Bonding method for jet pipe and flexible plug cover of solid rocket engine and sealing tool

A technology for engine nozzles and solid rockets, applied in the direction of pipes/pipe joints/pipes, pipe elements, connecting components, etc., can solve the problems of uneven pressure on the bonding profile, affecting production efficiency, and line contact pressure, etc. The effect of improving the bonding quality, low price and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, so as to facilitate a clearer understanding of the present invention, but they do not limit the present invention.

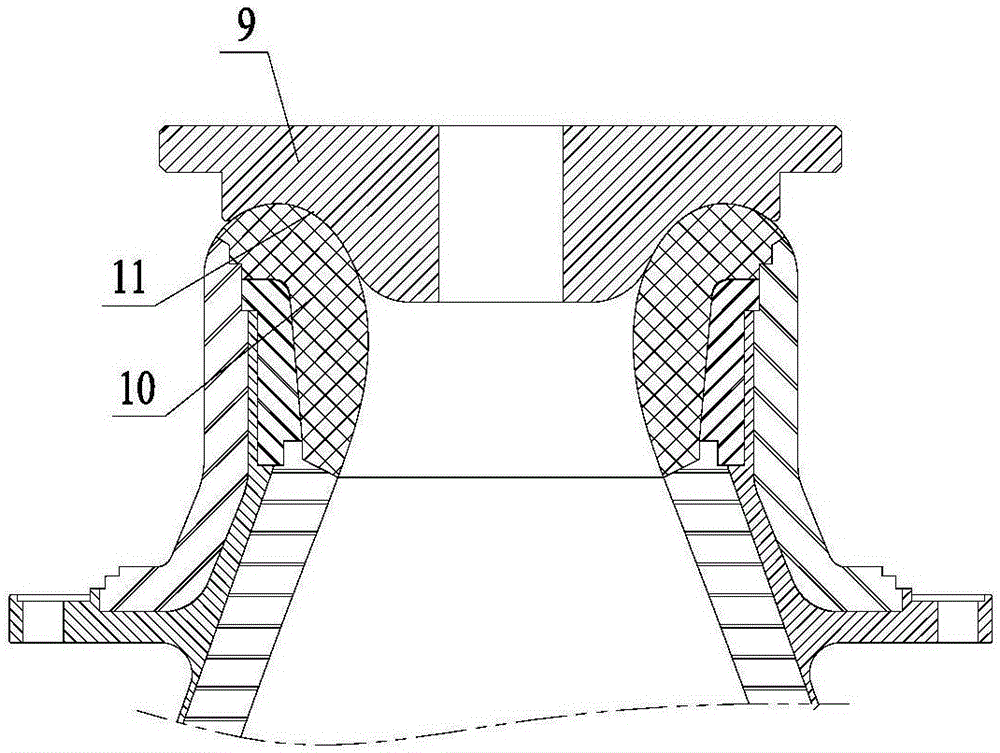

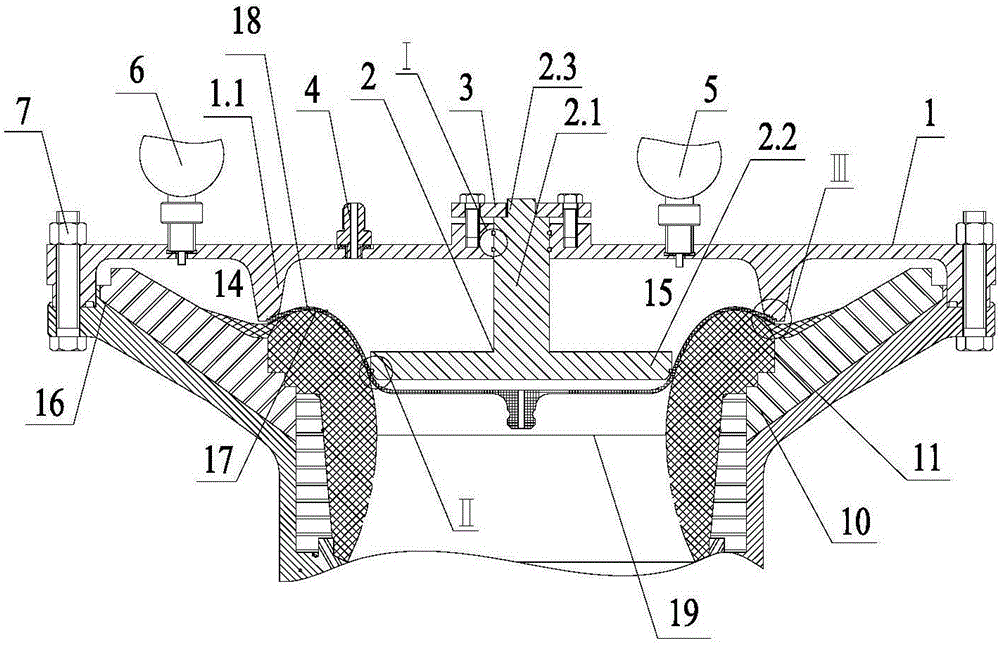

[0027] The sealing frock adopted in the following examples, combined with figure 2 As shown, including the sealing plate 1, the base 2, the pressing plate 3, the pressing joint 4, the first pressure gauge 5 and the second pressure gauge 6, the minimum thickness of the sealing plate 1 should meet the strength requirements of the pressurized pressure in subsequent use; The middle part of the plate 1 is provided with a support rod connection hole, the base 2 includes a bottom plate 2.2 and a support rod 2.1 connected to the bottom plate 2.2, and the upper end 2.3 of the support rod 2.1 is inserted into the support rod connection hole in the middle part of the sealing plate 1 until it extends Into the middle through hole of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com