Rocket engine nozzle system

A rocket engine and nozzle technology, which is applied in the direction of rocket engine devices, engine manufacturing, engine components, etc., can solve the problems of discontinuity, inability to solve the flow at the outlet of the nozzle, and inability to optimize the space of the center body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

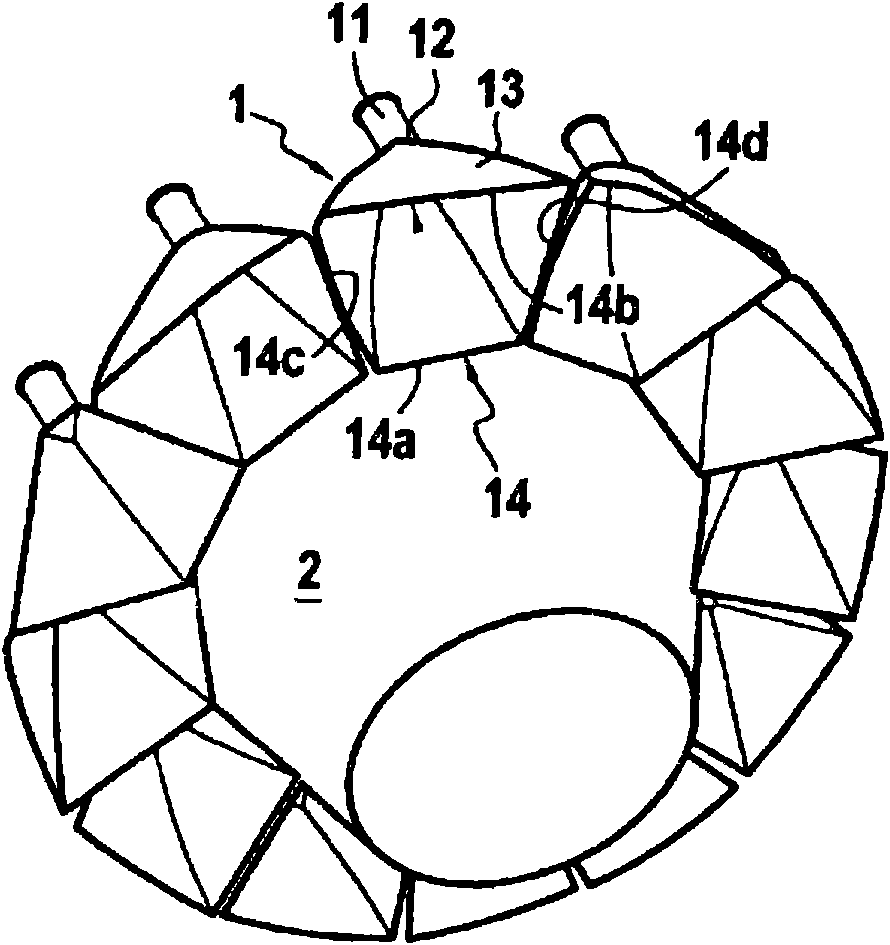

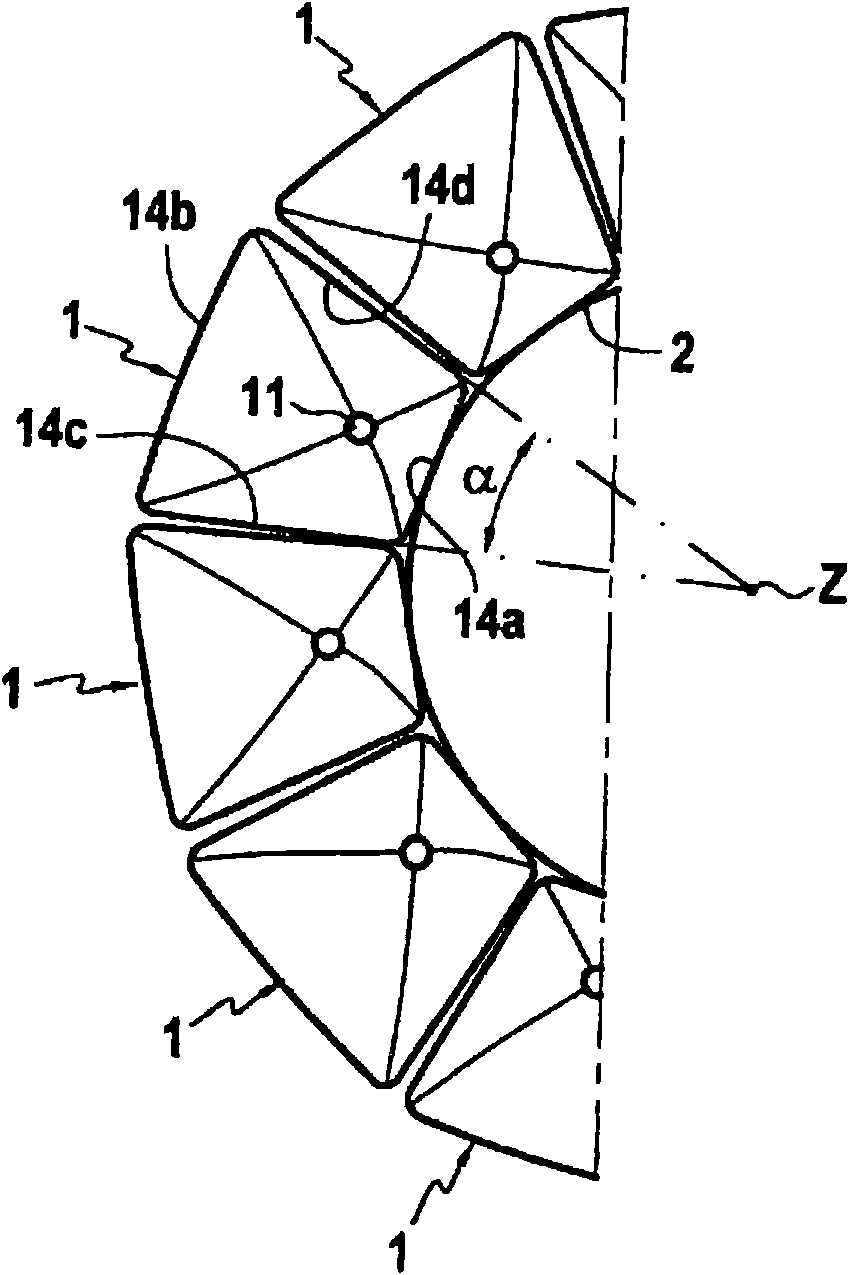

[0027] figure 1 is a general perspective view of a rocket motor nozzle system comprising a particular embodiment of the present invention comprising an axially symmetrical central body 2 of substantially frustoconical shape associated with a set of individual nozzles of asymmetrical shape In combination, said nozzles are arranged in an annular form around the central body, these individual nozzles are suitable to optimize the space they occupy and to avoid creating in the air flow where they leave the individual nozzles 1 to join to the outer side walls of the central nozzle 1 Discontinuity where gas from nozzle 1 expands along the wall.

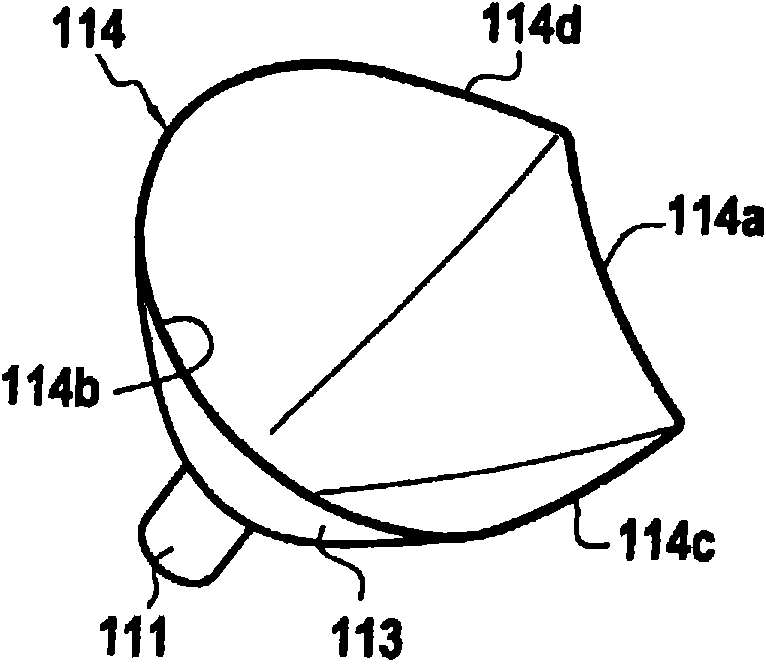

[0028] Each individual nozzle 1 has a circular nozzle throat 12 connected to the combustion chamber 11, and a diverging portion 13 terminating in a generally trapezoidal outlet portion 14, wherein each side 14a to 14d of the outlet portion may have some The particular shape, whether rectilinear or curved, depends on the constraints of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com