Test device and method for researching friction characteristics between tire and actual pavement

A friction characteristic and test device technology, which is applied in the direction of automobile tire testing, measuring devices, and mechanical devices, can solve problems such as large energy consumption, increased equipment power, and difficult control of wheel slip rate, and achieves a smooth torque transmission process. , shorten the adjustment time, eliminate the effect of heating phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

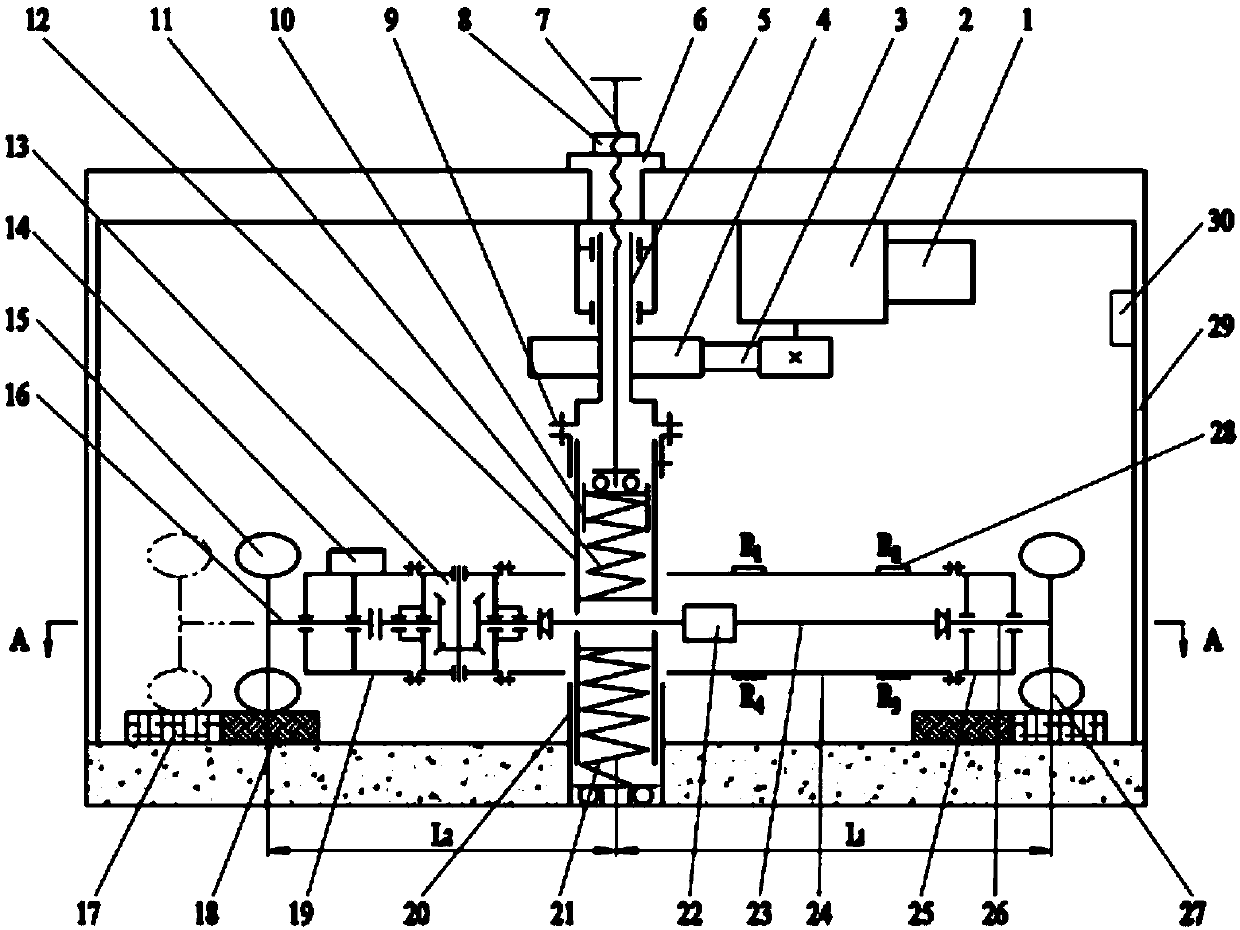

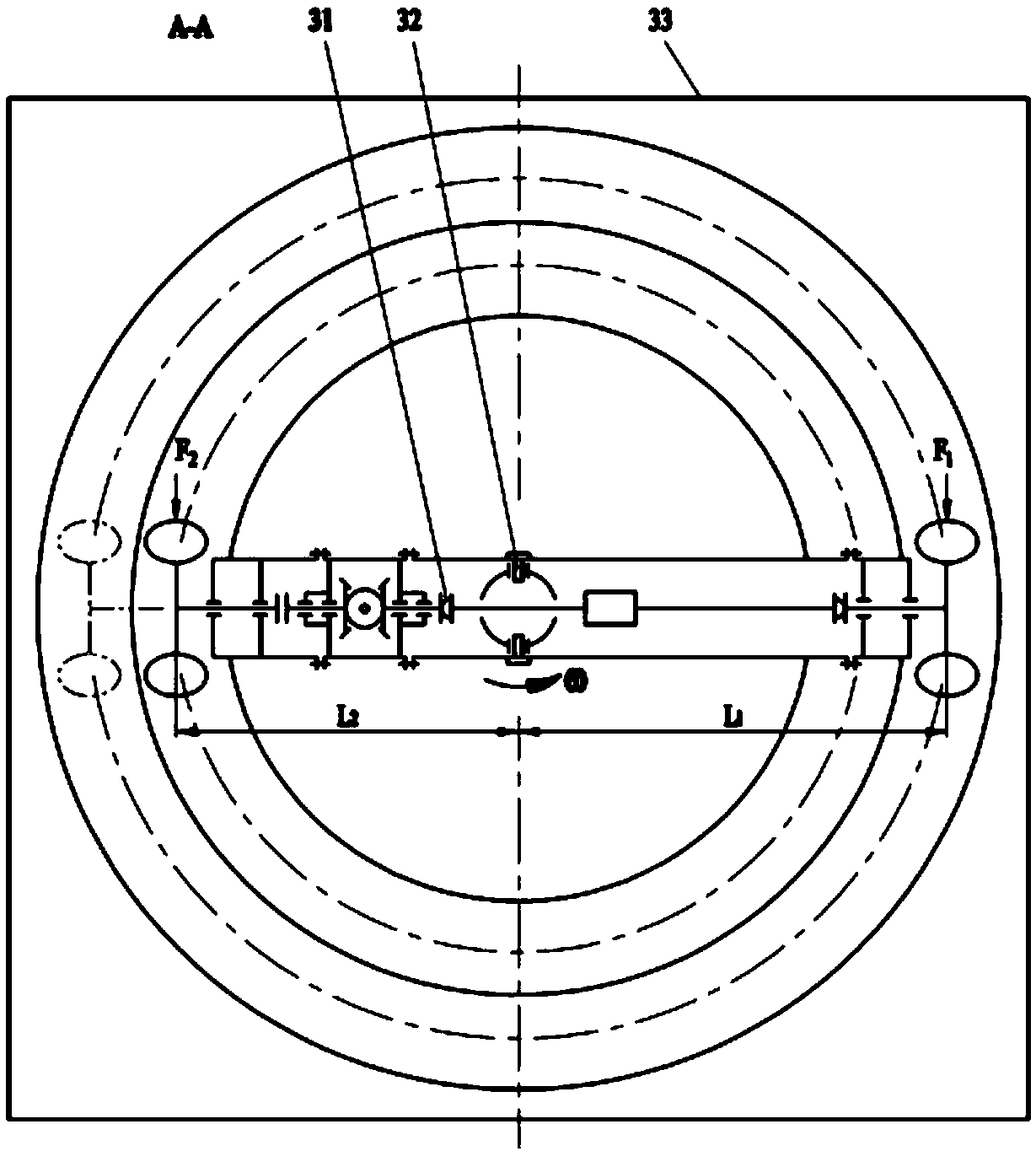

[0043] Such as figure 1 , figure 2 , the radius of the testing wheel 27 is equal to that of the auxiliary wheel 15, and the length L of the rotating arm of the testing wheel 27 1 Length L greater than the arm of the auxiliary wheel 15 2 , the transmission ratio of the power transmission box 13 is minus 1, that is, the rotational speeds of the two shaft ends of the power transmission box 13 are equal in magnitude and opposite in direction.

[0044] The motor 1 is equipped with a speed regulating device, the motor 1 is directly connected with the reducer 2, the reducer 2 is fixedly installed on the top of the frame 29, the output shaft of the reducer 2 is connected with the driven pulley 4 through the belt 3, and the driven pulley 4 It is fixedly connected with the central tube shaft 5; the central tube shaft 5 is hollow in the axial direction, and a loading screw 7 is arranged inside the central tube shaft 5, and the loading screw 7 is arranged on the axis of the central tub...

Embodiment 2

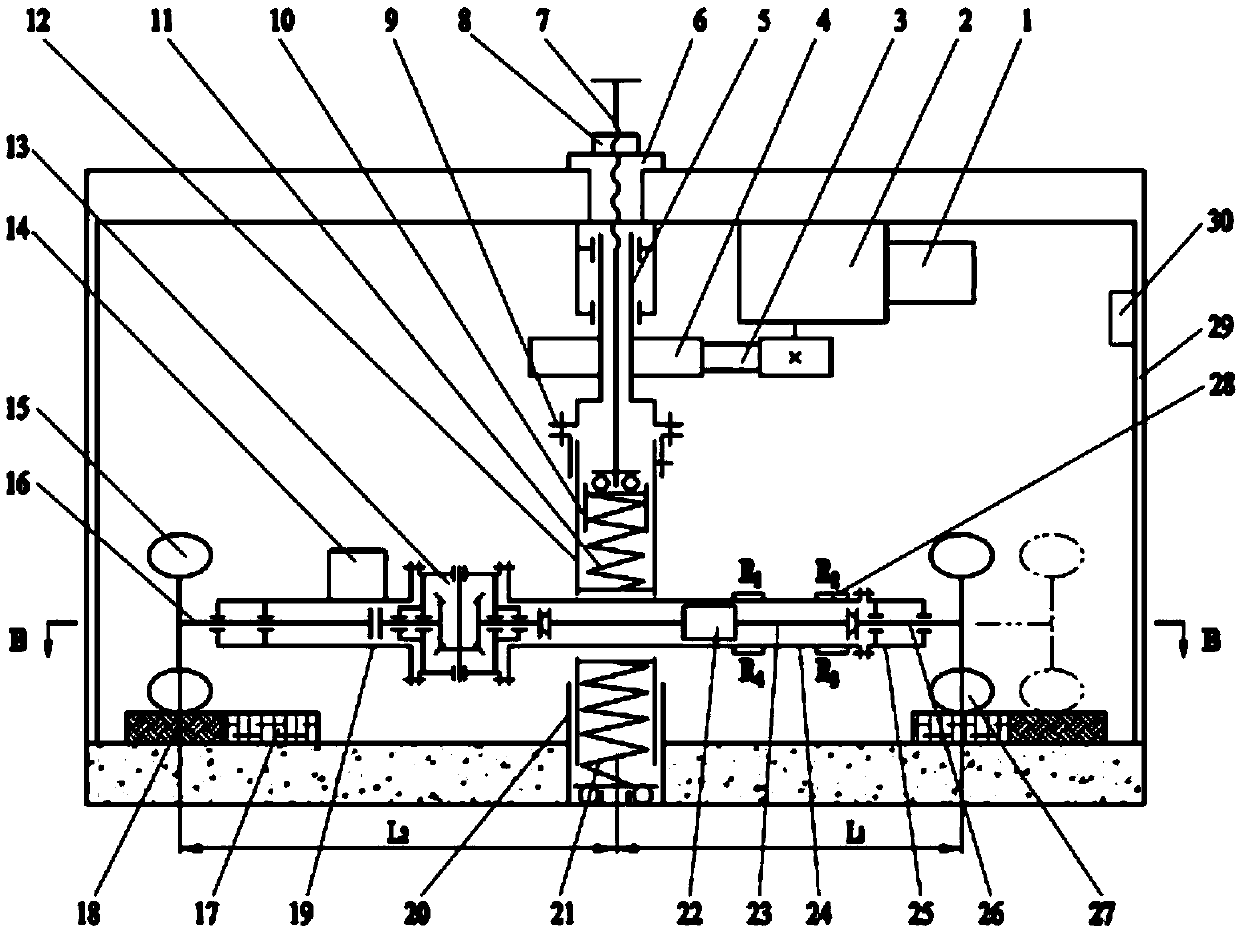

[0067] Such as image 3 , Figure 4As shown, in this embodiment, there is a large hole in the horizontal direction between the upper partition and the lower partition in the loading sleeve 12, and the rotating arm 24 passes through this large hole, and the rotating arm is driven by the driving pin 32. 24 is hinged with the loading sleeve 12, and the L 1 2 , the test loop 17 is arranged on the inside, and the auxiliary loop 18 is arranged on the outside. All the other structures are the same as in Example 1.

[0068] At this time, the auxiliary wheel 15 does not slip, but the running speed is fast, the actual speed of the test wheel 27 is slow, and it slips backward, and the slip rate σ is calculated according to the following formula:

[0069]

[0070] When the rotating arm 24 rotates at an angular velocity ω, the test wheel 27 slides backward, and the ground gives the test wheel 27 a forward friction force F 1 , friction force F 1 It is to drive the rotating arm 24 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com