Automatic assembly line for feeding, cutting and punching pipe automatically

An automatic feeding and assembly line technology, applied in metal sawing equipment, other manufacturing equipment/tools, metal processing, etc., can solve the problems of high labor intensity, low working efficiency, and skewed cuts in drilling operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing.

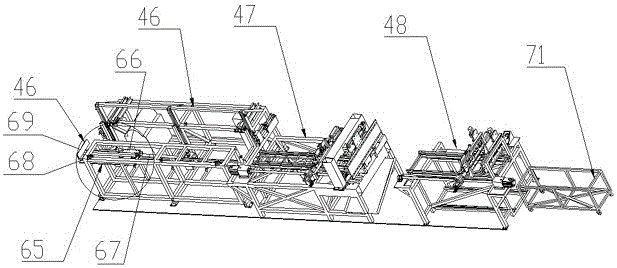

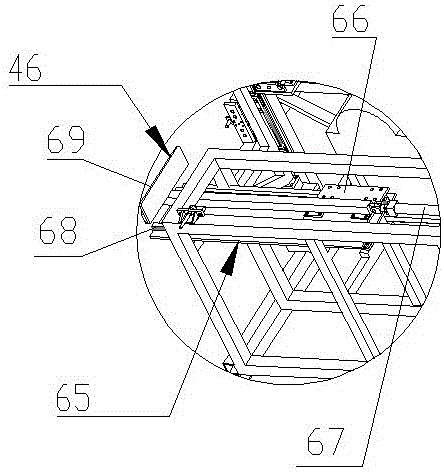

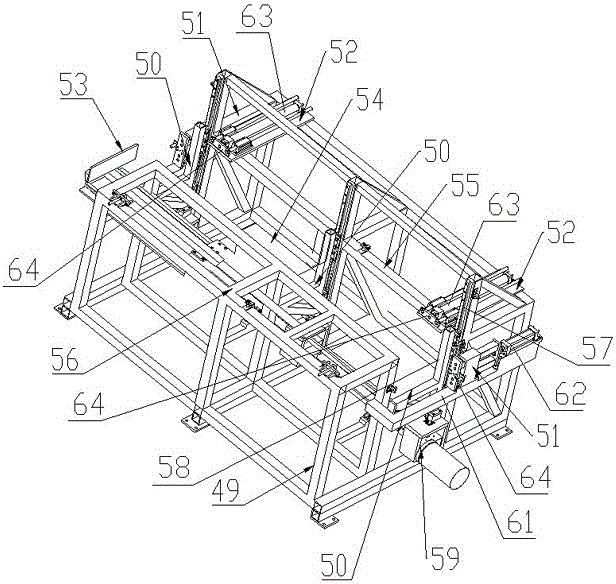

[0030] Such as Figure 1 to Figure 4As shown, an automatic assembly line for automatic feeding, cutting, and punching of pipes includes a front feeding mechanism 46, a middle feeding and cutting mechanism 47, and an automatic punching and unloading mechanism 48 arranged sequentially from left to right. The feeding mechanism 46 includes a first support frame 49, a lifting mechanism 50, a pipe clamping mechanism 51, a widthwise pushing mechanism 52 and a long-term pushing mechanism 53, and the middle part in the width direction of the first support frame 49 is provided with a downwardly recessed Material-lifting channel 54, the first support frame 49 has push zone 55 and feeding zone 56 in the same horizontal plane respectively on the both sides above material-lifting channel 54; The lifting mechanism 50 is made up of a first guide rail 57, a lifting frame 58 and a verticall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com