Stranding machine stranding tension automatic monitoring system

A technology of automatic monitoring system and stranding machine, applied in general control system, control/adjustment system, computer control and other directions, can solve the problems of poor cable torsion resistance, difficult to balance adjustment, uneven core tension, etc. The requirements of mechanical properties and the effect of improving the level of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

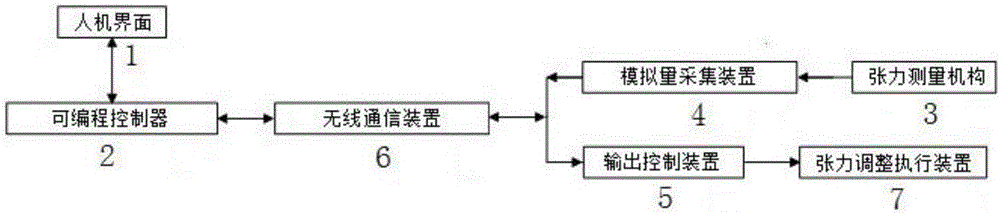

[0024] Such as figure 1 In the described embodiment, the automatic monitoring system for strand tension of the stranding machine includes

[0025] Man-machine interface 1 for operators to monitor or adjust tension adjustment control parameters and store and record production process data online at the production site;

[0026] Programmable controller 2 that regulates the running state of the entire system; human-machine interface 1 transmits the set tension adjustment control parameters to programmable controller 2, and displays the process data of programmable controller 2 in real time. At the same time, the man-machine interface 1 Online storage and recording of the production process data of the equipment in the memory of the man-machine interface 1; the programmable controller 2 adjusts the control parameters according to the set tension a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com