Method for preparing rocket engine jet pipe and special equipment thereof

A rocket engine and nozzle technology, applied in the direction of machines/engines, casting molding equipment, metal processing equipment, etc., can solve problems such as difficult inner holes, preparation of multi-layer composite coating structures, difficult preparation of high temperature resistance, and erosion resistance. To achieve the effect of improving structure, strong binding force and improving compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A preparation method of a rocket engine nozzle, which comprises the following steps:

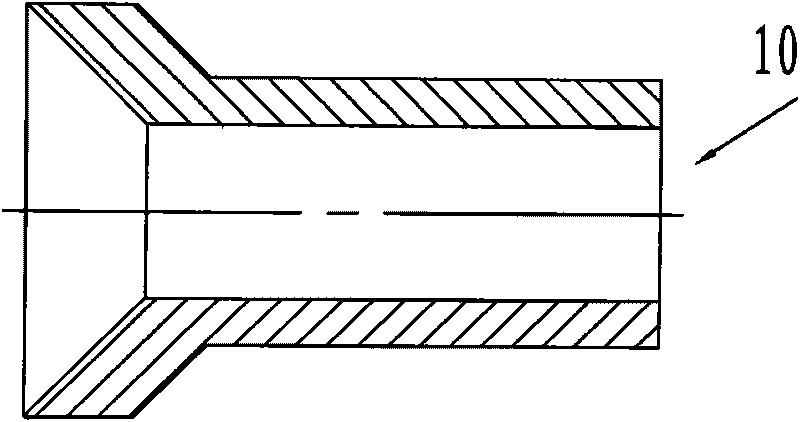

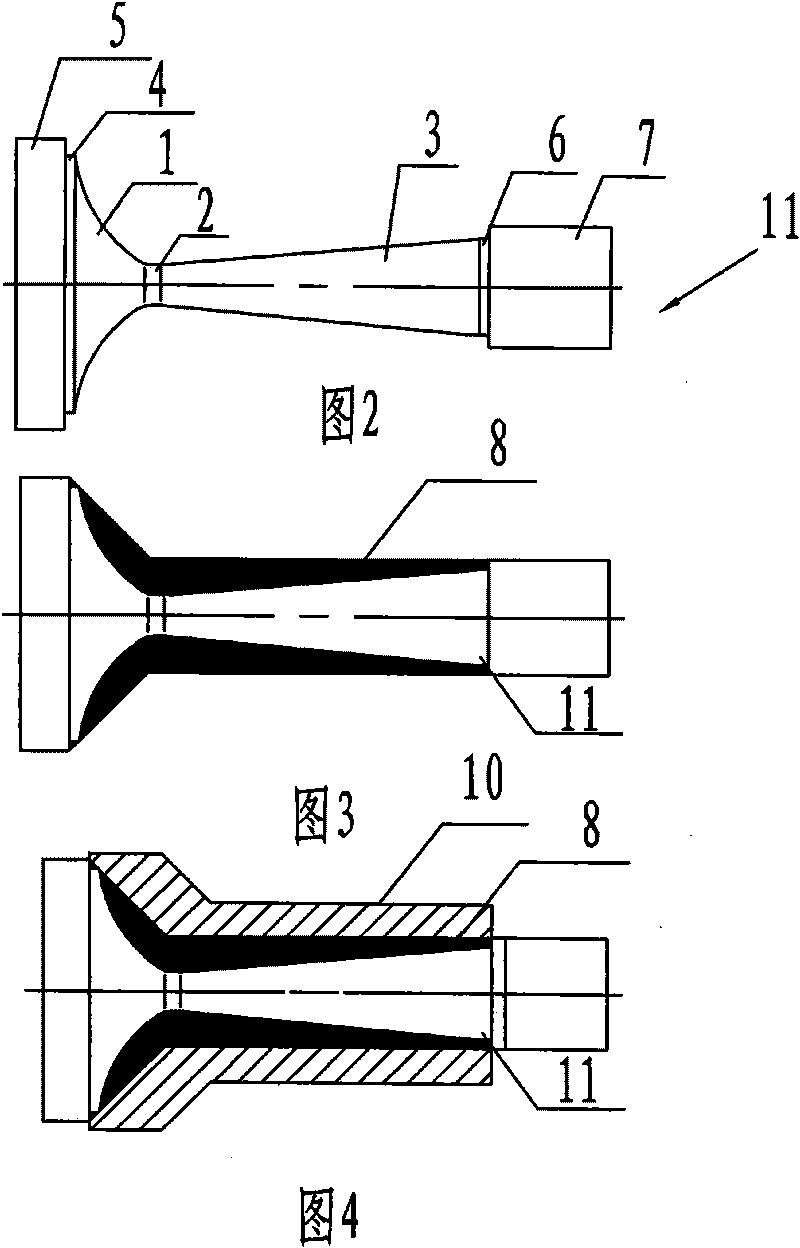

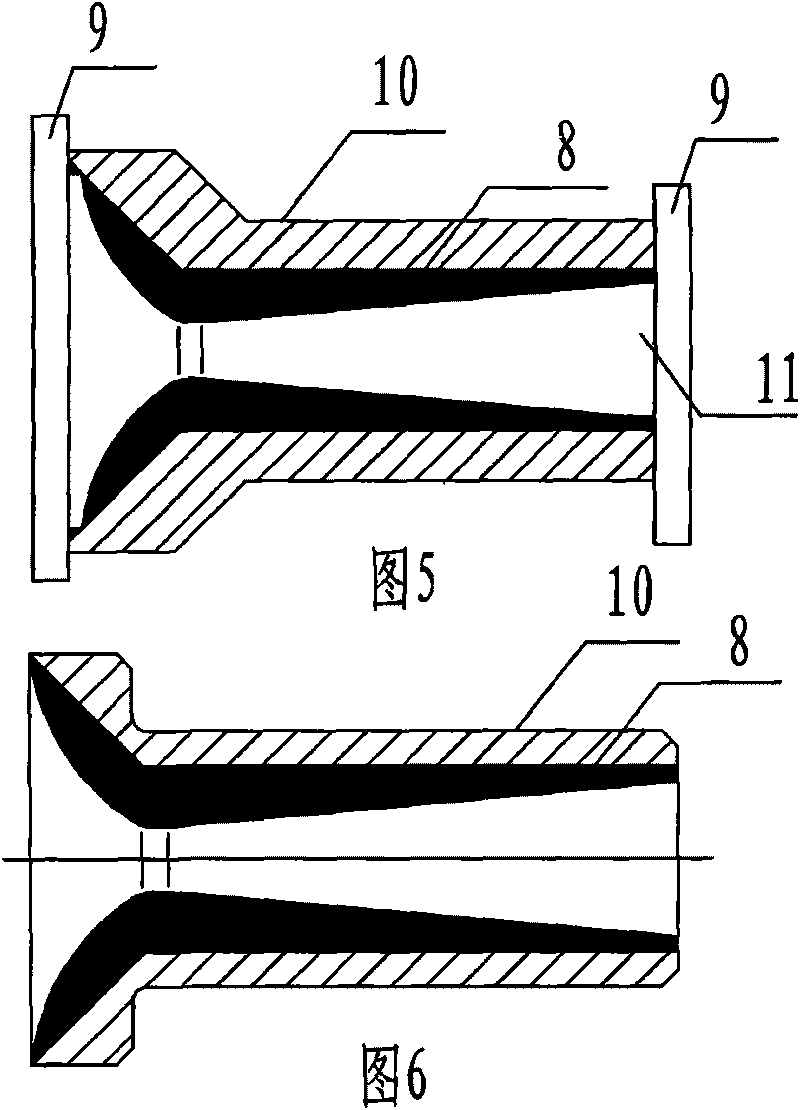

[0050] (1) Using molybdenum as the material to prepare such as figure 1 A blank for a rocket engine nozzle shown; also prepared as figure 2 Graphite mandrels fitted with the inner bore of the prepared nozzle shown;

[0051] (2) Degreasing the graphite mandrel with gasoline and acetone to remove all dirt on the surface of the graphite mandrel, then put the graphite mandrel into an electric furnace and bake at 450°C to 500°C for 1 At the same time, put the tantalum powder, molybdenum powder and zirconia powder for spraying into the oven, bake at 120°C for more than 30min, and then sieve with 120 mesh. Sieve, remove sieve residue;

[0052] Then, the surface of the mandrel is sprayed with tantalum powder, zirconia powder and molybdenum powder by the plasma spraying method. The layer in contact with the mandrel is the tantalum powder layer, the middle is the alternating layer of zircon...

Embodiment 2

[0060] A method for preparing a rocket engine nozzle, the specific steps and process parameters of which are the same as those in Embodiment 1, the difference is that high-strength steel is used as a material to prepare a rocket engine nozzle blank.

Embodiment 3

[0062] like figure 2 As shown in the figure, a mandrel is characterized in that: it includes a converging section 1, a throat 2 and an expanding section 3; two cylinders are respectively arranged at both ends of the mandrel, and cylinders are arranged at the end of the converging section 1 in turn A4 and cylinder B5, a cylinder C6 and a cylinder D7 are arranged in sequence at the end of the expansion section 3; the diameter of the cylinder A4 is equal to the maximum diameter of the convergent section 1, and the diameter of the cylinder B5 is greater than the diameter of the convergent section 1 The maximum diameter, the diameter of the cylinder C6 is equal to the maximum diameter of the expansion section 3, the diameter of the cylinder D7 is greater than the maximum diameter of the expansion section 3; the above-mentioned core rod is a graphite core rod.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com