Vertical type method for processing nozzle cooling channel of liquid-propel land rocket engine

A technology for engine nozzles and cooling channels, applied in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve problems such as long time-consuming, poor installation positioning accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

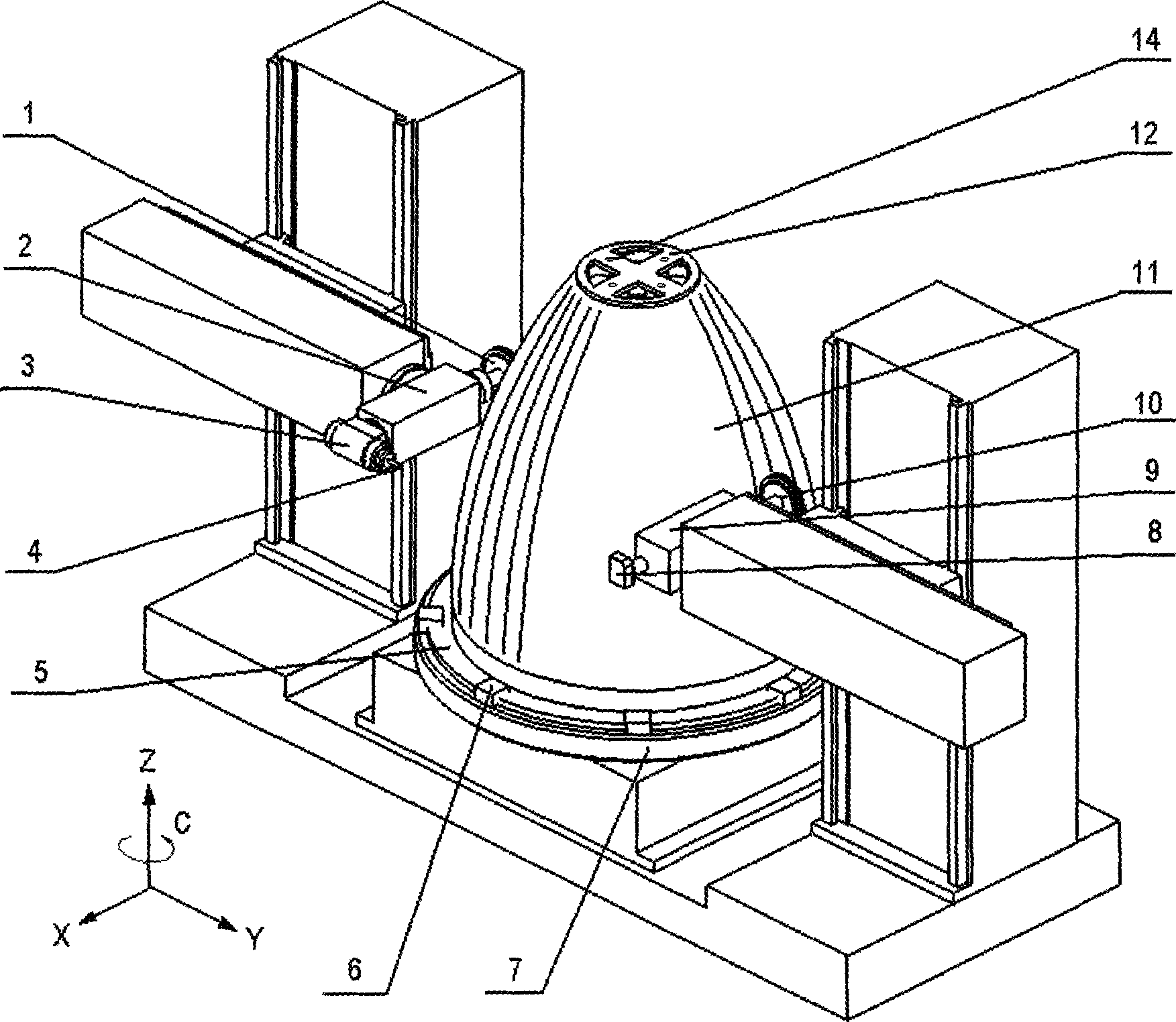

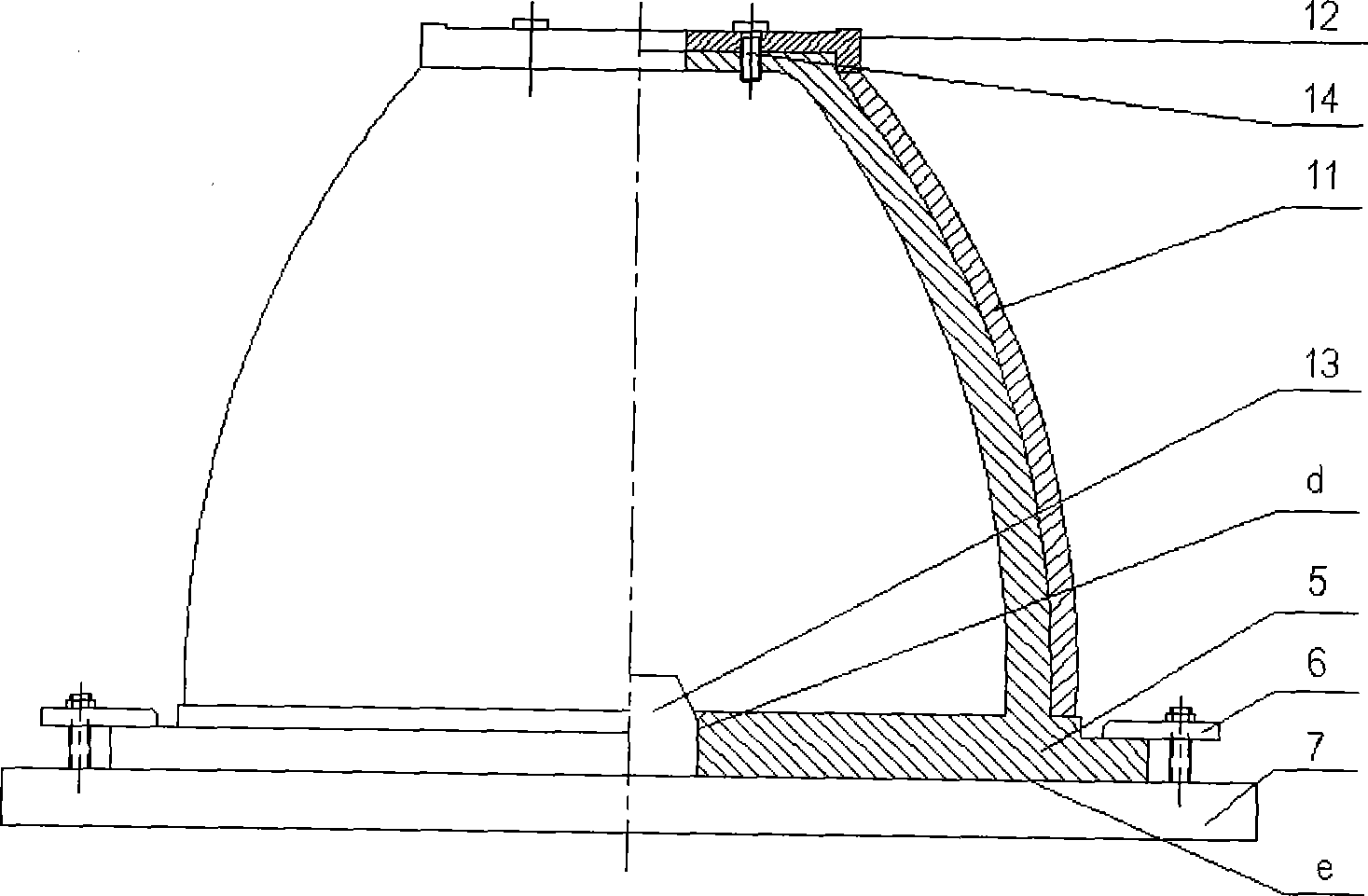

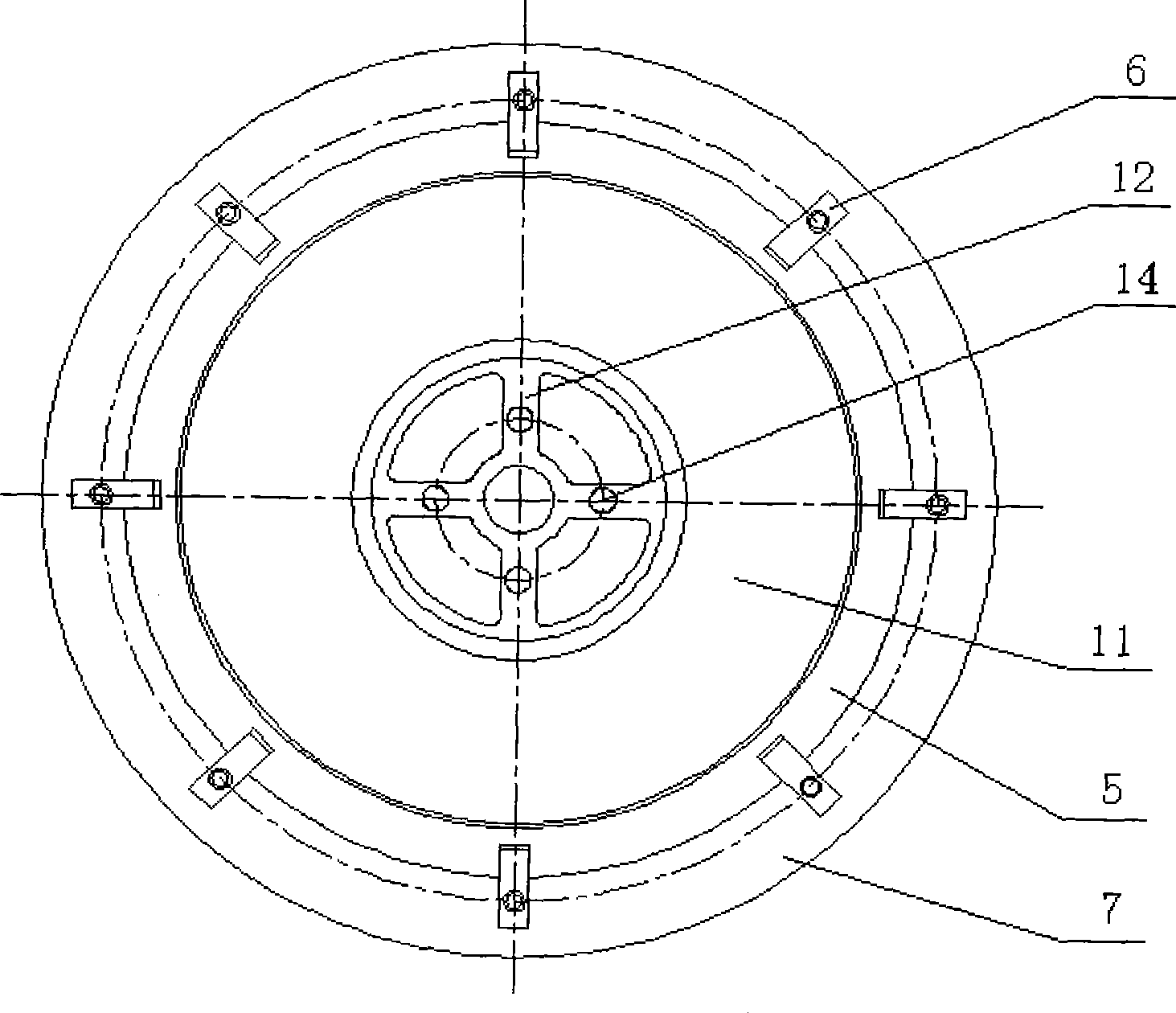

[0042] The embodiments of the present invention will be described in detail in conjunction with the drawings and technical solutions. Process the cooling channel of a nozzle of a certain type of liquid rocket:

[0043] (1) Before the nozzle 11 is hoisted, at first ensure that the milling measurement adapter 9 and the milling root cleaning adapter 2 are in a safe position to prevent collisions during hoisting; figure 1 , figure 2 As shown, the nozzle membrane 5 is placed on the table top e of the rotary table by hoisting, so that the positioning cylindrical pin 13 located at the center of the rotary table 7 and the center hole d of the nozzle membrane 5 are clearance matched to realize the nozzle tire The mold 5 is positioned with "one pin on one side"; the nozzle membrane 5 is compressed by eight pressure plates 6 with bolts evenly distributed in the circumference of the rotary table 7; the nozzle 11 is hoisted on the nozzle on the tube membrane 5; tighten the screw 14 to m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com