Steam drying device of continuous pigment dyeing padding mangle

A paint dyeing and pad dyeing machine technology, applied in the direction of drying gas arrangement, drying, drying machine, etc., can solve the problems of slow fabric travel, not compact and reasonable, scattered system settings, etc., to improve drying efficiency and low noise , the effect of uniform tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

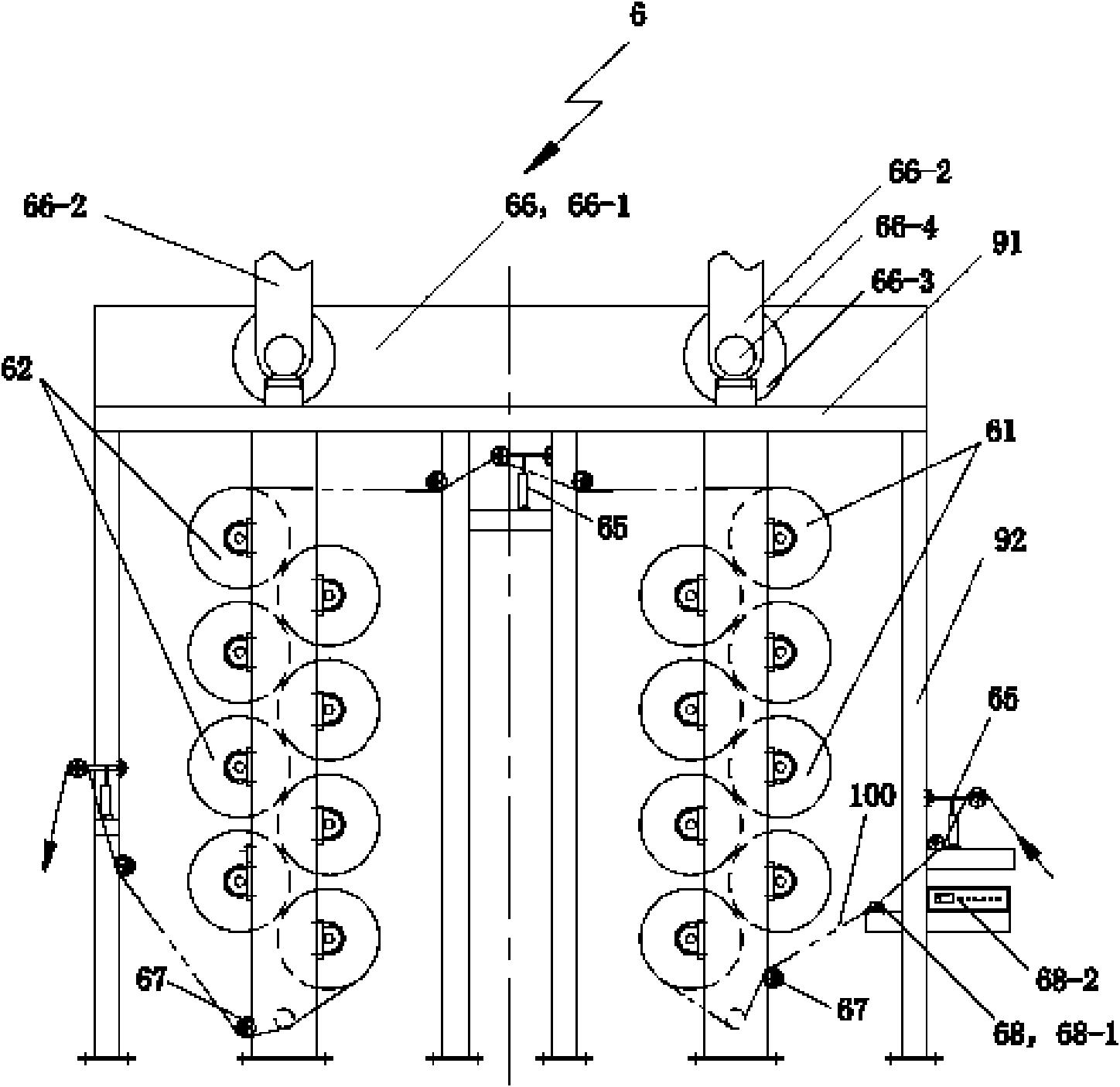

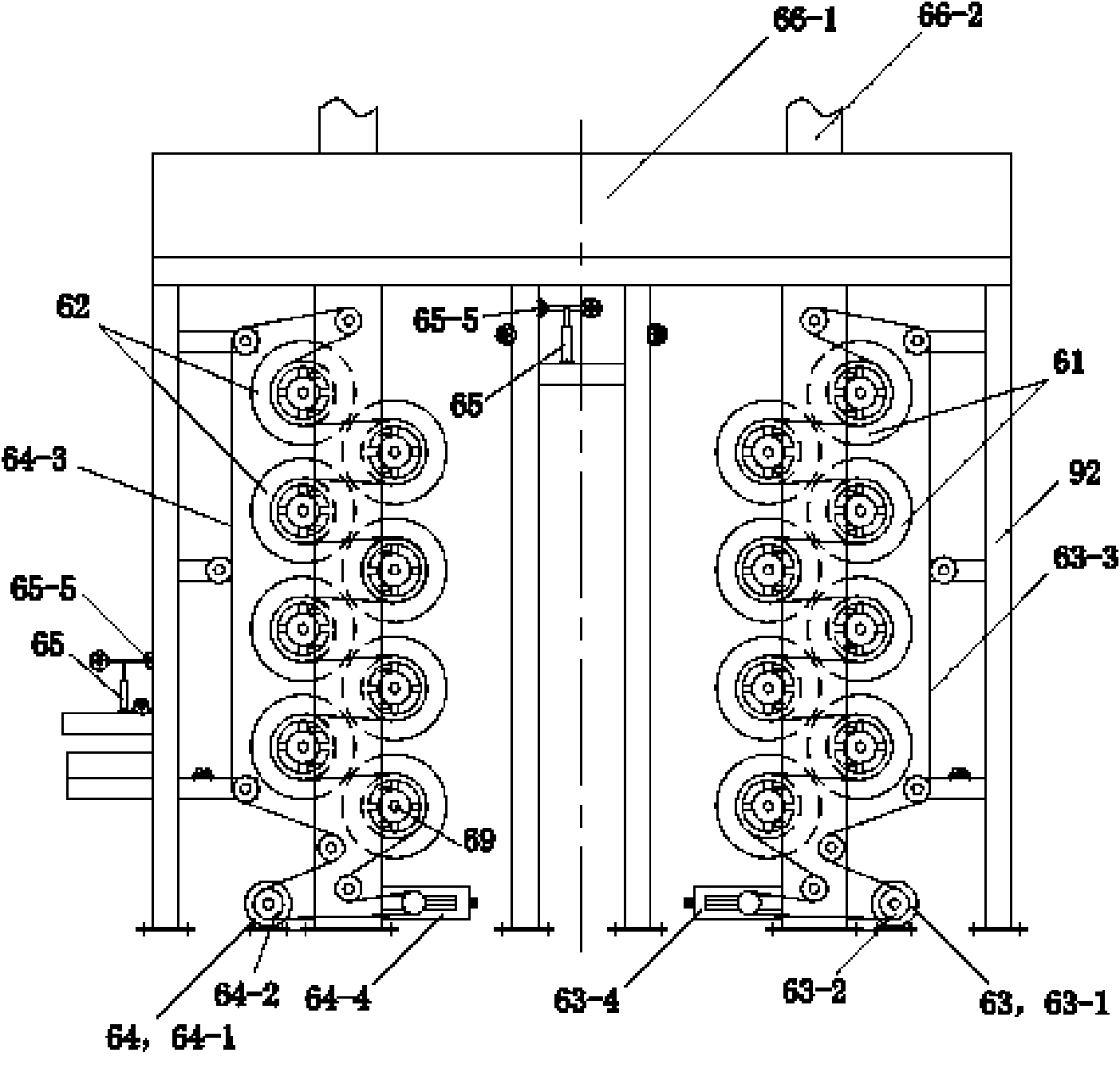

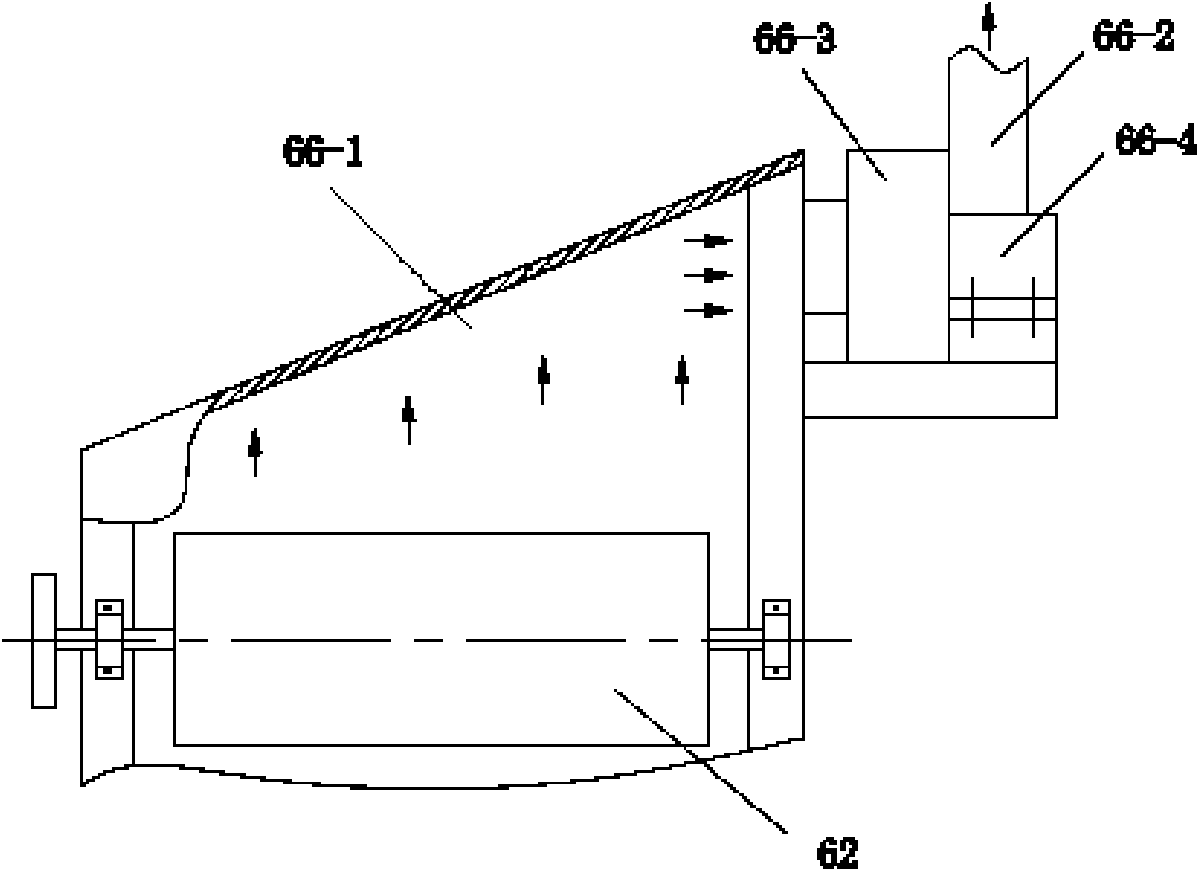

[0041] See figure 1 and figure 2 , the steam drying device of the present embodiment includes a second frame 92 and a steam drying cylinder arranged on the second frame 92, a drying transmission mechanism, a tension adjustment device, a second moisture removal device 66, and a drying guide roller The group 67 and the moisture content detection device 68 also include a temperature sensor 69, an electric control box, a steam branch pipe and a pneumatic diaphragm valve with a feedback signal device.

[0042] The electric control box includes a programmable controller, a man-machine dialogue device and 2 frequency converters. Both the programmable controller and the man-machine dialogue device have communication ports; the programmable controller also has a temperature signal input terminal, two angle signal input terminals, a diaphragm valve control signal output terminal and two frequency conversion control signal output terminals. The man-machine dialogue device is electrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com