Improved stranding process of cable copper conductors

A process improvement, cable copper technology, used in cable/conductor manufacturing, circuits, electrical components, etc., can solve problems such as poor cable flexibility, cable short-circuit fault, conductor piercing insulation layer, etc., to achieve increased flexibility and stable mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiments, structures, features, and effects provided in accordance with the present invention will be described in detail below with reference to the drawings and preferred embodiments.

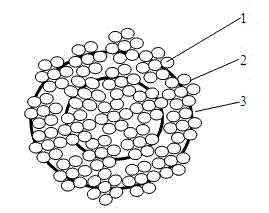

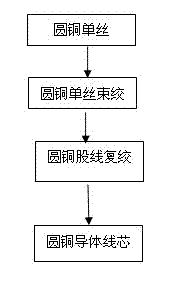

[0015] Such as figure 1 , 2 The shown improvement of a cable copper conductor stranding process includes the following steps:

[0016] (1) Use a stranding machine to bundle and twist multiple round copper monofilaments to the right to form round copper strands;

[0017] (2) Use a stranding machine to divide the multiple round copper strands into multiple layers and twist them to the left to form round copper conductor cores.

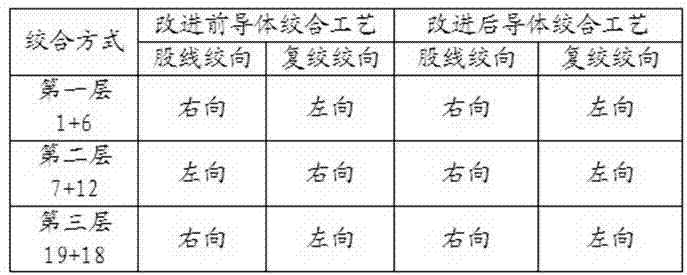

[0018] For example: the round copper conductor core is 37×40 / 0.40, that is, the round copper strands are 37 strands, each of which has 40 round copper monofilaments, and the diameter of the round copper monofilament is ∮0.4mm. Improve The comparison between the front conductor stranding process and the improved conductor stranding process is shown in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com