System and method for producing fracturing propping agent by taking red mud as raw material

A fracturing proppant and production system technology, applied in the field of new materials and artificial proppant production, to achieve the effects of reducing production costs, easy adjustment, and low manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1 Using pure red mud raw material

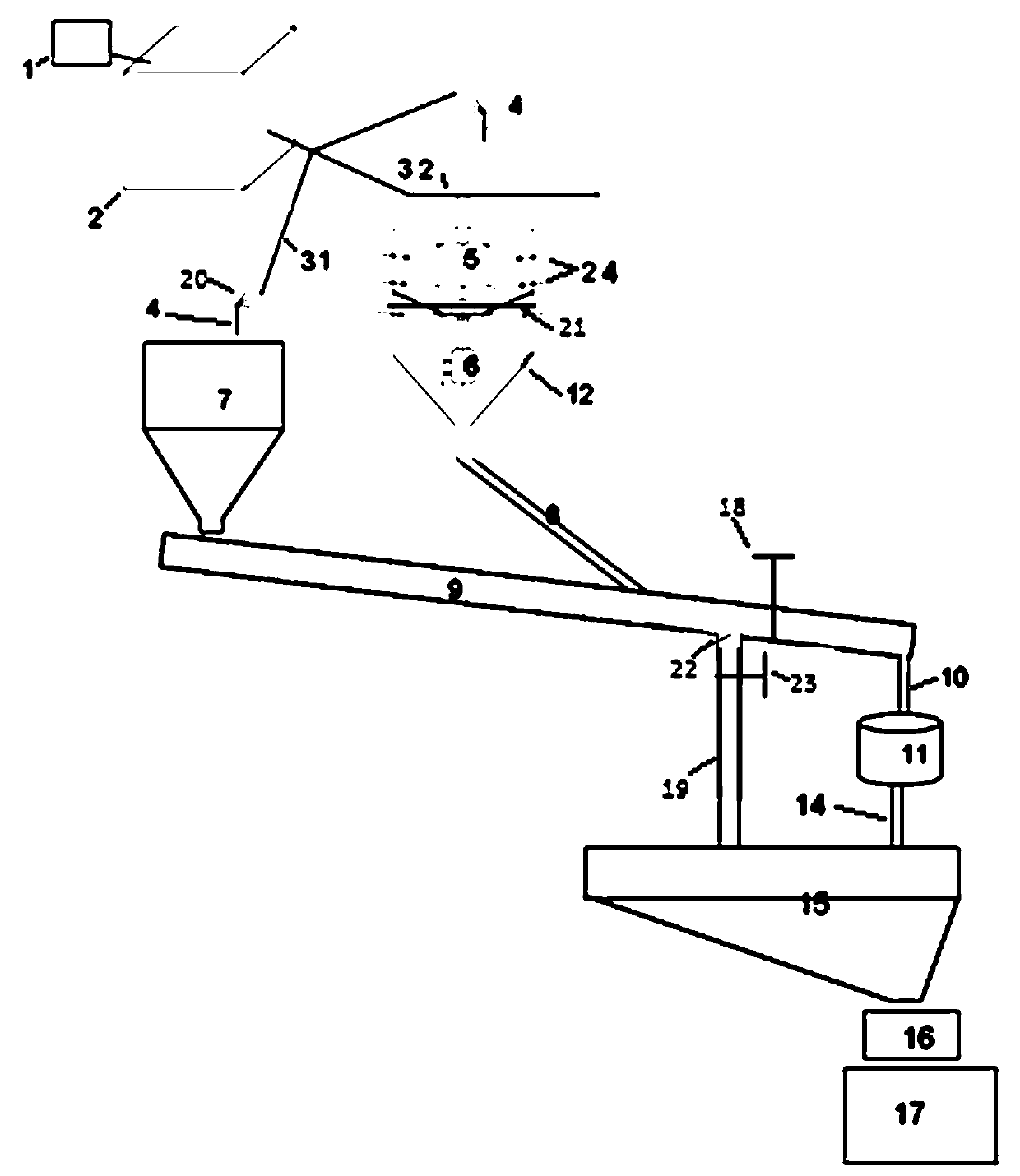

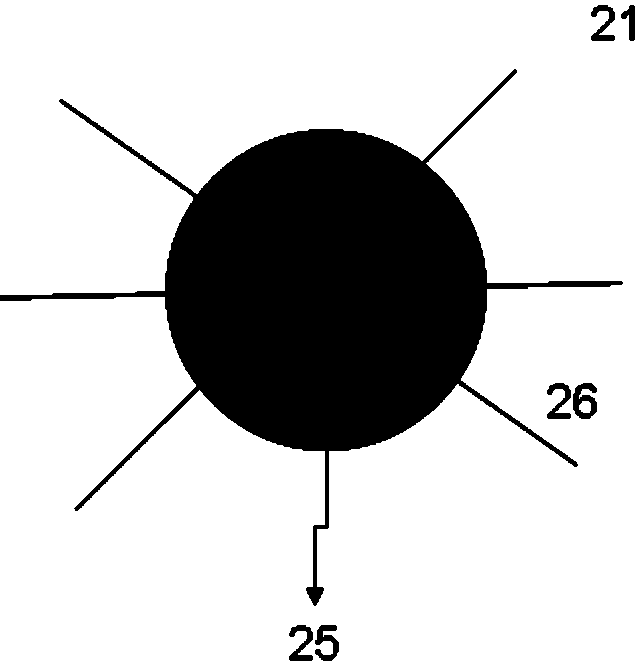

[0040] Such as figure 1 , figure 2 As shown, a production system of fracturing proppant using red mud as raw material includes feeder 1, high temperature furnace 2, channel 3, high pressure gas pipeline 4, spinner 5, frequency modulation motor 6, blanking bin 7, and One metal slide pipe 8, heat preservation channel 9, second metal slide pipe 10, tempering furnace 11, outer cover 12, third metal slide pipe 14, screening equipment 15, electronic scale 16, packaging bag 17, first flashboard 18, The fourth metal chute 19, nozzle 20, grid plate 21, discharge opening 22, second flashboard 23, cooling air 24, heat-resistant steel plate 25, heat-resistant steel pipe or steel bar 26. The feeder 1 is connected to the high-temperature furnace 2, and the high-temperature furnace 2 outputs the melt through the first channel 31, and the melt flows to the front end of the channel 31, and flows down to the front of the high-pressure gas no...

Embodiment 2

[0056] Example 2 pure red mud

[0057] Red mud treatment:

[0058] Test parameters: Dry the red mud at 120° for 12 hours, put the red mud into a continuous ball mill, the size of the ball mill is 2.4 m × 9m, and 54 tons of steel balls are installed in the mill, and it is continuously air-selected through a 30-mesh sieve.

[0059] (1) Ingredients: pure red mud

[0060] The mass component of the red mud is: SiO 2 12.93, Al 2 o 3 14.90, Fe 2 o 3 21.92,TiO 2 11.52, CaO0.61, MgO1.11, Na 2 O 2.70, the rest are loss on ignition and trace components.

[0061] (2) High temperature melting: 1550°2h;

[0062] (3) Spinning to forming: the speed is 1400-1900rpm, and the qualified sample 20-40 mesh accounts for more than 80% in the production as the basis for speed adjustment; the particle size of the collected samples is 20-70 mesh.

[0063] The collected samples are 20-70 mesh, which can be used instead of quartz sand proppant.

Embodiment 3

[0064] Example 3 red mud

[0065] The mass component of the red mud is: SiO 2 44.79 Al 2 o 3 11.16 Fe 2 o 3 17.51 TiO 2 2.04 CaO 0.78 MgO 0.06 Na 2 O 1.59. All the other refer to embodiment 1 or embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com