Flexible transmission tubular wire twisting machine

A flexible transmission and stranding machine technology, applied in the manufacture of electrical components, circuits, cables/conductors, etc., can solve the problems such as the decline of the accuracy of the whole machine and the performance of the equipment, the quality of the cable products, and the short service life of the equipment. The effect of slow machine accuracy and equipment performance, reduced coaxiality requirements, and long equipment life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

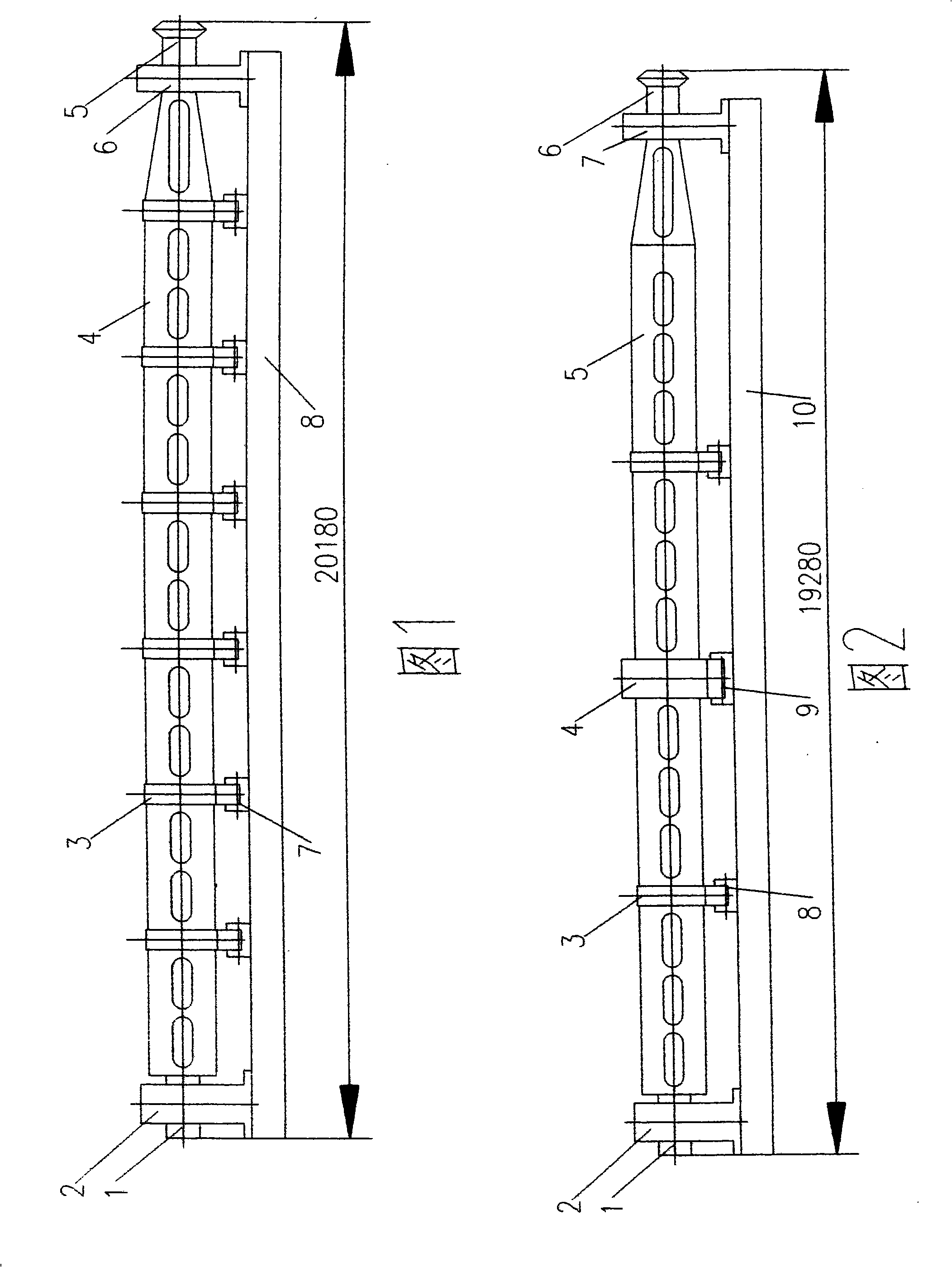

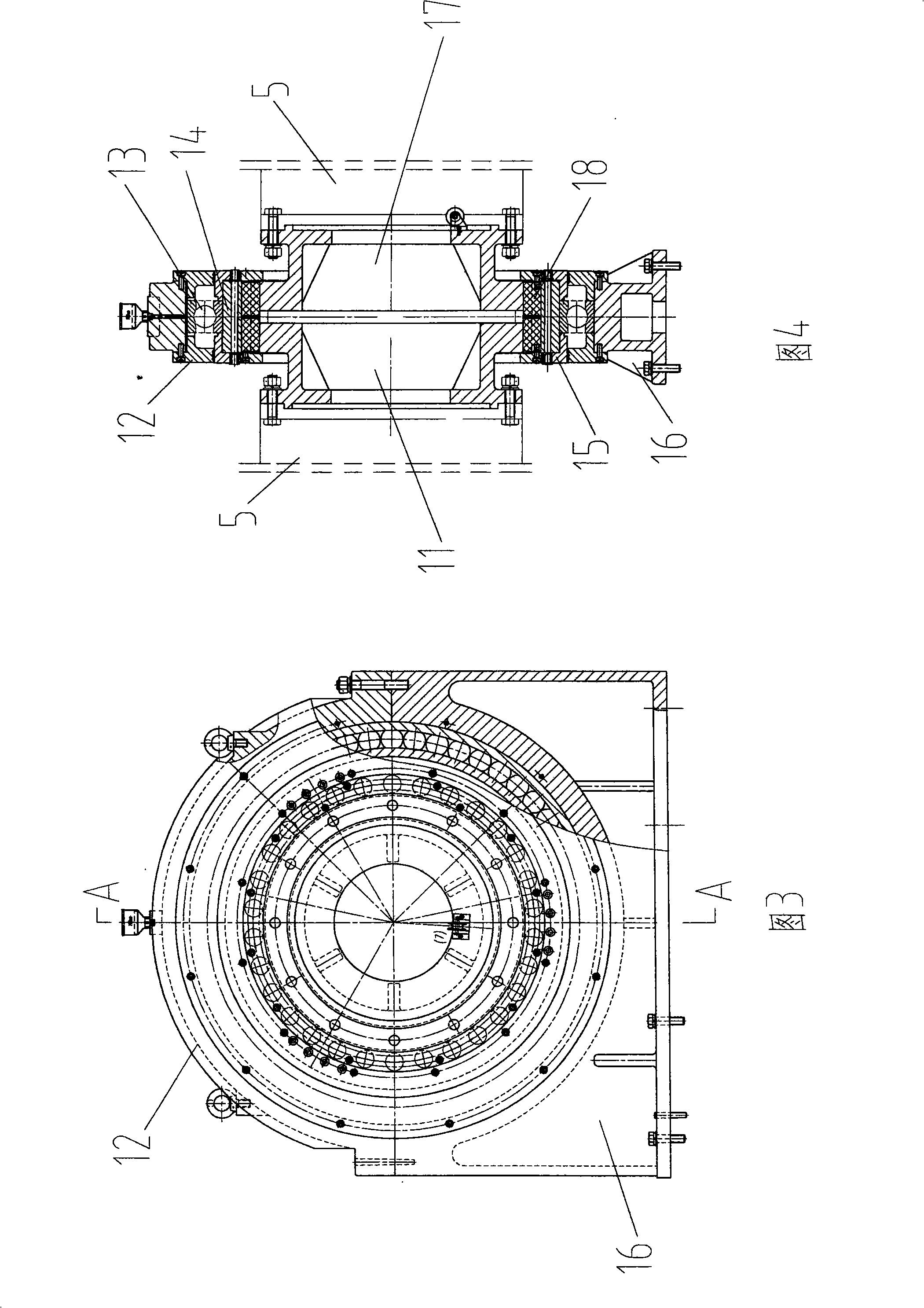

[0025] See Fig. 2: The main part of the tubular stranding machine is a rotating strand, which is composed of a cylinder body 5, a gearbox end bearing seat 2, a tail end bearing seat 7, a supporting roller 8, and a base 10. The bearing seat 2 at the gearbox end and the bearing seat 7 at the tail end are arranged at the two ends of the base 10, corresponding to each other; the two ends of the cylinder 5 have supporting shafts 1 and 6 respectively, which are supported on the bearing seat 2 at the gearbox end and the bearing seat at the tail end 7; the waist of the cylinder 5 has a plurality of supporting roller tracks 3 distributed axially; the supporting rollers 8 are arranged on the base 10, the number of which is the same as that of the supporting roller tracks 3, and each supporting roller 8 supports one supporting roller runway 3.

[0026] Because the length of the barrel 5 is very long, at least more than 10 meters, the total length of the barrel 5 is close to 20 meters for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com