Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

111 results about "Rocket engine nozzle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A rocket engine nozzle is a propelling nozzle (usually of the de Laval type) used in a rocket engine to expand and accelerate the combustion gases produced by burning propellants so that the exhaust gases exit the nozzle at hypersonic velocities.

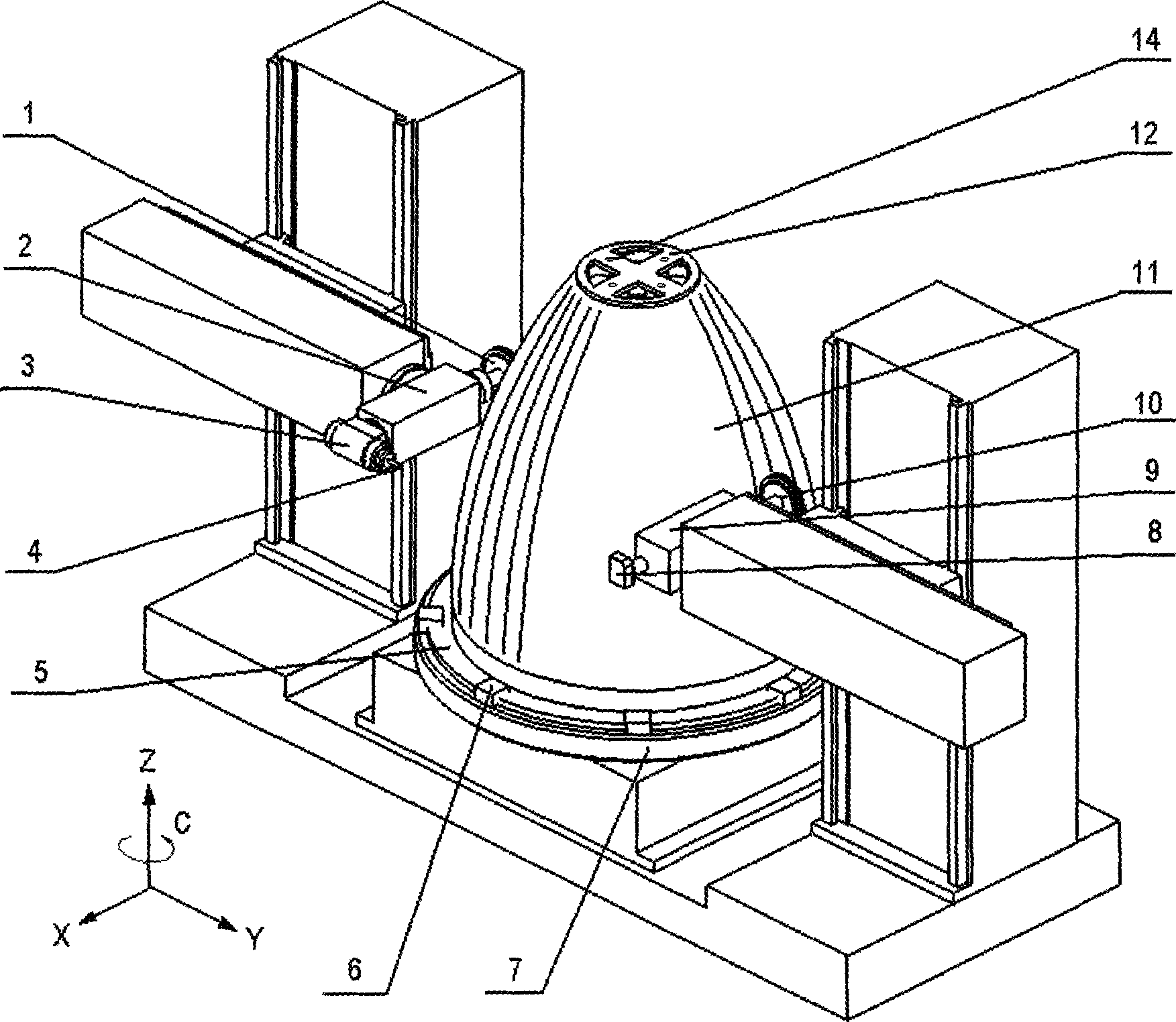

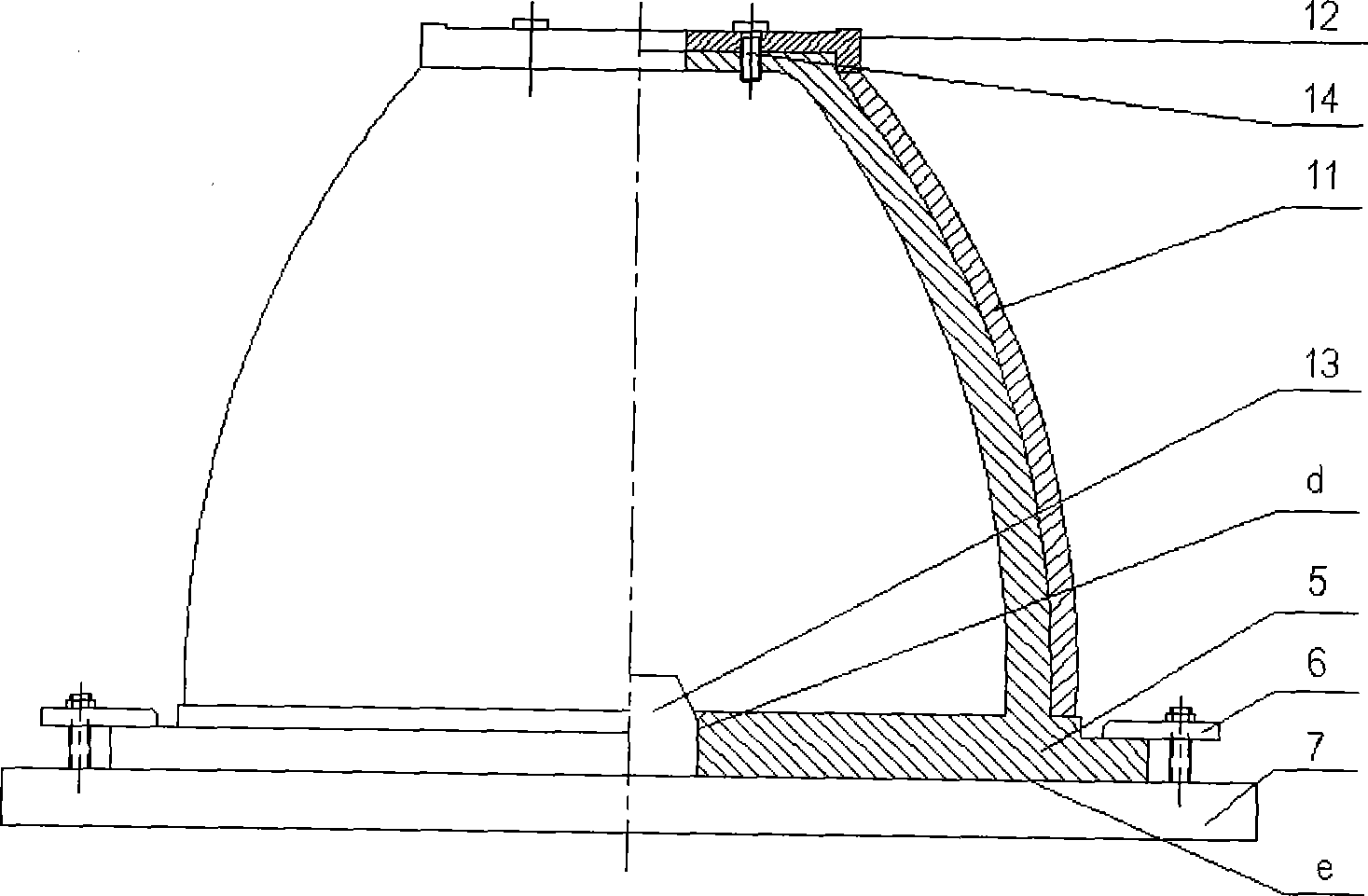

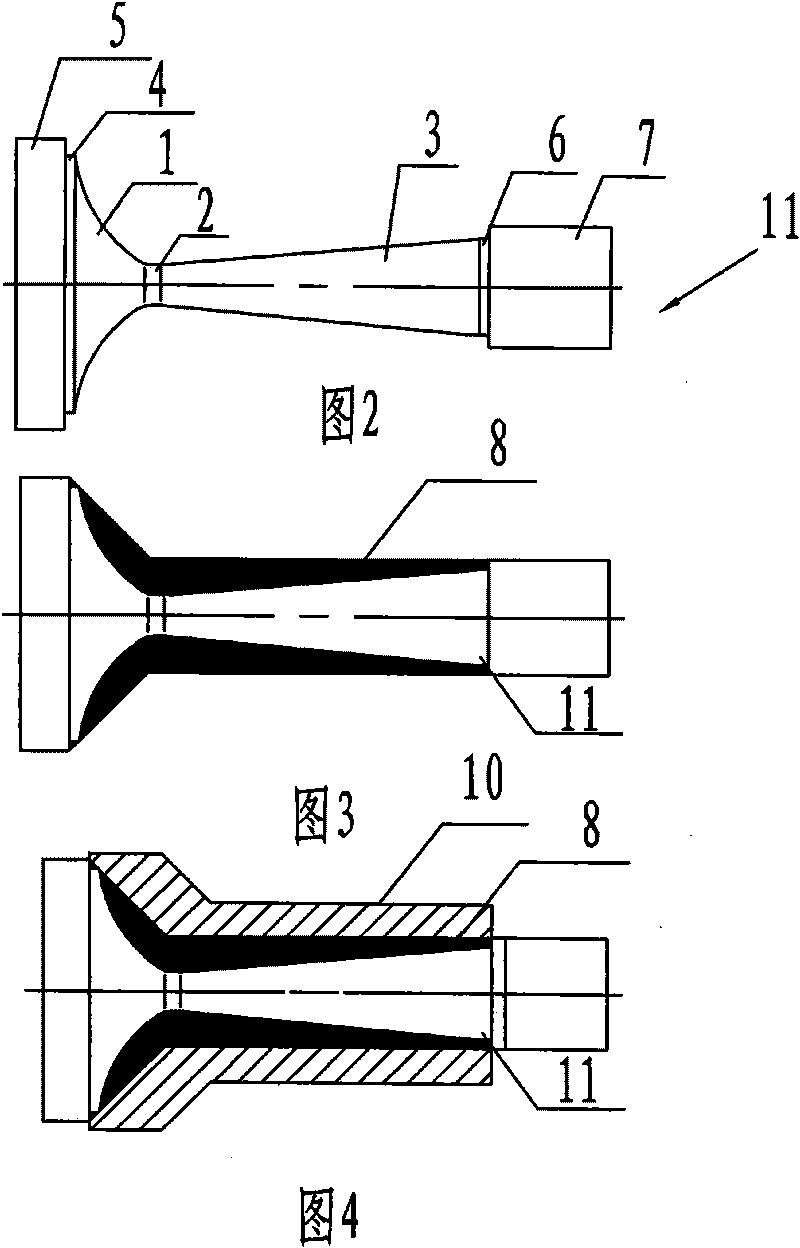

Vertical type method for processing nozzle cooling channel of liquid-propel land rocket engine

InactiveCN101412122AImprove smoothnessHigh-precision digital processingAutomatic control devicesMeasurement/indication equipmentsData setLaser sensor

The invention relates to a method for vertically processing a cooling passage of a liquid rocket engine thrust jet, which belongs to the processing method field of liquid rocket engine thrust jet. In the invention, the thrust jet adopts a vertical clamp; a single-point laser sensor scans bus bars strip by strip to acquire the actual profile of the thrust jet and a sampled data set to reconstruct the bus bars of the thrust jet strip by strip; the buses of the sampled data set are smoothed strip by strip to acquire a thrust jet smoothed data set; the data set of all the bus bars are compressed to acquire a compressed data set; and a cubic spline is used for performing interpolation to approximate the actual bus bars of the thrust jet. The milling tool position is calculated by dual milling head for symmetrical milling and high speed back chipping. The method realizes the integration of measurement and processing, finishes the treatments of profile measurement, milling groove and back chipping by one clamping, can satisfy the processing requirements on different physical dimensions and different bus bar linetypes, has high processing efficiency and good consistency, and realizes the digital processing with high efficiency and high precision of the cooling passage of the liquid rocket engine thrust jet.

Owner:DALIAN UNIV OF TECH

Method for preparing rocket engine jet pipe and special equipment thereof

InactiveCN101733614AOvercome the disadvantage of being limited to expensive molybdenum nozzlesMeet the needs of the working environmentMolten spray coatingFoundry mouldsRocket engine nozzleMachining

The invention provides a method for preparing a rocket engine jet pipe, which comprises the following steps: (1) preparing a blank of the rocket engine jet pipe and preparing a core rod of the blank; (2) spraying a coat on the surface of the core rod, grinding the surface of the core rod, and matching the ground core rod with the blank; (3) assembling the ground core rod and the blank on a press, and then sheathing the assembled whole; (5) performing hot isostatic pressing treatment on the sheathed whole in a hot isostatic pressing furnace; and (5) after the hot isostatic pressing treatment, removing the sheathed material and the core rod, and performing fine machining on the jet pipe blank with the coat to obtain the rocket engine jet pipe. The invention also provides special equipment for the preparation method. The method of the invention is not only suitable for the jet pipe with large inner hole size, but also suitable for the jet pipe with small inner hole size and with special requirement for the coat.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

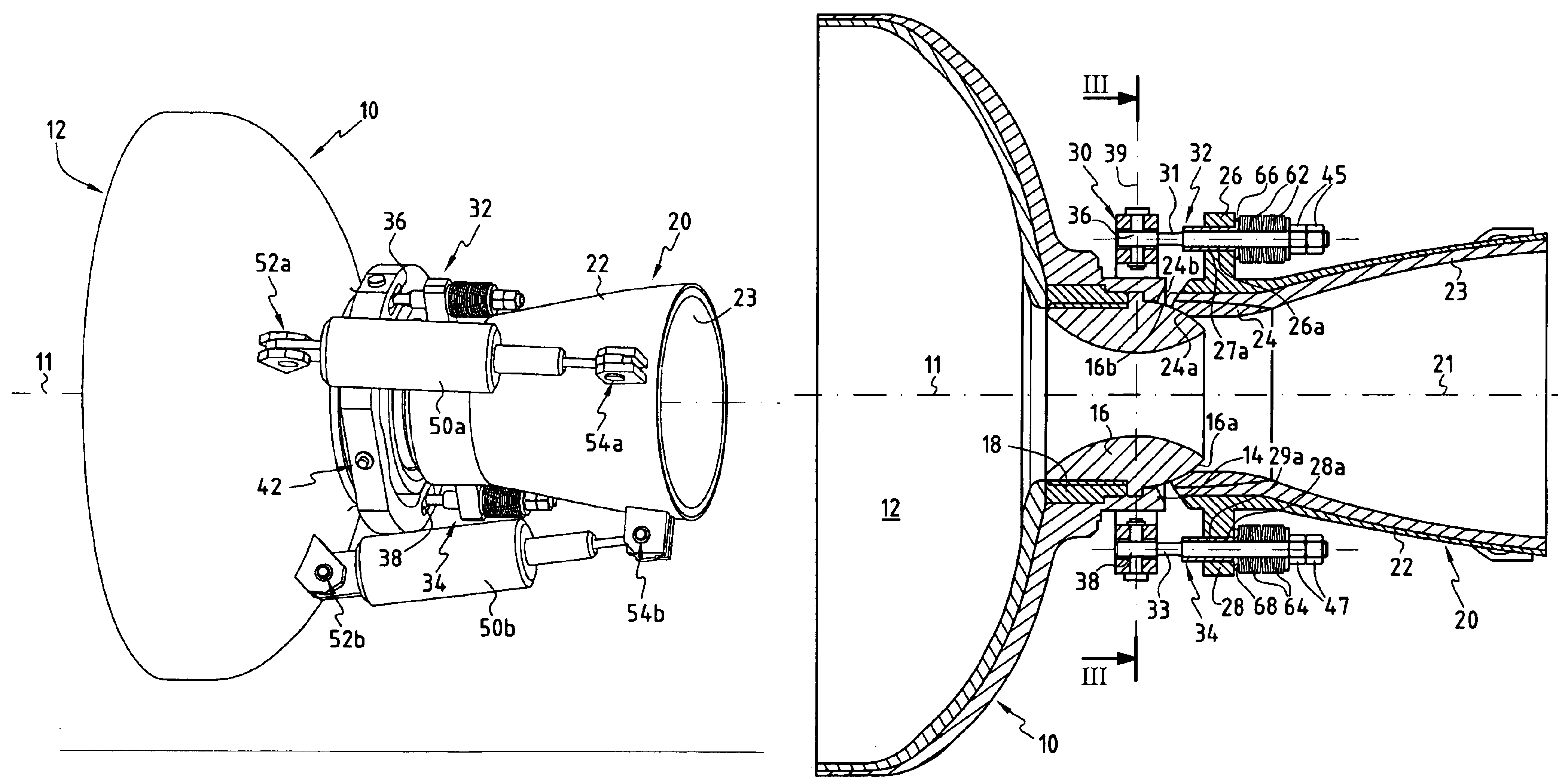

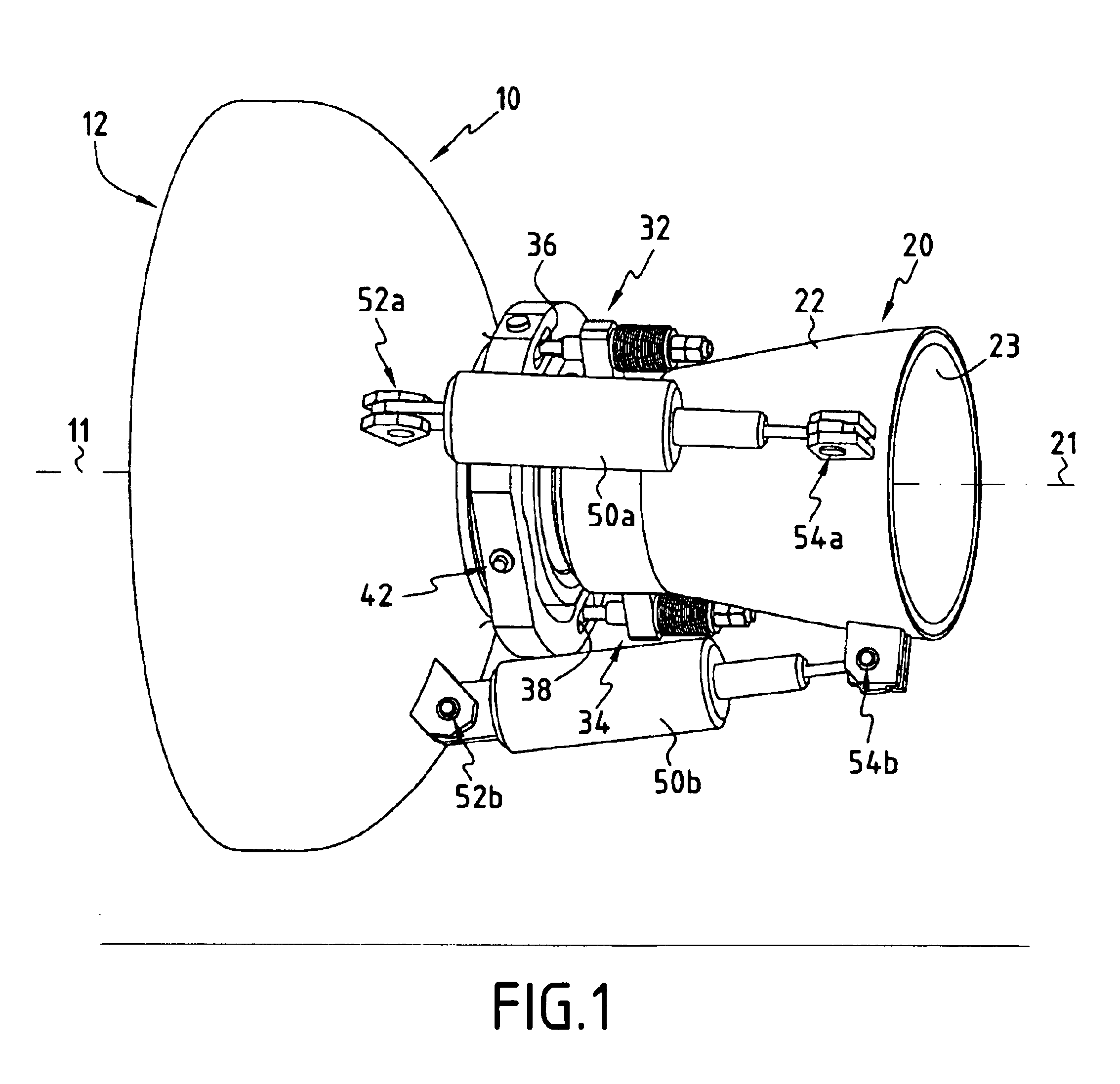

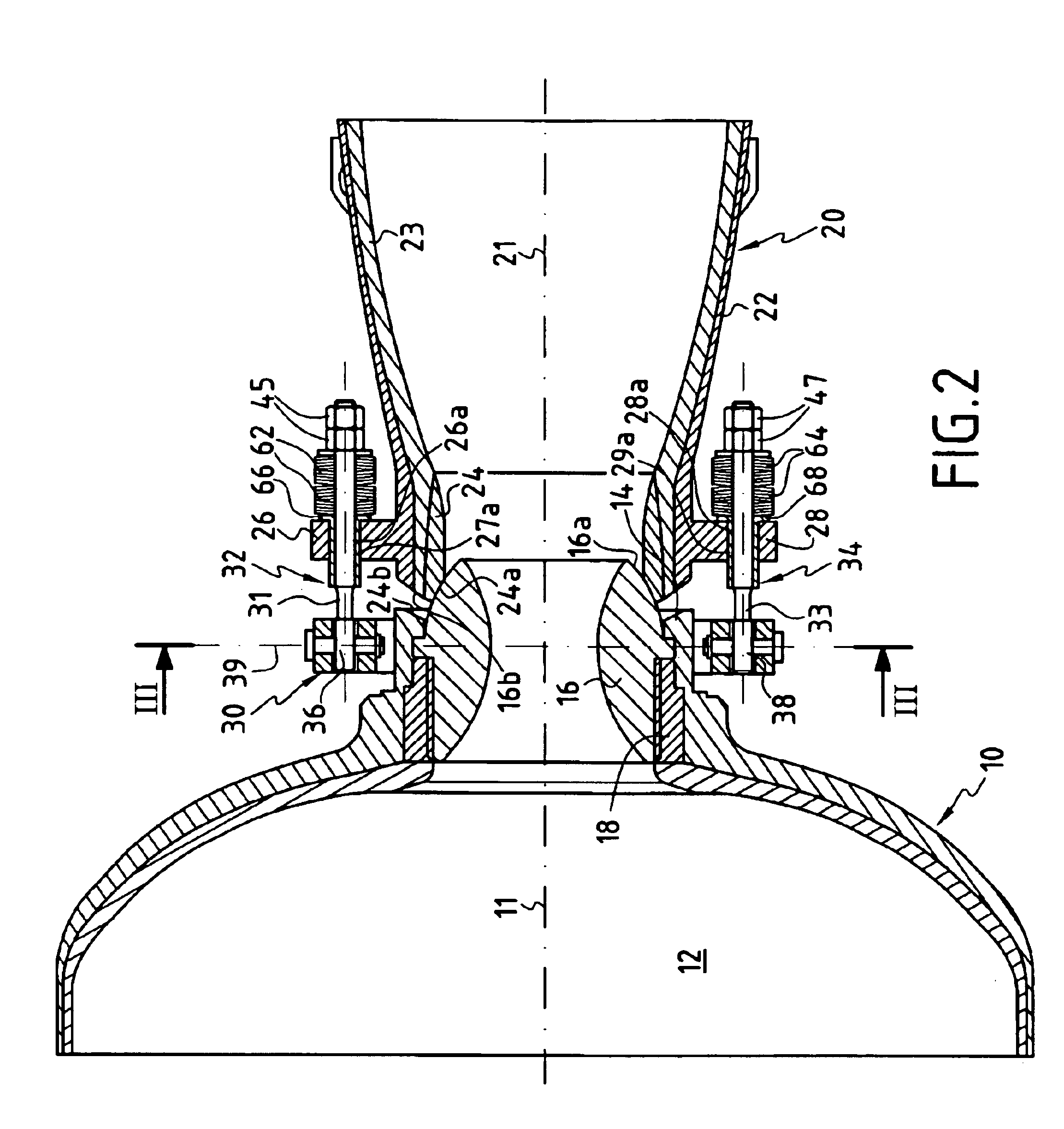

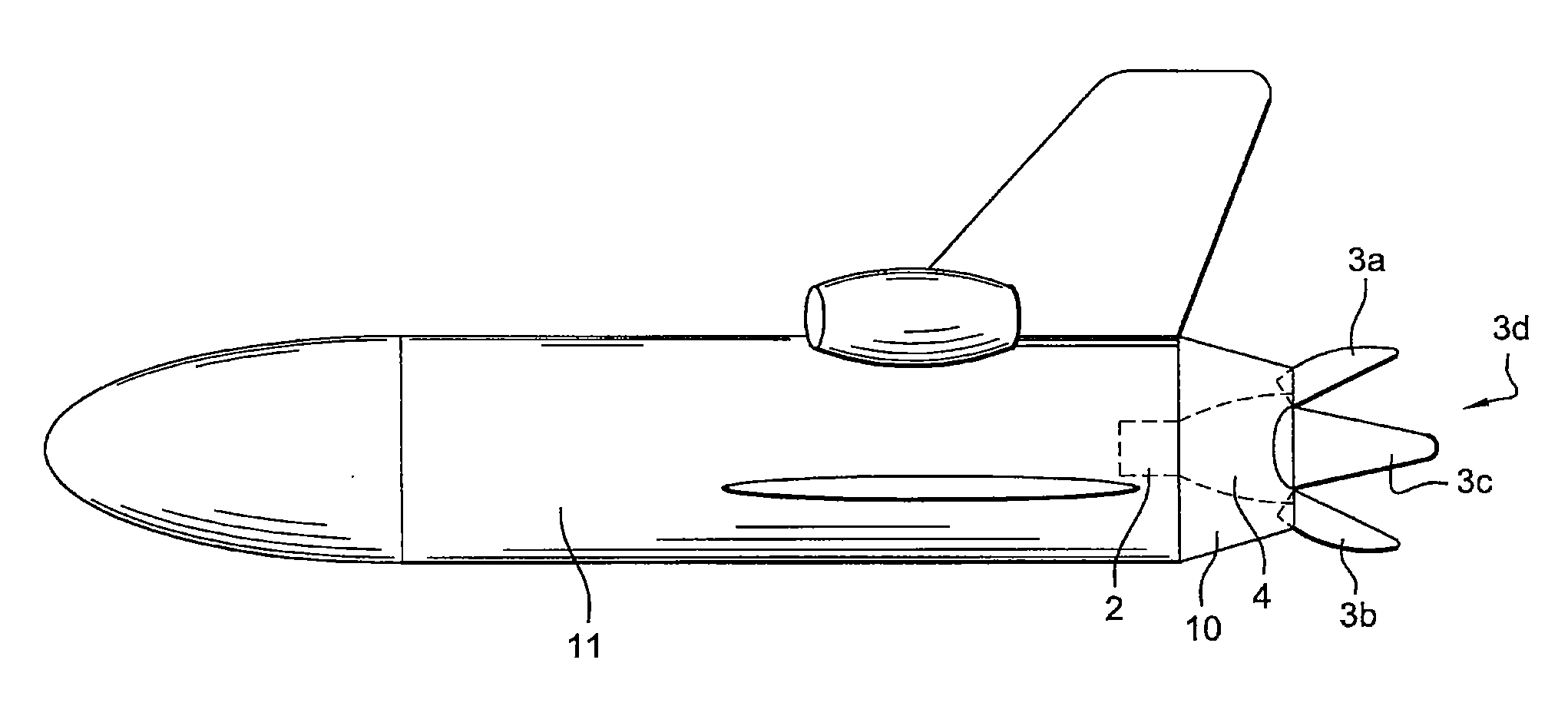

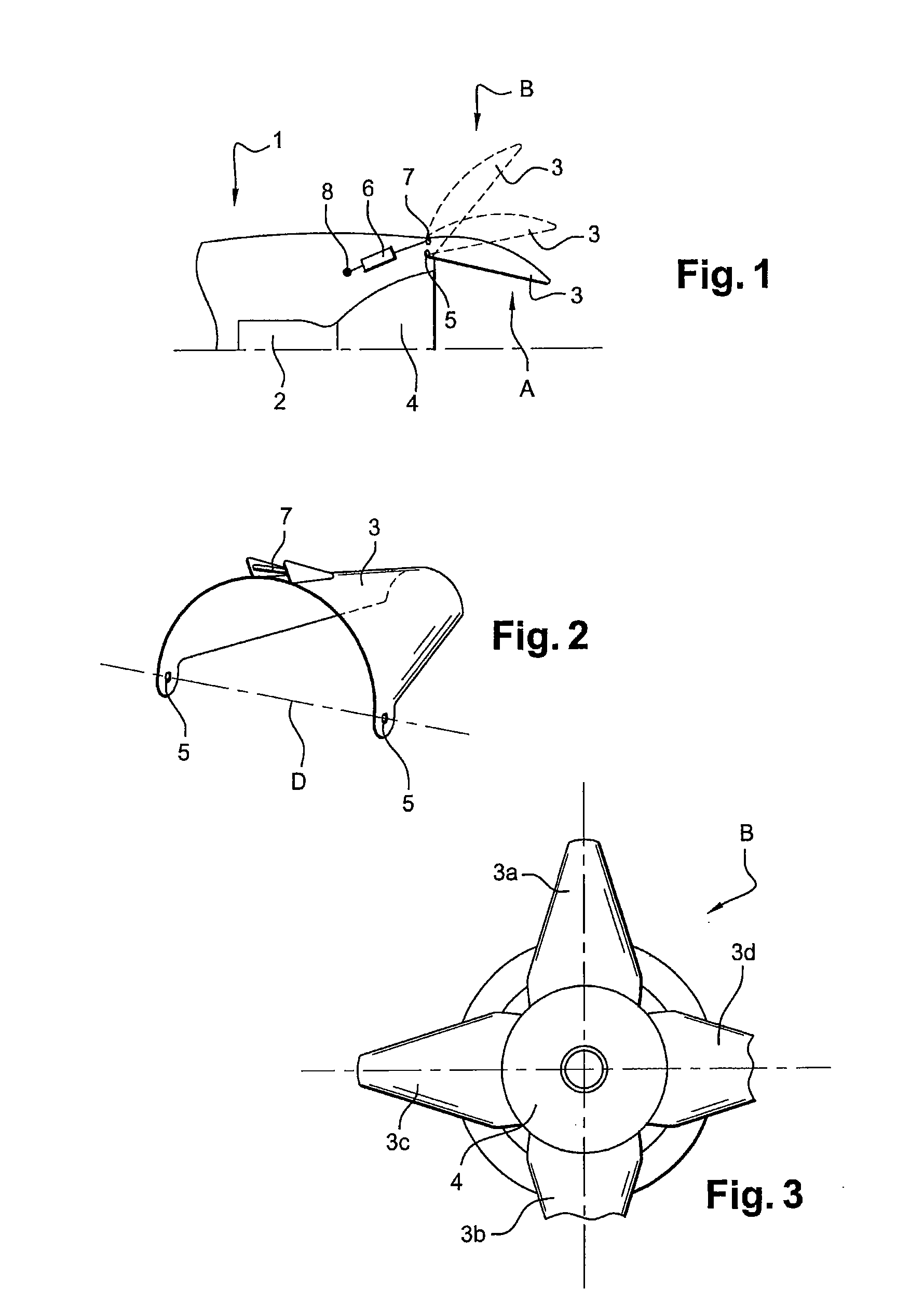

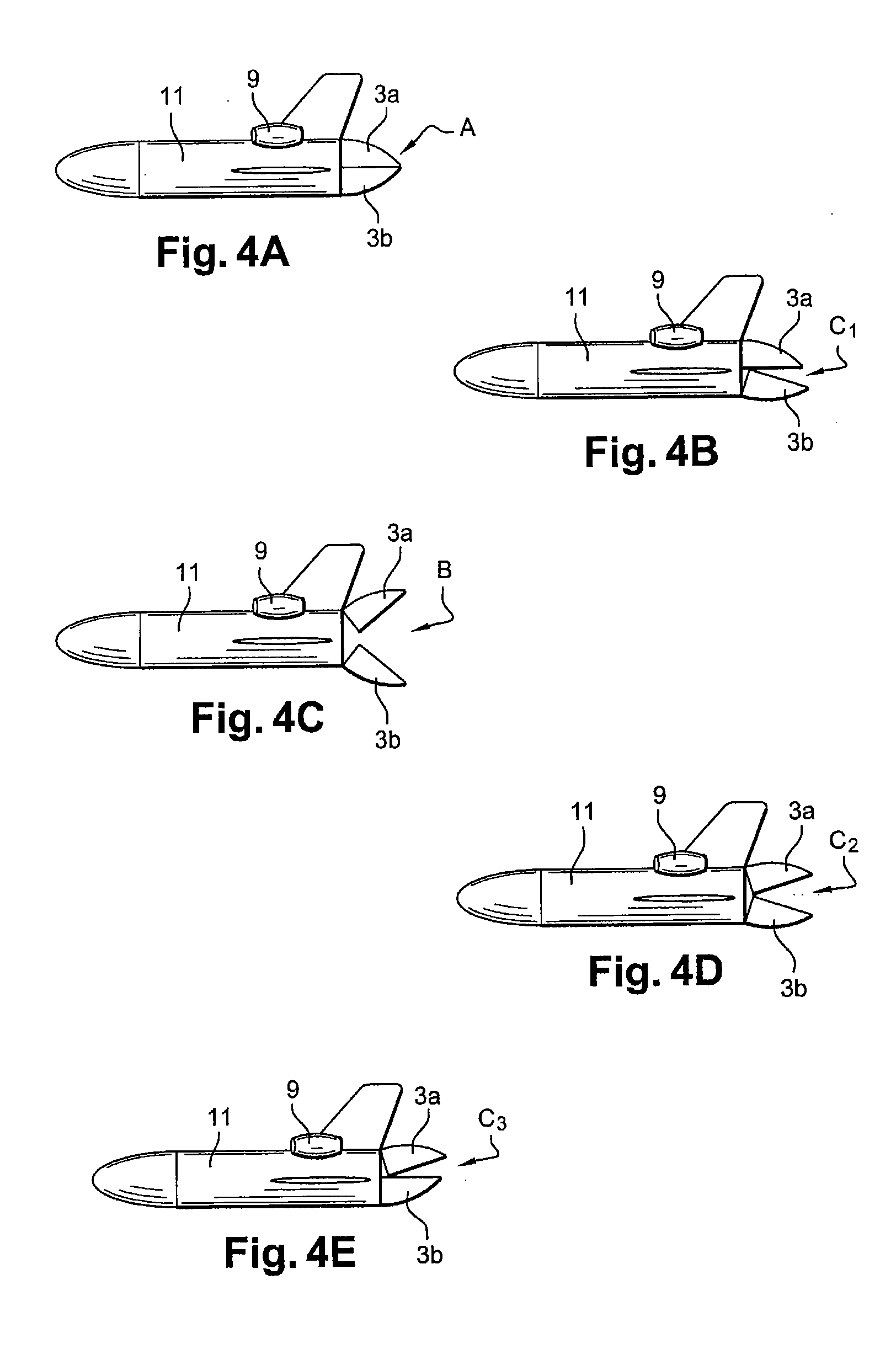

Rocket engine nozzle that is steerable by means of a moving diverging portion on a cardan mount

InactiveUS6948307B2Stable and reliableRocket engine plantsHot gas positive displacement engine plantsCombustion chamberActuator

Owner:GERAKL

Bonding method for jet pipe and flexible plug cover of solid rocket engine and sealing tool

ActiveCN106287101AImprove bonding qualitySimple methodPlastic deformation fasteningMaterial gluingElectrical junctionAtmospheric pressure

The invention discloses a bonding method for a jet pipe and a flexible plug cover of a solid rocket engine, and a sealing tool. The bonding method includes the steps that after the flexible plug cover and a jet pipe throat lining are bonded in advance, the sealing tool is mounted on the jet pipe, and the flexible plug cover and the sealing tool are matched to form a first sealed space area; and the first sealed space area is pressurized, the external molded surface of the bonding surface between the flexible plug cover and the jet pipe throat lining is pressurized in an air-pressure mode, and finally, pressure-maintaining solidification is carried out. By utilizing the non-directionality of air pressure, air pressure is applied to the flexible plug cover and acts on the external molded surface of the bonding surface, all points on the bonding surface are subjected to normal-direction stressing, surface-contact uniform stressing of the bonding surface is achieved, and therefore the bonding quality is improved; and in addition, the method is simple, operation is convenient, the period is short, the cost is low, and the bonding method is especially suitable for bonding of the jet pipe and the flexible plug cover of the large-diameter solid rocket engine.

Owner:湖北三江航天江北机械工程有限公司

Rocket engine tail jet flow simulation method and system

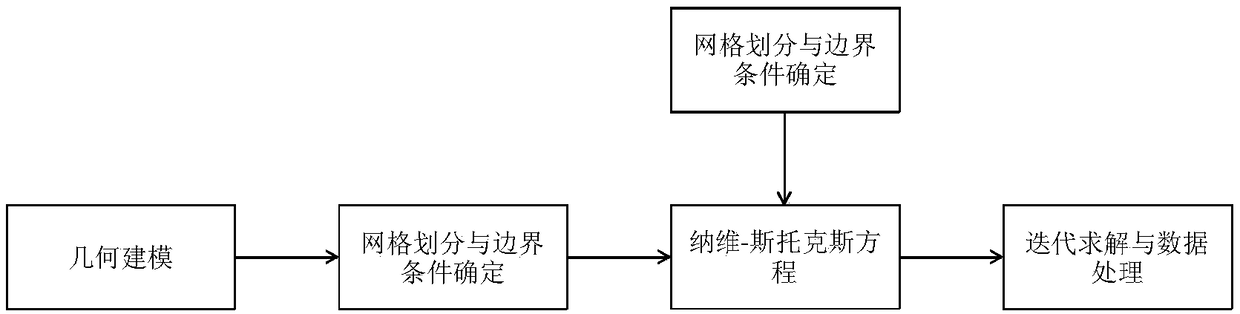

ActiveCN108304684AMake up for the inability to accurately predict supersonic compressible jet flow under large temperature gradientImprove accuracyGeometric CADSustainable transportationJet flowComputational model

The invention relates to a rocket engine tail jet flow simulation method and system. The method includes the steps of (1), establishing a three-dimensional geometric model with the size same as a rocket engine jet pipe; (2), conducting grid partition and encryption on the three-dimensional geometric model to determine boundary conditions; (3), establishing a calculation model to ensure that a tailjet flow process satisfies a viscosity Navier-Stokes equation; (4), conducting iterative solution on a rocket engine tail jet flow model by using a computational model, and completing the simulationprocess of rocket engine tail jet flow. A temperature-corrected SST k-omega turbulence model is adopted for calculating the rocket engine tail jet flow, the defect that existing turbulence models cannot accurately predict supersonic compressible jet flow under a large temperature gradient is remedied, the accuracy of a simulation result is significantly improved, and an error between the simulation result and an experimental result is reduced to 1%.

Owner:BEIJING AEROSPACE PROPULSION INST

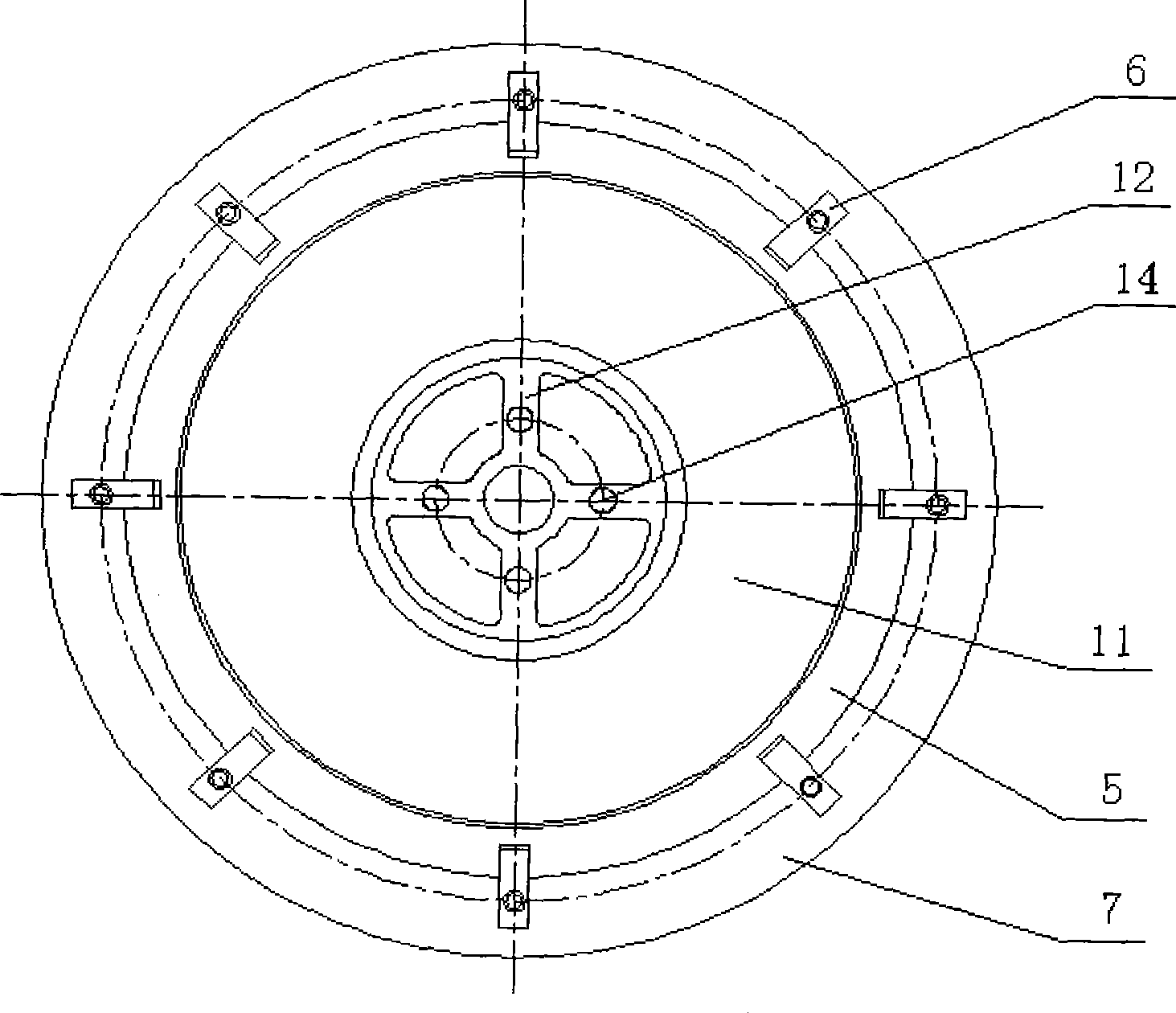

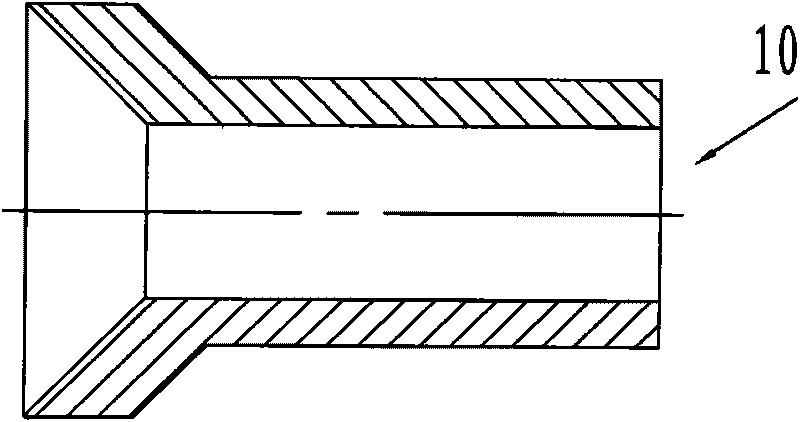

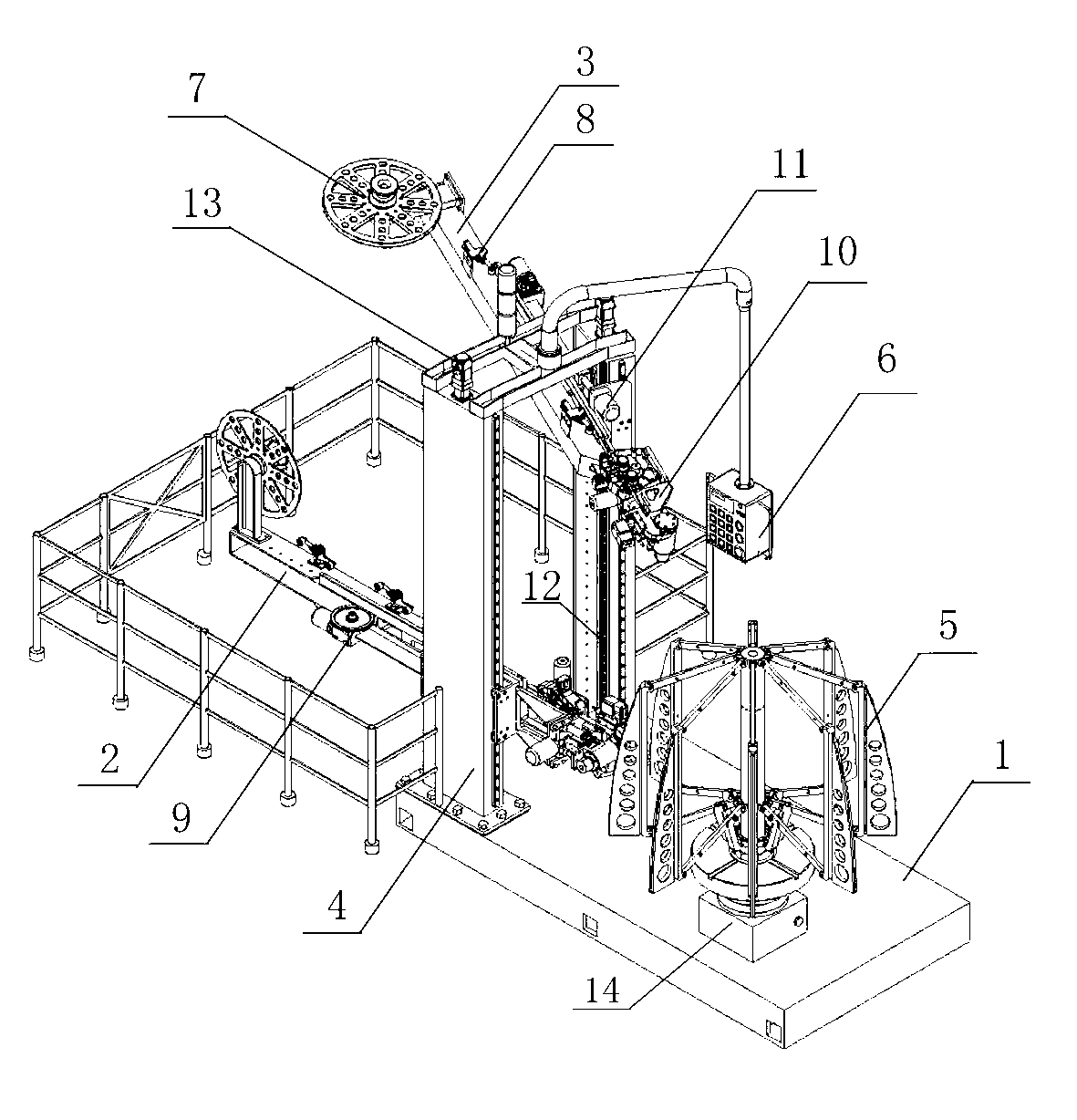

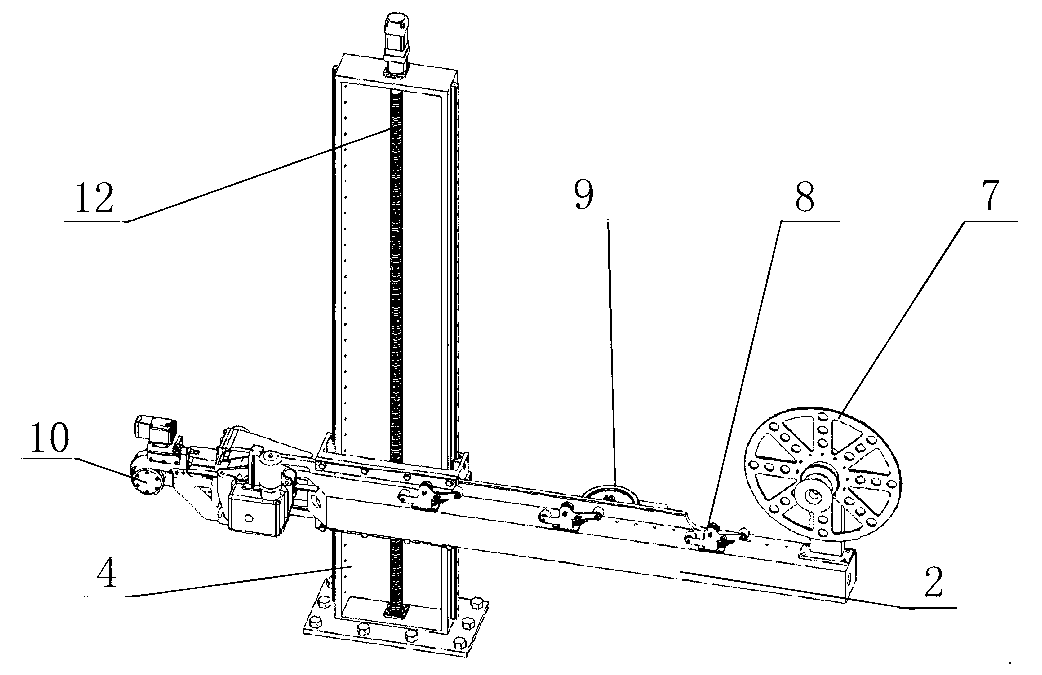

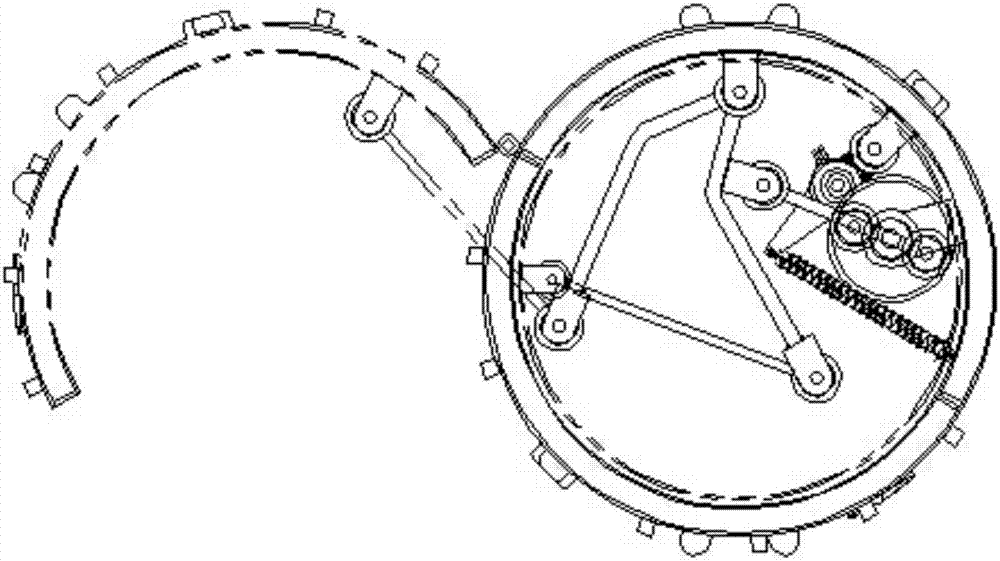

Rocket engine jet pipe brazing strip automatic rolling point welding machine and rolling point welding process

ActiveCN103192153ARealize full mechanizationFully automatedMetal working apparatusSolder feeding devicesEngineeringSpot welding

The invention relates to a rocket engine jet pipe brazing strip automatic rolling point welding machine and a rolling point welding process. The automatic rolling point welding machine comprises a body base, a rotating workbench, a tensioning pattern, a gate type support, a brazing strip disc, a controller, an angle adjusting mechanism, a longitudinal rolling point welding operating mechanical arm, an annular rolling point welding operating mechanical arm and the like. By the automatic rolling point welding machine, mechanical, automatic and intelligent longitudinal brazing strip and annular brazing strip rolling point welding are achieved on jet pipe components, welding efficiency is high, welding quality is good, welding point distances are adjustable, rolling point welding speed can be reach 3 points / second, and welding speed can reach more than 5 meters / second. The automatic rolling point welding machine has no noise, arc, splash, radiation and the like during welding, and is high in reliability, simple to operate, easy to maintain, and suitable for welding of rocket engine spraying pipes with the diameters of 260-1500mm.

Owner:ZHANGJIAKOU NORTH WELDING MACHINE CO LTD

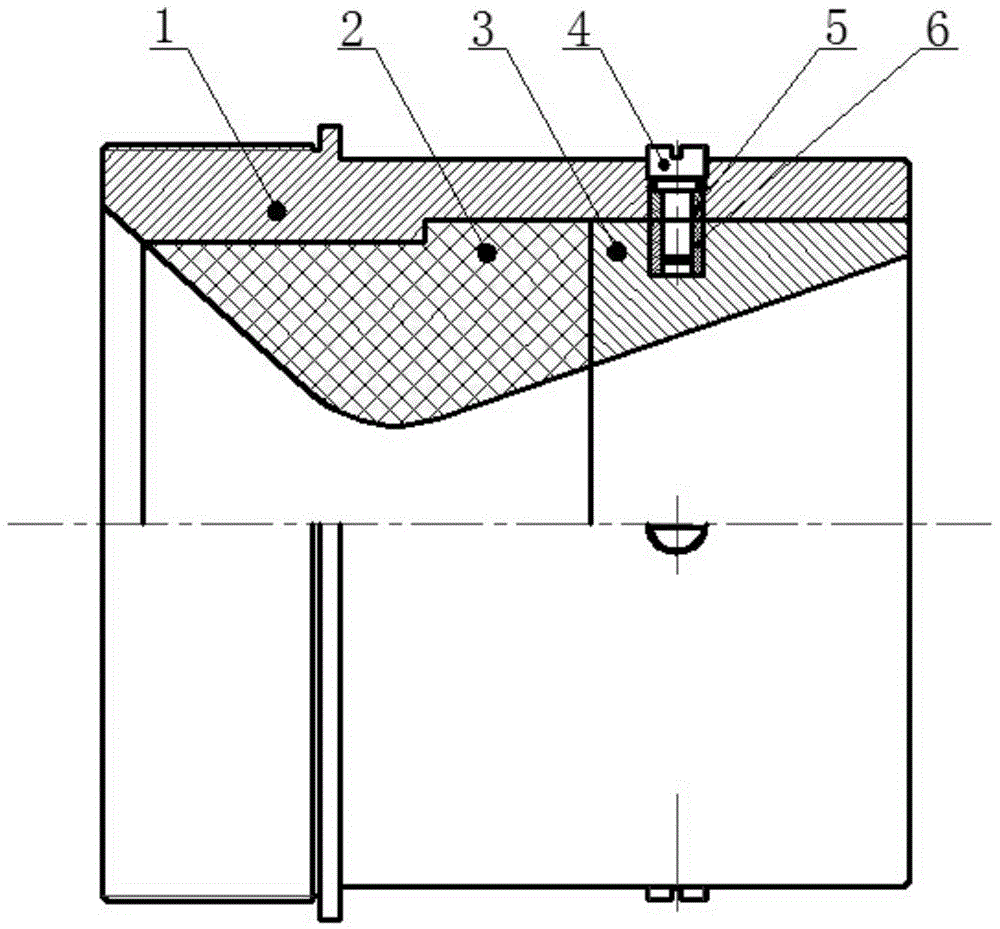

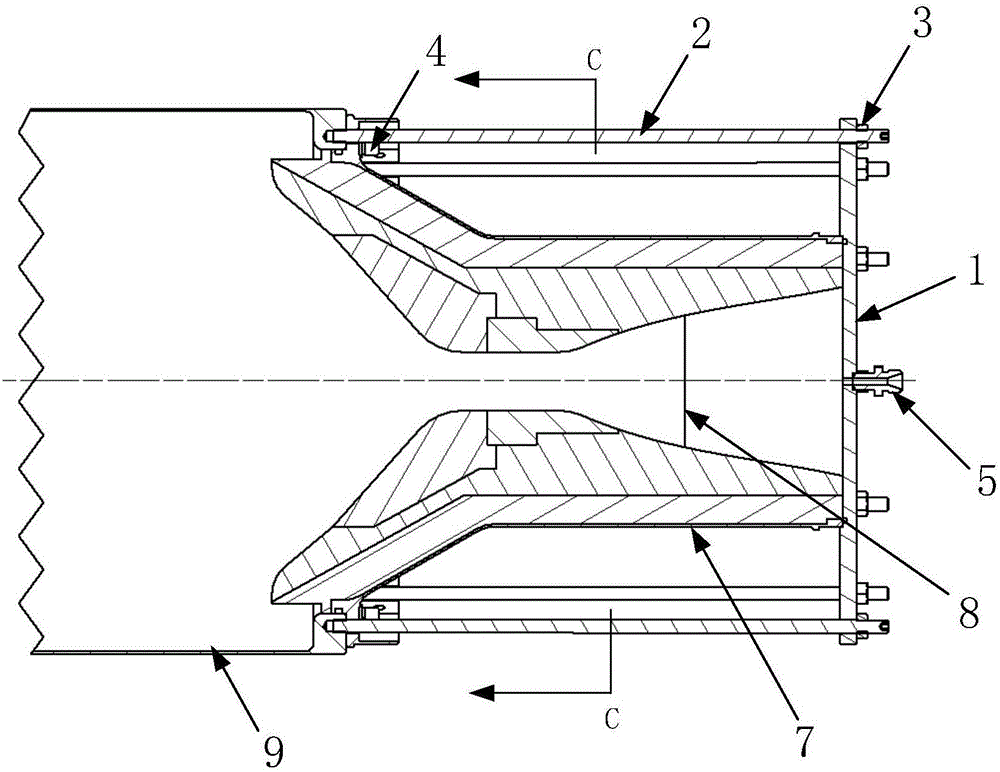

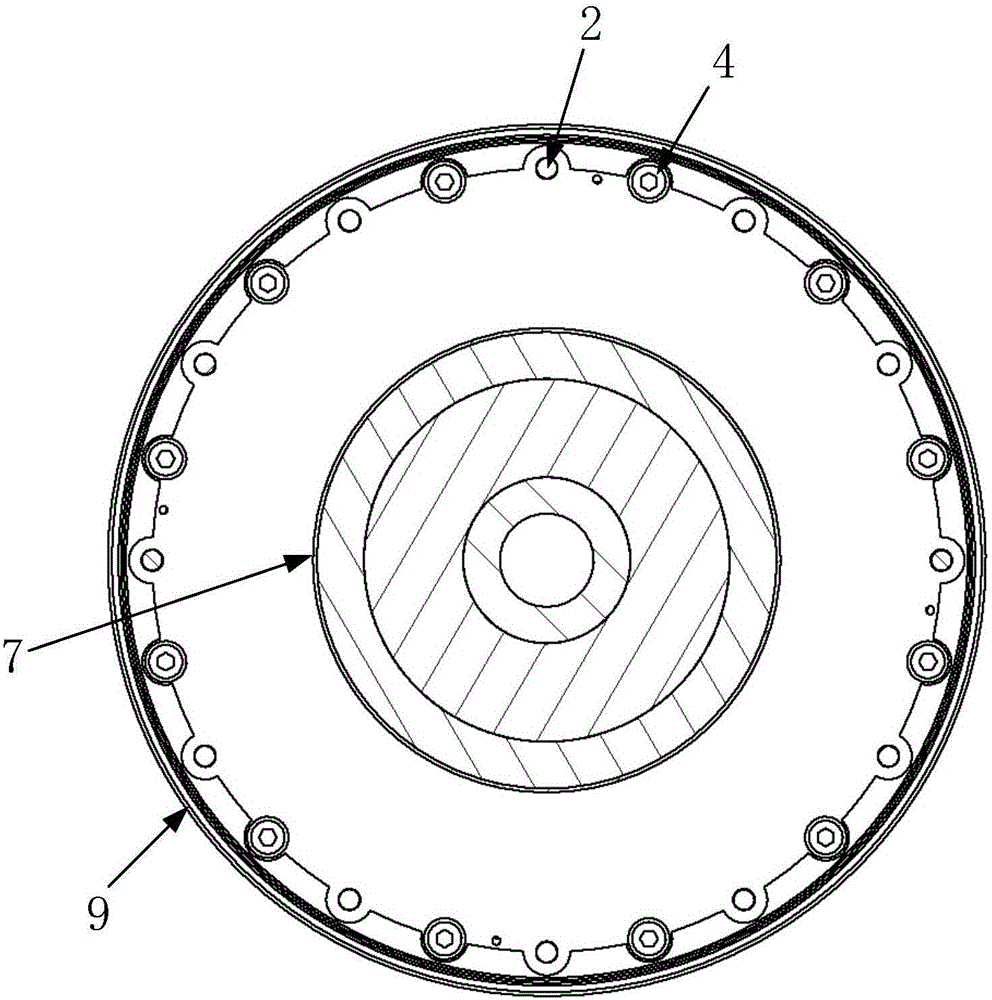

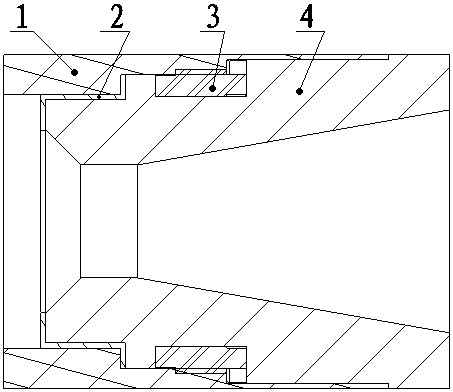

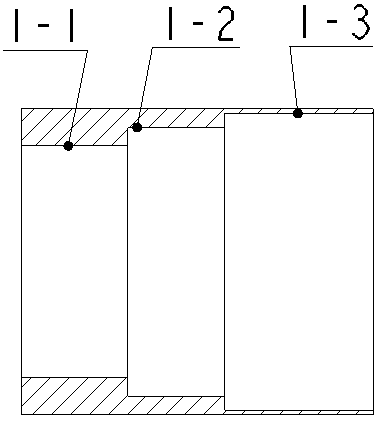

Adjustable double-pulse solid rocket engine jet pipe testing device

The invention discloses an adjustable double-pulse solid rocket engine jet pipe testing device. The adjustable double-pulse solid rocket engine jet pipe testing device comprises a jet pipe base, a throat lining piece, an expanding section component, a safety pin, an upper shearing sleeve and a lower shearing sleeve, wherein the throat lining piece is arranged at the fuel gas inlet end of the jet pipe base, the expanding section component is arranged at the fuel gas outlet end of the jet pipe base, the throat lining piece is matched with an annular step surface in the jet pipe base in a positioned mode through an annular step surface in the axial direction of the throat lining piece, the safety pin penetrates through a pin hole in the wall of the jet pipe base to stretch into a pin hole in the expanding section component, the upper shearing sleeve is arranged between the safety pin and the jet pipe base, the lower shearing sleeve is arranged between the safety pin and the expanding section component, and matched threads are arranged at corresponding positions of the ends, close to the outer wall of the jet pipe base, of the safety pin and the jet pipe base. By the adoption of the adjustable double-pulse solid rocket engine jet pipe testing device, testing safety can be improved, and testing cost can be reduced.

Owner:NANJING UNIV OF SCI & TECH

Method for analyzing swing high-speed jet characteristics of underwater engine nozzle

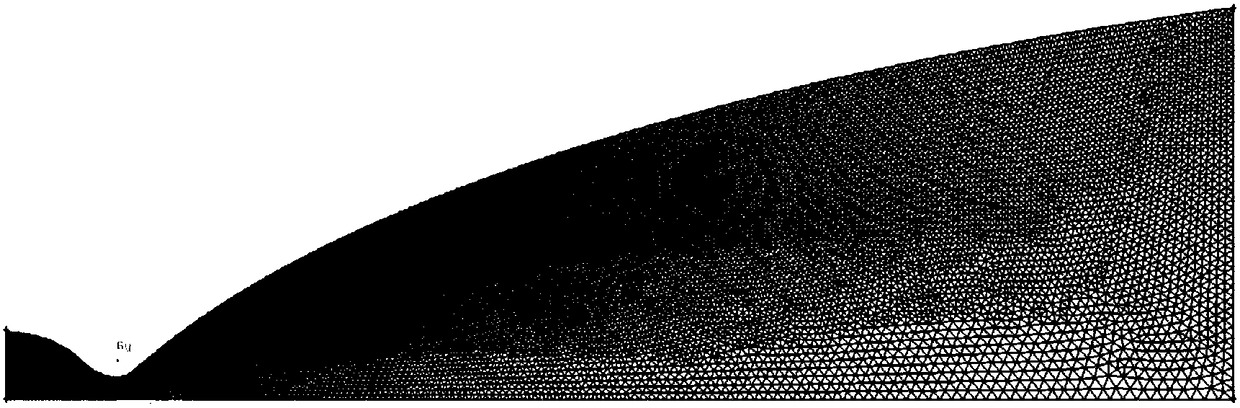

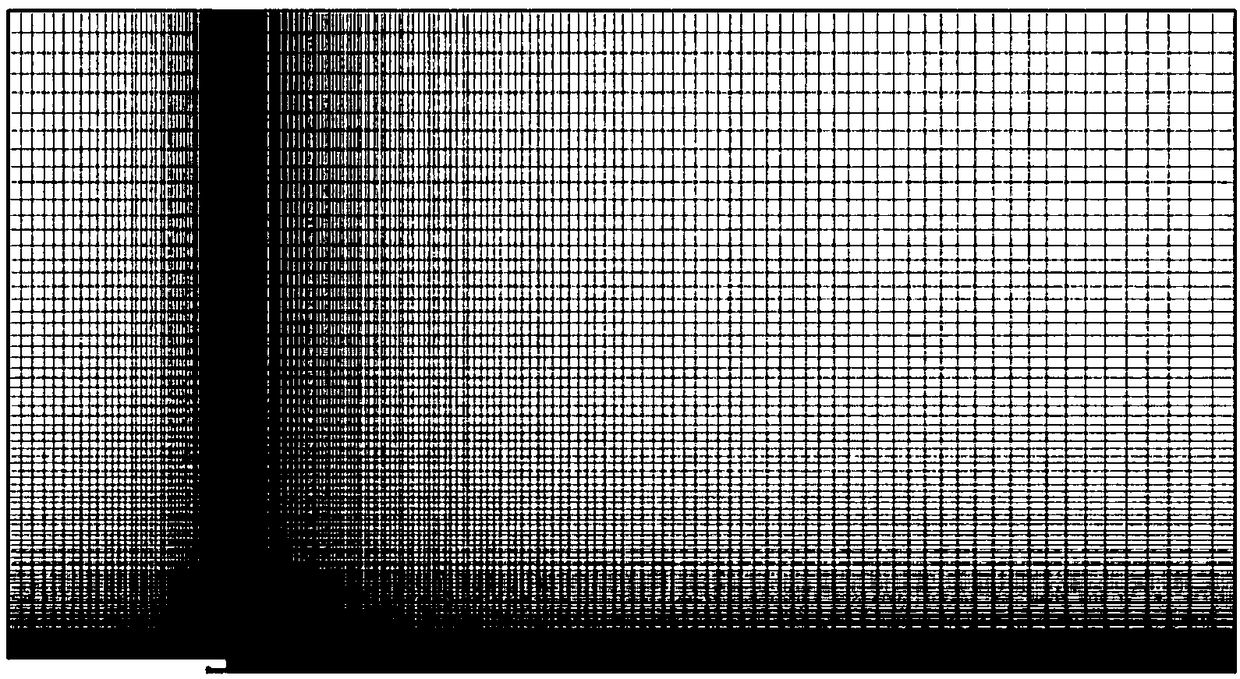

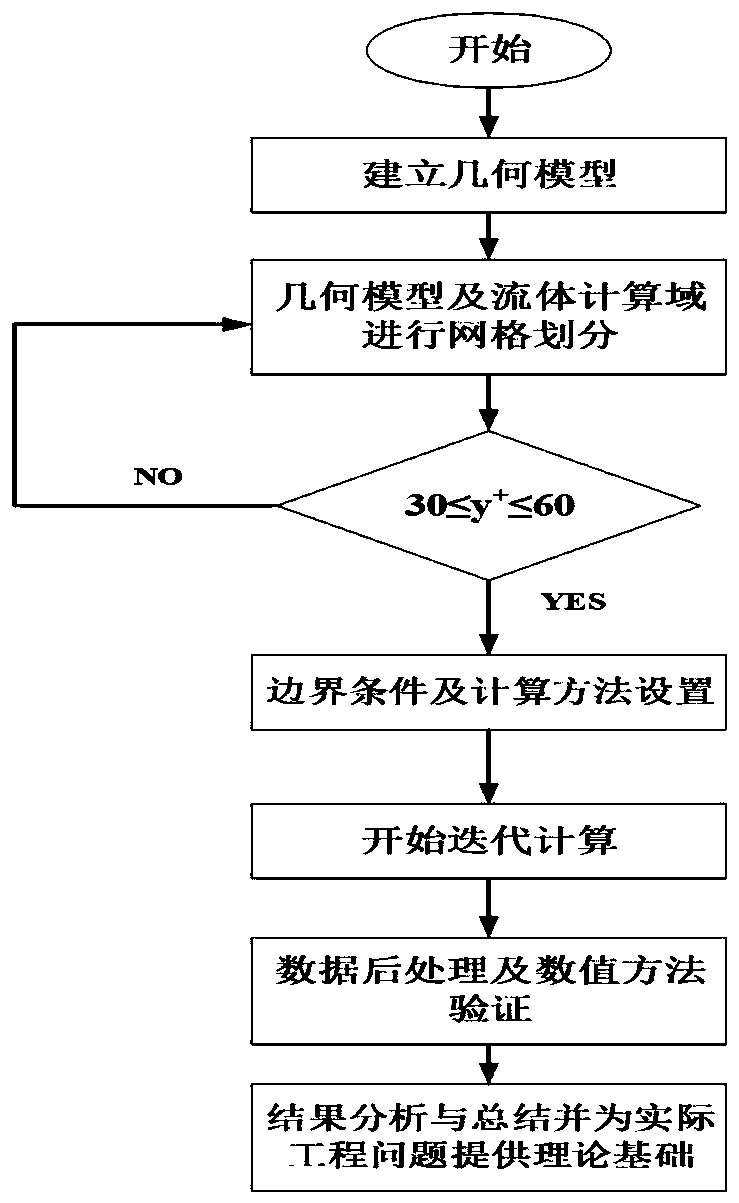

ActiveCN110222467AOptimal grid numberVerify accuracyGeometric CADDesign optimisation/simulationJet flowUnderwater

The invention discloses a method for analyzing swing high-speed jet characteristics of an underwater engine nozzle, and belongs to the field of fluid mechanical engineering. The implementation methodcomprises the following steps of: through establishing a geometric model of an underwater solid rocket engine nozzle, establishing a fluid calculation domain, carrying out geometric optimization on aninterface of the two fluid calculation domains, setting an interface between the calculation domains for data transmission to achieve simulation of the swing working condition of the nozzle, carryingout grid division on the fluid domains in a partitioned mode, carrying out grid independence verification, and obtaining the optimal grid number; importing the obtained final grid file into a FLUENTsolver, setting boundary conditions, an adopted calculation model and a calculation method, and carrying out solving; carrying out numerical simulation analysis and post-processing on a numerical calculation result. The rocket engine nozzle swing high-speed jet flow characteristic is accurately simulated and analyzed, the nozzle swing high-speed jet flow rule and mechanism can be easily disclosed,a theoretical basis is provided for the engine nozzle structure design of underwater powered missile launching, and the actual engineering application problem of underwater powered missile launchingis solved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

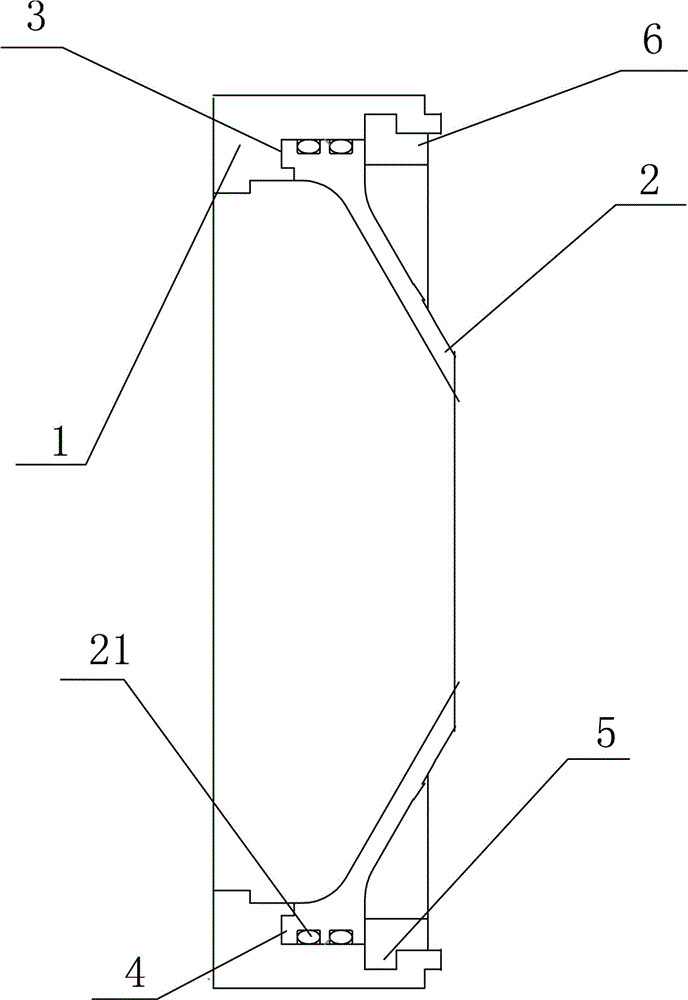

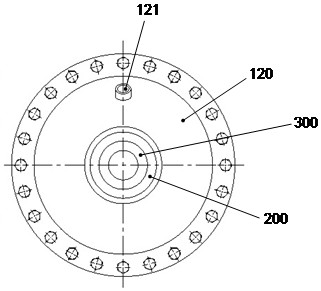

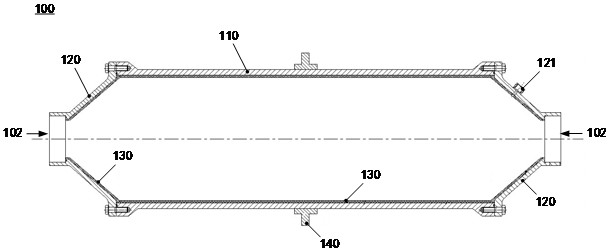

Solid-liquid rocket engine nozzle airtight inspection device

InactiveCN106837611AQuite stressfulConsiderable work pressureRocket engine plantsCombustion chamberEngineering

The invention discloses an airtight inspection device for a nozzle of a solid-liquid rocket engine, comprising a nozzle, a nozzle, a combustion chamber, a screw, a sealing ring and a plug for the nozzle. The nozzle and the combustion chamber are connected by fastening screws, the screw passes through the airtight device of the nozzle, the nozzle and the combustion chamber are connected, and the outlet part of the nozzle and the nozzle are connected through the design of the concave platform on the airtight device of the nozzle. The air-tight device cooperates and the sealing ring is added to realize the sealing of the nozzle; and the two-way pressurization during the air-tight inspection is realized through the nozzle, which significantly improves the pressure range that can be increased during the air-tight inspection of the nozzle. The invention is suitable for the airtight inspection of the combustion chamber and the nozzle connected by thread; the airtight device of the nozzle and the outlet part of the nozzle are sealed by the sealing ring; The connection of the nozzle eliminates the need to separately fix the parts of the nozzle airtight device, which facilitates the implementation of the airtight inspection process.

Owner:BEIHANG UNIV

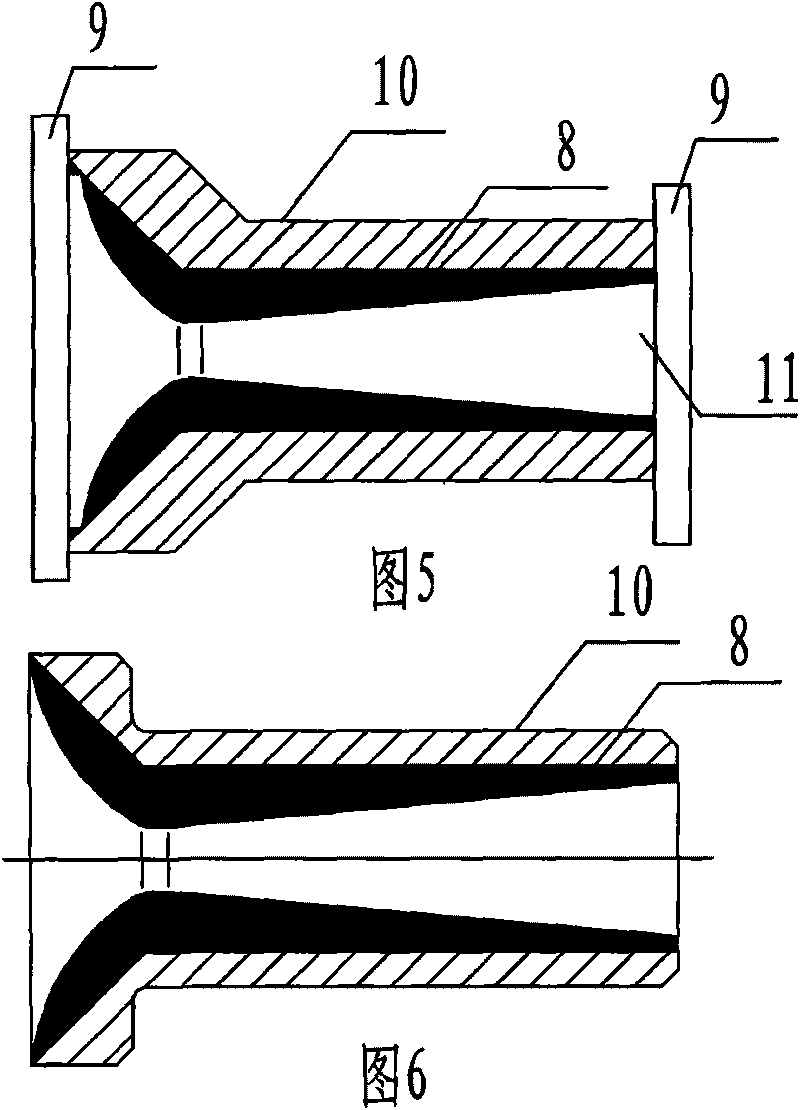

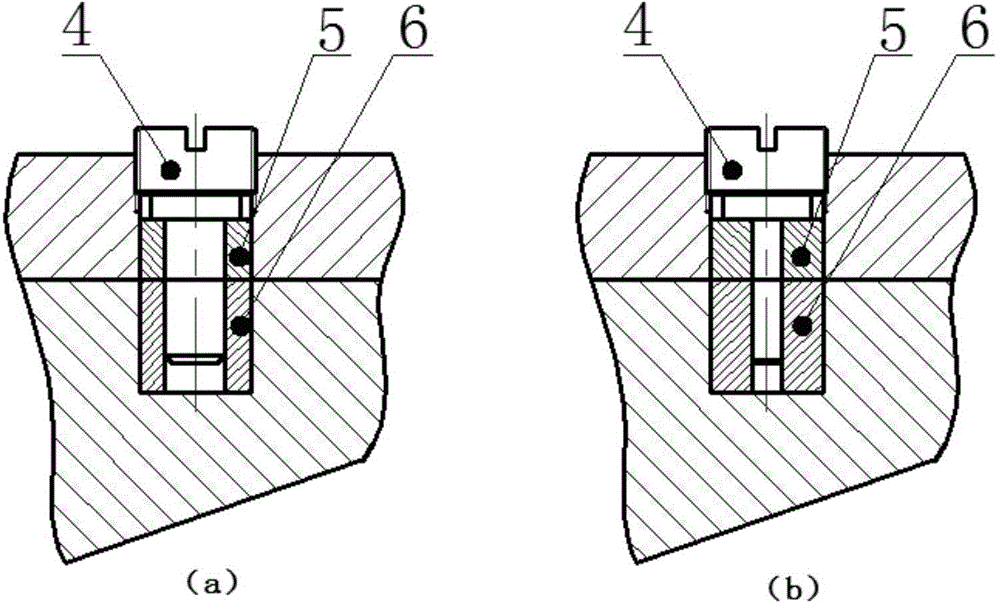

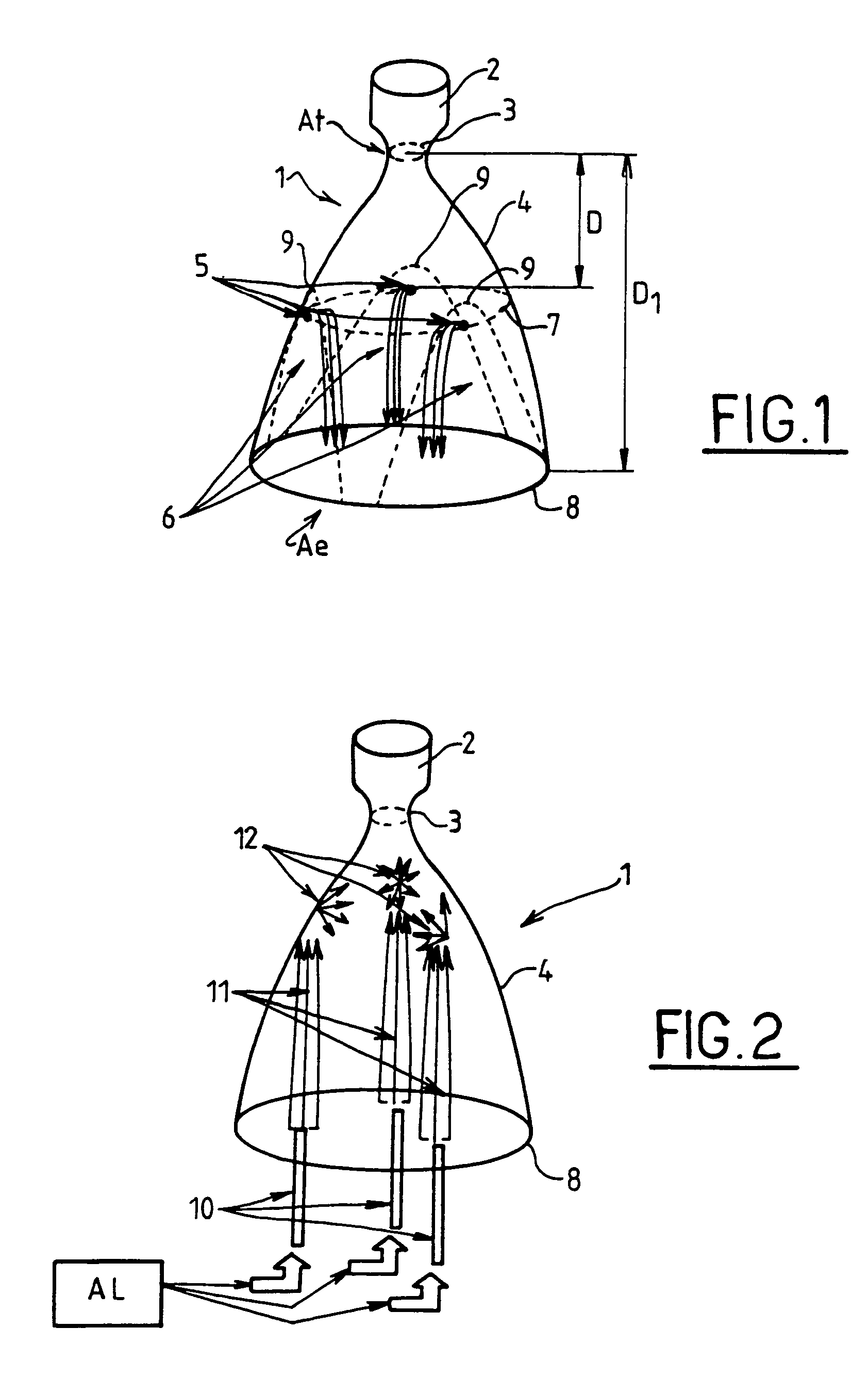

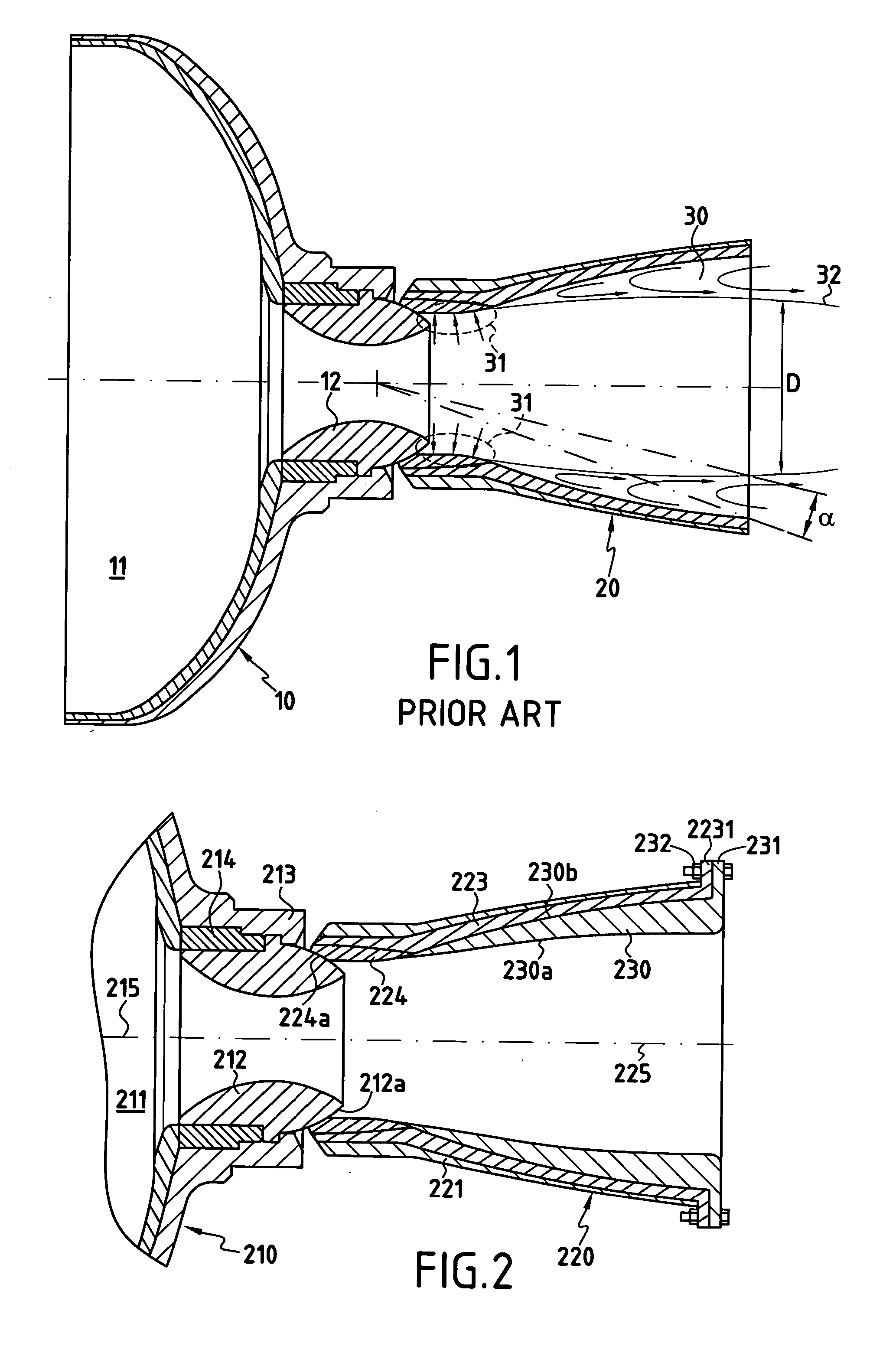

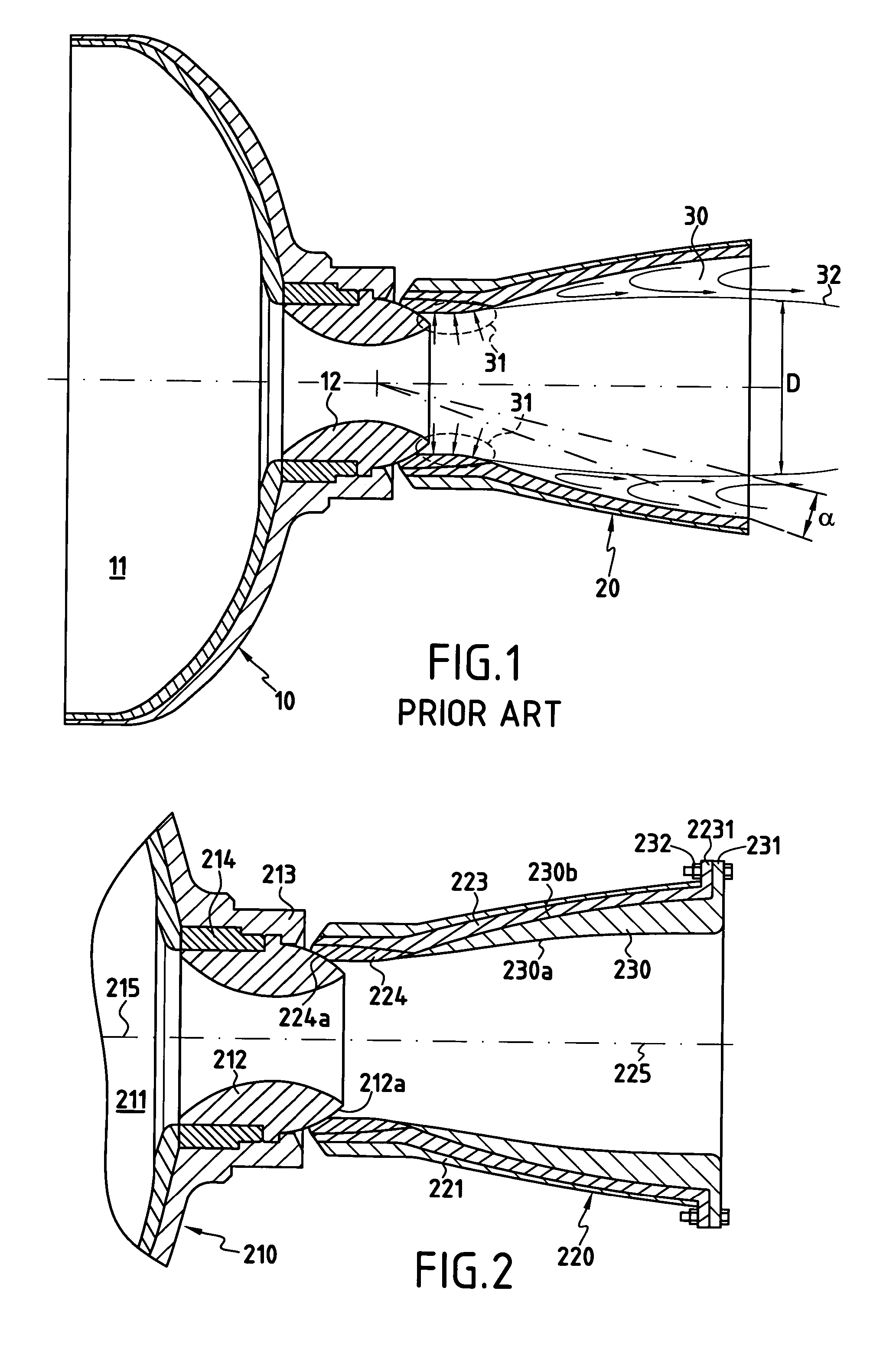

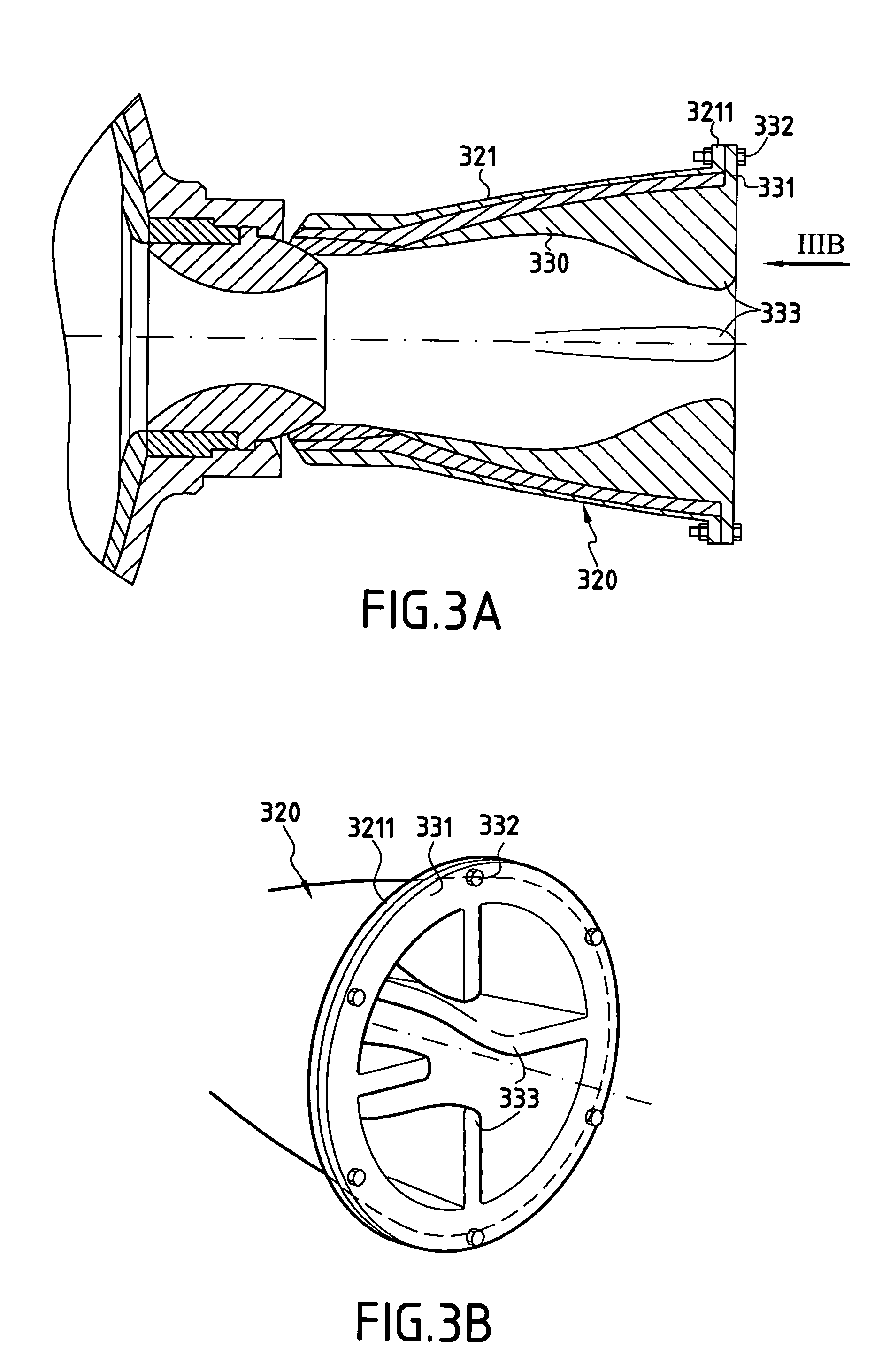

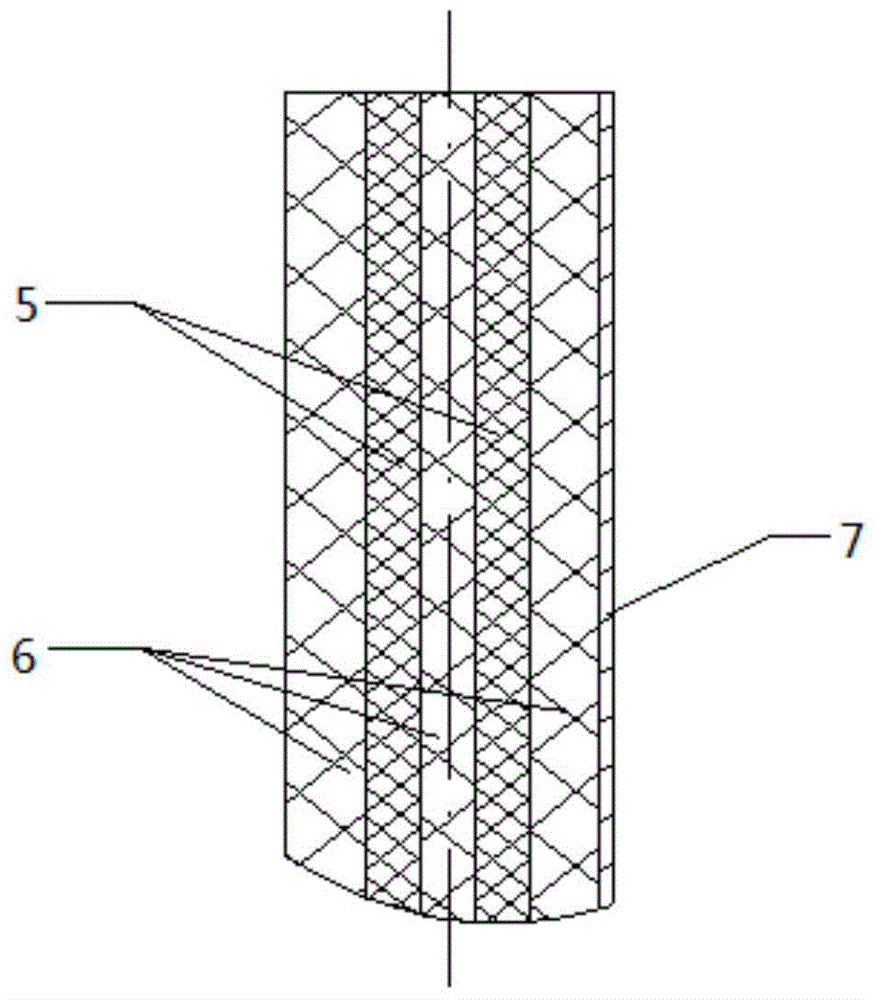

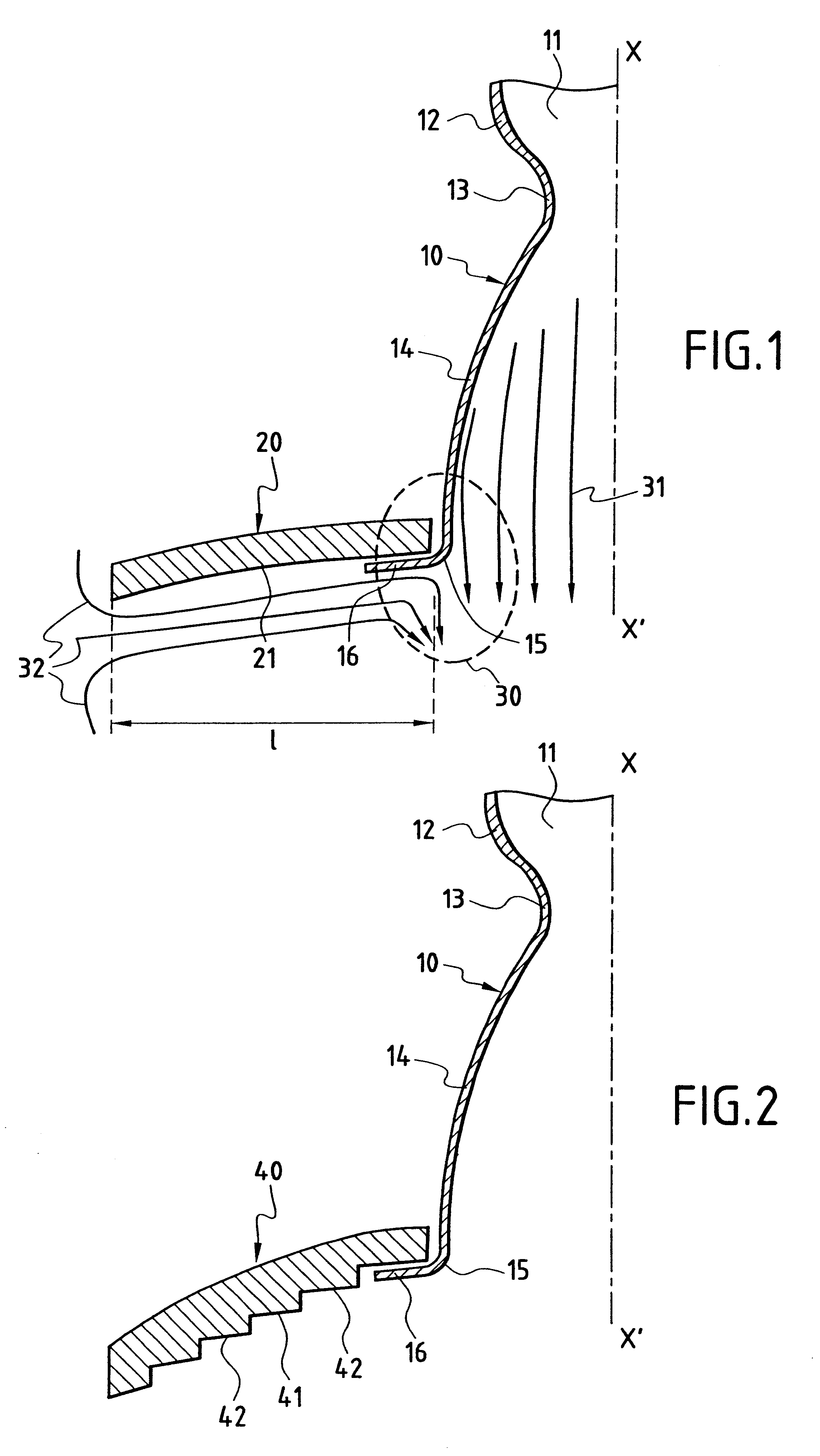

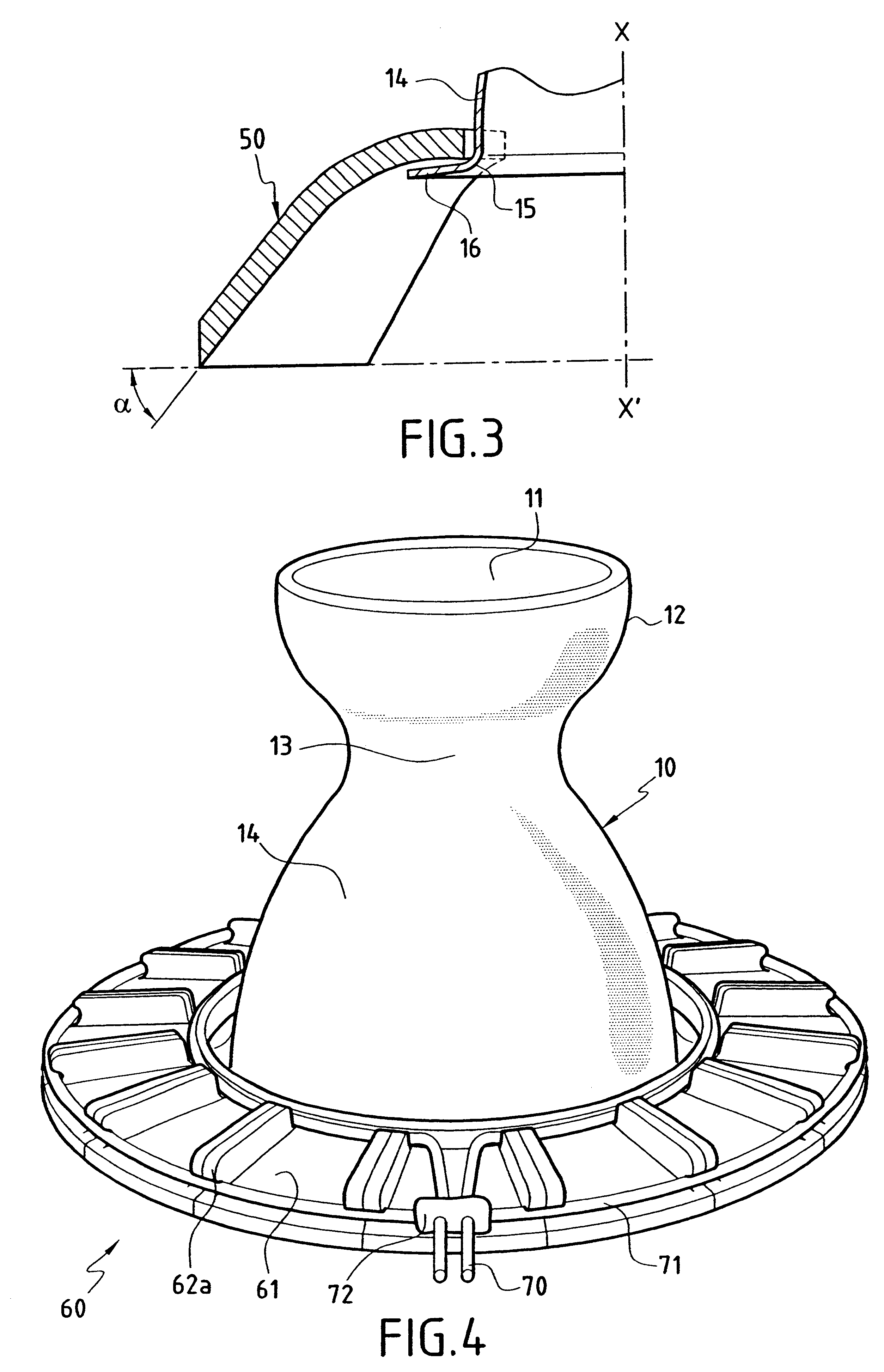

Method of achieving jet separation of an un-separated flow in a divergent nozzle body of a rocket engine

InactiveUS6996973B2Avoid instabilityReduce loadCosmonautic vehiclesEngine manufactureInitiation pointControl system

The invention relates to a rocket engine nozzle comprising a system for controlling jet separation of the flow in the nozzle, wherein said control system exhibits a plurality of separation triggering elements (5, 10) arranged in such a way as to generate, from mutually spaced initiation points (9), distinct zones (6) of jet separation, so as to form a three-dimensional separation of the flow.The flow control system can exhibit at least two triggering elements (5, 10).

Owner:EUROPEAN SPACE AGENCY

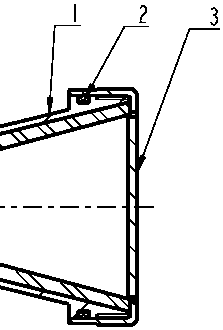

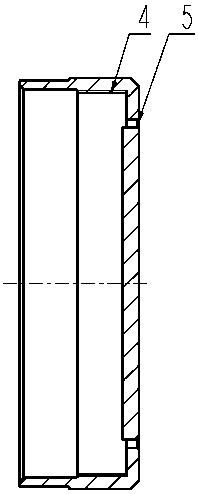

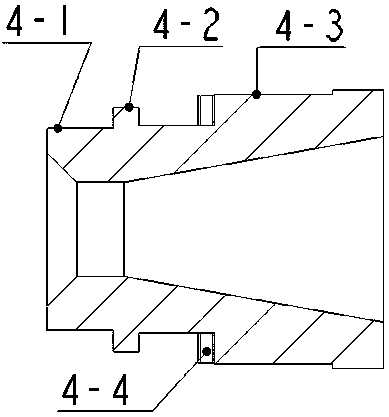

Connecting and sealing device

ActiveCN105888881AReduce structural massGuaranteed reliabilityRocket engine plantsEngineeringRocket engine nozzle

The invention discloses a connecting and sealing device comprising a shell and a spraying pipe connected with the shell. An assembling groove is formed in the inner wall of the shell; the spraying pipe is provided with an assembling step matched with the assembling groove; a clamping groove is further formed in the shell and is internally provided with a snap ring matched with the clamping groove; and part of the snap ring is installed in the clamping groove, and part of the snap ring is tightly clamped to the spraying pipe. The device is complete in function and convenient to operate and has high universality. At present, the device has been applied to many products, many experiments are successfully completed, a good effect is achieved, the assembling problem of a spraying pipe of a small-diameter solid rocket engine can be solved, and the purposes of reducing the structural mass and improving the assembling efficiency are achieved.

Owner:HUBEI SANJIANG AEROSPACE JIANGHE CHEM TECH

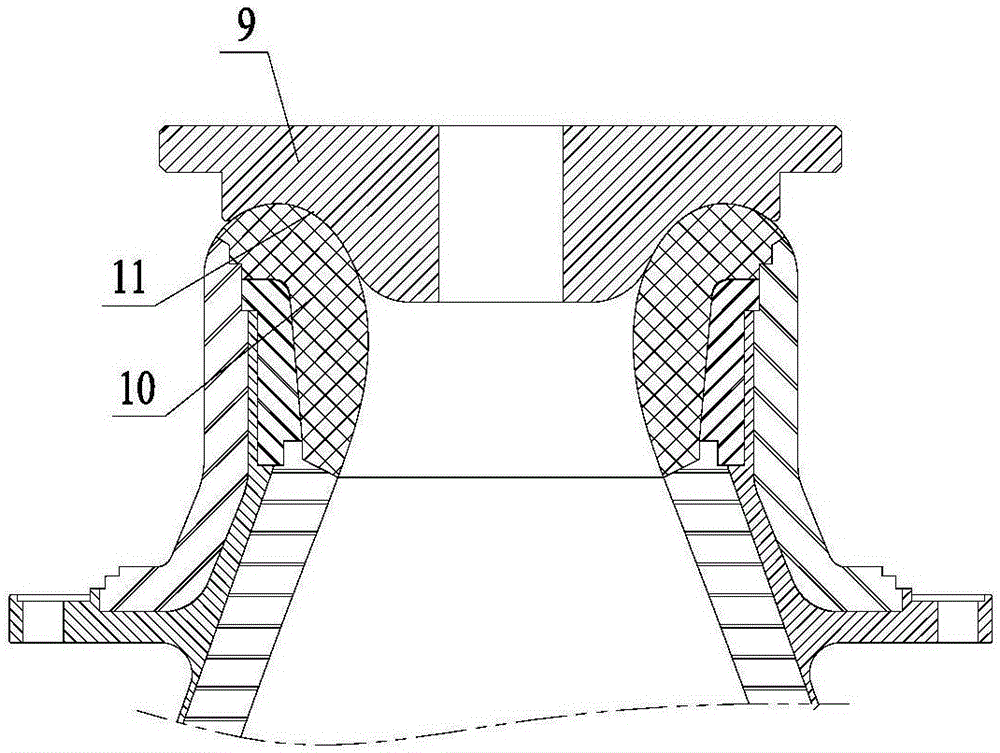

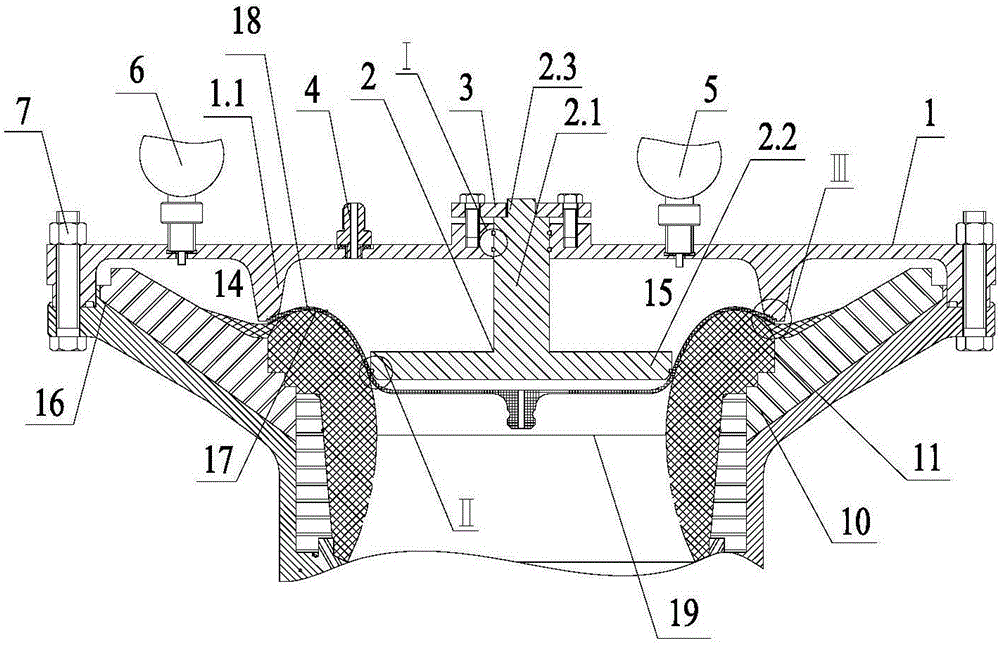

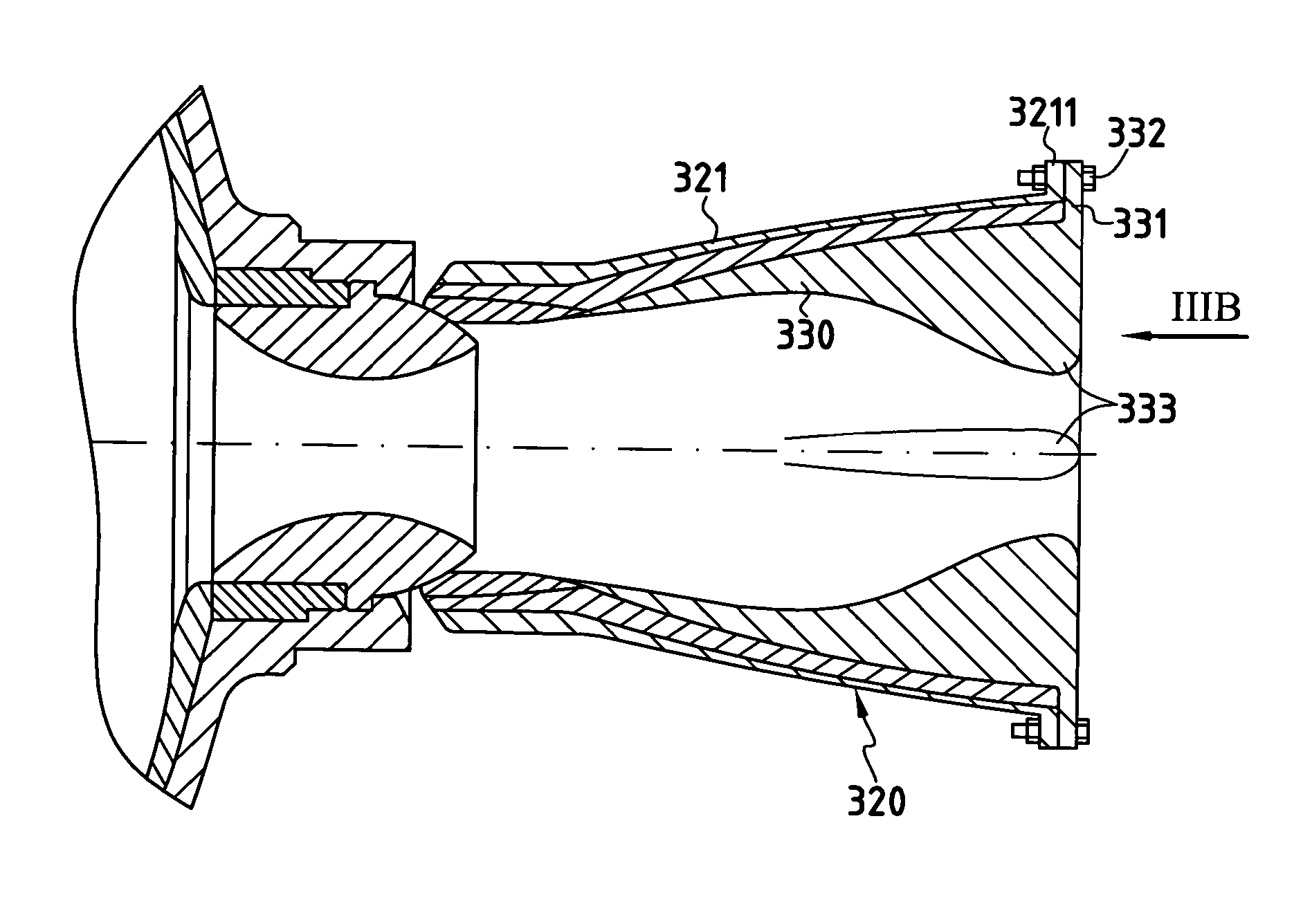

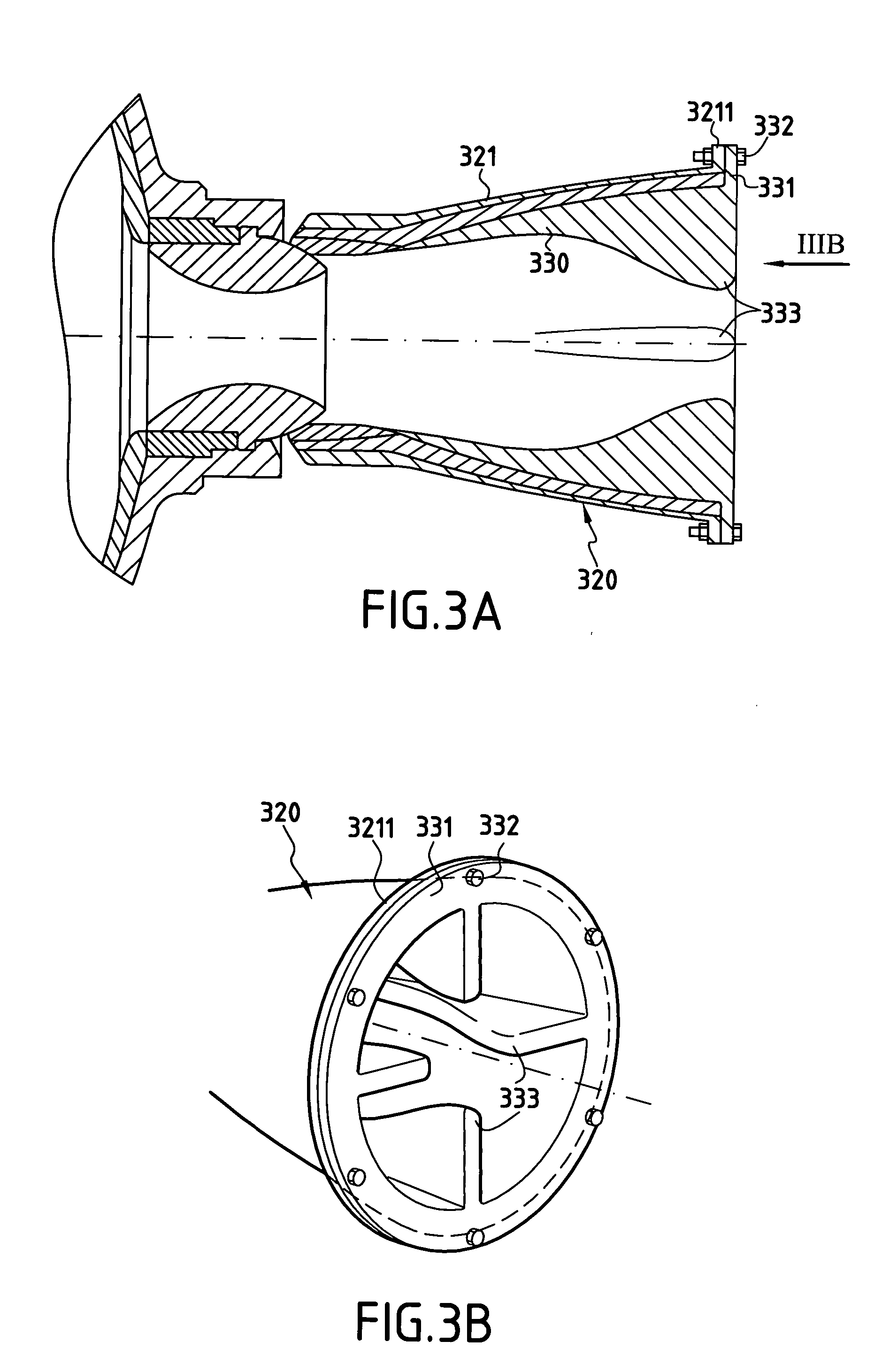

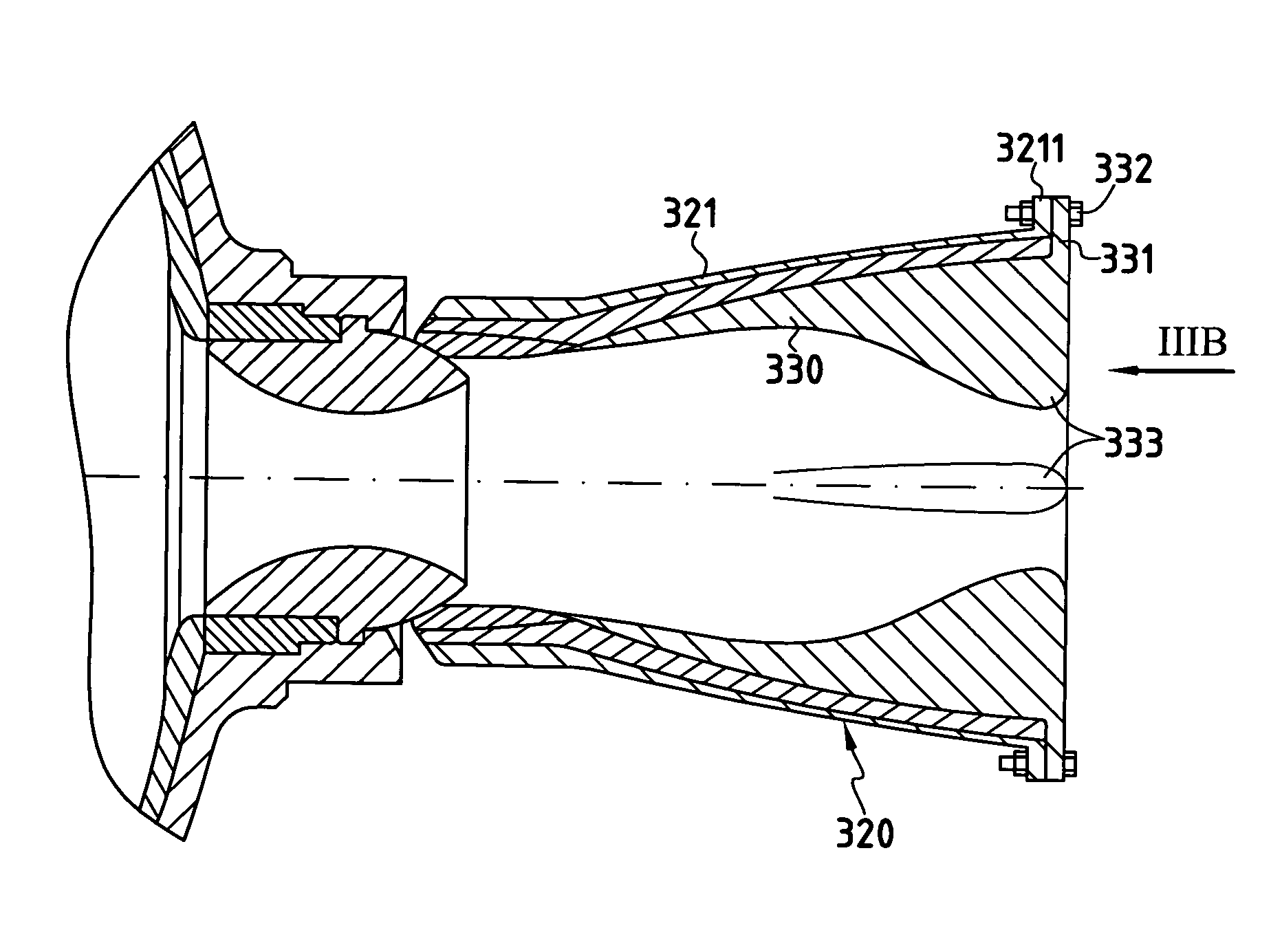

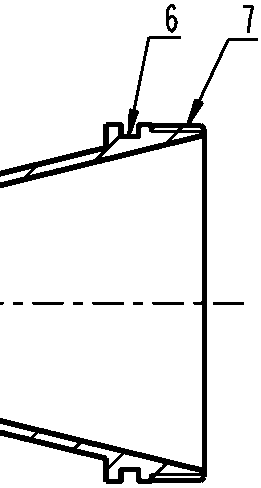

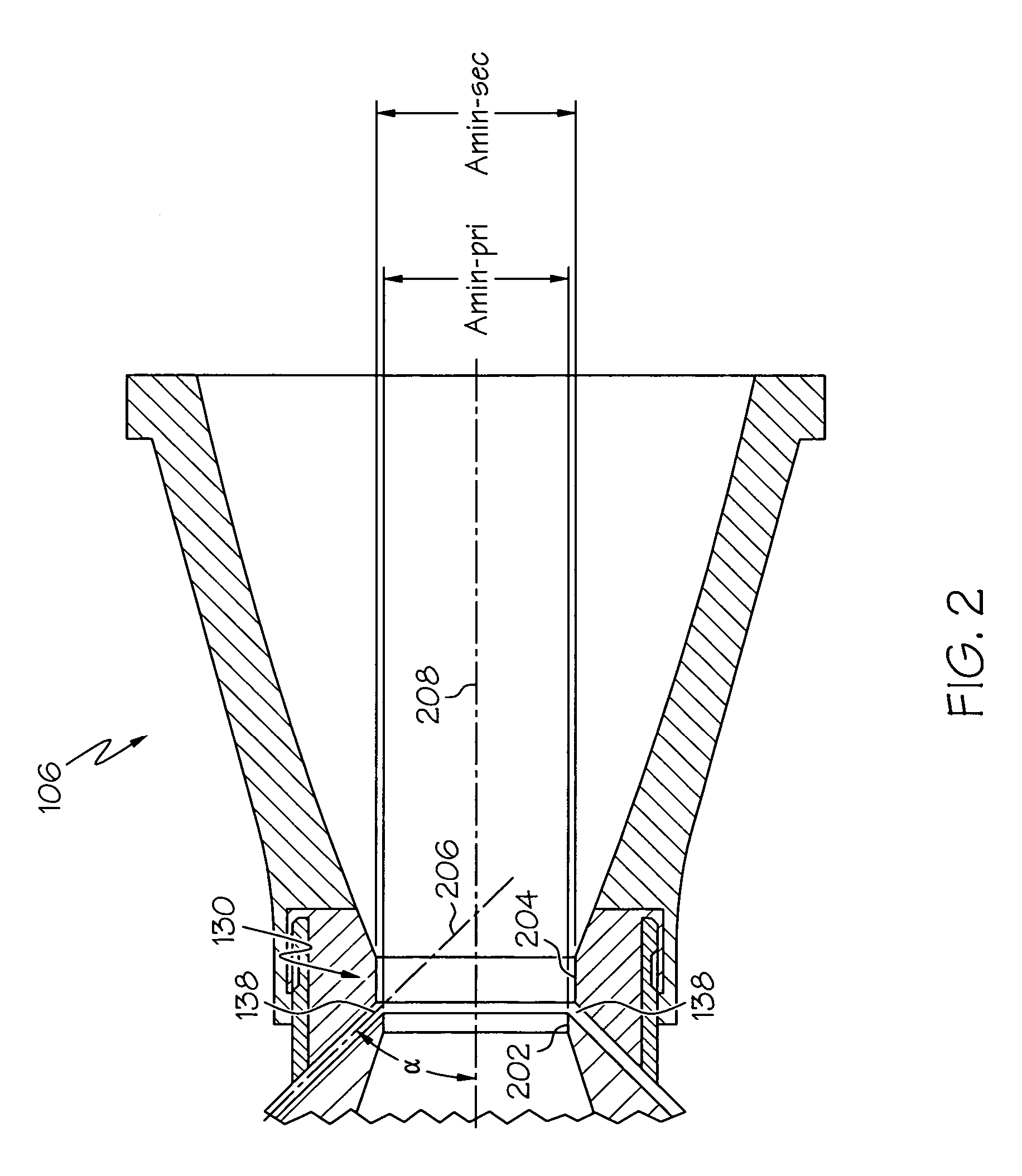

Adapter device for a rocket engine nozzle having a movable diverging portion

ActiveUS20050229587A1Reducing and eliminating influenceReduce diverging natureAircraft navigation controlPower plant exhaust arrangementsCombustionRocket engine nozzle

An adapter device for controlling a rocket engine nozzle under conditions of external pressure that can lead to the jet separating inside the nozzle, the nozzle being fitted with a diverging portion that is movably mounted relative to a stationary portion of the nozzle, thrust deflection then being achieved by swivelling the diverging portion so as to deflect the jet of combustion gas in contact with the inside wall of the diverging portion. The device includes a structure disposed inside the diverging portion in such a manner as to reduce the diverging nature of the flow section thereof and to increase the bearing area of pressure forces exerted by the jet on the diverging portion during swivelling thereof.

Owner:ROXEL FRANCE

Adapter device for a rocket engine nozzle having a movable diverging portion

ActiveUS7406821B2Reducing and eliminating influenceReduce diverging natureAircraft navigation controlPower plant exhaust arrangementsCombustionRocket engine nozzle

An adapter device for controlling a rocket engine nozzle under conditions of external pressure that can lead to the jet separating inside the nozzle, the nozzle being fitted with a diverging portion that is movably mounted relative to a stationary portion of the nozzle, thrust deflection then being achieved by swivelling the diverging portion so as to deflect the jet of combustion gas in contact with the inside wall of the diverging portion. The device includes a structure disposed inside the diverging portion in such a manner as to reduce the diverging nature of the flow section thereof and to increase the bearing area of pressure forces exerted by the jet on the diverging portion during swivelling thereof.

Owner:ROXEL FRANCE

Small solid rocket engine jet pipe blocking cover

InactiveCN108194231AImprove reliabilityFirmly connectedRocket engine plantsRocket engine nozzleRocket engine

The invention relates to a jet pipe blocking cover, in particular to a small solid rocket engine jet pipe blocking cover. The jet pipe blocking cover is provided with a blocking cover connecting thread and a shearing groove. The jet pipe blocking cover is connected with the side wall of a jet pipe shell through the blocking cover connecting thread, and the shearing groove is formed in the face, incontact with the jet pipe, of the blocking cover. According to the small solid rocket engine jet pipe blocking cover, reliable connection of the blocking cover can be achieved, working reliability ofa solid rocket engine is improved, and the small solid rocket engine jet pipe blocking cover is suitable for most small solid rocket engines.

Owner:内蒙动力机械研究所

Spacecraft afterbody device

ActiveUS20100327108A1Reduce weightIncreasing vehicle 's aerodynamic dragAmmunition projectilesCosmonautic environmental control arrangementAerodynamic dragSpray nozzle

An afterbody device for a spacecraft fitted with at least one rocket engine at the rear of the craft includes at least one movable cover element designed to take a first position, masking and reducing the vehicle's rear drag, where it prolongs the vehicle's fuselage around at least one part of a rocket engine nozzle of the vehicle and extends beyond the rear of the vehicle's fuselage, and to take a second position fully deployed, increasing the vehicle's aerodynamic drag.

Owner:ARIANEGRP SAS

Preparation method of multiscale material reinforced resin-based antifriction and antiwear composite

Owner:SHANGHAI UNIV

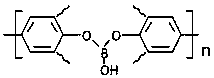

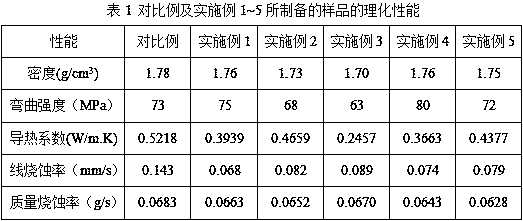

High silica/phenolic aldehyde material with excellent ablation resistance and heat insulation performance and preparing method thereof

InactiveCN110407606AImprove heat resistanceImproves ablation resistanceCeramicwareFiberPolymer science

The invention discloses a high silica / phenolic aldehyde material with excellent ablation resistance and heat insulation performance. Boron phenolic resin is dissolved in absolute ethyl alcohol with the volume ratio of 1:1-1:20, and then stirred and dispersed uniformly; then, high silica fibers, aerogel powder, potassium hexatitanate crystal whiskers and SiC micropowder are added in sequence and stirred and dispersed uniformly; then drying is conducted for 12-72 hours at the temperature from the room temperature to 120 DEG C, and then the solvent ethyl alcohol is removed to obtain a fiber prepreg; finally, the fiber prepreg is loaded into a mold, and hot press molding, cooling and demolding are conducted to obtain the high silica / phenolic aldehyde material with excellent ablation resistanceand heat insulation performance. The high silica / phenolic aldehyde material has high heat stability, a low heat conductivity coefficient, low density and good ablation resistance; when the high silica / phenolic aldehyde material is used for a jet pipe of an engine of a rocket, the harsh requirements of the engine for the heat insulation performance and ablation resistance can be met with a smallerthickness, and the high silica / phenolic aldehyde material has an important significance in performance improvement and weight reduction of the engine.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

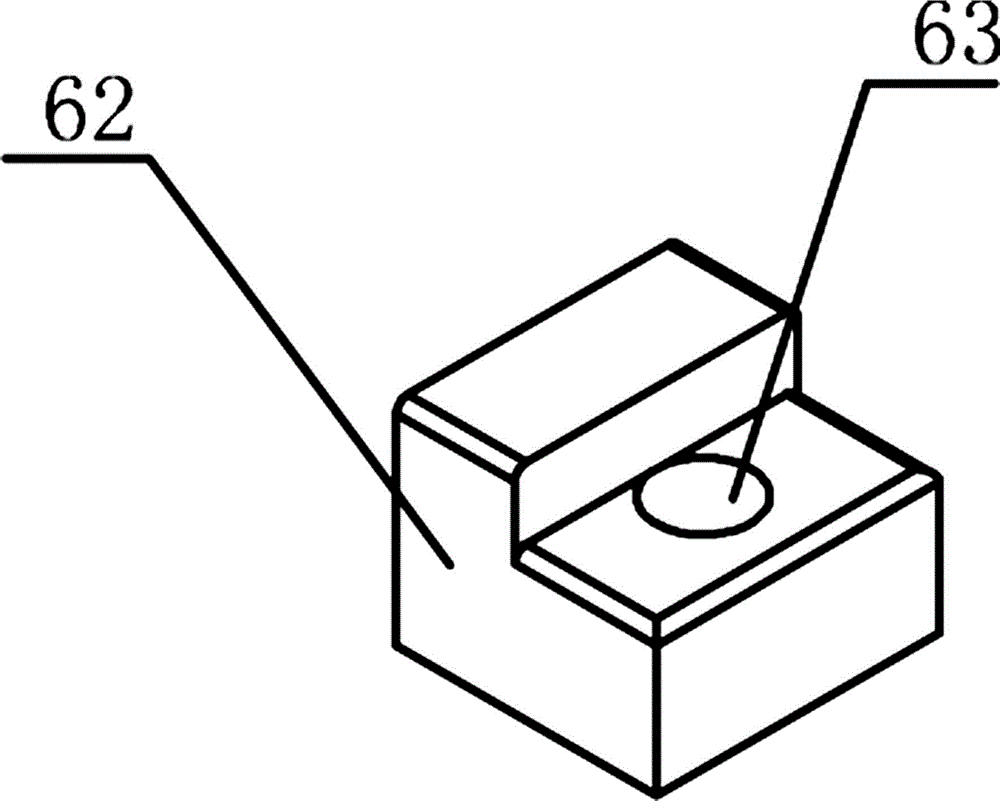

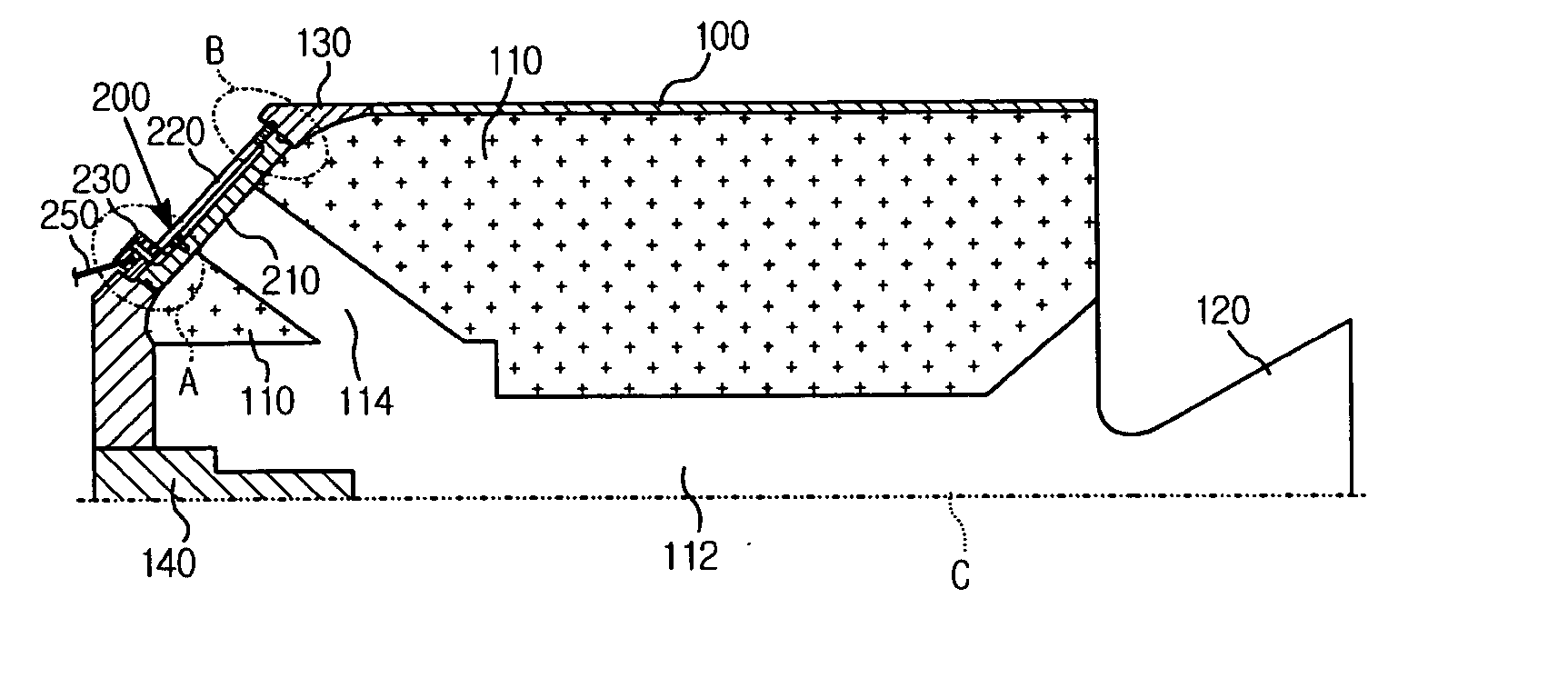

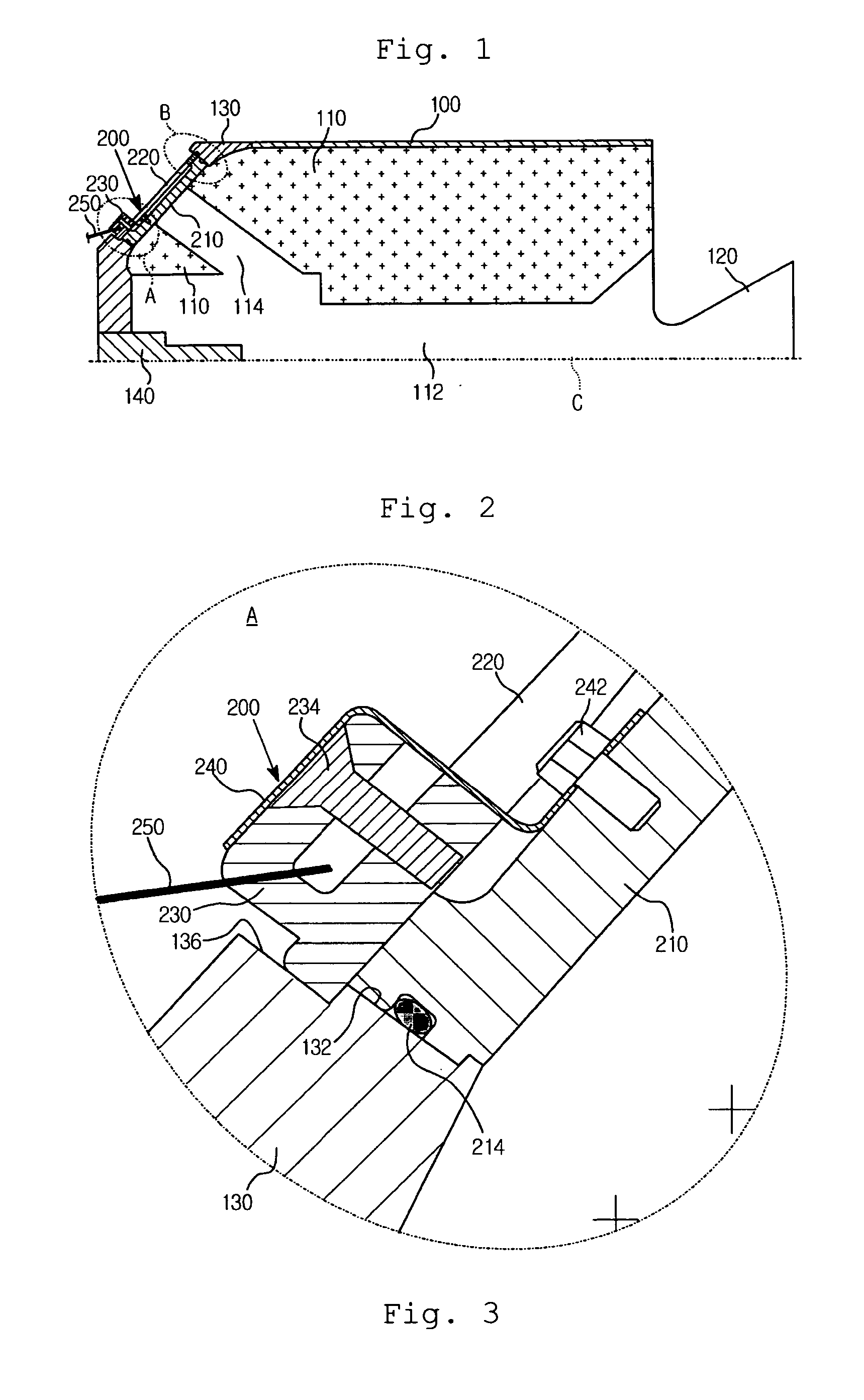

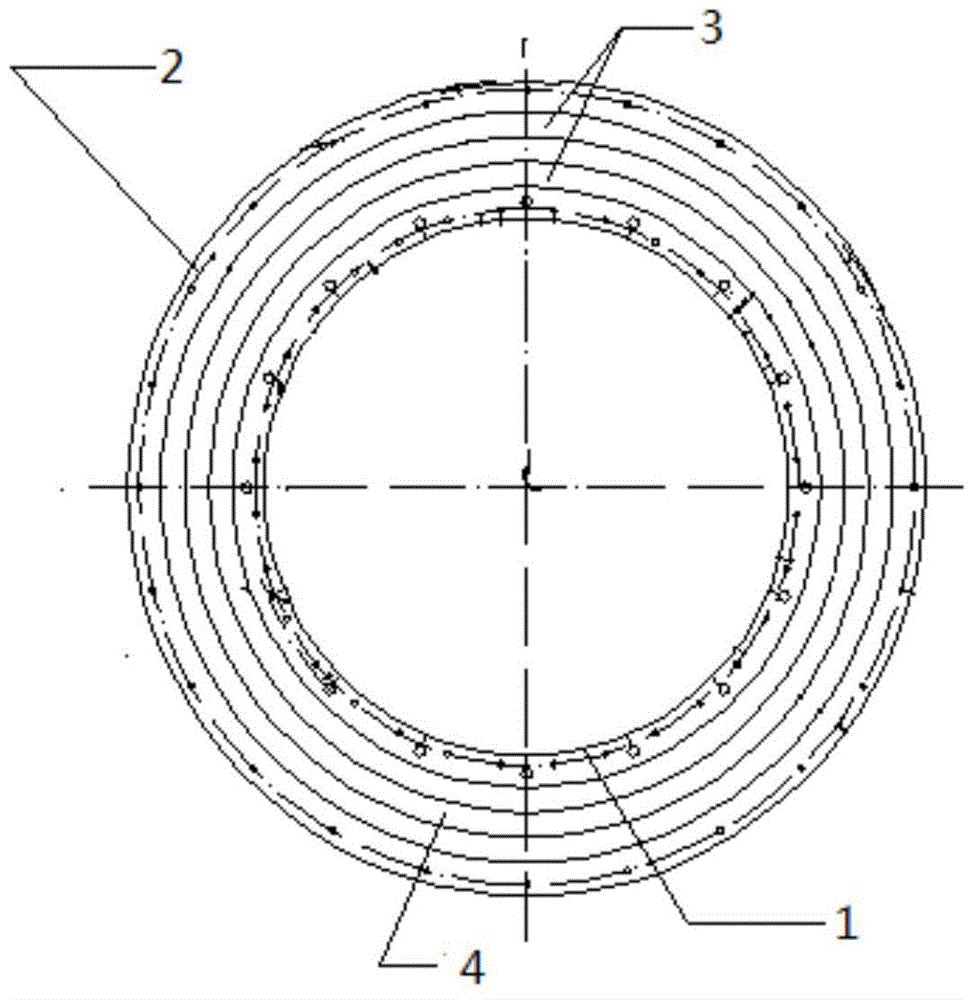

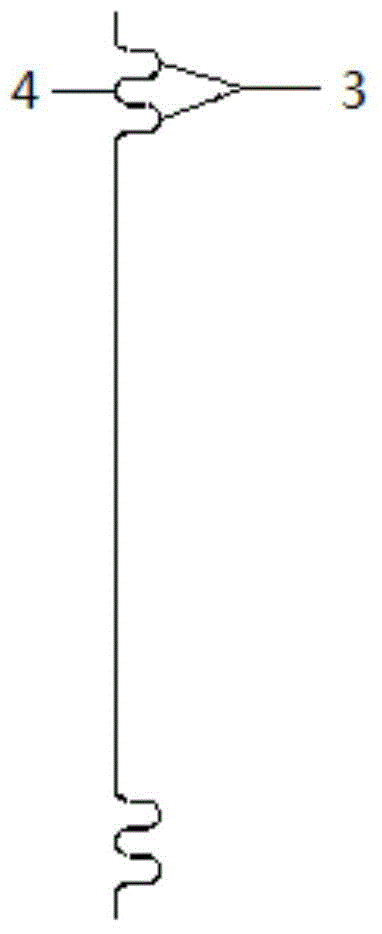

Thrust termination device for solid rocket motor

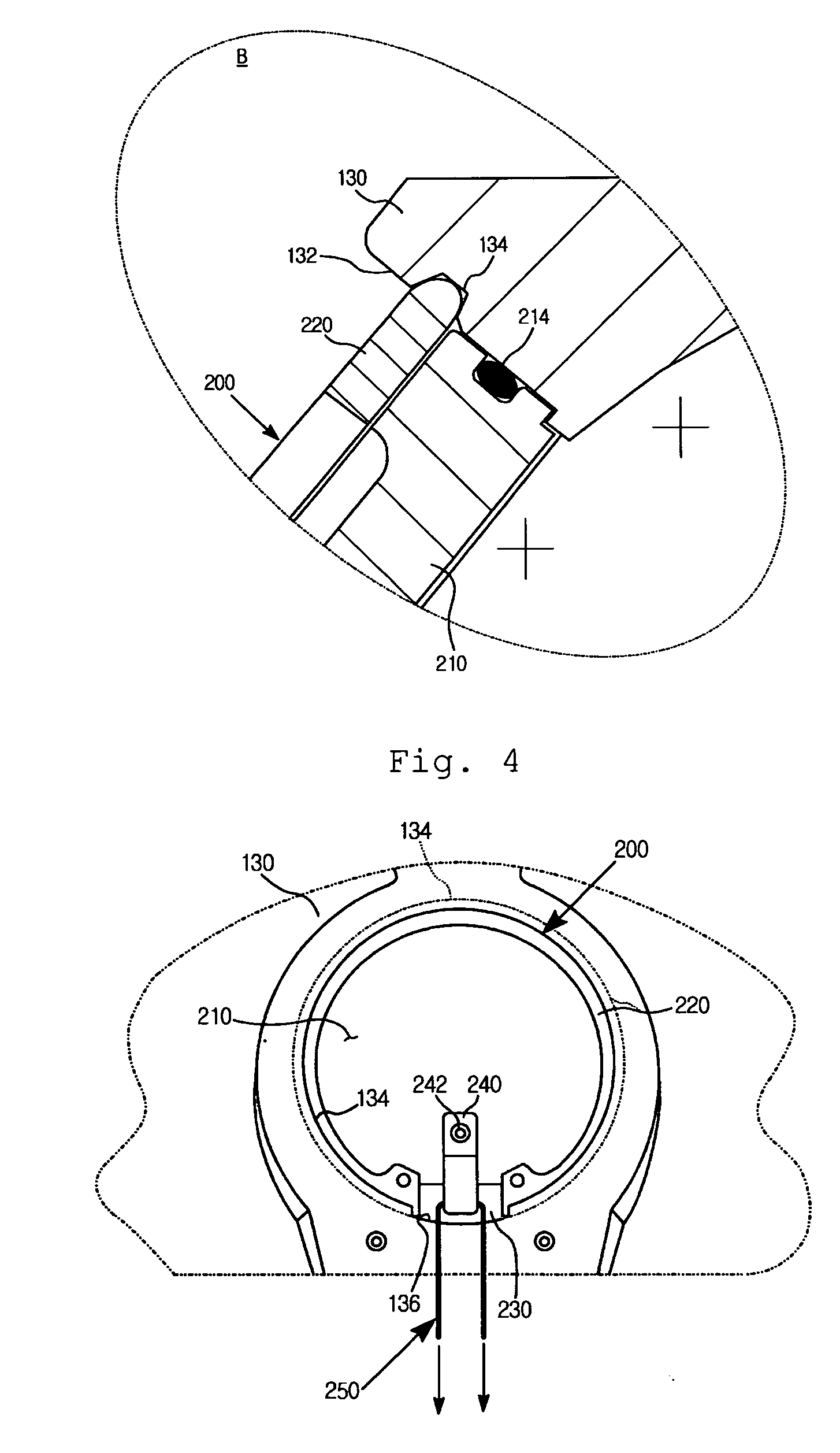

Disclosed is an abrupt opening apparatus of a pressurized chamber in an intended procedure to accomplish thrust termination for a stage separation of the solid rocket motor. It can open trust termination ports with simple mechanical structure to thereby terminate the normal thrust of a nozzle reliably, if it is intended to terminate the normal thrust produced from the nozzle of the rocket motor to thereby impede the forward movement of the rocket motor by producing the reverse thrust. The thrust termination device for the rocket motor comprises a closure 210 for closing the thrust termination ports in an air-tight structure; a snap ring 220 for supporting the closure 210; a wedge 230 arranged between both free ends of the snap ring; a wedge fixing plate 240 for fixing the wedge; and, a pulling wire 250 linked to the wedge at one end thereof for extracting the wedge by being drawn when the thrust termination is performed.

Owner:AGENCY FOR DEFENSE DEV

Preparation method of refractory high-entropy alloy skeleton-copper spontaneous perspiration composite structure

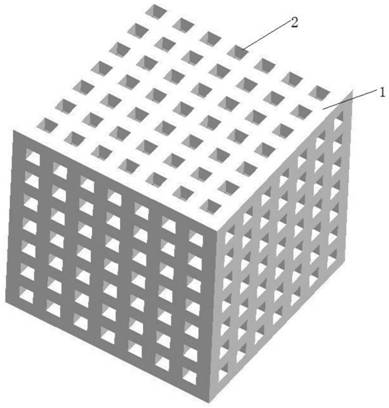

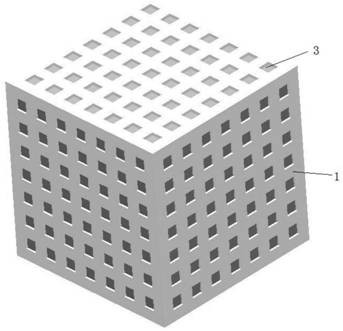

ActiveCN112024902AGood mechanical propertiesHigh strengthAdditive manufacturing apparatusSelective laser meltingHigh entropy alloys

The invention discloses a preparation method of a refractory high-entropy alloy skeleton-copper spontaneous perspiration composite structure. The method comprises the following steps of: smelting a refractory high-entropy alloy raw material to obtain an alloy ingot, and preparing refractory high-entropy alloy powder from the alloy ingot by using a plasma rotating electrode atomization method; forming the refractory high-entropy alloy powder into a preset porous skeleton structure through an electron beam or selective laser melting additive manufacturing process; and infiltrating metal copper into the porous skeleton structure by adopting an infiltration process, thereby obtaining the refractory high-entropy alloy skeleton-copper spontaneous perspiration composite structure. The structure has the characteristic of spontaneous perspiration, and is suitable for high-temperature parts such as rocket engine nozzle throat inserts, thrust chamber injector panels, missile warhead nose cones and electromagnetic gun tracks. The prepared composite structure has the advantages that the forming process is simple, the porosity can be conveniently designed and adjusted according to actual requirements, the mechanical property is good, high temperature resistance and thermal shock resistance can be achieved, and high practical value is achieved.

Owner:JIANGSU UNIV OF SCI & TECH +2

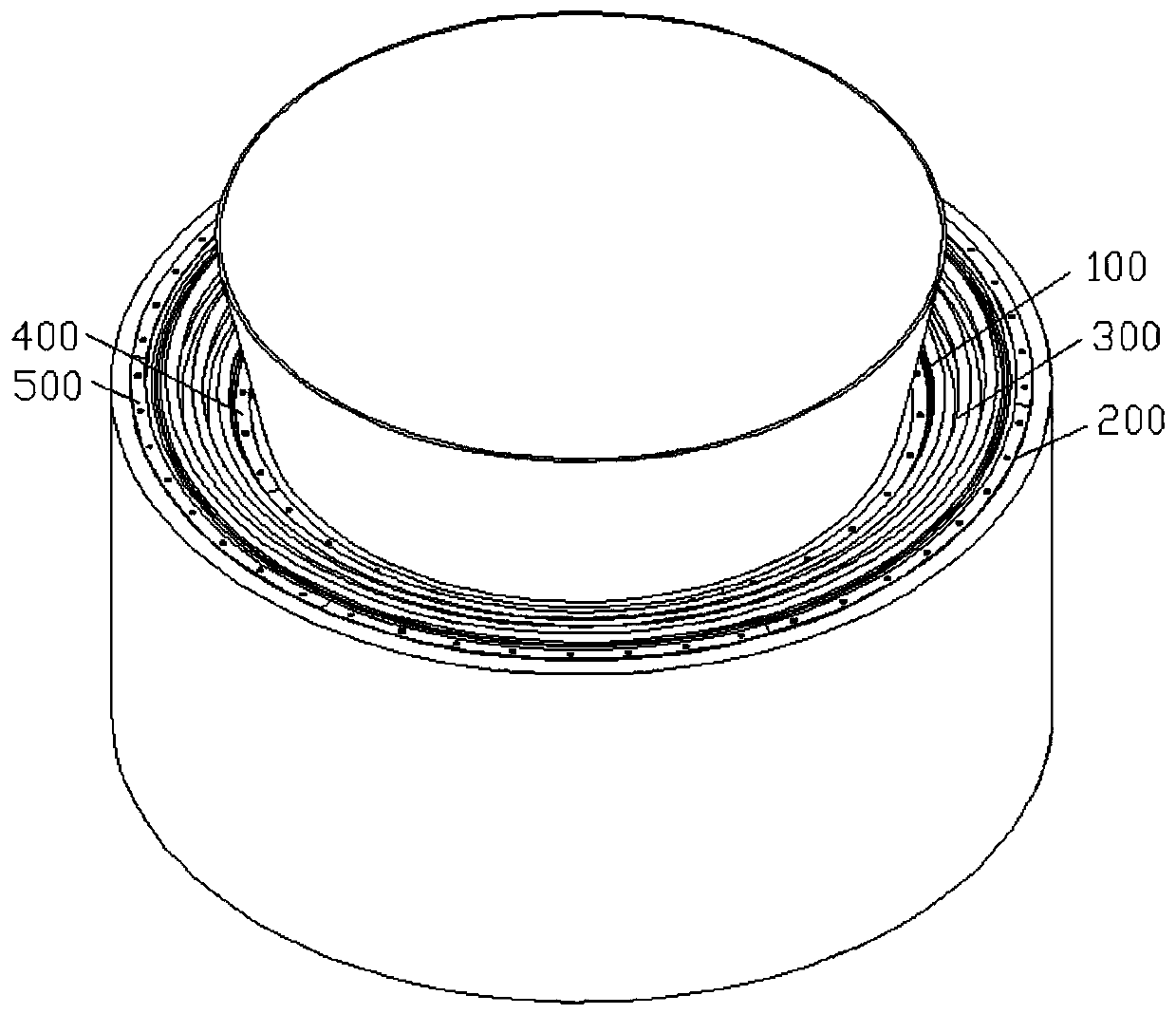

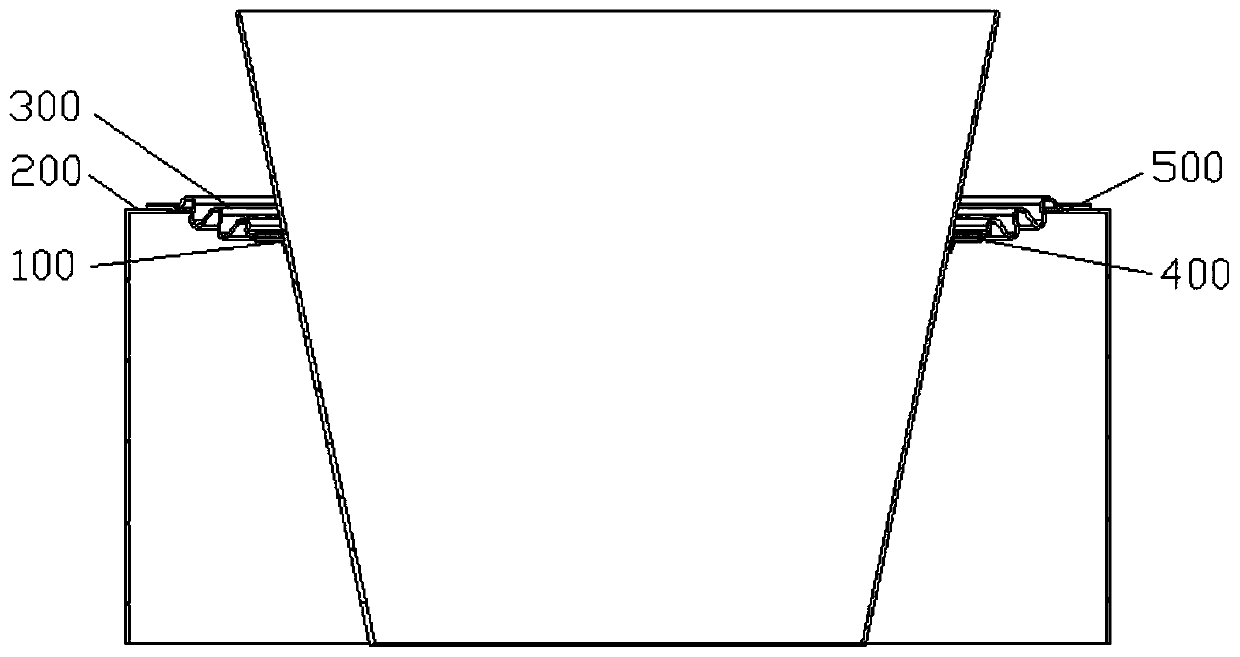

Heat-proof device for swing type rocket engine nozzle

The invention discloses a heat-proof device for a swing type rocket engine nozzle, and belongs to the technical field of heat-proof and insulation devices for space launch. The heat-proof device for the swing type rocket engine nozzle comprises a nozzle flange, a cabin shell rear end cover and a heat-proof telescopic apron board; the nozzle flange is connected with an inner ring end surface of theheat-proof telescopic apron board, and the cabin shell rear end cover is connected with an outer ring end surface of the heat-proof telescopic apron board; the section of the heat-proof telescopic apron board is of a corrugated structure; and the heat-proof telescopic apron board is made of flexible ablation-resistant heat-proof materials. The problems that the structure is cracked due to poor ductility, and internal equipment is burnt by flame backflow since the apron board is of a flat plate type or conical surface heat insulation structure made of metal or composite materials are solved. The heat-proof telescopic apron board is made of flexible ablation-resistant heat-proof materials, and the section is of the corrugated structure, the flame of an engine can be prevented from flowing back to the interior of a cabin body, the returned flame is blocked from entering the cabin body, and the heat-proof device has high barrier property on ablation property and gas flow.

Owner:TIANJIN ISTAR ADVANCED MATERIAL TECH CO LTD

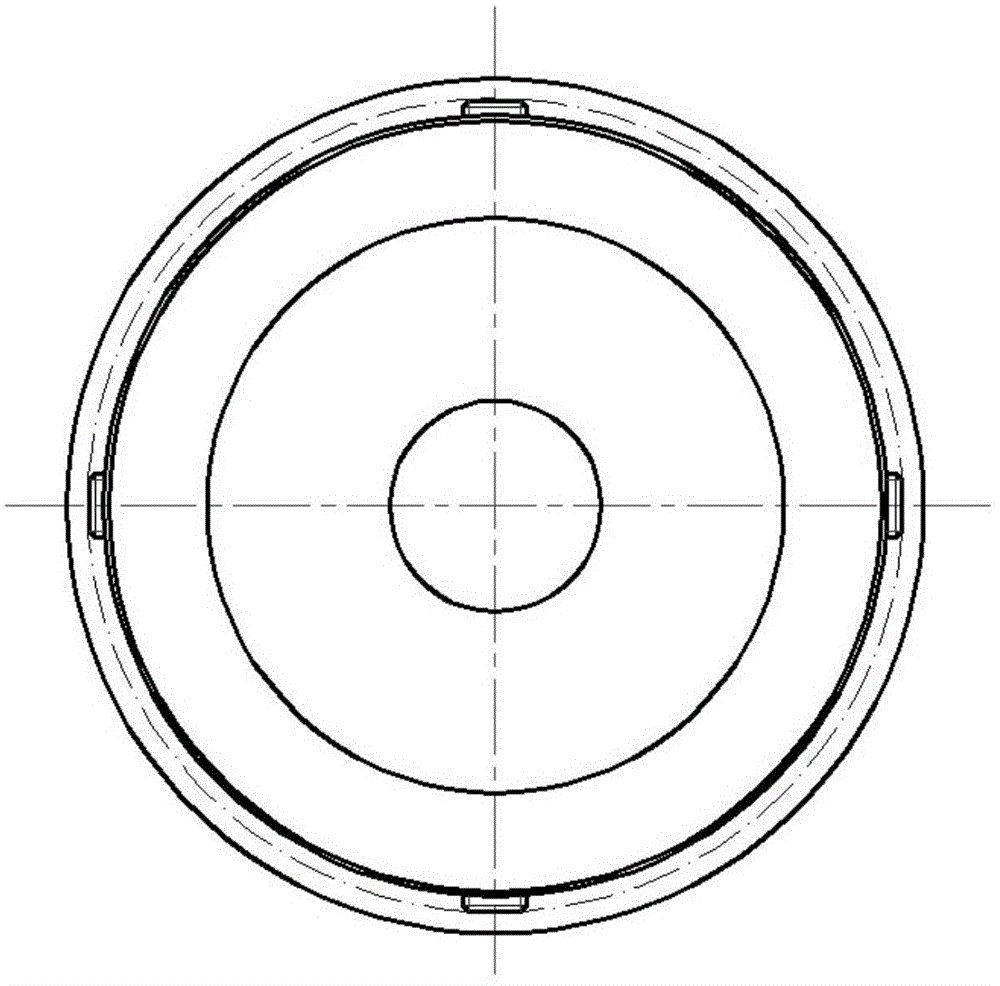

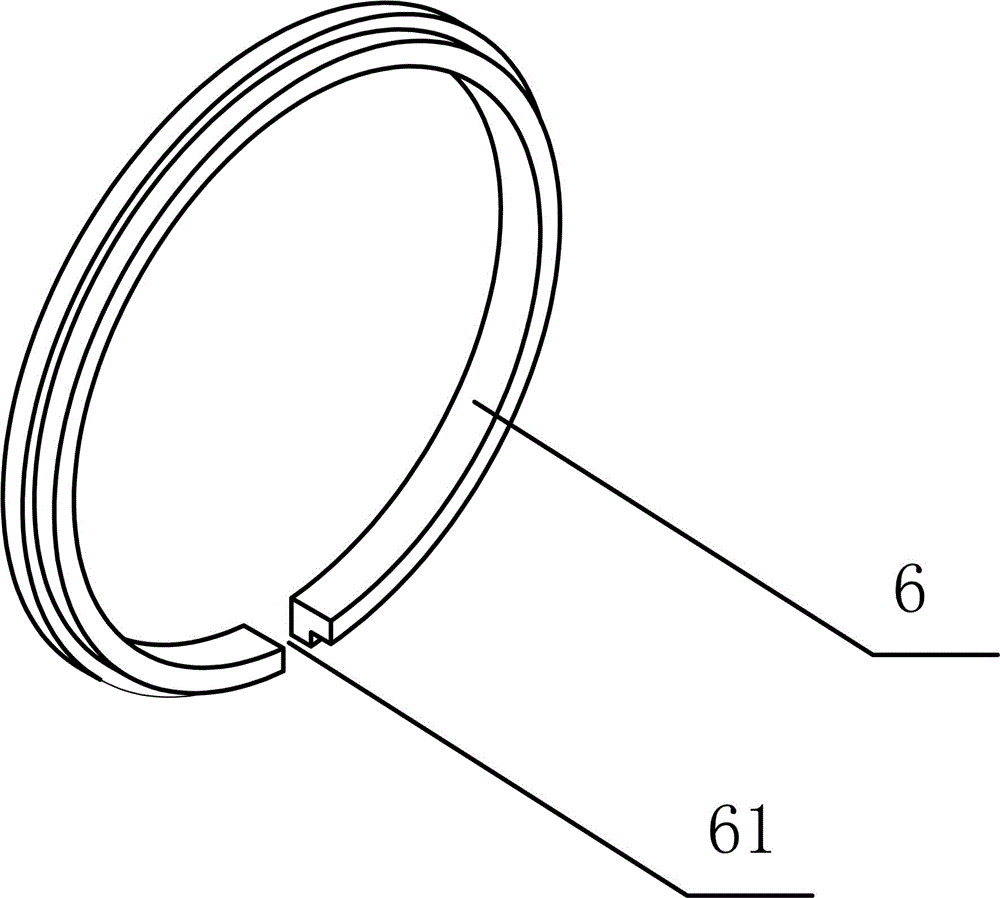

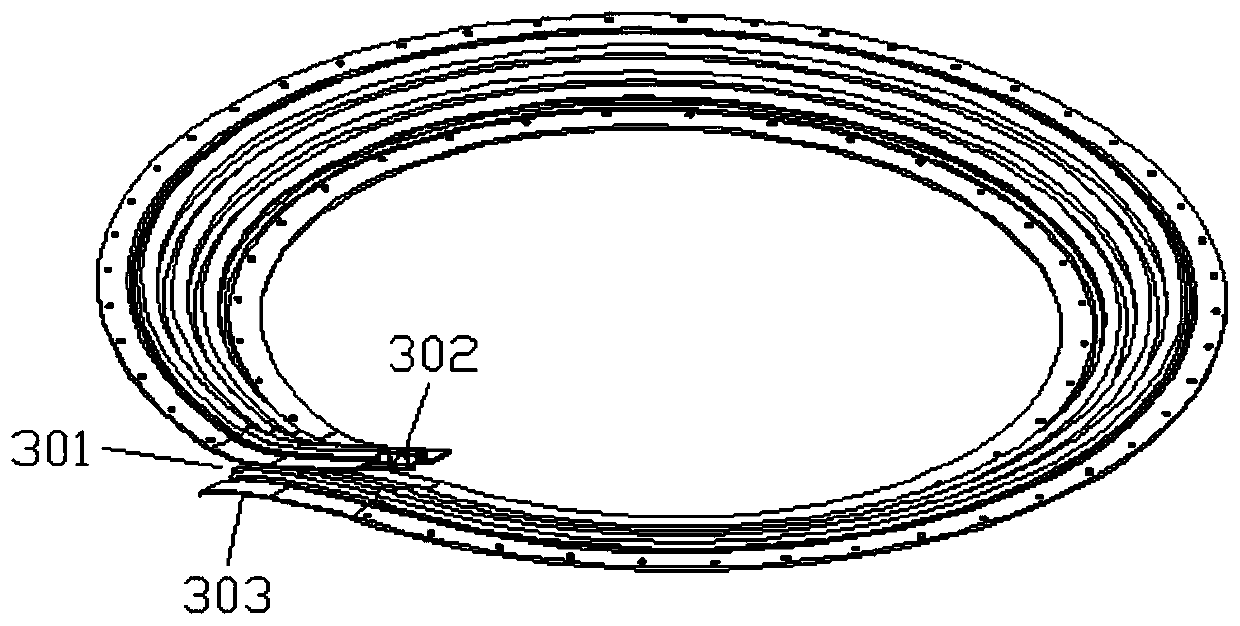

Mould pressing corrugated type flexible flame isolation device

ActiveCN105464839AAchieving protection against radiant heatRealize functionRocket engine plantsThermal radiationRadiant heat

The invention relates to the technical field of heat protection and insulation, in particular to a mould pressing corrugated type flexible flame isolation device. The device aims to solve the problem that a heat emission rocket stern room is prone to the frustrating effect of engine flame take-off aftereffect back scrolling and long-term heat radiation. The mould pressing corrugated type flexible flame isolation device is characterized in that the whole mould pressing corrugated type flexible flame isolation device is of a ring type structure, and an inner shearing edge, an outer shearing edge and a corrugated structure are arranged on the ring type structure; the inner shearing edge is located on the innermost side of the ring type structure and is fixedly connected with a spraying pipe flange of the rocket stern room; the corrugated structure is located on the outer side of the inner shearing edge; the outer shearing edge is located on the outer side of the corrugated structure and fixedly connected with the lower end face of the rocket stern room; the inner shearing edge is used for being tightly attached to a rocket engine, the outer shearing edge is used for being tightly attached to the rocket stern room, and the corrugated structure is used for providing space for swinging of the rocket engine. Flexible compensation for a swinging engine spraying pipe is finished, the whole radiant heat prevention and flame reflux ablation prevention functions are also achieved, and the good comprehensive performance is achieved.

Owner:BEIJING INST OF ASTRONAUTICAL SYST ENG +1

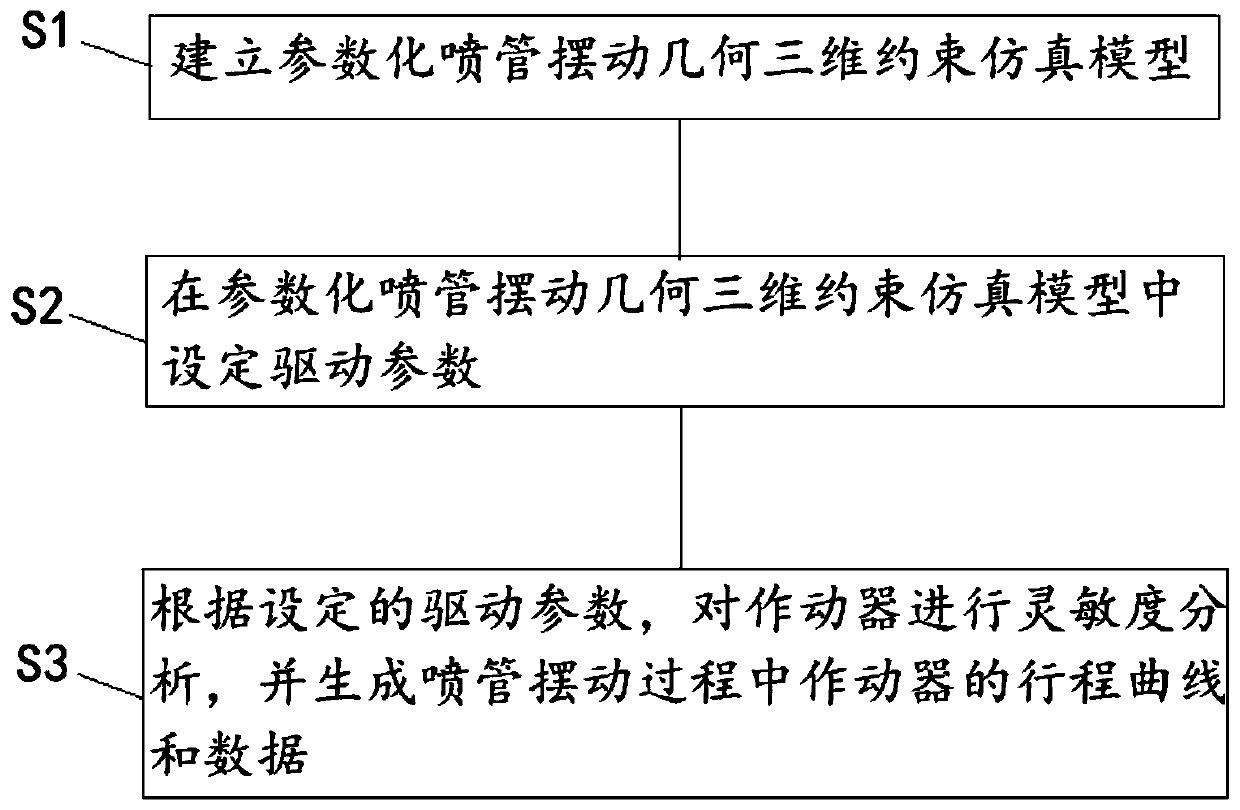

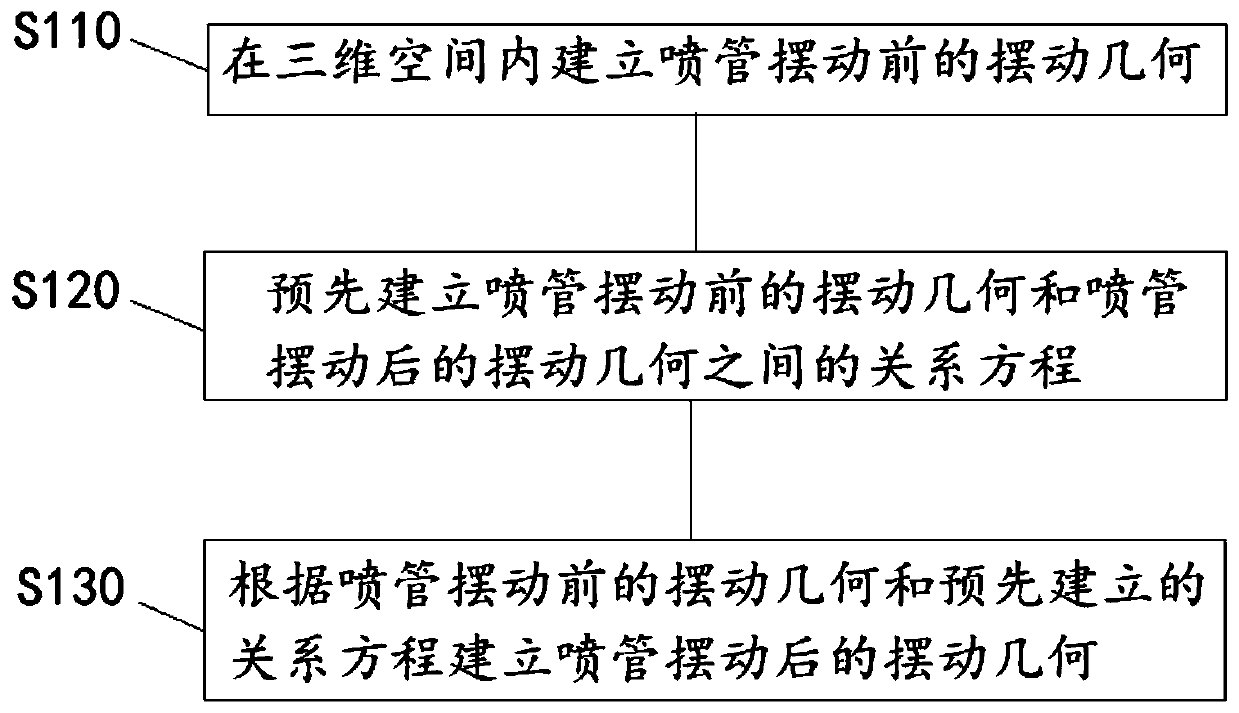

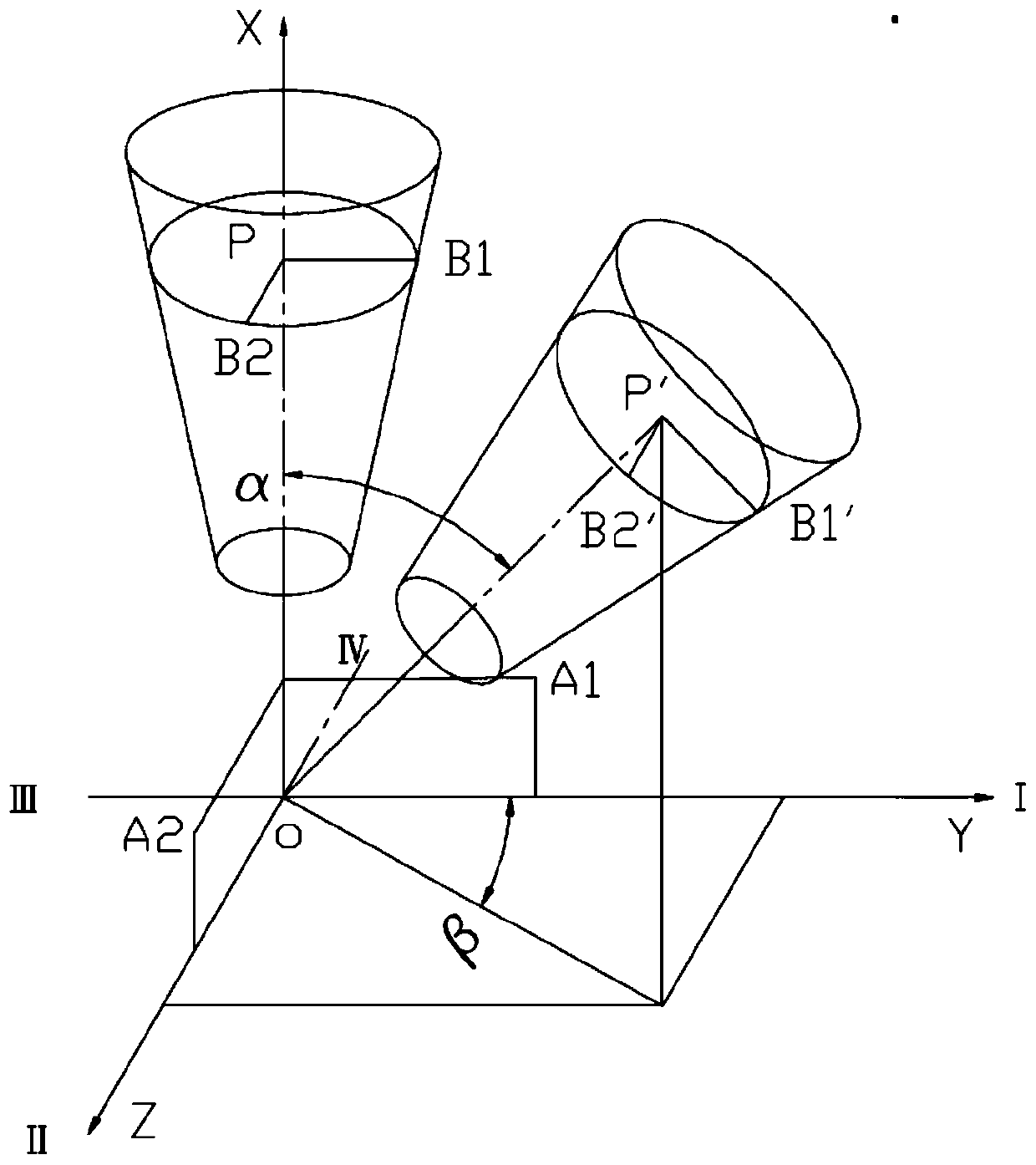

Rocket engine nozzle swing simulation analysis method and system

ActiveCN111553028ALower level requirementsReduce labor intensityGeometric CADSustainable transportationClassical mechanicsActuator

The invention provides a rocket engine nozzle swing simulation analysis method and system. The rocket engine nozzle swing simulation analysis method comprises the following steps: establishing a parameterized nozzle swing geometric three-dimensional constraint simulation model; setting driving parameters in the parameterized nozzle swing geometry three-dimensional constraint simulation model; according to the set driving parameters, conducting sensitivity analysis on the actuator, and generating a stroke curve and data of the actuator in the swing process of the spray pipe. According to the rocket engine nozzle swing simulation analysis method, a parameterized nozzle swing geometry three-dimensional constraint simulation model is established, and actuator stroke curve data is directly generated during nozzle design and used for verifying a rocket flight control algorithm.

Owner:北京中科宇航技术有限公司

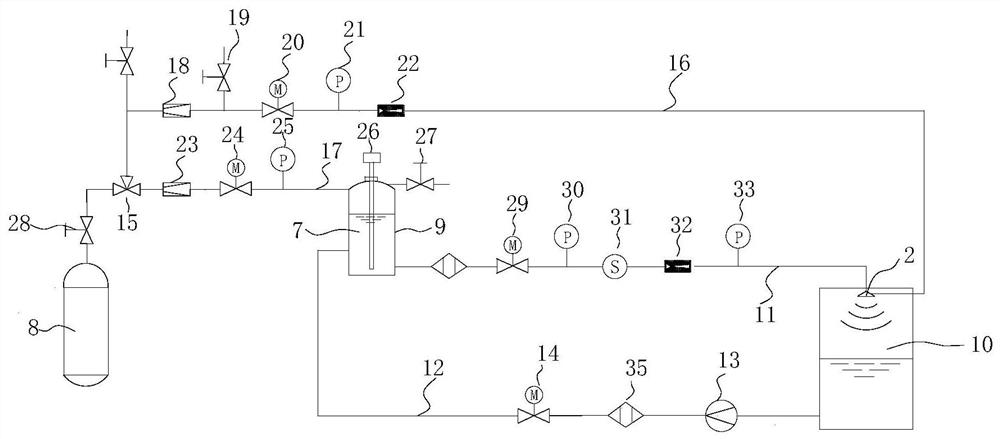

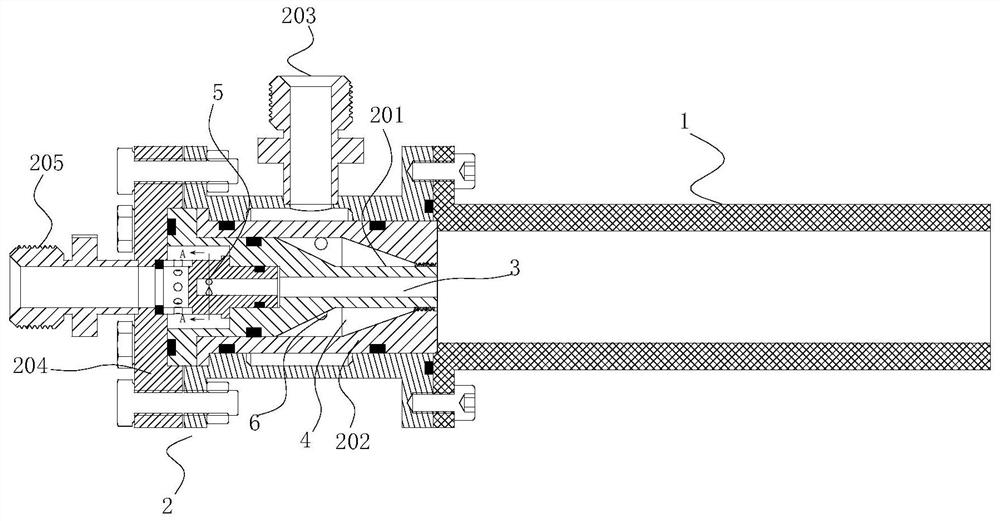

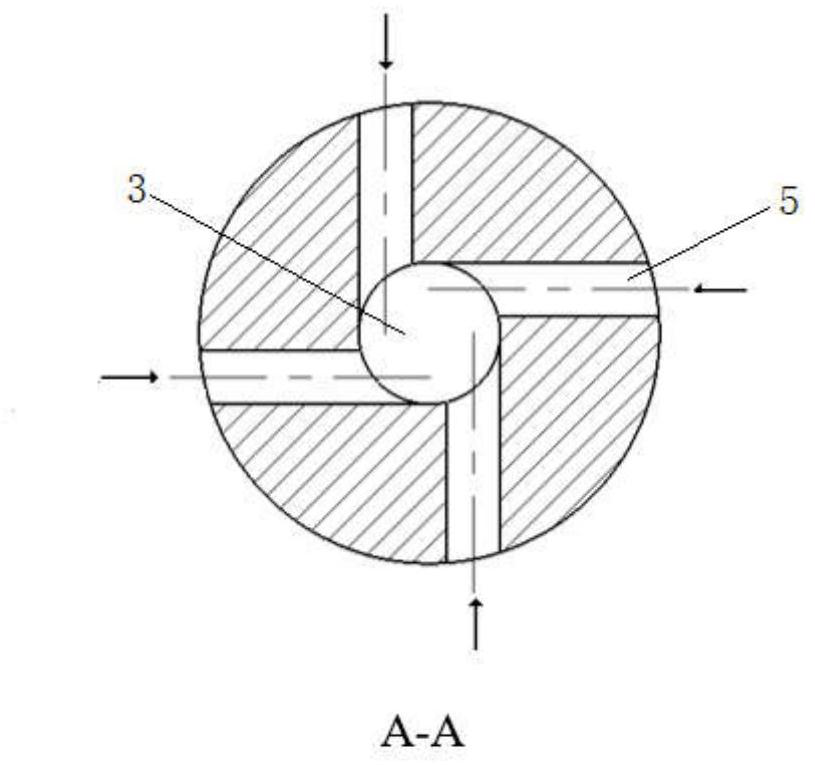

Test platform for rocket engine nozzle atomization test

InactiveCN112345257AOvercome the defects of large scale and high riskEasy to doGas-turbine engine testingJet-propulsion engine testingCombustion chamberAtomizer nozzle

The invention discloses a test platform for a rocket engine nozzle atomization test, which comprises a transparent combustion chamber and a swirl atomization nozzle arranged on the transparent combustion chamber, and is characterized in that a first injection flow channel and a second injection flow channel with the same injection direction are formed in the swirl atomization nozzle; the first injection flow channel is located in the second injection flow channel, the inlet end of the first injection flow channel is closed, a water inlet tangent to the peripheral wall of the first injection flow channel is formed in the inlet end of the first injection flow channel, and the inlet end of the second injection flow channel is closed. A gas inlet tangent to the peripheral wall of the second injection flow channel is formed in the inlet end of the second injection flow channel, the water inlet is communicated with a pressure water source, and the gas inlet is communicated with a pressure nitrogen source. The test platform overcomes the defects that an existing engine supply system is large in scale, high in risk and the like, meanwhile, the test platform does not relate to the open firecombustion process, and researchers can conveniently conduct a nozzle atomization test manually.

Owner:CENT SOUTH UNIV

Device for displacing to nozzle outlet or eliminating jet separation in rocket engine nozzles, and a nozzle including the device

InactiveUS6572030B2Reduce and control phenomenonSeparation can be eliminated and reducedPower plant exhaust arrangementsPropulsive elementsEngineeringRocket engine nozzle

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

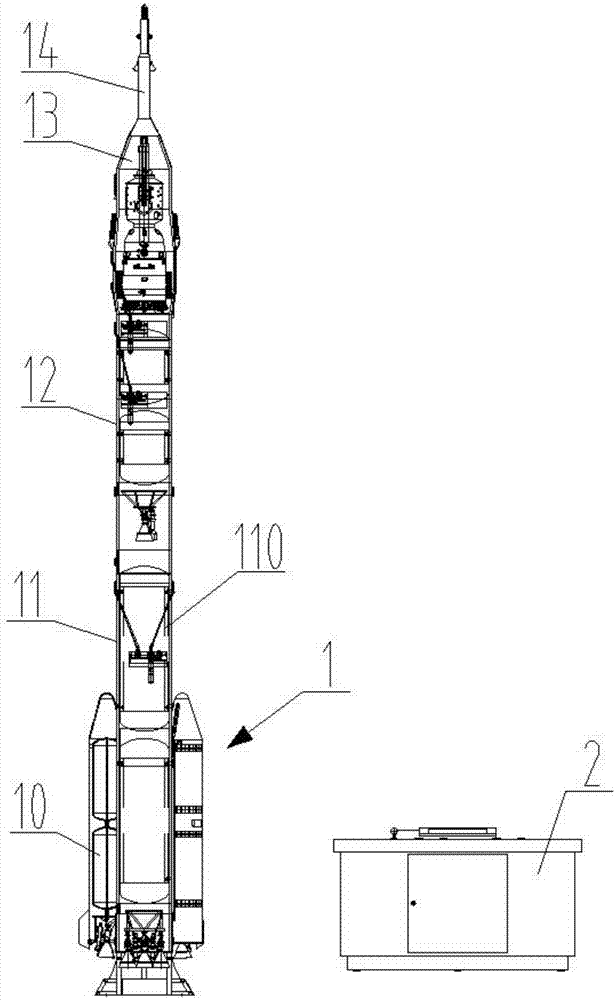

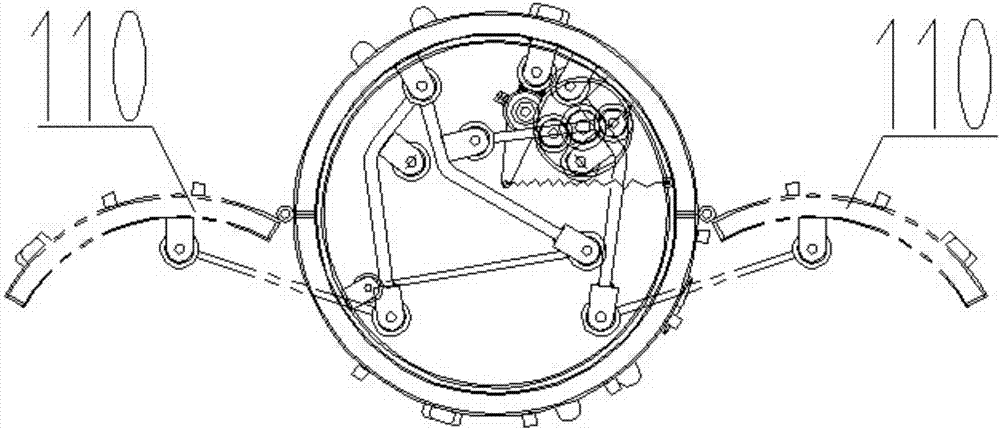

Display structure and display method of Long-March II F-type rocket

ActiveCN107274772ALively displayImprove display effectEducational modelsGraphicsStructural composition

The invention provides a display structure and display method of a Long-March II F-type rocket. The display structure includes a rocket dynamic simulation model, a lighting and voice device, a console and a graphic & text board. The rocket dynamic simulation model comprises a booster, a core one-stage rocket, a core two-stage rocket, a fairing and an escape tower. The booster has a transparent shell. The core one-stage rocket includes a core one-stage rocket shell and a core one-stage rocket engine nozzle. The core one-stage rocket engine nozzle is connected with a core one-stage rocket swing mechanism. The fairing includes a fairing shell and a spaceship. The spaceship is connected with the escape tower. The escape tower is connected with a vertical lift drive mechanism. According to the invention, the method of combining an array and dynamic demonstration is adopted, the main part of the rocket is presented to the audience by dynamic section processing, the audience can observe the internal structure of the Long March II F-type rocket model clearly and intuitively to understand the main structural composition and related functions of the rocket, and the display form is more lively.

Owner:CHINA SCI & TECH MUSEUM

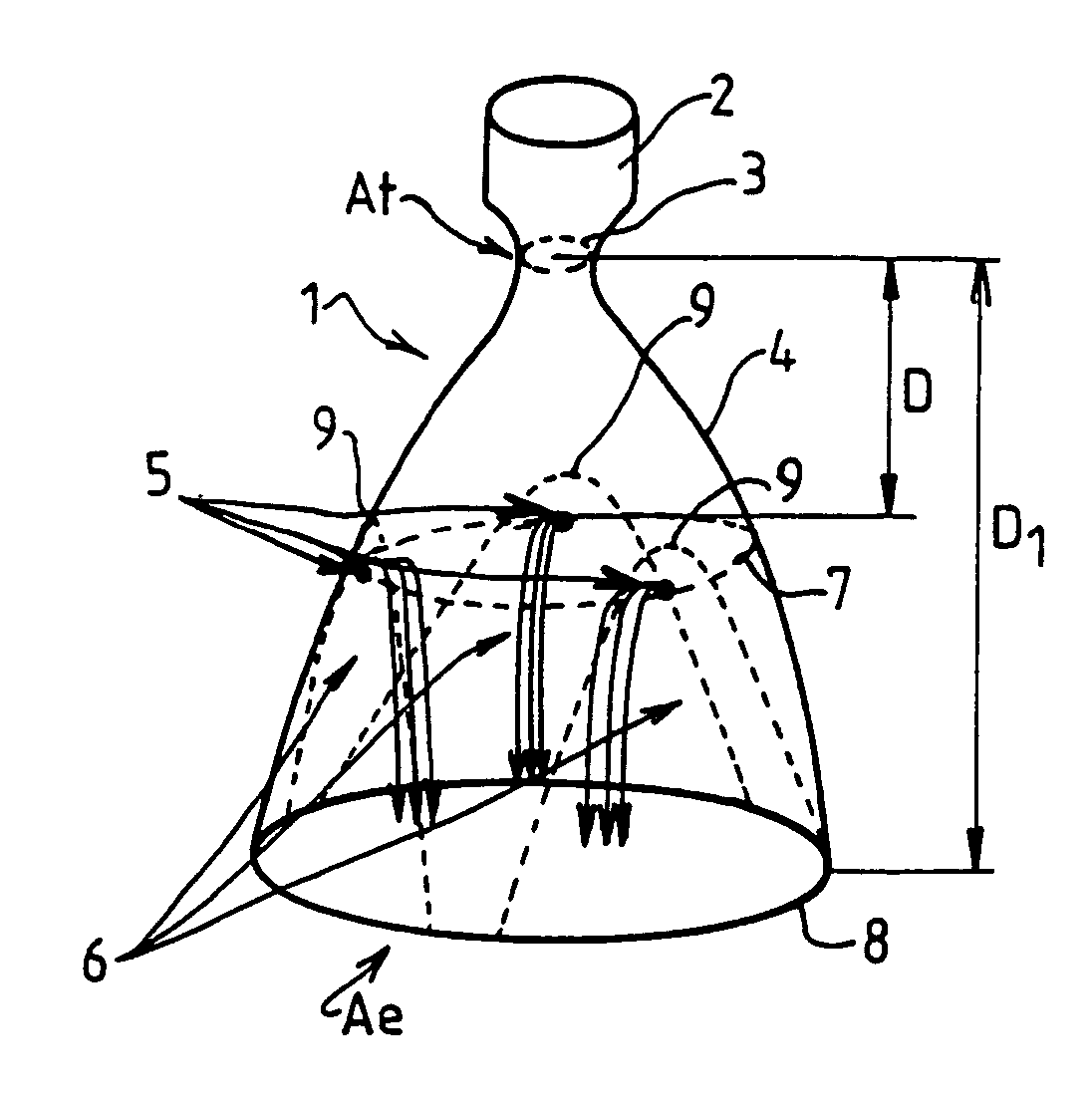

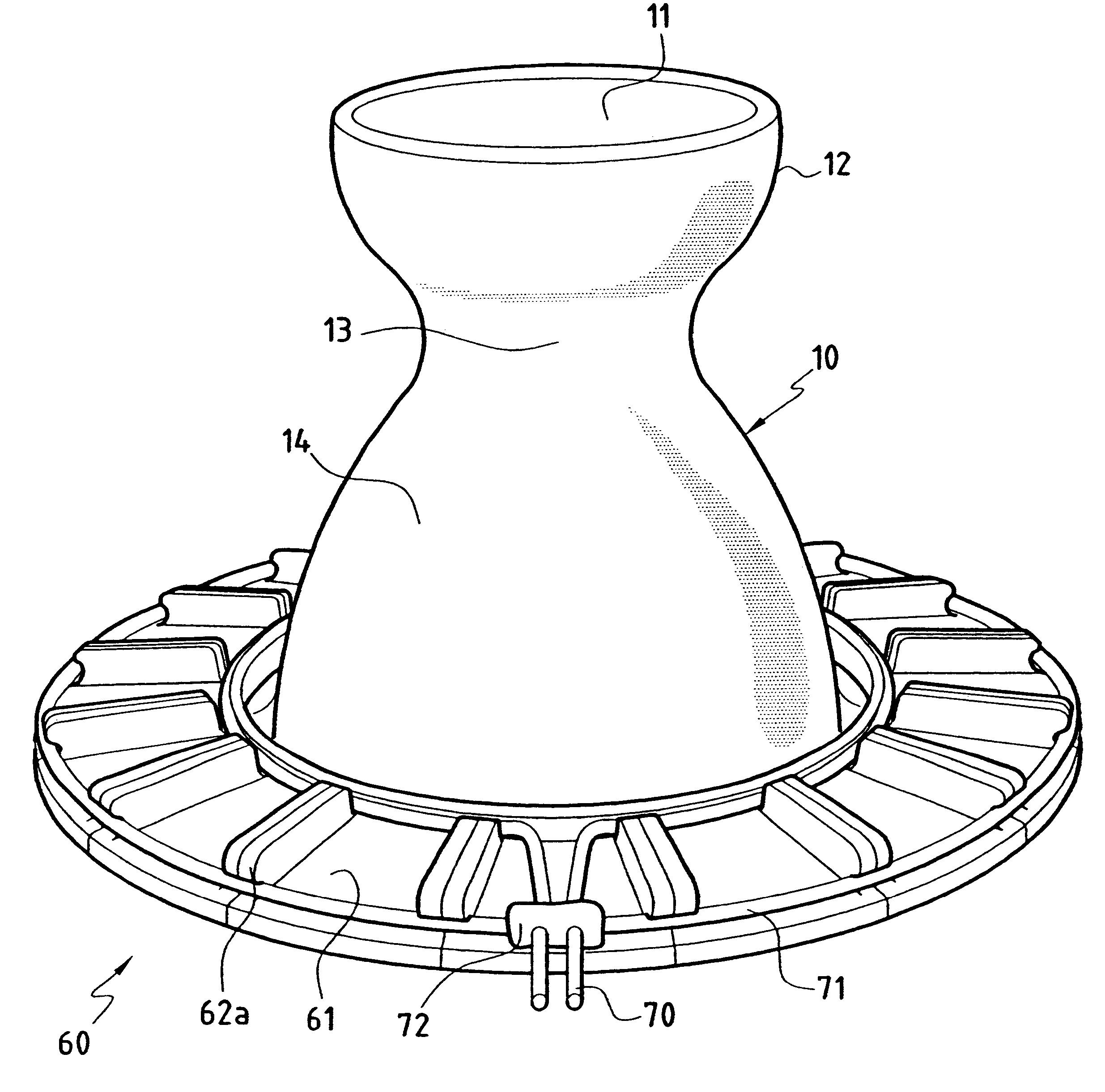

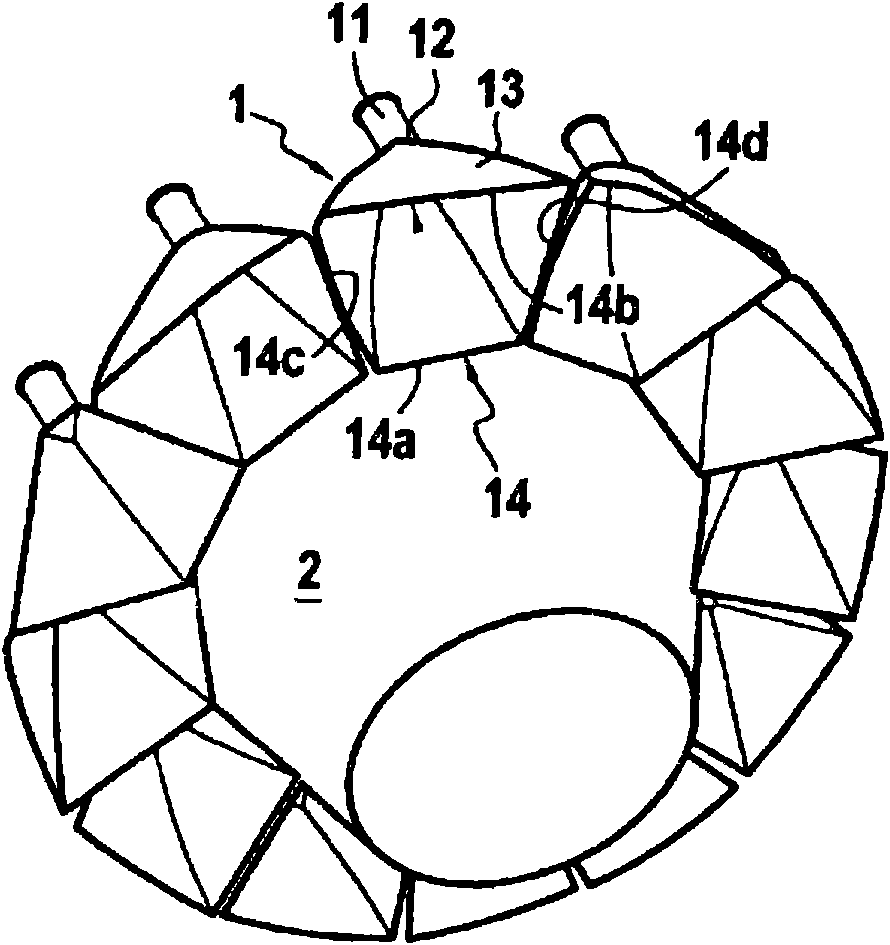

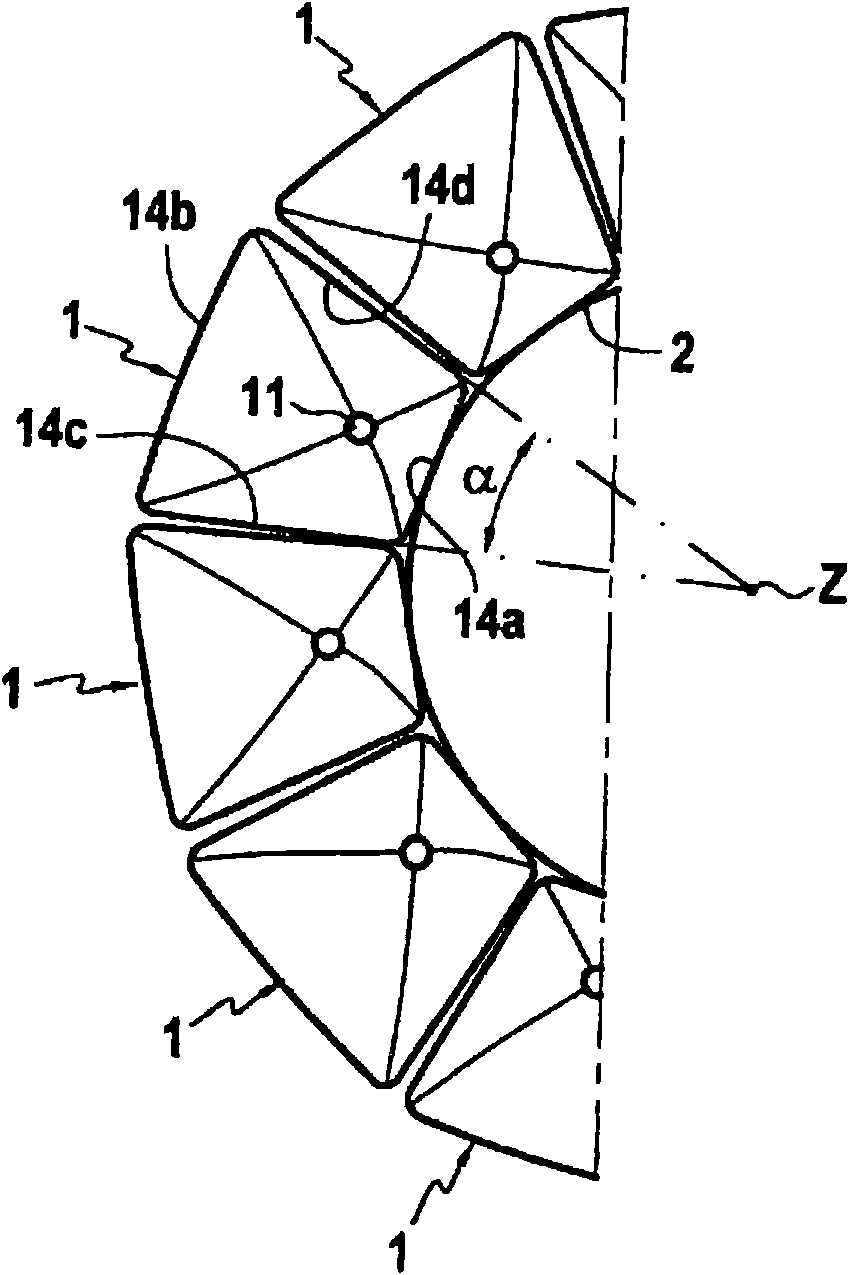

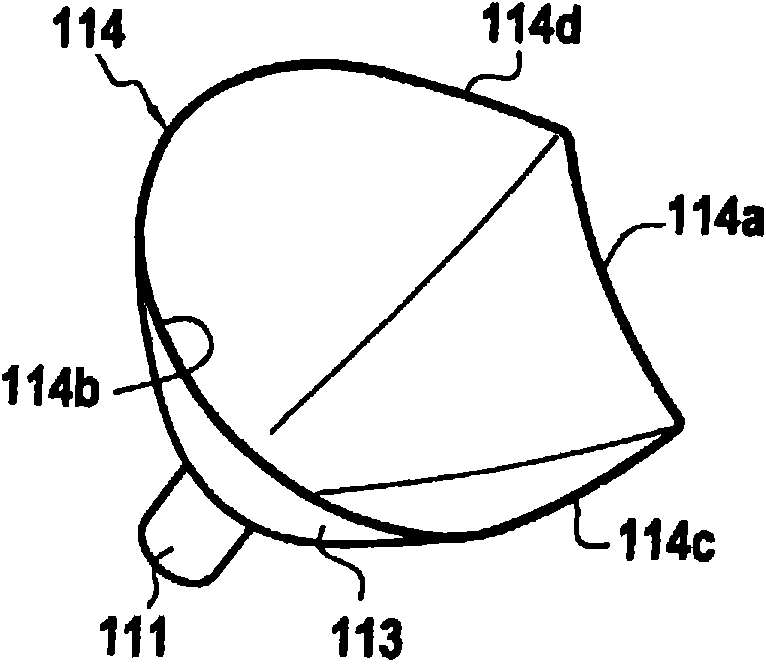

Rocket engine nozzle system

The rocket engine nozzle system comprises a set of individual nozzles distributed in a ring around a central core of axially symmetrical shape that presents a central axis. Each individual nozzle placed at the periphery of the central core comprises a circular section throat for receiving gas from a combustion chamber, and a diverging portion that is tangential to the central core. The diverging portion has an outlet section that presents first and second lateral sides that converge radially towards the central axis of the central core, a curved outer side having its convex side facing outwards, and an inner side situated in the vicinity of the central core.

Owner:ARIANEGRP SAS

Connection sealing structure for nozzle assembly of solid rocket engine

The invention relates to a connecting sealing structure of a nozzle assembly of a solid rocket engine. The spray pipe expansion section is a cylindrical structure with an inner cavity in a trumpet shape, a first step, a second step and a third step are sequentially arranged on the outer surface of the spray pipe expansion section, the spray pipe shell is sleeved outside the spray pipe expansion section, the inner cavity of the spray pipe shell is provided with a first step groove, a second step groove and a third step groove, the first step groove and the second step groove, and the third stepis matched, a sealant is arranged between the first step of the nozzle expanding section and the first step groove of the nozzle shell, the second step part of the spray pipe expansion section is provided with a concave annular installation groove, and the retaining ring is arranged in the concave annular mounting groove and forms a thread pair with the spray pipe shell. The structure can be applied to the connection of almost all small solid rocket engine nozzle assemblies, in particular, to address such limitations as structural space, it is desirable to withstand higher impact and higher weatherability, the nozzle assembly connecting structure with the problems of temperature shock resistance performance requirement and the like provides a high reliability. the structure is simple andcompact, and the processing technology is simple and convenient.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

High-thermal-conductivity low-expansion graphite for rocket engine nozzle and preparation method of high-thermal-conductivity low-expansion graphite

The invention discloses high-thermal-conductivity low-expansion graphite for a rocket engine nozzle. The high-thermal-conductivity low-expansion graphite is mainly prepared from petroleum coke powder,crystalline flake graphite powder and modified high-temperature asphalt. The modified high-temperature asphalt is obtained by carrying out sulfur vulcanization treatment on high-temperature asphalt.The preparation method of the graphite comprises the following steps: shaping petroleum coke and crystalline flake graphite, kneading the shaped petroleum coke and crystalline flake graphite with thehigh-temperature modified asphalt, flaking, crushing, standing, carrying out isostatic pressing, carbonizing, dipping, and finally graphitizing to obtain the high-thermal-conductivity low-expansion graphite. According to the invention, the graphite takes the petroleum coke powder as a main material, the crystalline flake graphite as an auxiliary material and the sulfur modified asphalt as a binder, and reasonably matches the types and proportions of aggregates, so that the high thermal conductivity and low expansion coefficient of the graphite can be effectively enhanced while the strength index of the graphite is basically maintained, thereby reducing the expansion coefficient difference between the graphite and refractory ceramic and improving the strength of the refractory ceramic. Rocket engine spray pipe using requirements are met.

Owner:HUNAN CHANGYU NEW CARBON MATERIALS

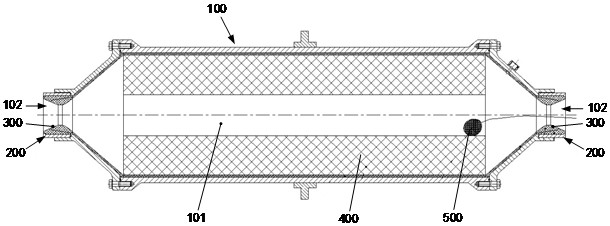

Testing device for rocket engine nozzle throat liner

ActiveCN112555057AHigh precisionReduce consumptionRocket engine plantsCombustion chamberRocket engine nozzle

The embodiment of the invention provides a testing device for a rocket engine nozzle throat liner. The testing device comprises a test engine unit and at least two spray pipe units. The test engine unit is provided with a combustion chamber and at least two output ends, each output end is provided with a gas channel, and the two ends of each gas channel communicate with the combustion chamber of the test engine unit and the external environment of the test engine unit separately. Each spray pipe unit is detachably connected into the corresponding gas channel. Each spray pipe unit is used for correspondingly bearing different types of throat liner test pieces. The combustion chamber is used for generating a real gas environment simulating a rocket engine and testing the throat lining test pieces at the at least two output ends. According to the embodiment of the testing device for the rocket engine nozzle throat liner, different types of throat liner test pieces can be ablated at the same time in the same ablation test, the real same test environment is realized, the ablation performance comparison assessment precision of different types of throat liner test pieces can be greatly improved, and the test cost is reduced.

Owner:星河动力(北京)空间科技有限公司 +2

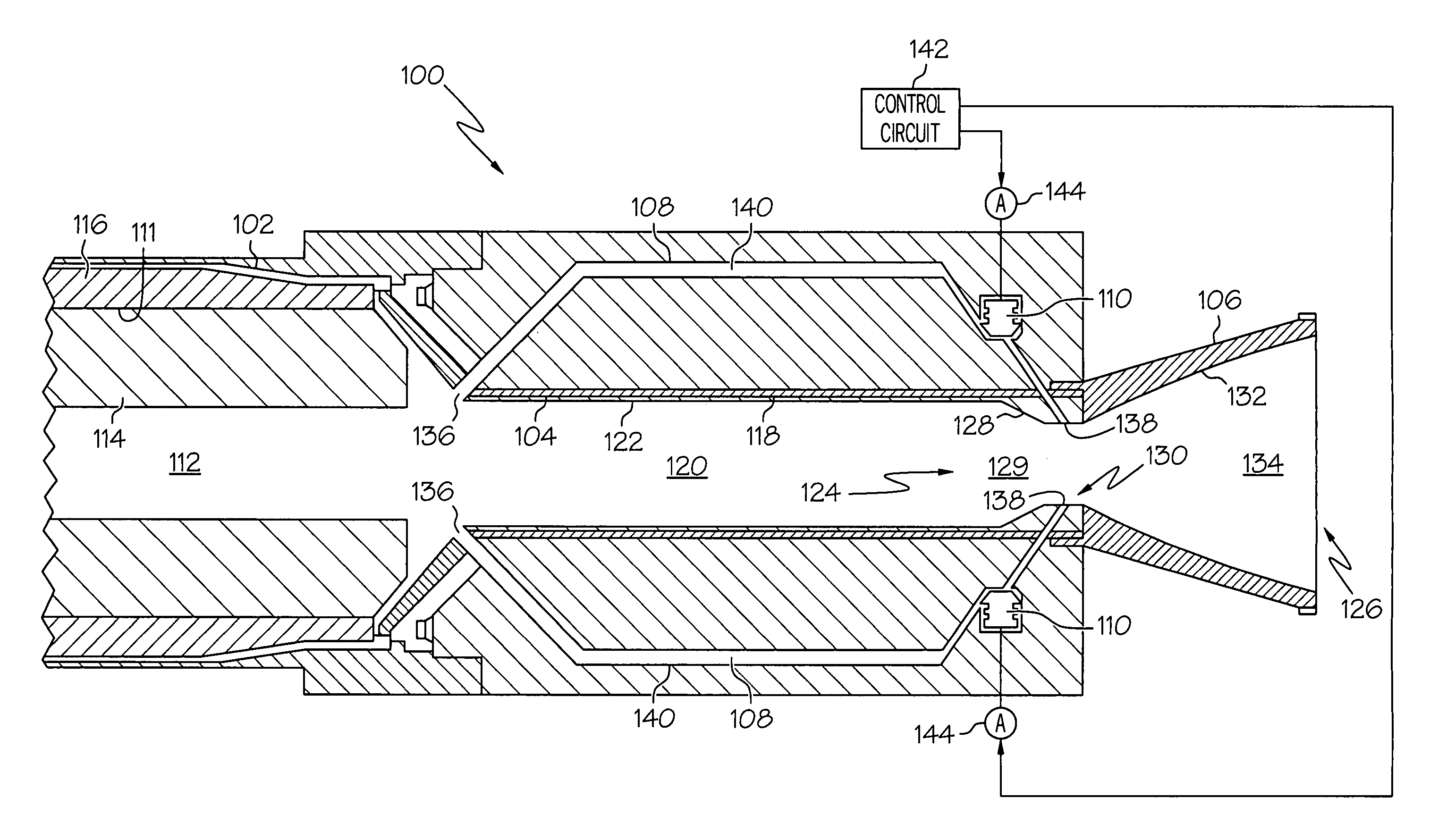

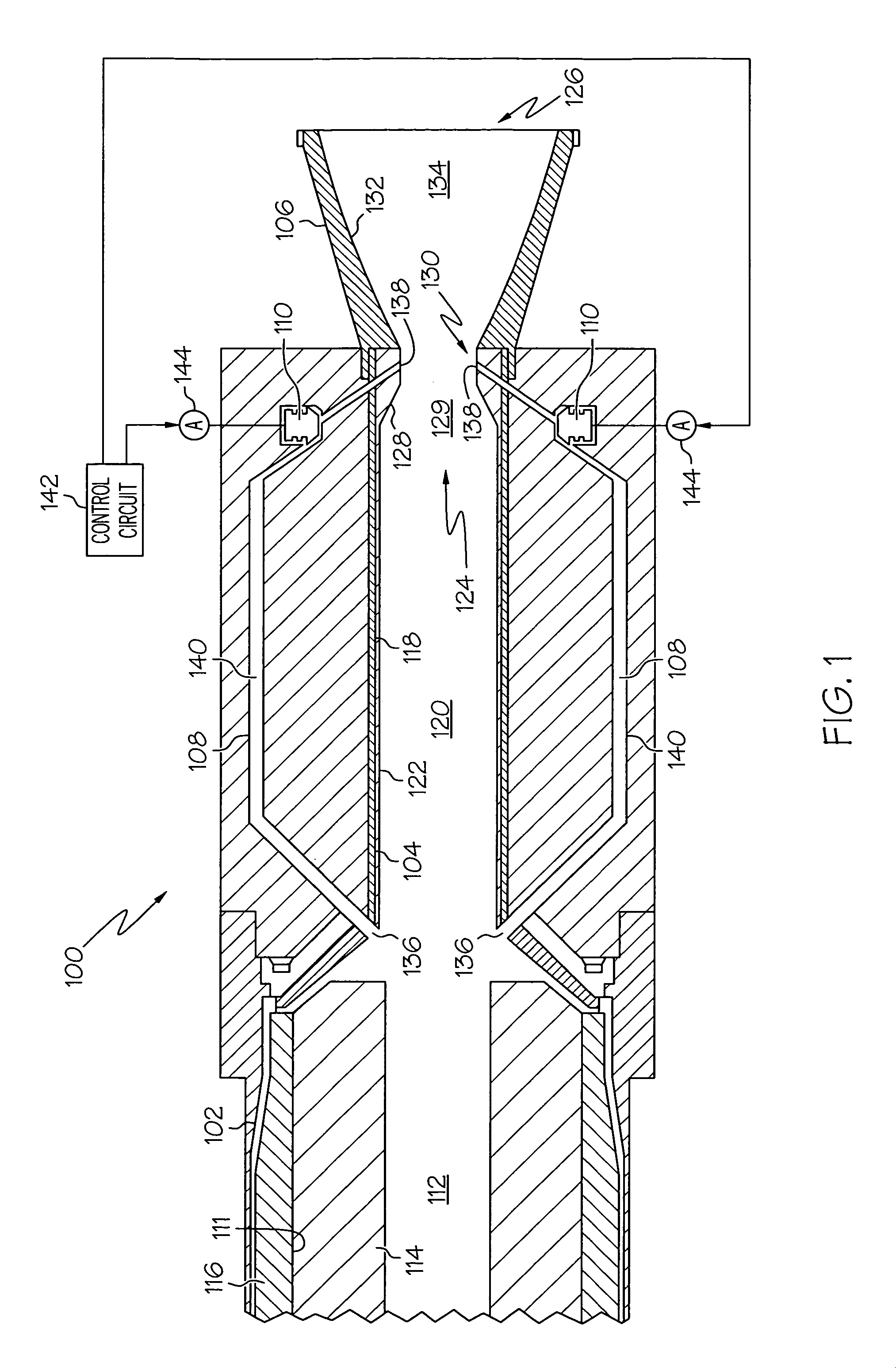

Rocket motor nozzle throat area control system and method

InactiveUS7464535B2Not significantly affect overall motor efficiencyLess expensiveAircraft navigation controlCosmonautic vehiclesCombustion chamberControl system

A solid rocket motor including a combustion chamber, in which propellant is ignited to produce combustion gas, and a nozzle having a throat with an effective flow area, implements a system and method to inject gas into the nozzle throat to control its effective cross sectional flow area. Controlling the effective cross sectional flow area of the nozzle throat in turn controls combustion chamber pressure, thus the burn rate of the propellant in the combustion chamber, and thus the thrust generated thereby.

Owner:HONEYWELL INT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com