Machine vision cutting method applied to laser cutting machine

A technology of laser cutting machine and machine vision, which is applied in the direction of instruments, computer components, character and pattern recognition, etc. It can solve the problems of low recognition accuracy, demanding environmental light source recognition, complicated operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described below in conjunction with drawings and embodiments.

[0056] According to the embodiment of complete implementation of the present invention as follows:

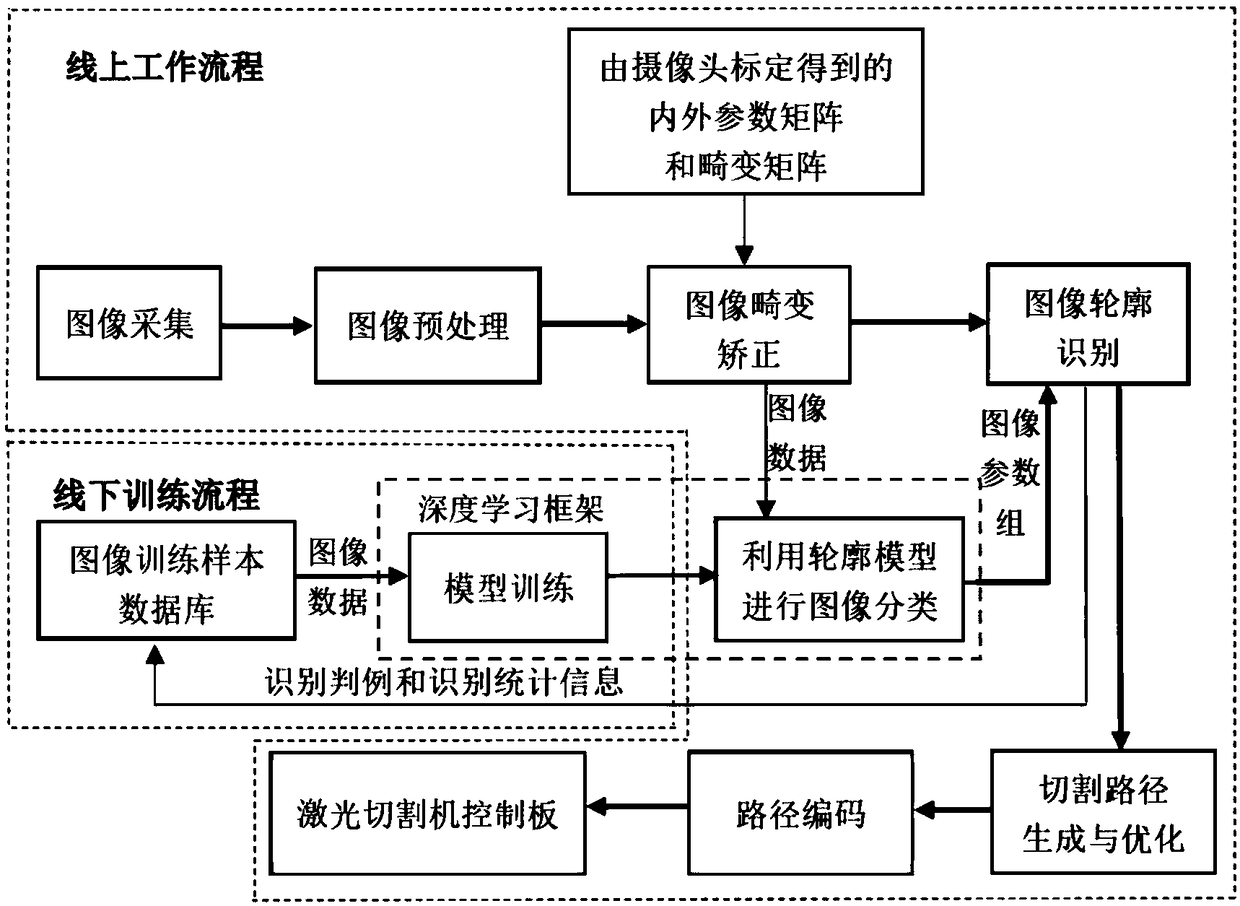

[0057] (1) Image preprocessing, image coordinate mapping, image shape gradient correction, white balance processing and exposure compensation operations are performed sequentially on the image.

[0058] (2) Image distortion correction specifically includes:

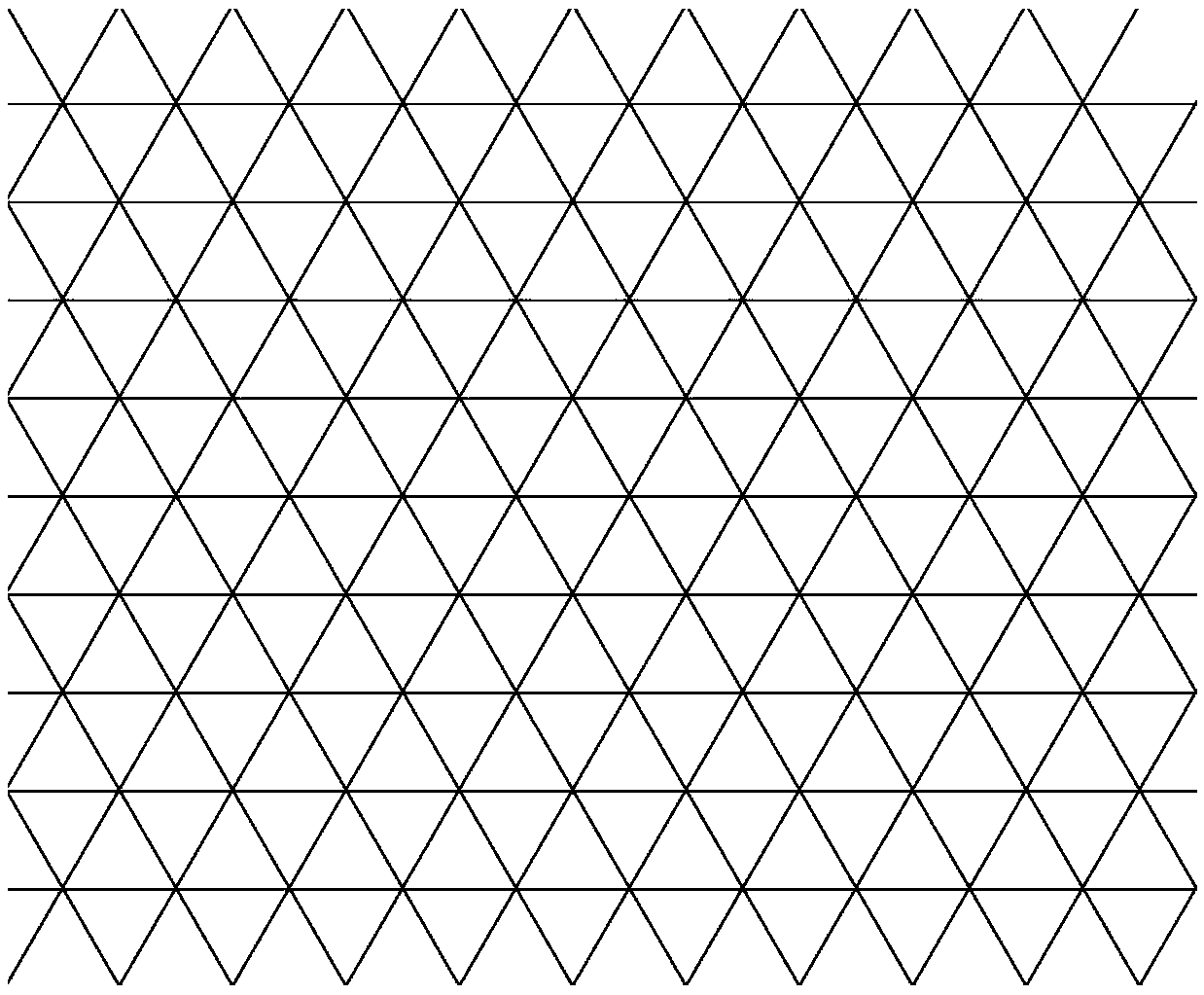

[0059] (1.1) Use a laser cutting machine to engrave an equilateral triangle grid pattern with a triangle side length of 5cm on the white plane material on the cutting platform. The specific implementation is as follows figure 1 shown;

[0060] (1.2) The imaging module used by the laser cutting machine adopts an industrial CCD camera.

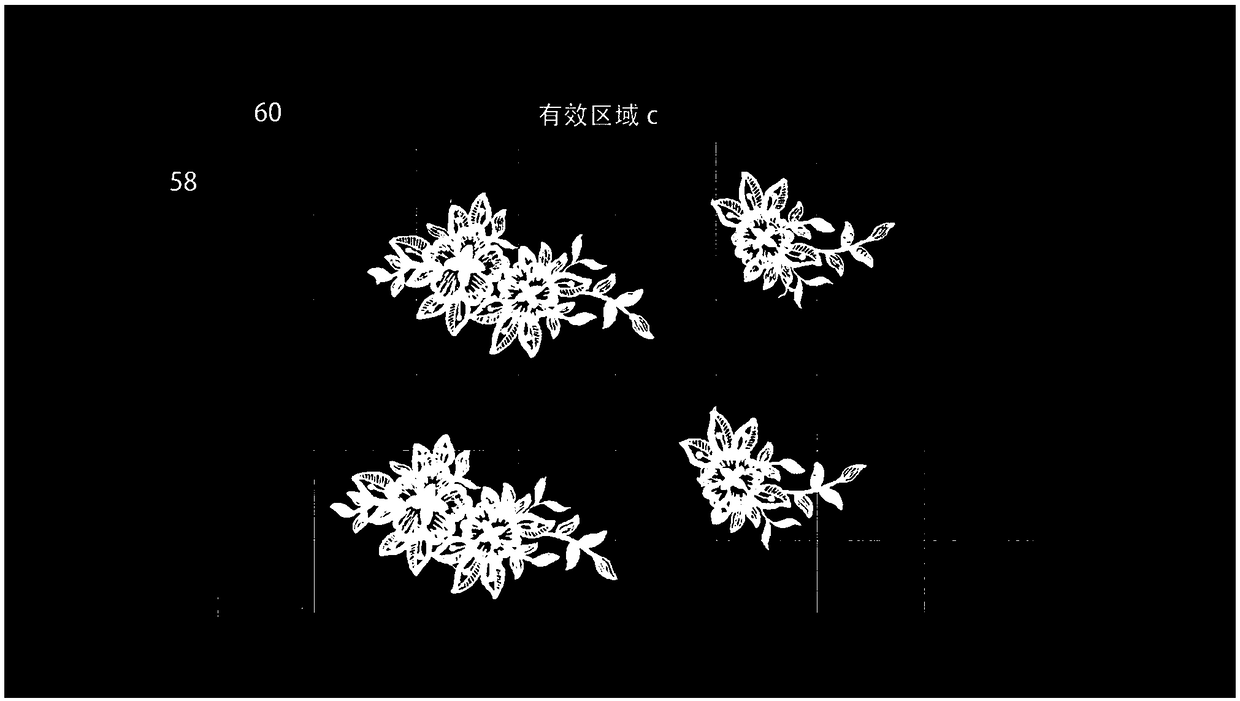

[0061] First, the imaging module collects the calibration image m1 engraved by the laser cutting machine with the regular triangular grid pattern and the RGB image of the existing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com