Hand-held stranding machine applied to enameled wire

An enameled wire and stranding machine technology, applied in the field of stranding machines, can solve the problems of low work efficiency, uneven twisting, laboriousness, etc., and achieve the effect of high work efficiency and avoiding slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

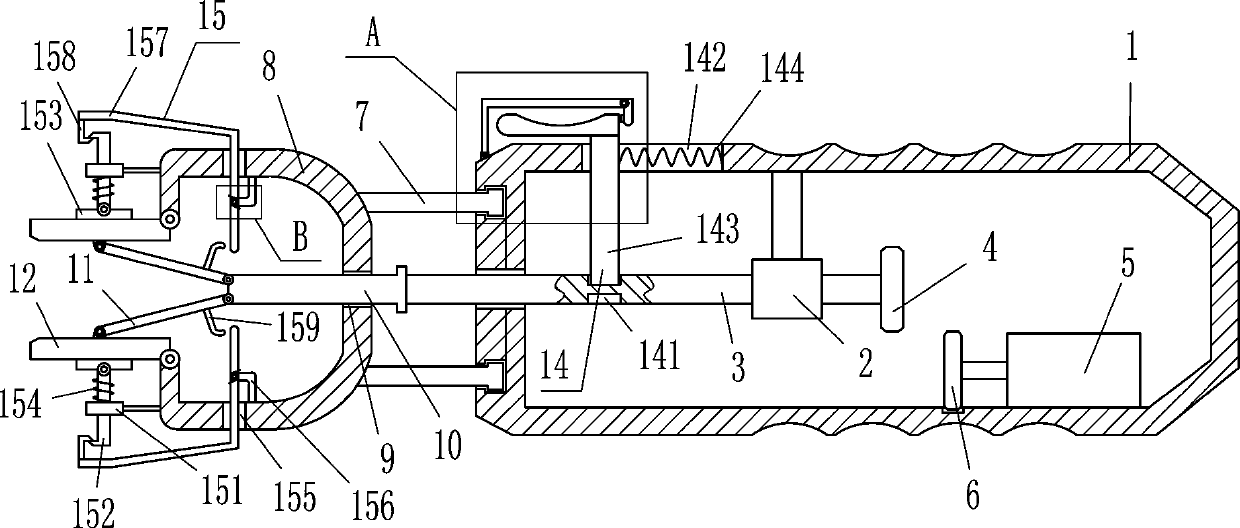

[0019] refer to figure 1 with figure 2 , a hand-held stranding machine for enameled wire, including a cylinder 1, a guide sleeve 2, a round rod 3, a first gear 4, a drive motor 5, a second gear 6, an annular slider 7, a special-shaped frame 8, a square Rod 10, connecting rod 11, splint 12 and drive mechanism 14, guide sleeve 2 is fixedly connected to the top left side of the cylinder body 1, and a circular rod 3 is slidingly installed inside the guide sleeve 2, and the left end of the circular rod 3 runs through the cylinder body 1. In the middle part on the left side, the first gear 4 is fixedly connected to the right end of the circular rod 3. A driving mechanism 14 is provided between the circular rod 3 and the upper left side of the cylinder body 1. The driving motor 5 is installed on the right side of the inner bottom of the cylinder body 1. The output shaft of the drive motor 5 is connected with the second gear 6 through a coupling, and the second gear 6 cooperates wit...

Embodiment 2

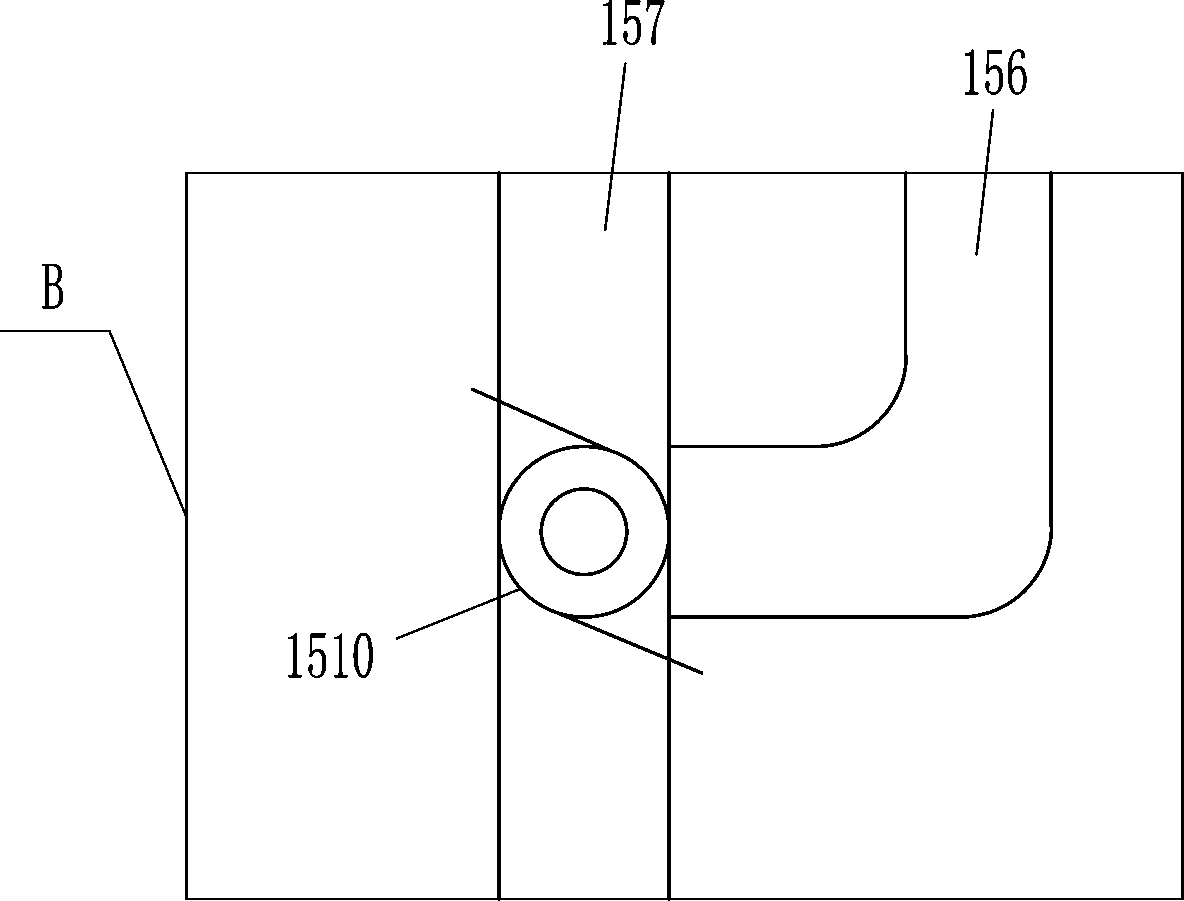

[0024] On the basis of embodiment one, refer to Figure 1-Figure 3, also includes the clamping mechanism 15 that can compress the splint 12, and the clamping mechanism 15 includes a guide sleeve 151, a movable rod 152, a pressing plate 153, a second spring 154, an L-shaped rod 156, an L-shaped contact rod 157, a card Bar 158, fixed bar 159 and torsion spring 1510, guide cover 151 is all installed on the upper and lower sides on the outer left side of special-shaped frame 8, and slide type is provided with movable bar 152 in guide cover 151, and the movable bar 152 inner ends of both sides up and down are all arranged. Hinged with the pressure plate 153 that can compress the splint 12, the second spring 154 is wound between the inside of the movable rod 152 on the upper and lower sides and the inner surface of the guide sleeve 151 on the upper and lower sides. Hole 155, guide hole 155 is provided with L-type contact rod 157, and the left side of L-type contact rod 157 inner sid...

Embodiment 3

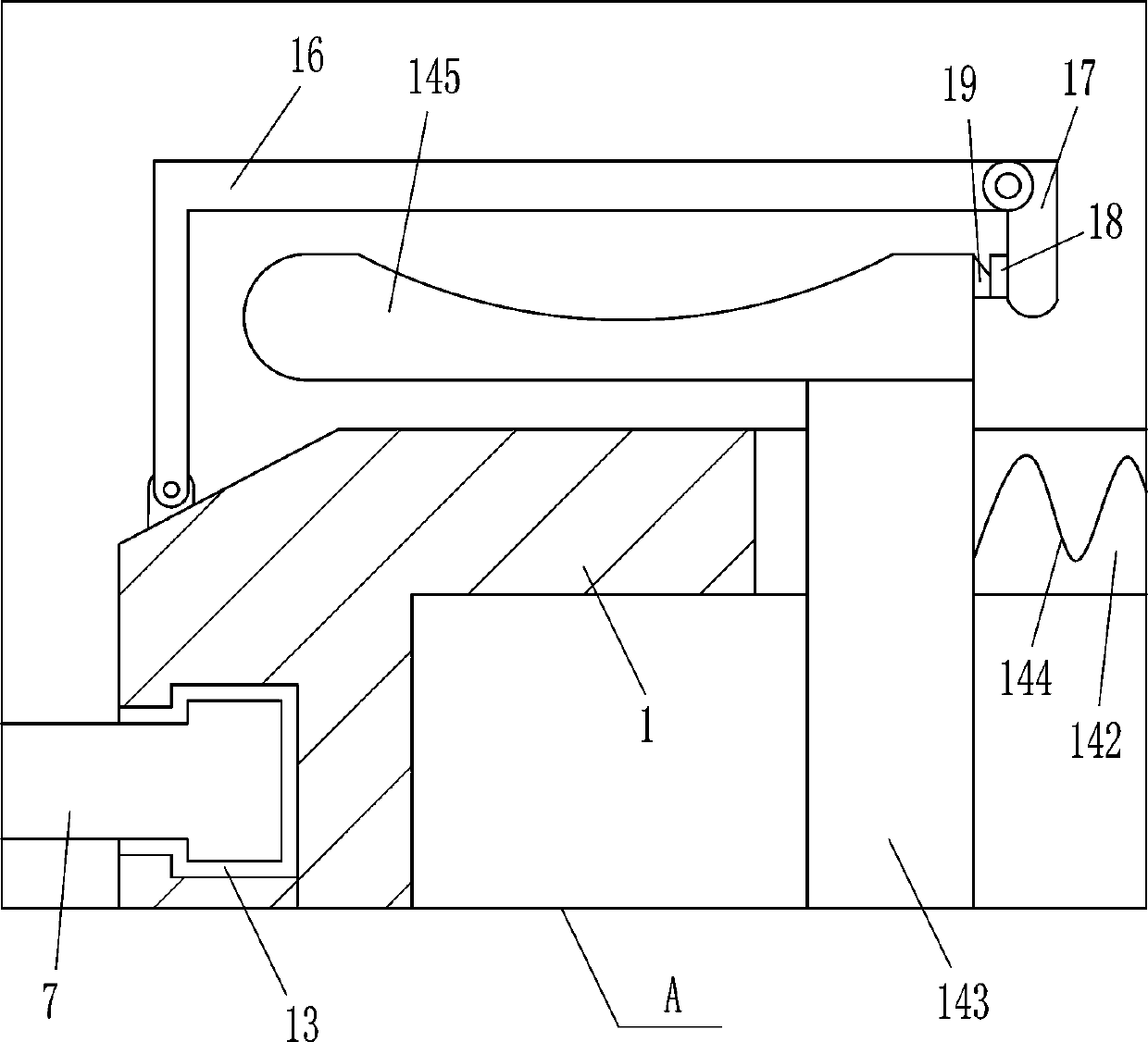

[0027] On the basis of embodiment one and embodiment two, refer to Figure 1-Figure 3 , also includes movable frame 16, movable plate 17, magnet 18 and iron block 19, cylinder body 1 outer top left side is hinged with movable frame 16, movable frame 16 right side is hinged with movable plate 17, movable plate 17 left side The bottom is fixedly connected with a magnet 18 , and the upper part of the right side of the push plate 145 is fixedly connected with an iron block 19 , and the iron block 19 contacts and cooperates with the magnet 18 .

[0028] When the enameled wire moves between the clamping plates 12 on the upper and lower sides, the operator can pull the movable plate 17 to swing upward, and the upward swing of the movable plate 17 drives the magnet 18 to swing upward, and the upward swing of the magnet 18 is separated from the iron block 19, and stops pulling the movable plate 17 , then pull the movable frame 16 to swing upwards without covering the push pedal 145, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com