Mine air-supplied universal joint rotor piston concrete sprayer

A technology of concrete spraying machine and rotor piston, which is applied in mining equipment, earthwork drilling, wellbore lining, etc. It can solve the problems of seal wear and replacement, short service life, complex structure, etc., and achieve sealing and lubrication without sealing lubrication , the effect of smooth transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

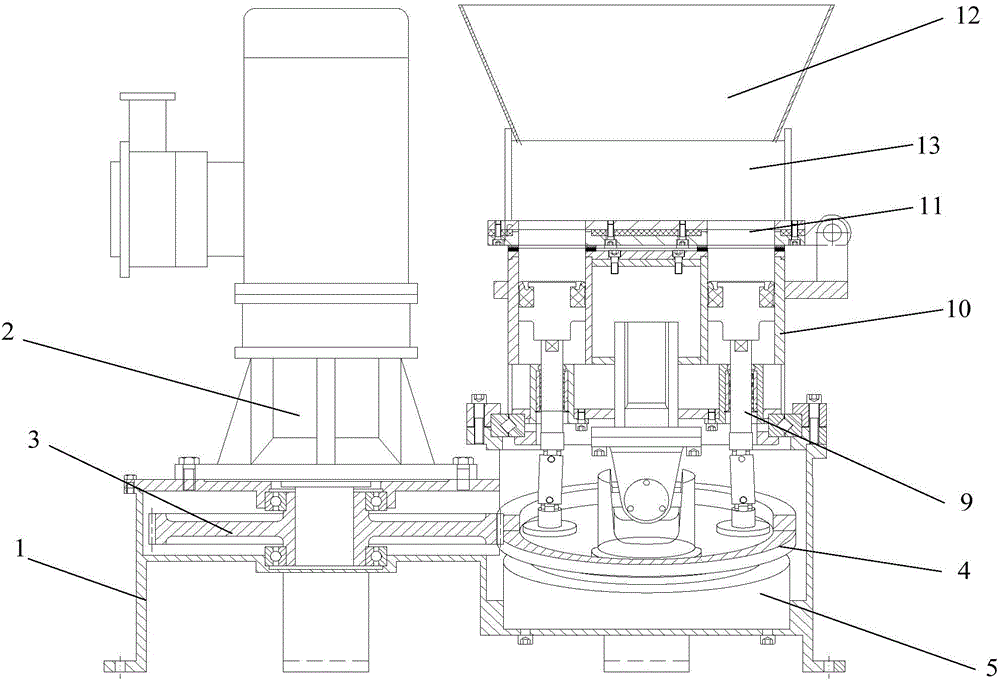

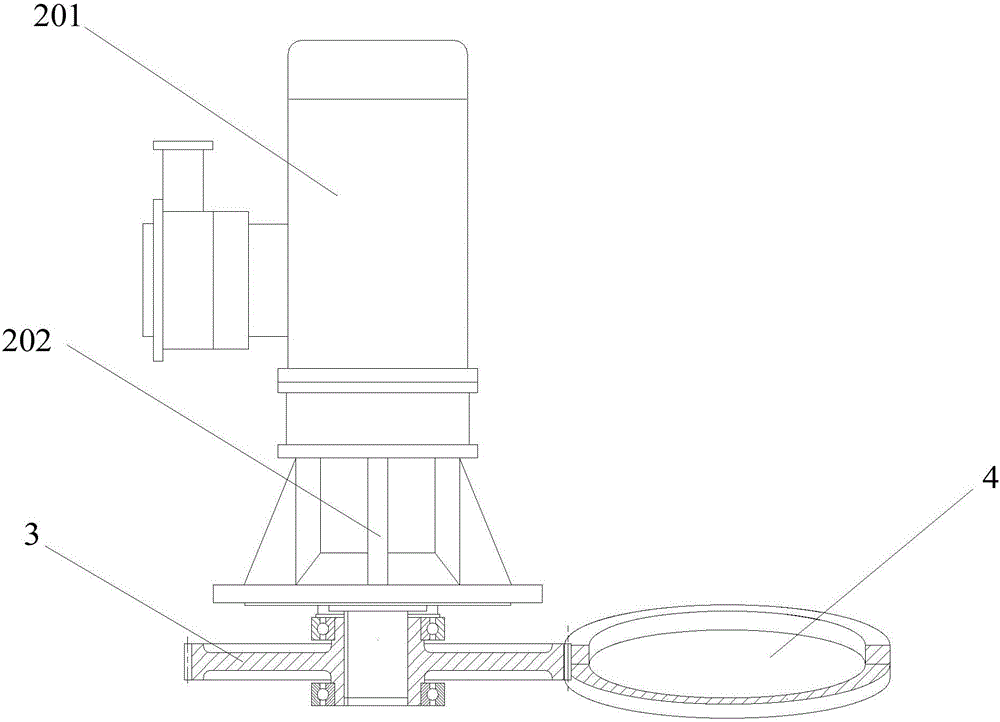

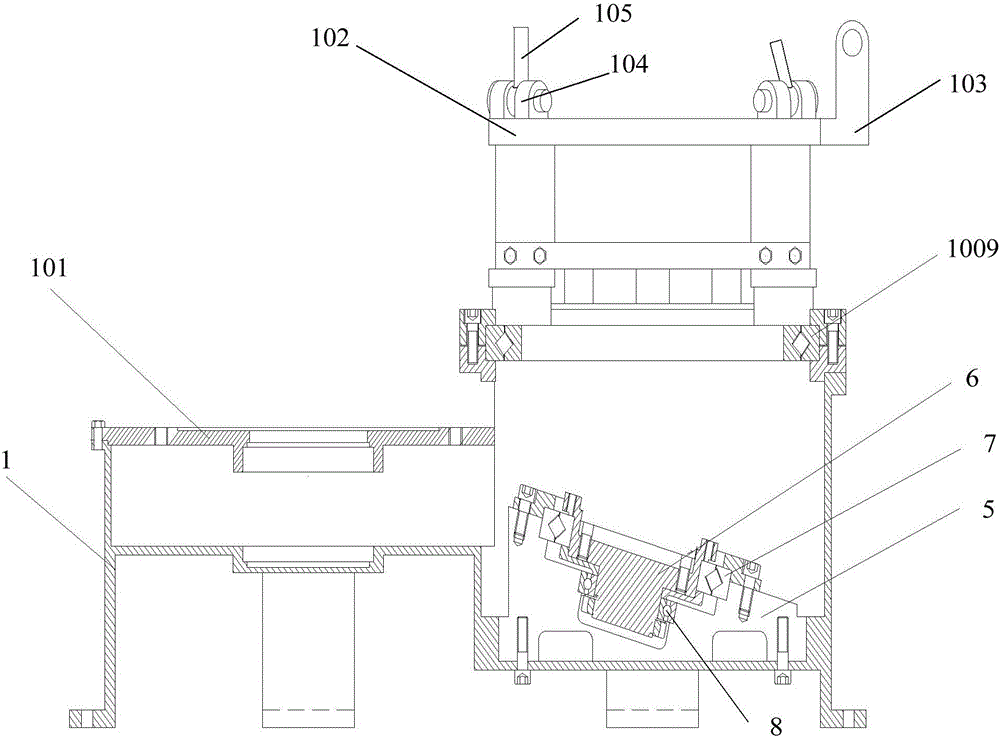

[0037] Such as Figure 1 to Figure 9 As shown, the mine air-supplied universal joint rotor piston type concrete spraying machine includes a frame 1 with a power station and a driving spraying station on the frame 1. Frame 1 is a casting shell, and it is the installation supporting part of other mechanisms, and the bottom end of frame 1 is cast with supporting foot.

[0038] A rotor cylinder 10 is arranged on the driving spraying station, and the rotor cylinder 10 includes a rotor housing 1002. An odd number of cylinder housings 1003 are arranged in the rotor housing 1002, and a cylinder inner liner 1004 is arranged in the cylinder housing 1003, and inside the cylinder The bushing 1004 is attached to the inner wall of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com