Solid-liquid rocket engine nozzle airtight inspection device

An engine nozzle and airtight inspection technology, which is applied in the direction of rocket engine devices, jet propulsion devices, machines/engines, etc., can solve the problem of difficult operation and inability to accurately check the airtight performance and airtightness of the connecting part of the nozzle and the combustion chamber. Complicated devices and other problems, to achieve the effect of increasing flexibility and simple and quick air-tight inspection operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] specific implementation plan

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

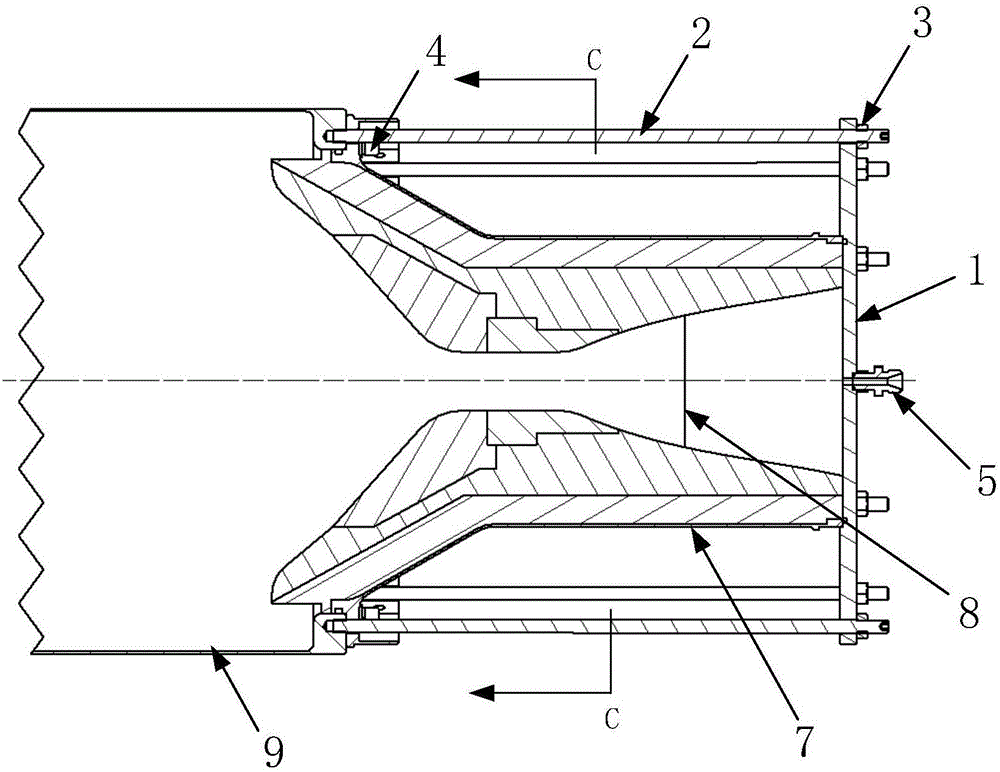

[0020] The nozzle airtight inspection device of the present invention comprises a nozzle airtight tooling 1, a screw rod 2, a nut 3, a fastening screw 4 and a nozzle 5, such as figure 1 shown.

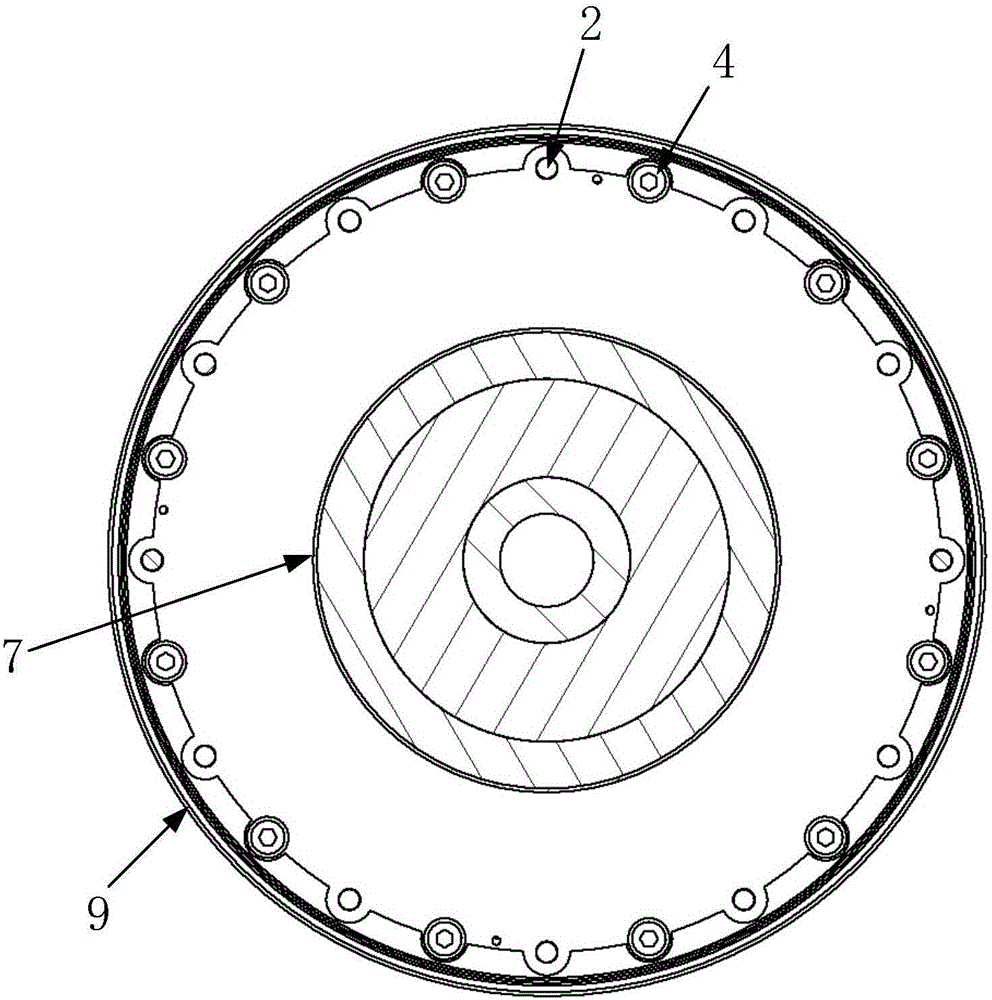

[0021] The nozzle airtight tooling 1 is a circular plate-shaped structure, and 12 through holes are evenly opened on the outer edge of the surface; at the same time, 24 threaded holes are evenly opened on the circumference of the connection between the nozzle 7 and the combustion chamber 9, such as figure 2 Shown; The 24 threaded holes run through the step that is designed on the nozzle pipe 7 and cooperates between the end faces of the combustion chamber 9, and extends to the rear end face of the combustion chamber. The 12 threaded holes at intervals among the 24 threaded holes are used as screw mounting holes, which correspond to the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com