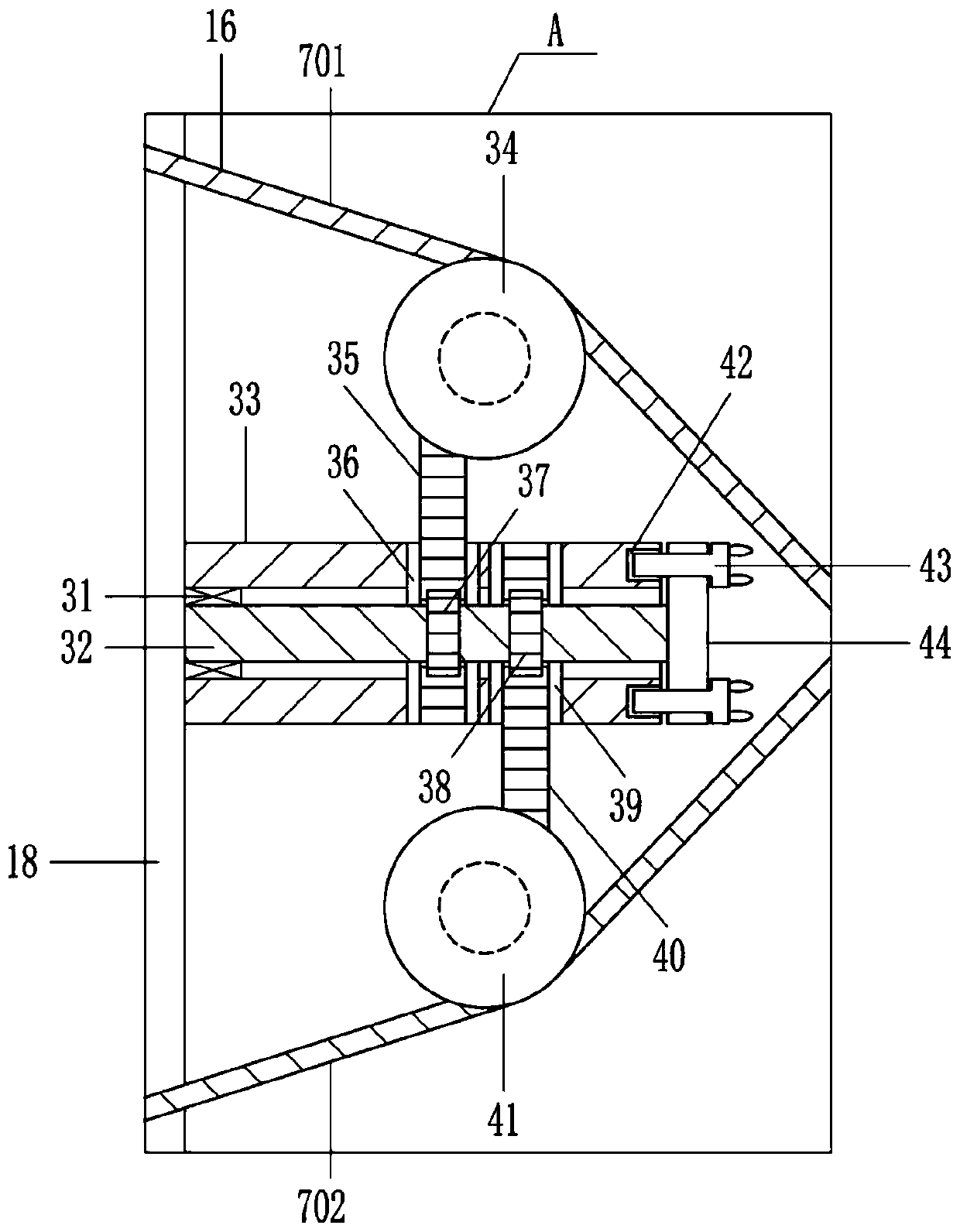

[0030] A high-safety wire twisting machine such as Figure 1-8As shown, it includes a first pillar 1, a first fixed plate 2, a driving motor 3, a first transmission wheel 4, a first rotating shaft 5, a first bevel gear 6, a first bobbin 7, a first bearing seat 8, The second bevel gear 9, the second rotating shaft 10, the table board 11, the first guide wheel 12, the wiping block 13, the second guide wheel 14, the cleaning tank 15, the second pillar 16, the guide frame 17, the mounting plate 18, the second Bobbin 19, third bobbin 20, first circular gear 21, second bearing seat 22, third rotating shaft 23, second fixing plate 24, second circular gear 25, third bearing seat 26, fourth bearing Seat 27, second drive wheel 28, fourth rotating shaft 29, drive belt 30, first electric wire 701 and second electric wire 702; 11 The other side of the bottom; the first fixed plate 2 is fixed on the side of the first pillar 1 close to the second pillar 16, and the drive motor 3 is fixed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com