Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Good truncation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

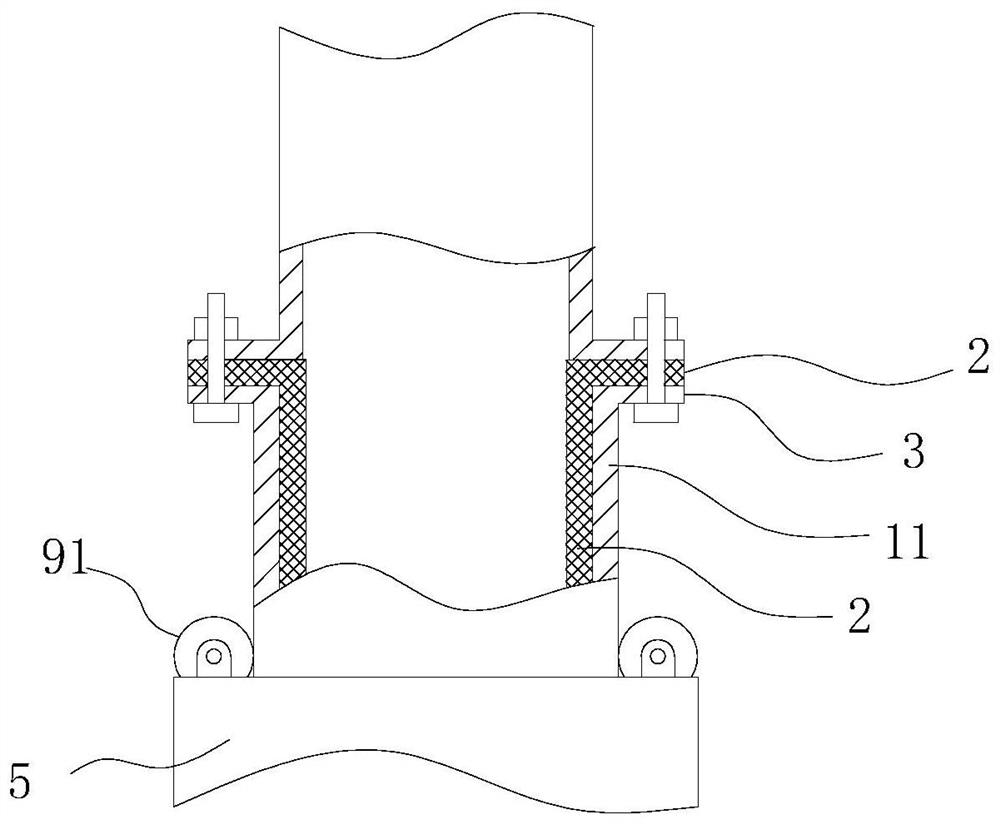

Power cable cutting device

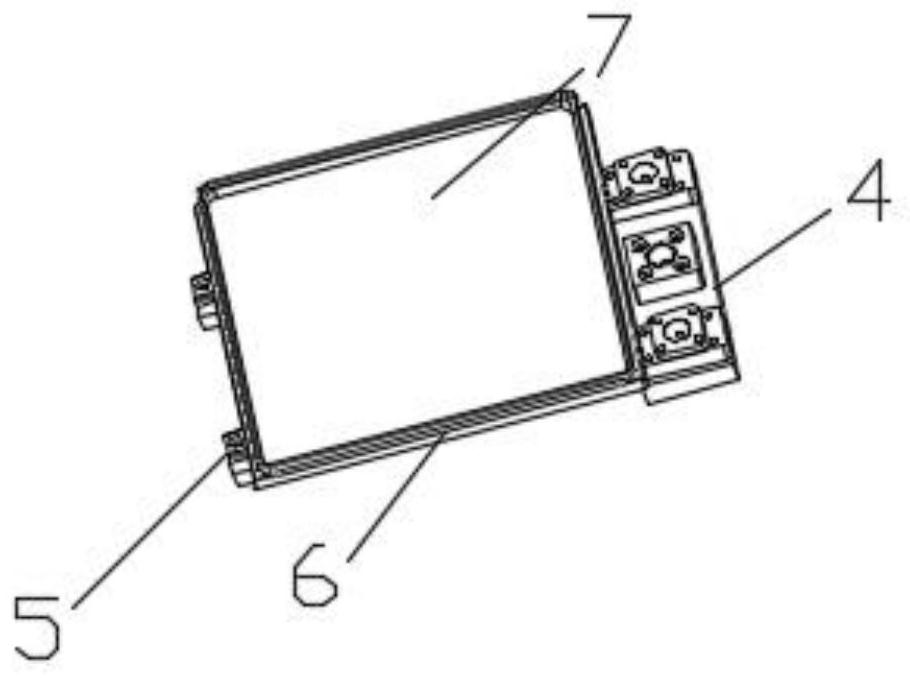

PendingCN107775699AGood truncation effectConvenient truncationApparatus for cutting/splicing cablesMetal working apparatusPower cableSlide plate

The invention discloses a power cable cutting device. The power cable cutting device comprises a support base, wherein vertical plates are arranged on the left side wall and the right side wall of thesupport base; a convex plate is arranged above a second slider; a second cylinder is fixedly mounted on the front side wall of the convex plate and fixedly connected with the outer side wall of a second fixture block through a cushion block; a cutter is located above a first fixture block and the second fixture block. According to the power cable cutting device, a third motor is started to drivea cable feed roller to perform paying off, while a to-be-cut cable penetrates through the through holes in the left vertical plate and the right vertical plate, the second cylinder is started to drivethe second fixture block to move backwards, so that the to-be-cut cable is located between the first fixture block and the second fixture block, then the second cylinder drives the second fixture block to move forwards to clamp the to-be-clamped cable, left-right movement can be realized by a mobile table, accordingly, the cutter is enabled to move to the right sides of the first fixture block and the second fixture block, and a second motor is started to drive the cutter to rotate for cutting the cable.

Owner:丁家琪

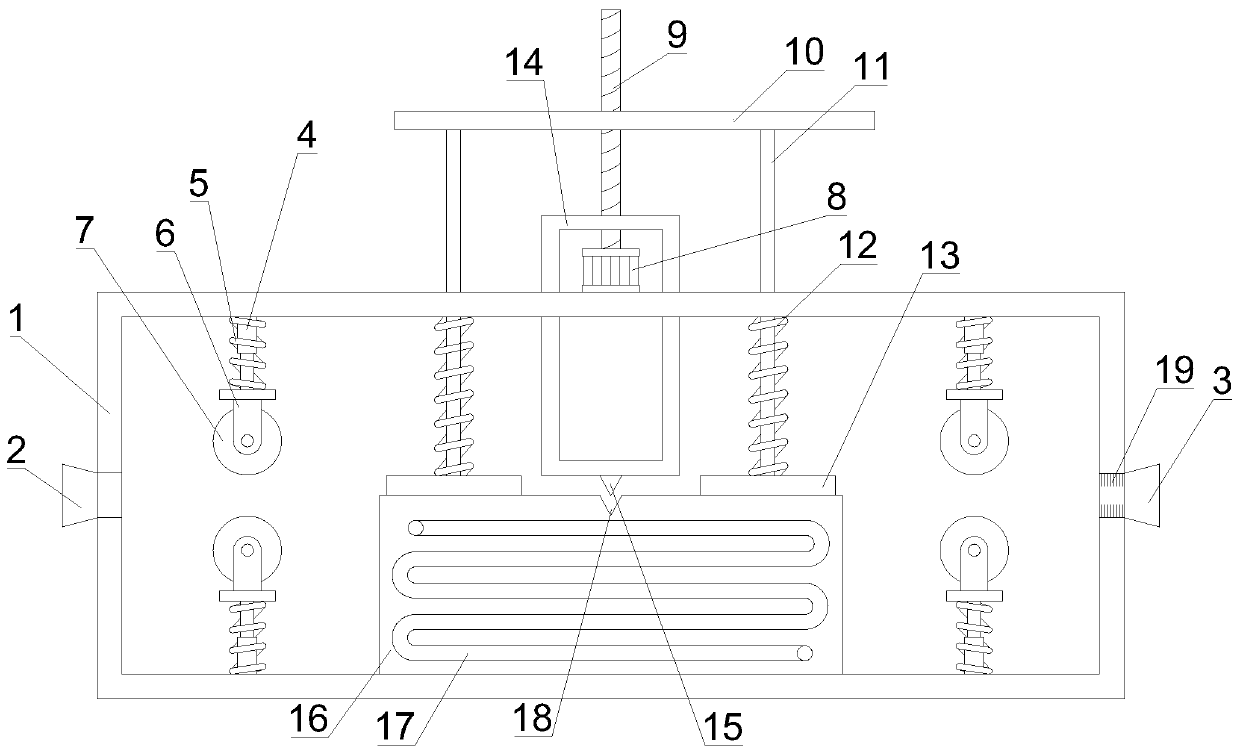

Fast cutting off device for hardware parts

ActiveCN107096962AControl altitudeFully truncatedMaintainance and safety accessoriesEngineeringKnife blades

The invention relates to a cutting off device, in particular to a fast cutting off device for hardware parts. The invention solves the technical problem of providing a cutting device for a covering steel plate for production of a circuit board, which is light and handy, fast in cutting off and good in cutting off effect. In order to solve the technical problem above, the invention provides such a fast cutting off device for hardware parts, which comprises a bottom plate, first guide rods, first guide covers, a moving rod, a lifting device, a top plate, a moving device, a lifting rod, a mounting rod, a second motor, a blade, first supports, and the like; the first guide rods are symmetrically welded on the left side and the right side of the top of the bottom plate, the top plate is welded on the top ends of the two first guide rods, the middle of the bottom of the top plate is provided with the lifting device, and the bottom of the lifting device is connected to the lifting rod. By controlling the lifting device to move up and down, the blade is controlled in an optimal position, such that the cutting off effect is better, and by driving the blade to move left and right through the moving device, the cutting off is more thorough.

Owner:NANTONG KAIDI AUTOMATIC MACHINERY

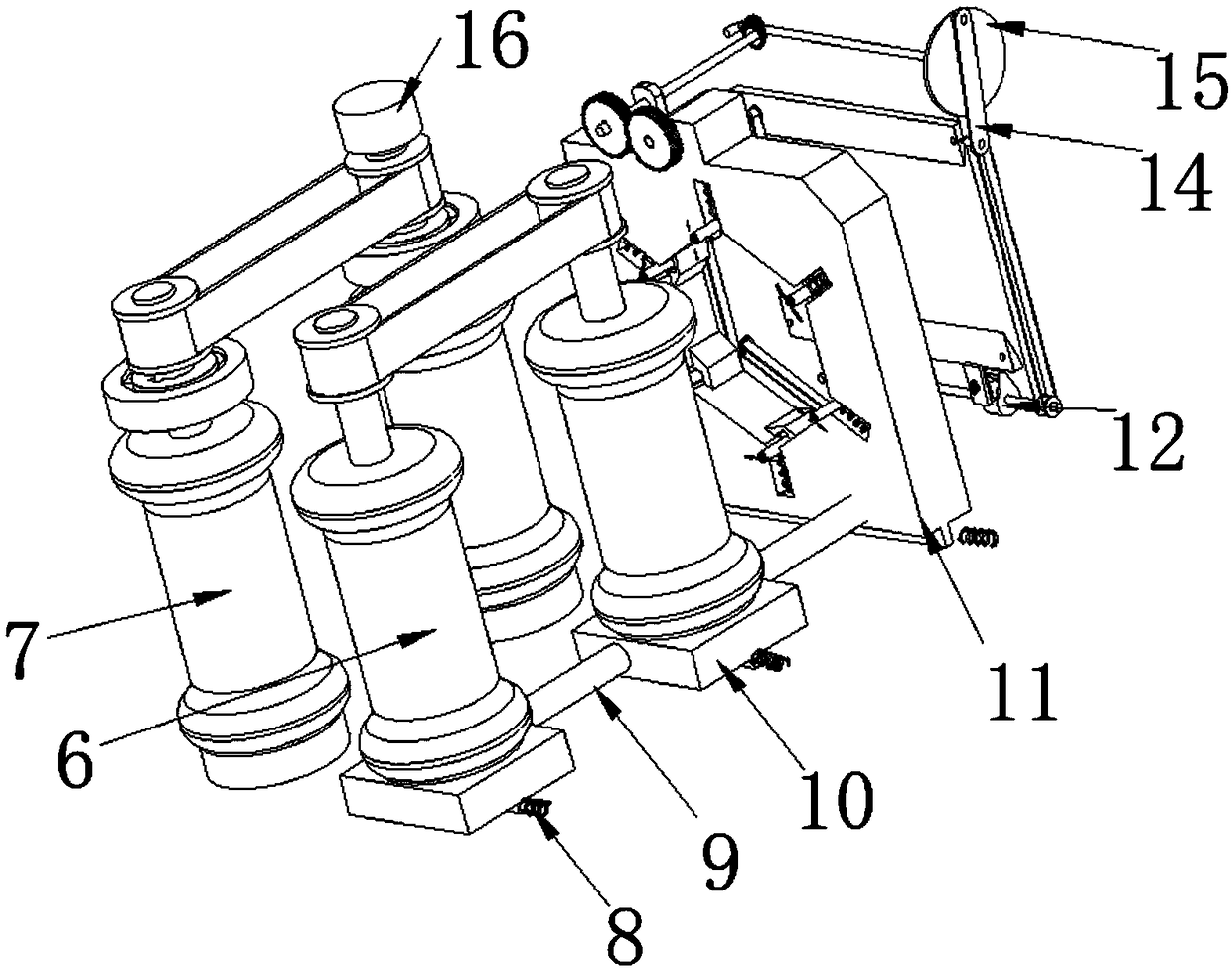

Sugarcane cutting machine

InactiveCN109176633AGood peeling effectShorten the timeVegetable peelingMetal working apparatusEngineeringDrive motor

The invention discloses a sugarcane cutting machine. The sugarcane cutting machine comprises a shell, a finished product box, a peeling mechanism, a cutting off mechanism and a driving mechanism; a driving device is arranged in the shell, the peeling mechanism and the cutting off mechanism are fixed to the top of one side of the shell, the driving mechanism is composed of transmission rolling shafts, fixed rolling shafts, limiting springs, a connecting rod, sliding blocks and a driving motor, the top of the shell is fixedly connected with the driving motor through an L-shaped plate, the transmission rolling shafts, the fixed rolling shafts, the limiting springs and the sliding blocks are symmetrically arranged in the shell, the sliding blocks are in sliding connection with the inner wall of the bottom of the shell, and the two sliding blocks are fixedly connected through the connecting rod. According to the sugarcane cutting machine, through the dual-shaft motor, the peeling mechanismand the cutting-off mechanism are driven at the same time, the two mechanisms can operate at the same time, time is saved, synchronism is increased, through a series of transmission connections, blades can move at the same time, the cutting off effect is better, and work efficiency is improved.

Owner:杭州湘甬机械设备有限公司

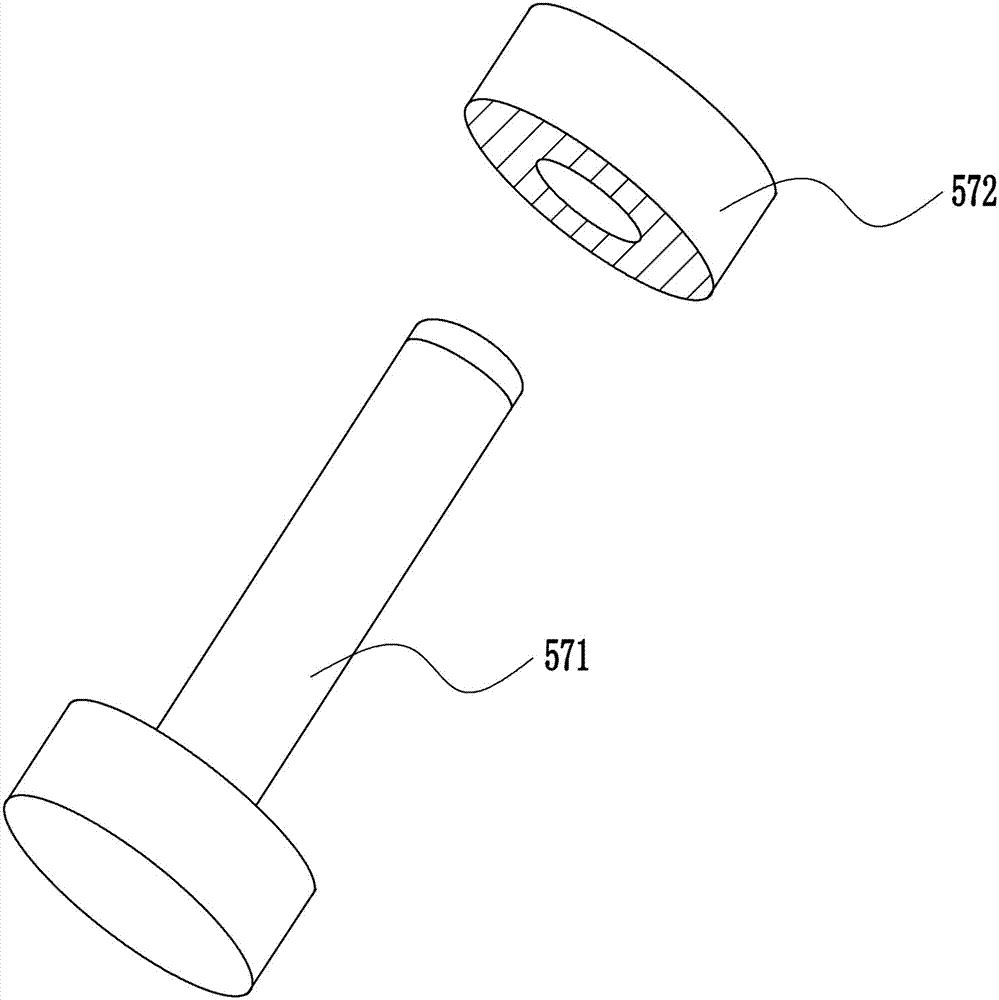

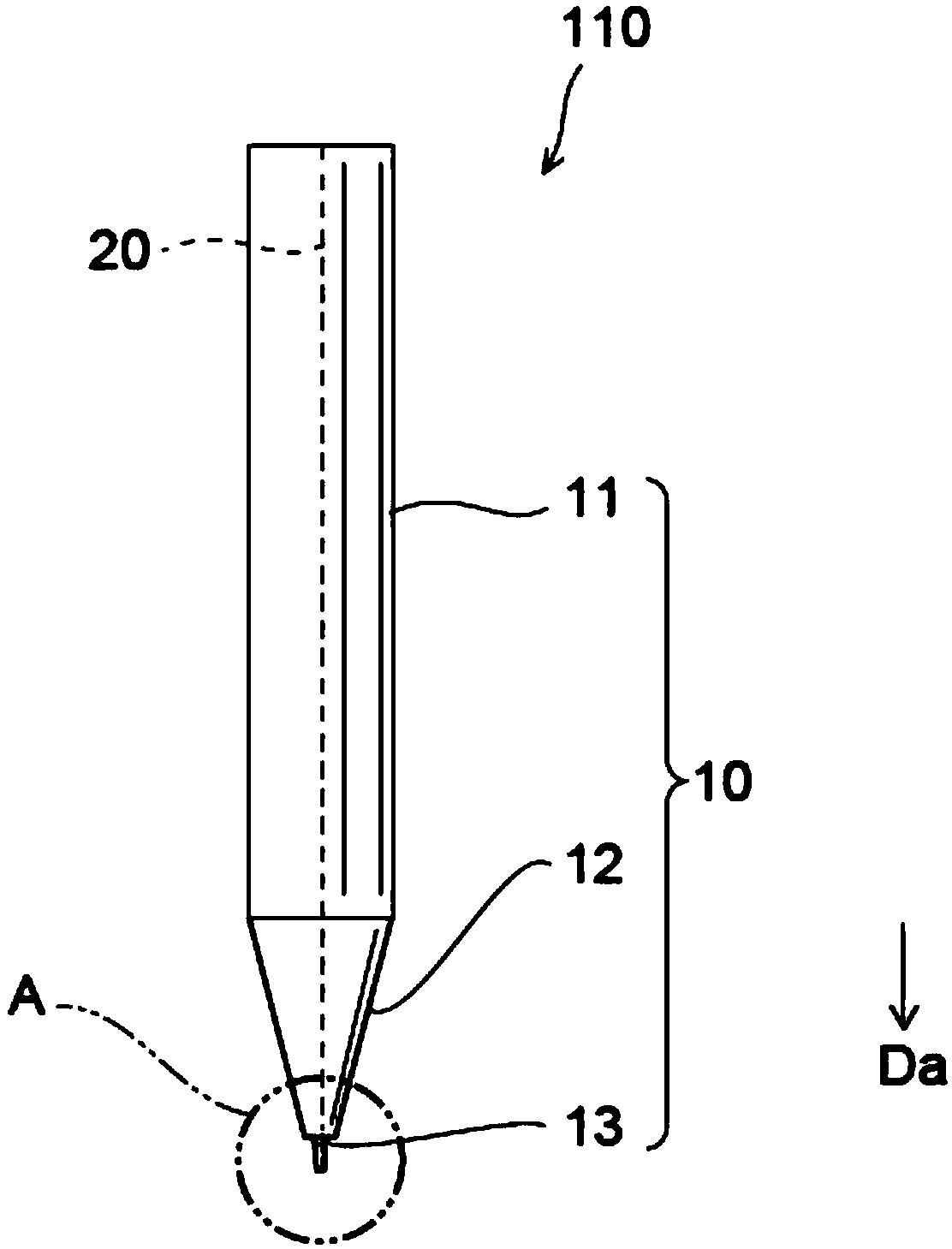

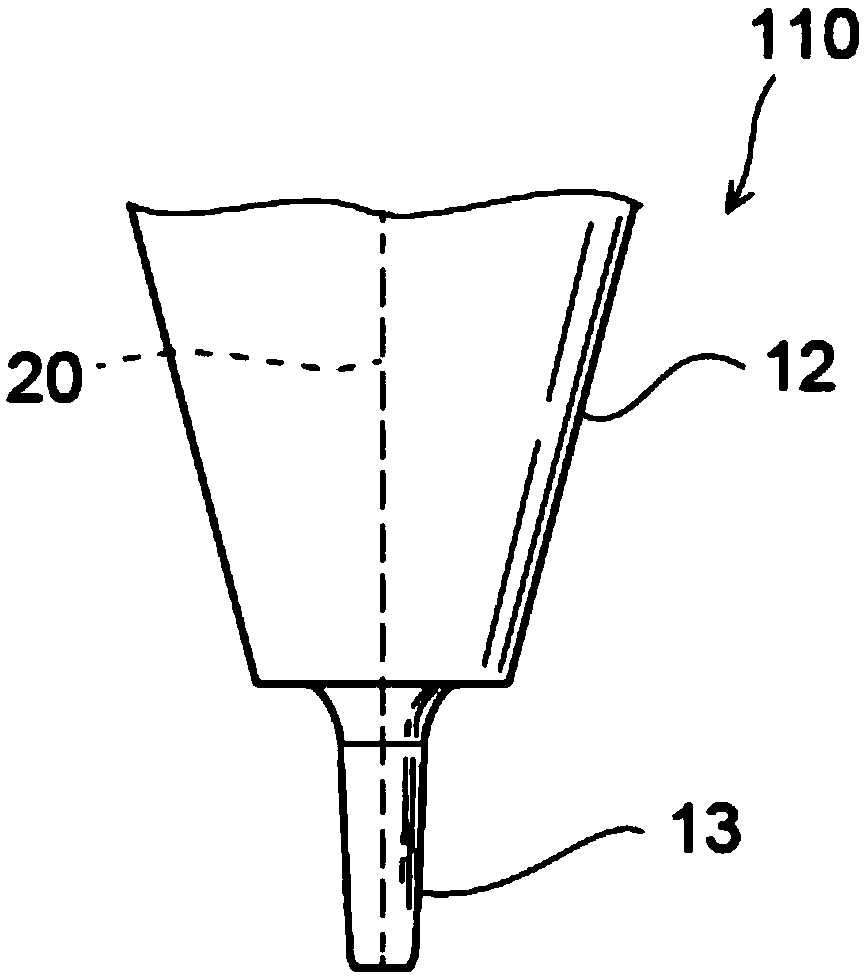

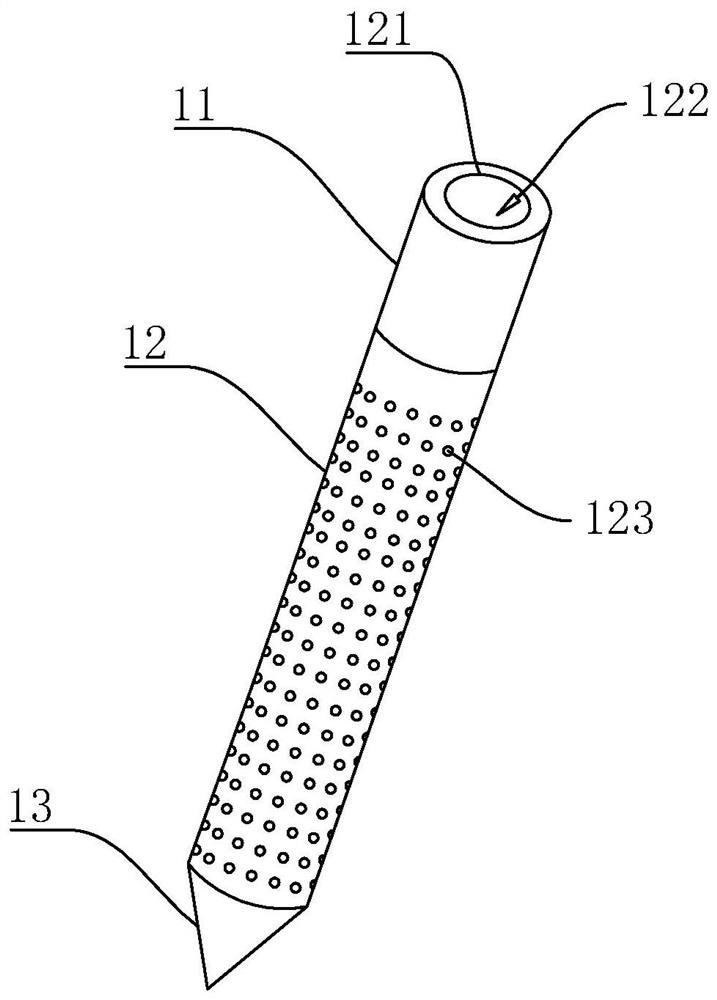

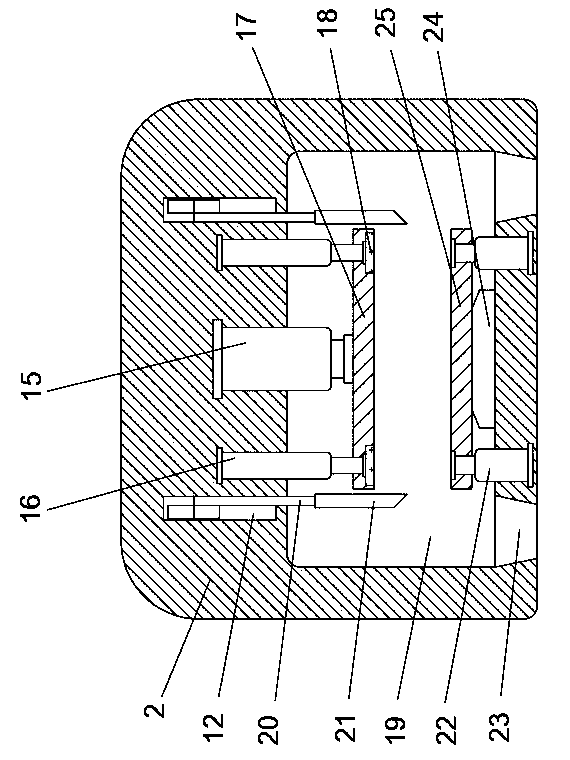

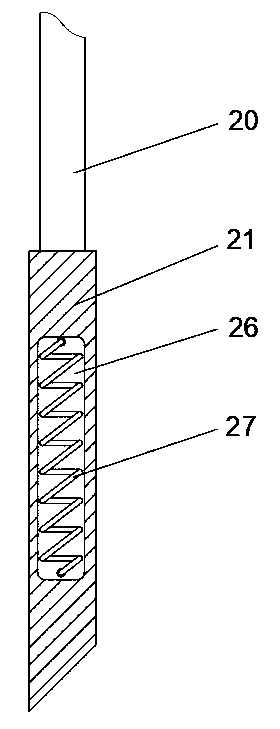

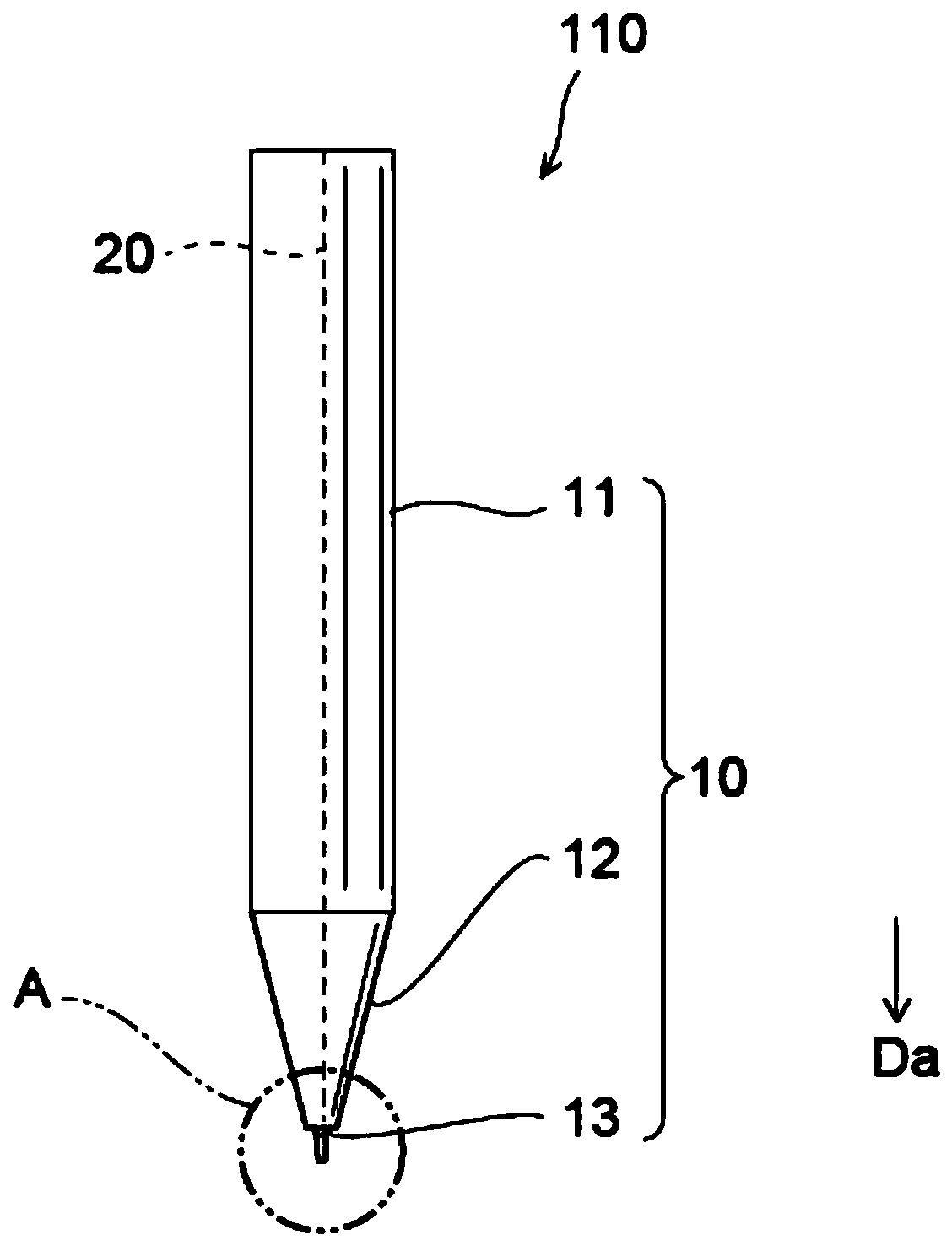

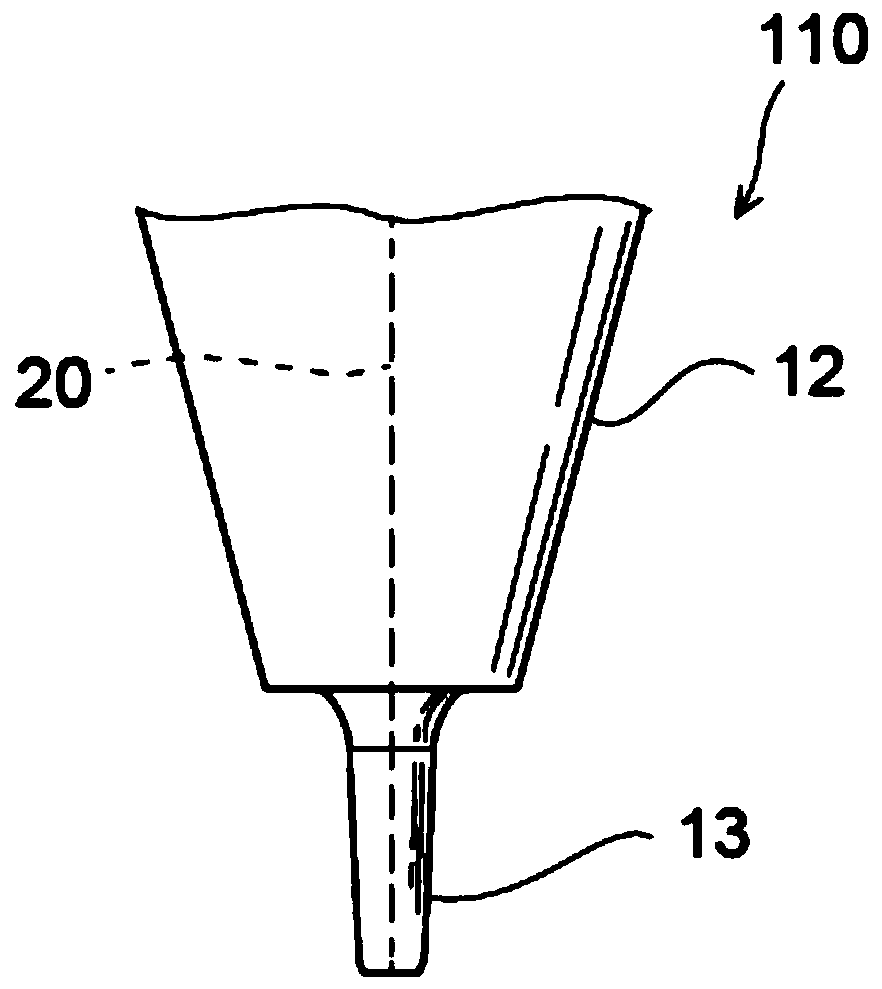

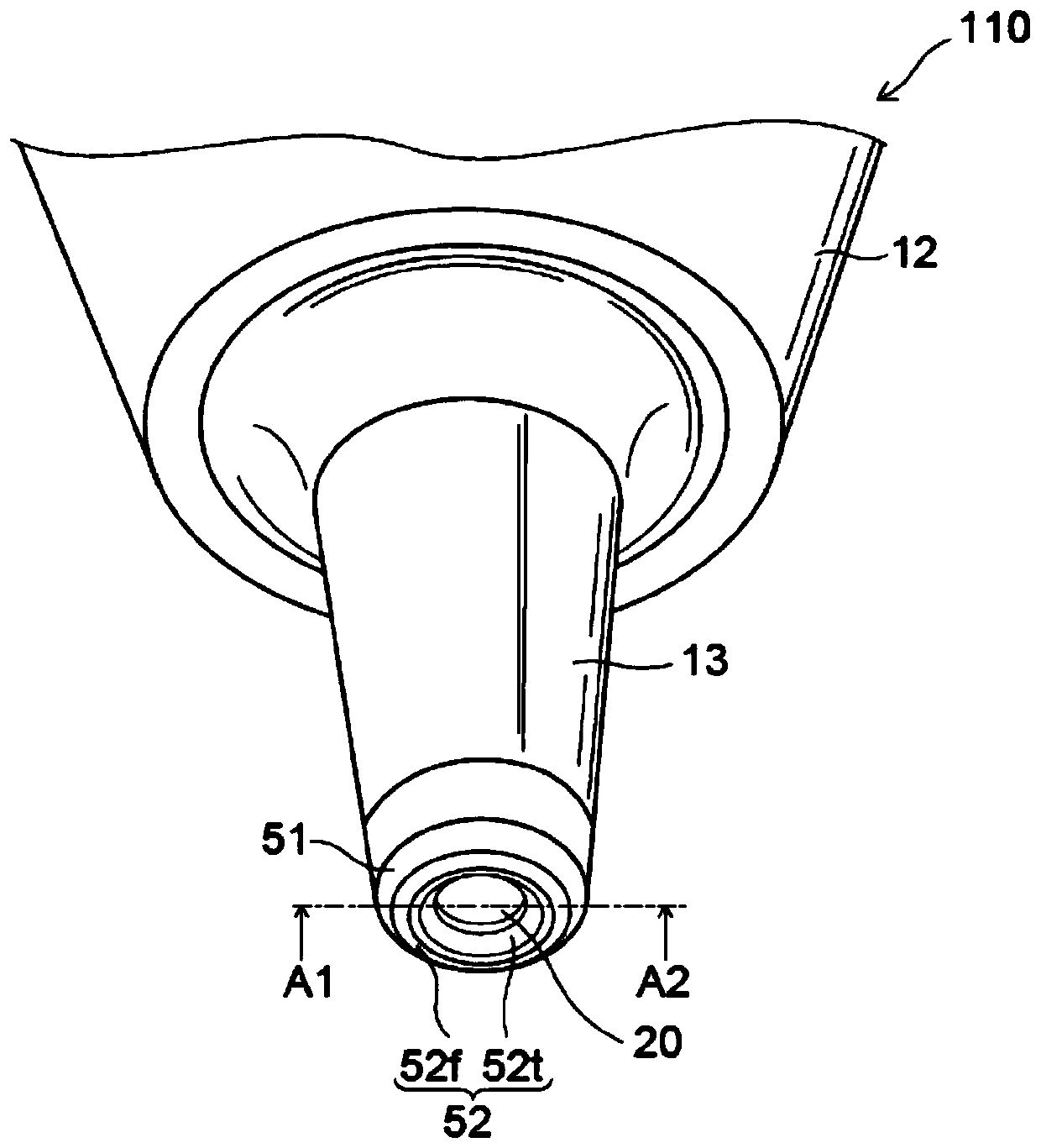

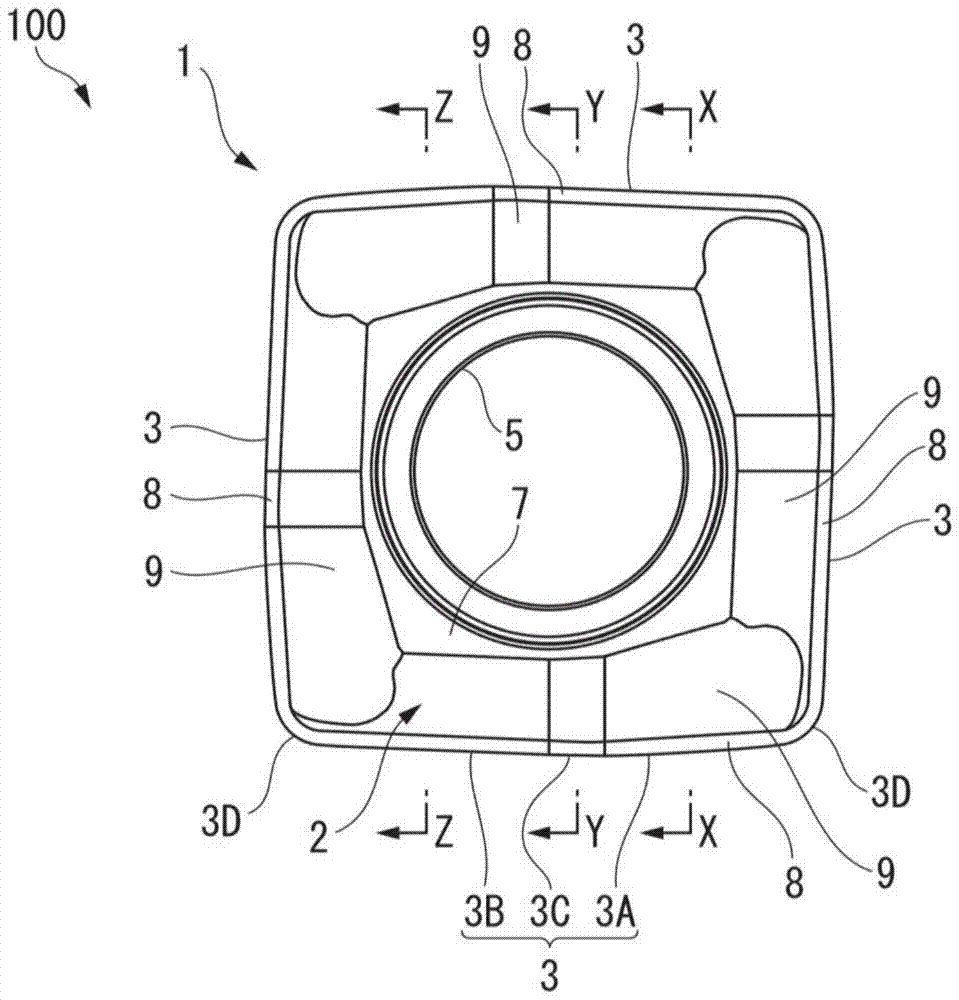

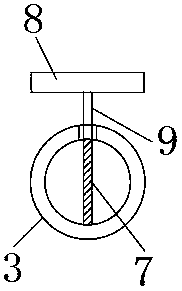

Bonding capillary

ActiveCN107710394AGood truncation effectEasy to slideSolid-state devicesSemiconductor/solid-state device manufacturingBiomedical engineeringRoot mean square

Owner:TOTO LTD

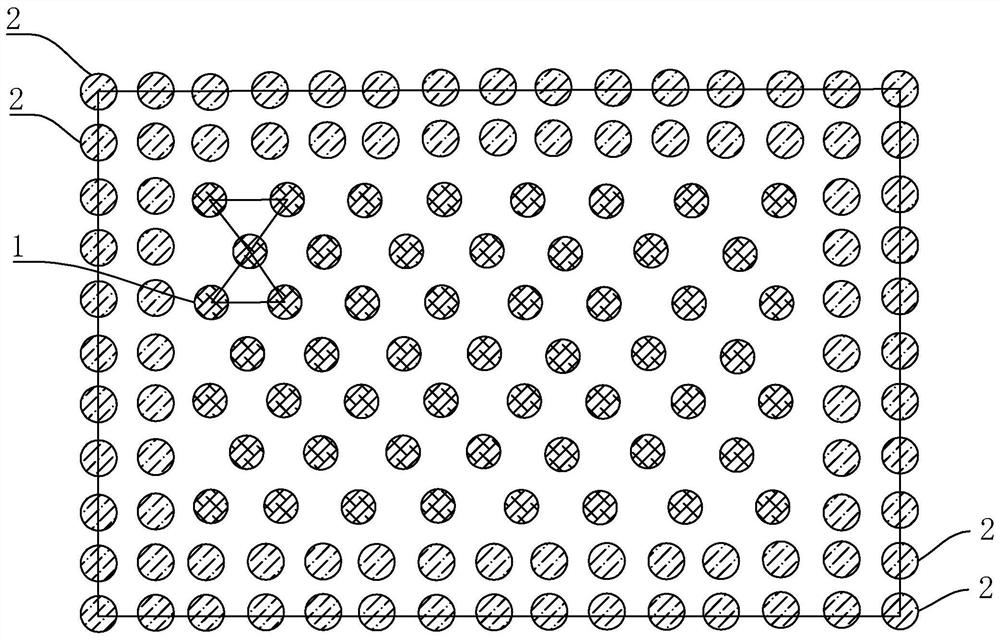

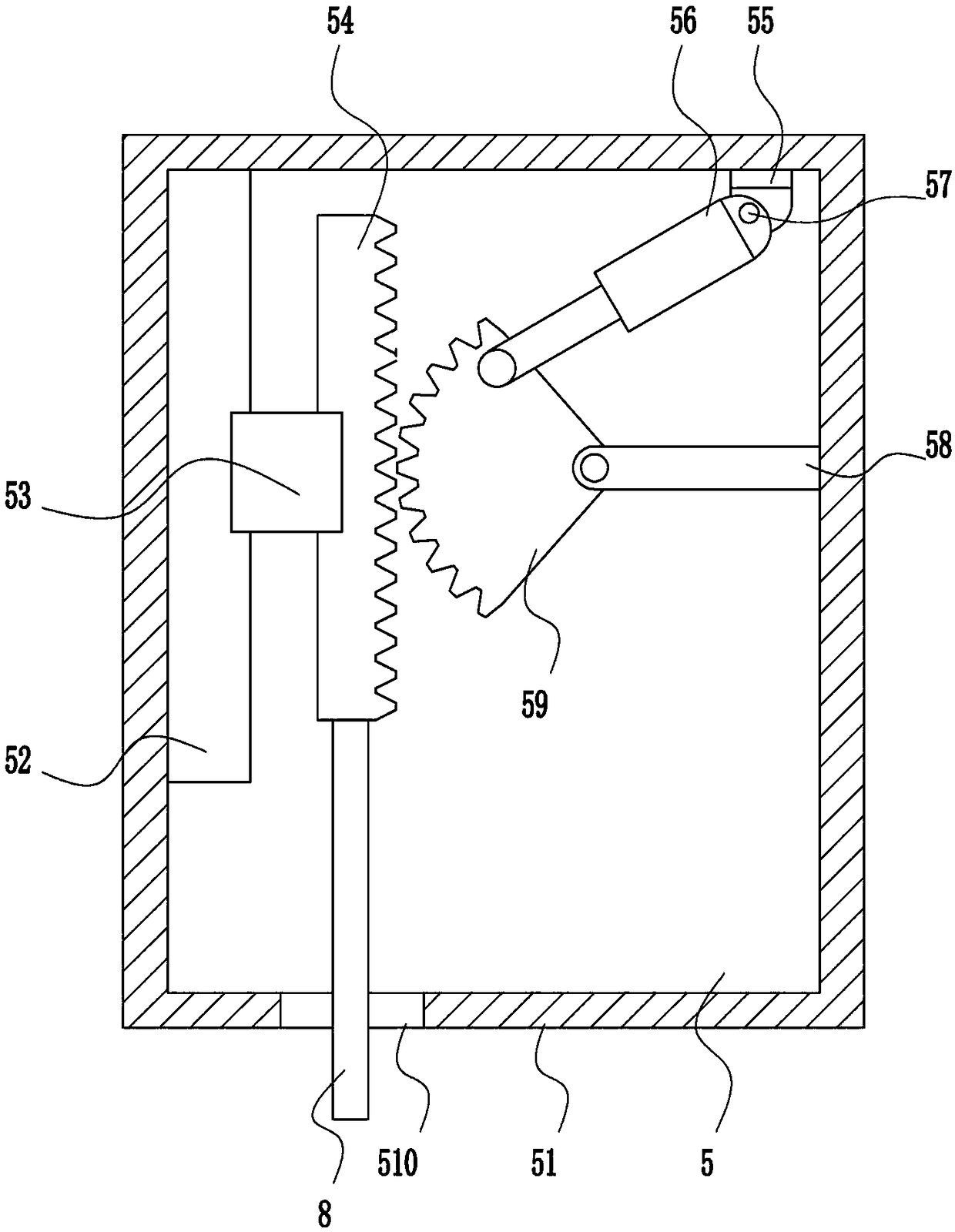

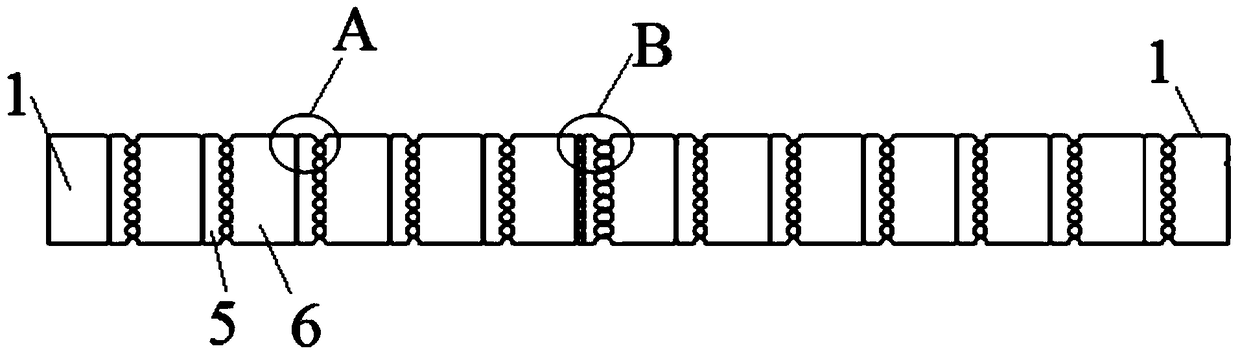

Melt for DC fuse link

ActiveCN105428178AFusing speed is fastGood truncation effectEmergency protective devicesDc circuitComputer science

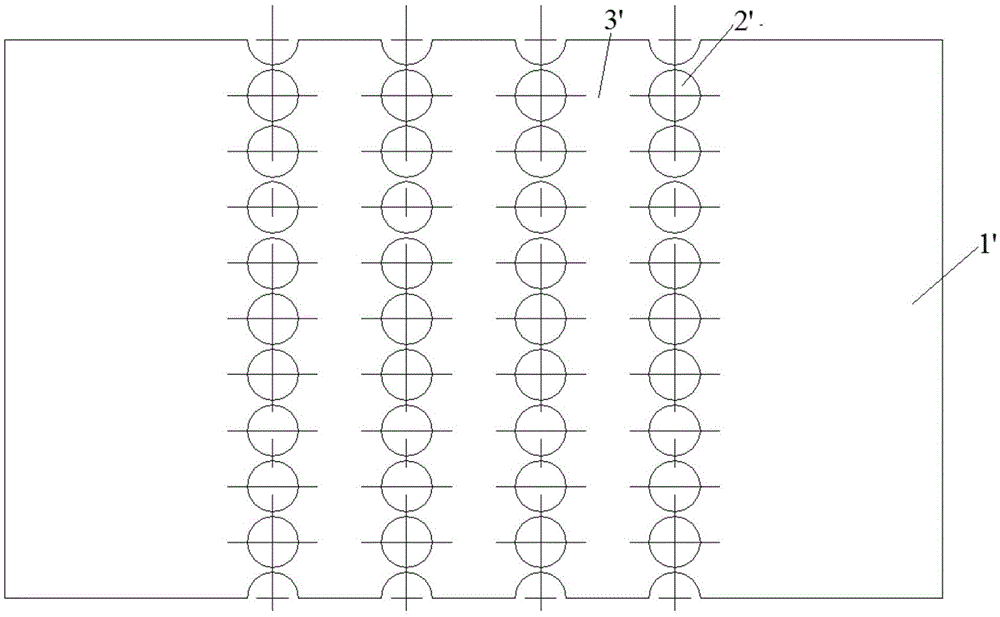

The invention discloses a melt for a DC fuse link, which comprises two melt bodies. Each melt body is provided with multiple columns of first holes and multiple columns of second holes, and the size of each first hole is smaller than that of the second hole; the multiple columns of first holes and the multiple columns of second holes, at intervals from left to right, are distributed on the corresponding melt bodies; the two melt bodies are connected in a partial overlapping mode, the overlapped place of the two melt bodies is provided with two columns of first holes and a column of third holes from left to right, and each third hole is formed by partially overlapping two second holes. The melt for the DC fuse link of the invention can provide reliable protection for a related DC circuit and elements.

Owner:上海电器陶瓷厂有限公司

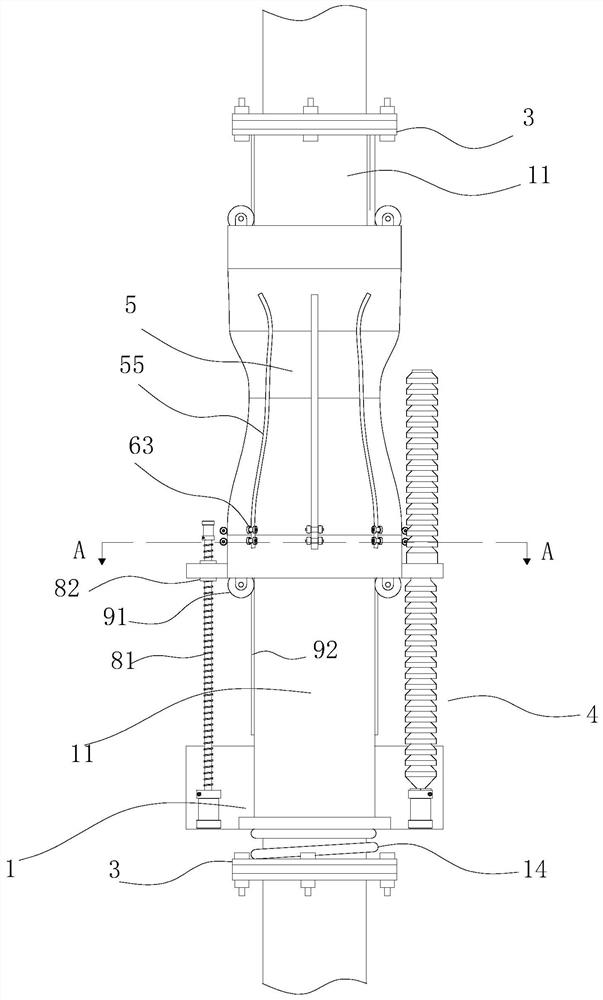

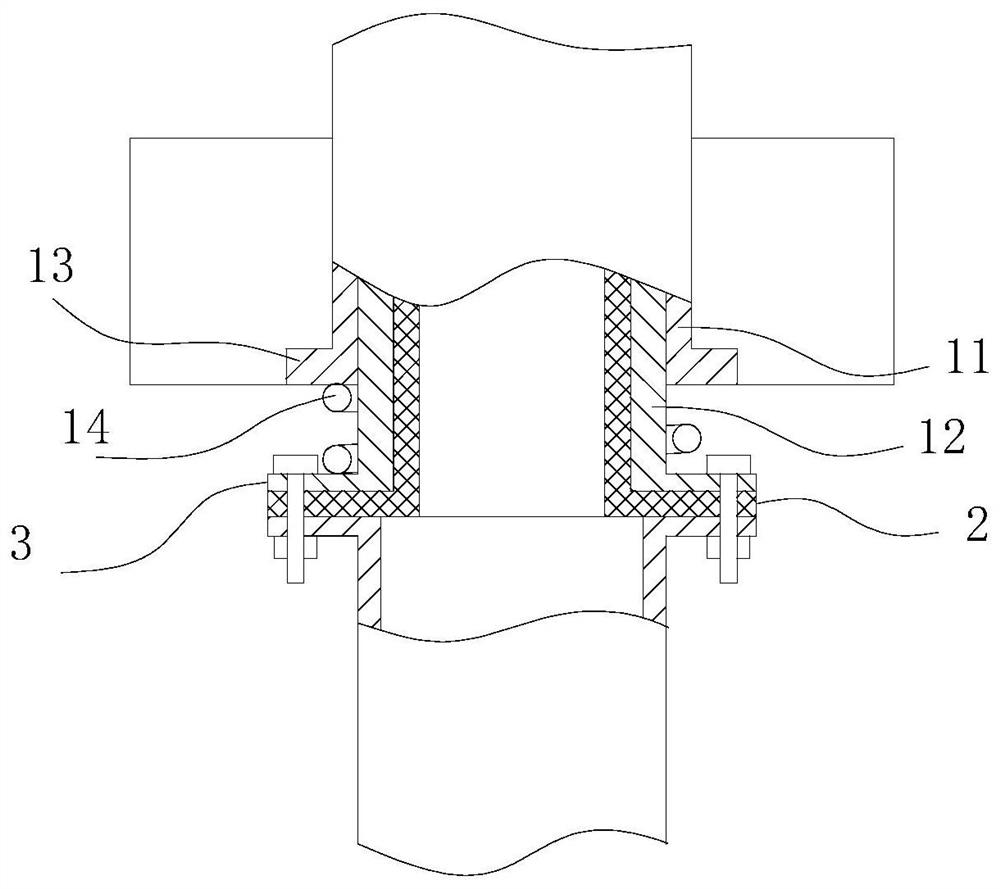

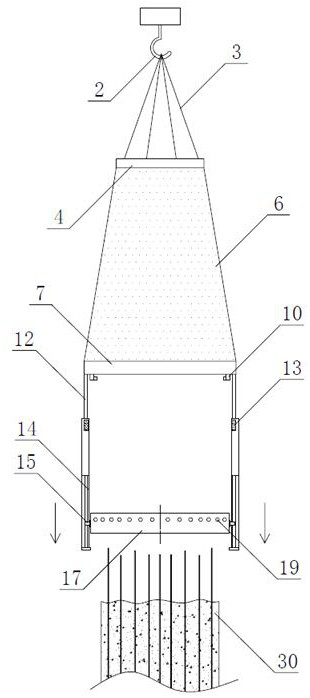

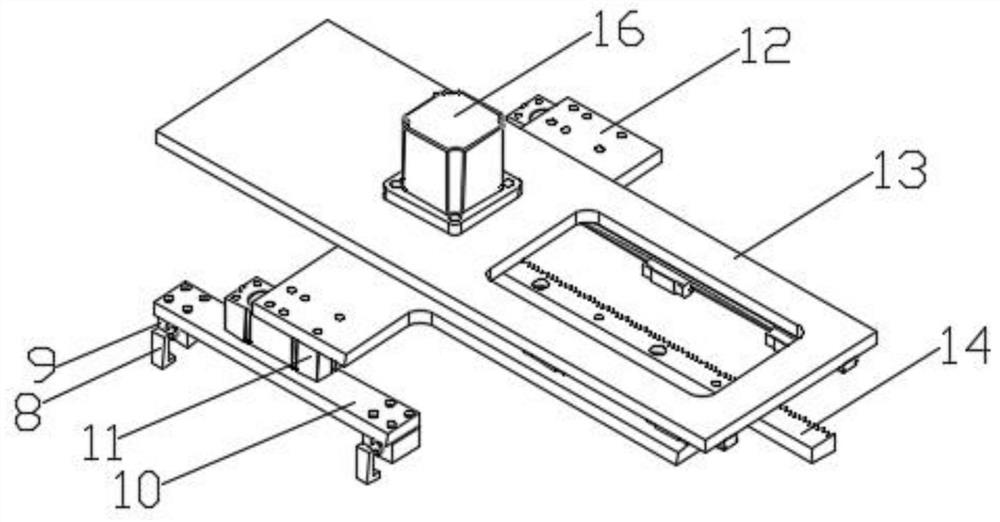

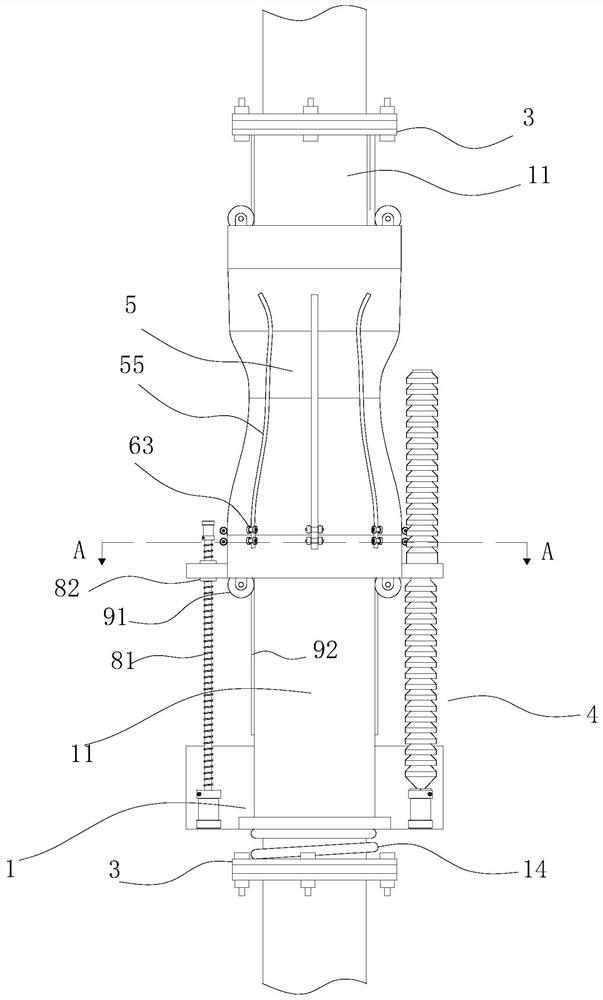

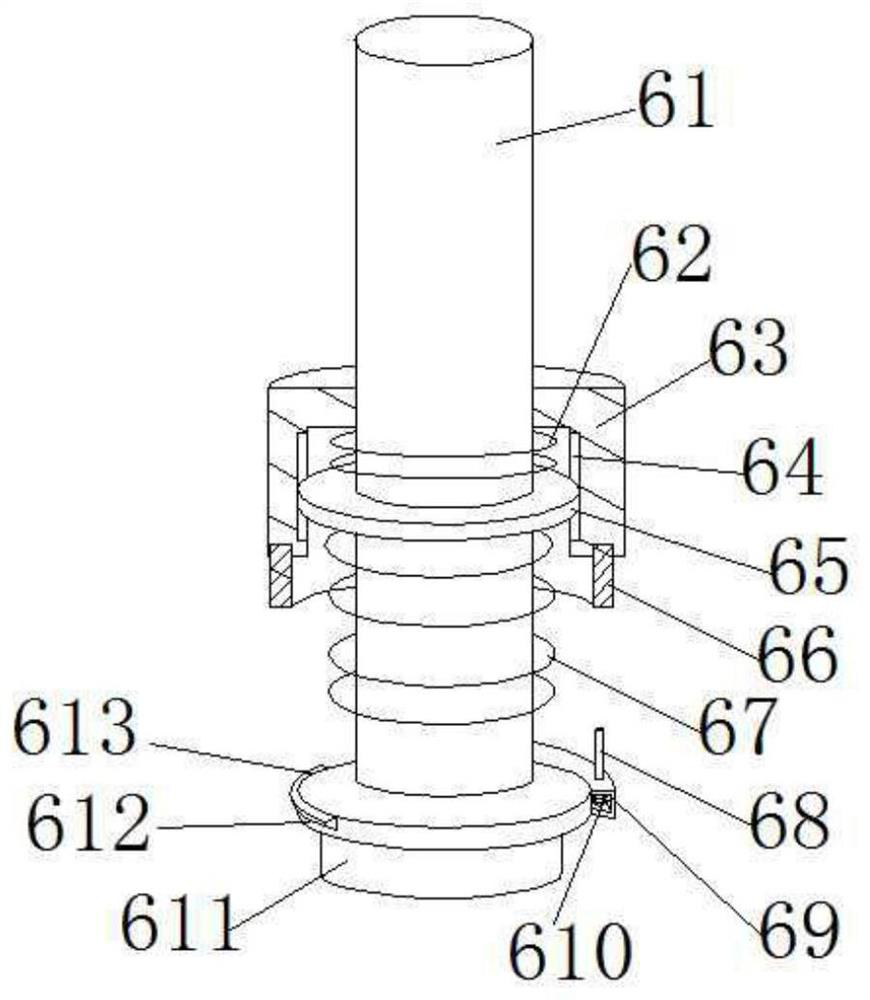

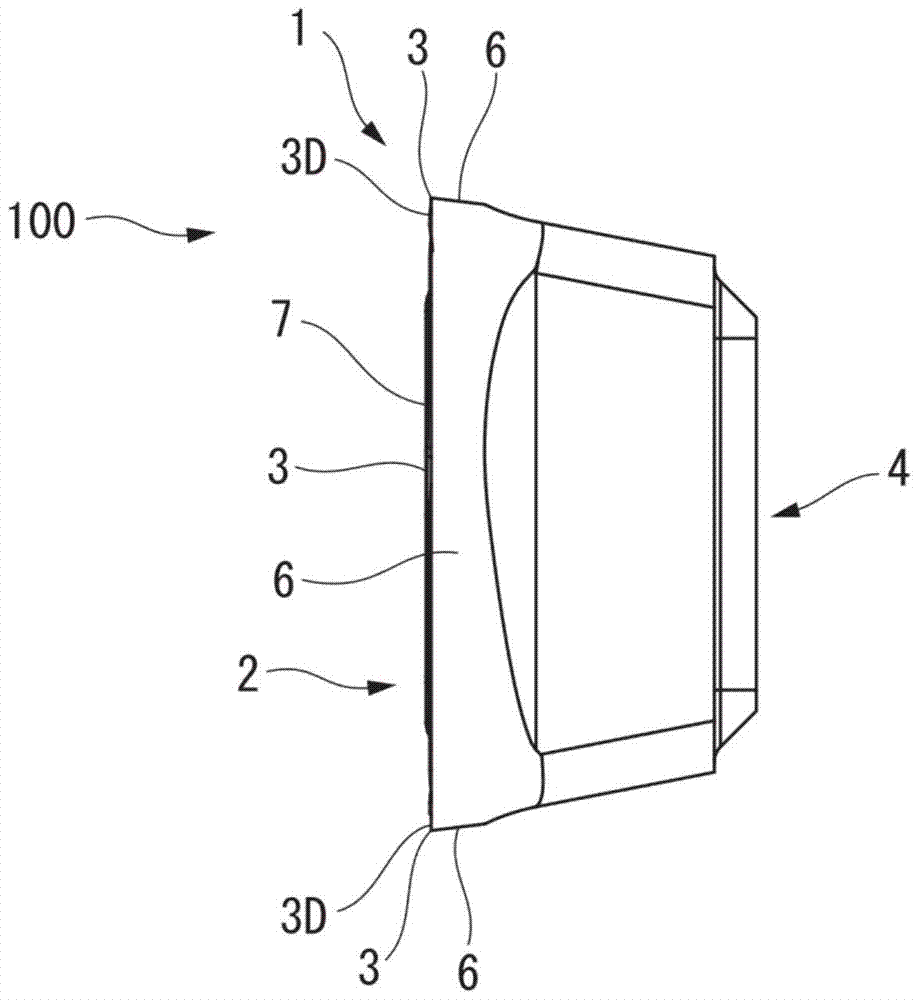

Automatic butt-joint positioning and cutting-off structure for concrete pile head

ActiveCN113199639AFast and accurate dockingFast and accurate positioningWorking accessoriesGrain treatmentsButt jointClassical mechanics

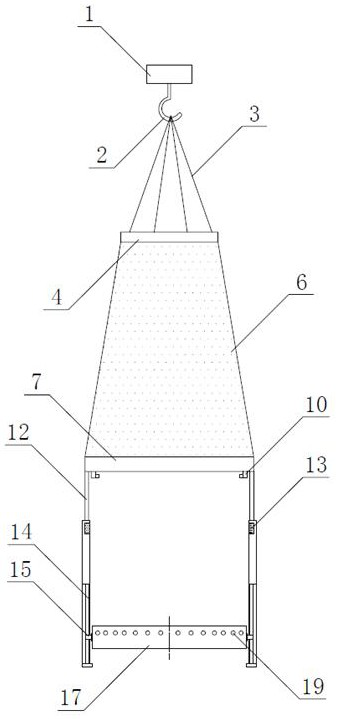

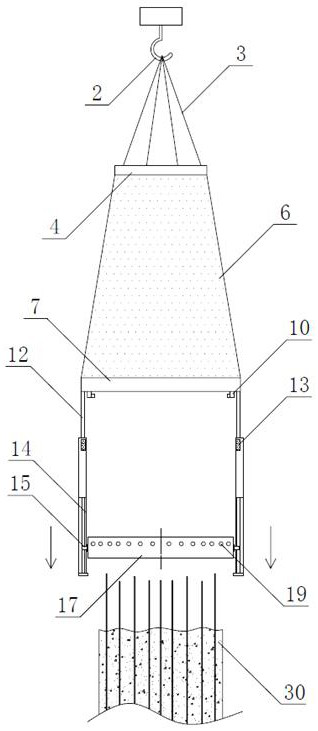

The invention discloses an automatic butt-joint positioning and cutting-off structure for a concrete pile head. The automatic butt-joint positioning and cutting structure for the concrete pile head comprises a lifting appliance (1) and a hanging ring (4) and is characterized in that the lower end of the hanging ring (4) is fixed to the small opening end of a positioning conical cylinder (6), a fixing ring (7) is fixed to the lower portion of the large opening end of the positioning conical cylinder (6), a connecting piece (5) is fixed in the hanging ring (4), the lower end of the connecting piece (5) is located on the axial lead of the positioning conical cylinder (6) and connected with the top end of a vertical supporting rod (8) through a ball-head-shaped hinge shaft, the bottom of the fixing ring (7) is fixed to the upper end of a vertical fixing arm (12), a lifting mechanism is installed at the lower end of the vertical fixing arm (12), and the lifting connecting end of the lifting mechanism is connected with a cutting, stripping and chiseling-away assembly. The structure is reasonable, automatic butt joint positioning can be achieved, the position of a broken cut-off surface can be accurately controlled, the situation that the cut-off length is too large or insufficient is avoided, and the construction efficiency is greatly improved.

Owner:湖北远大建设集团有限公司

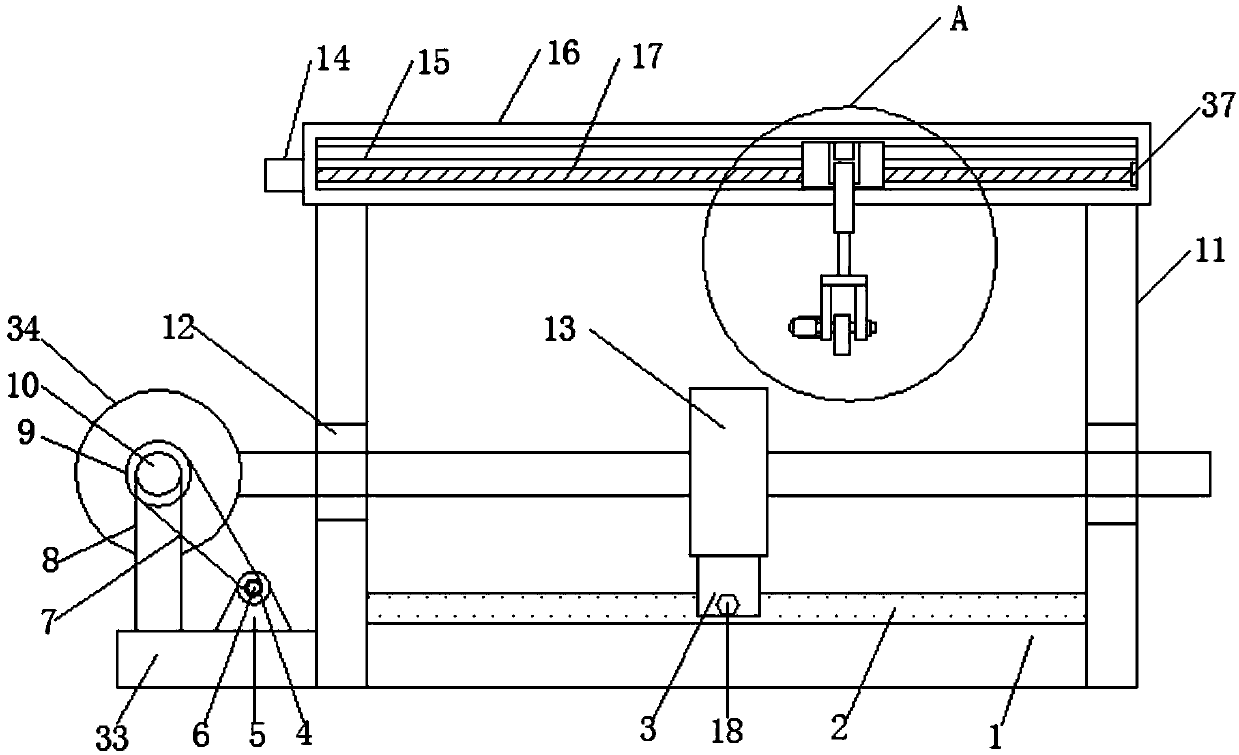

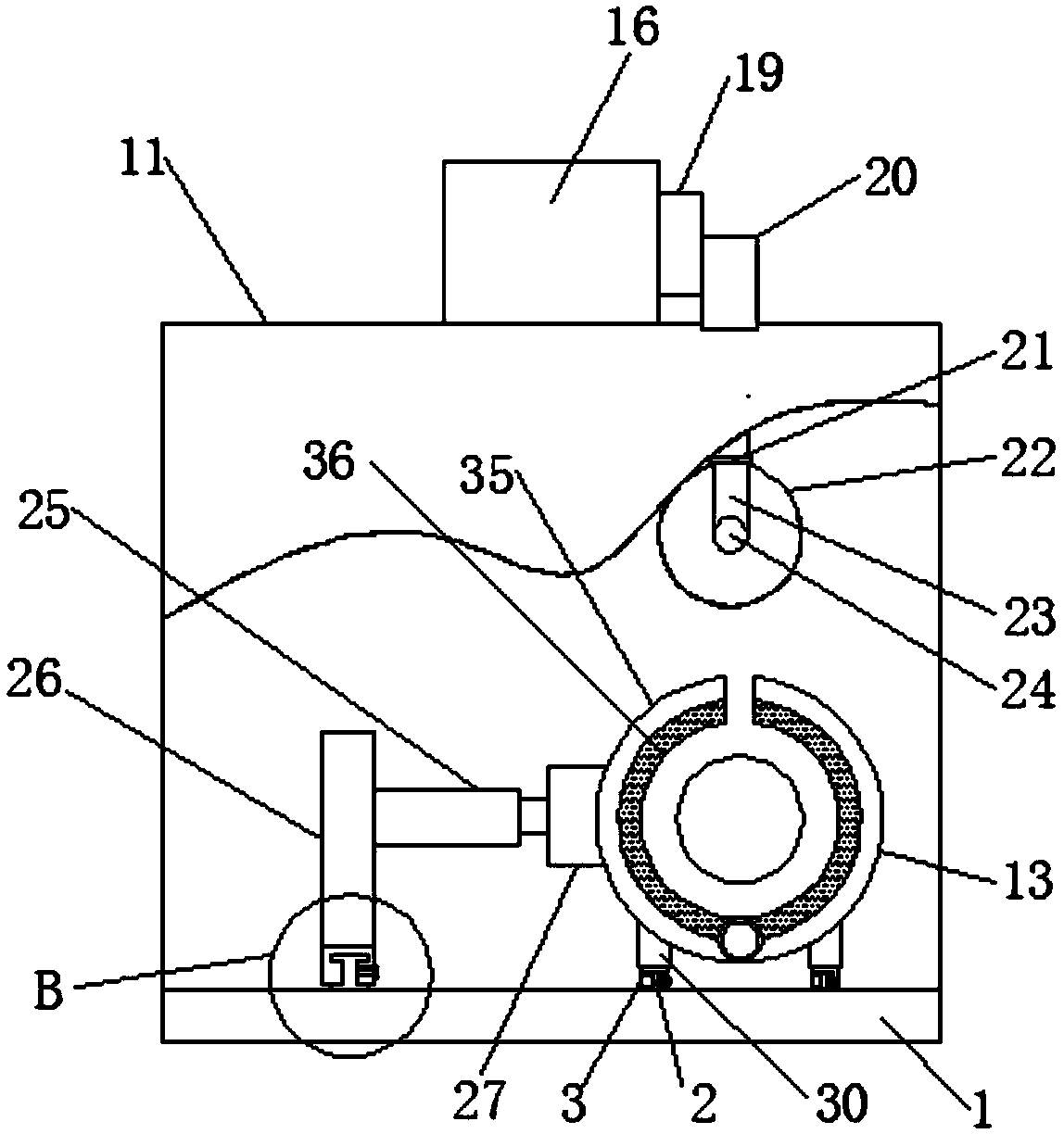

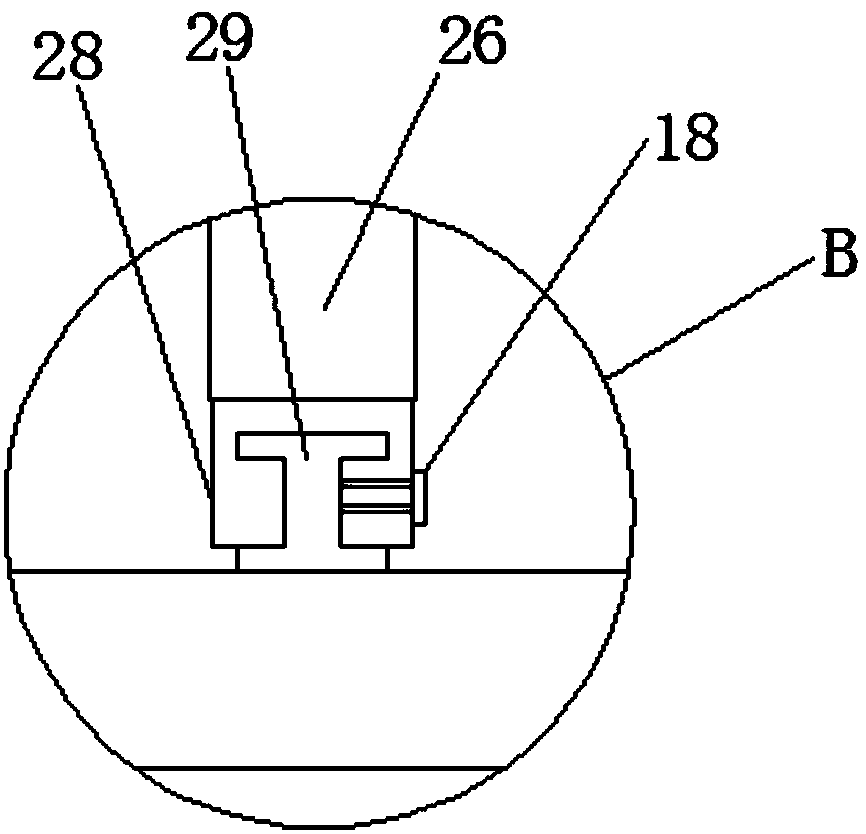

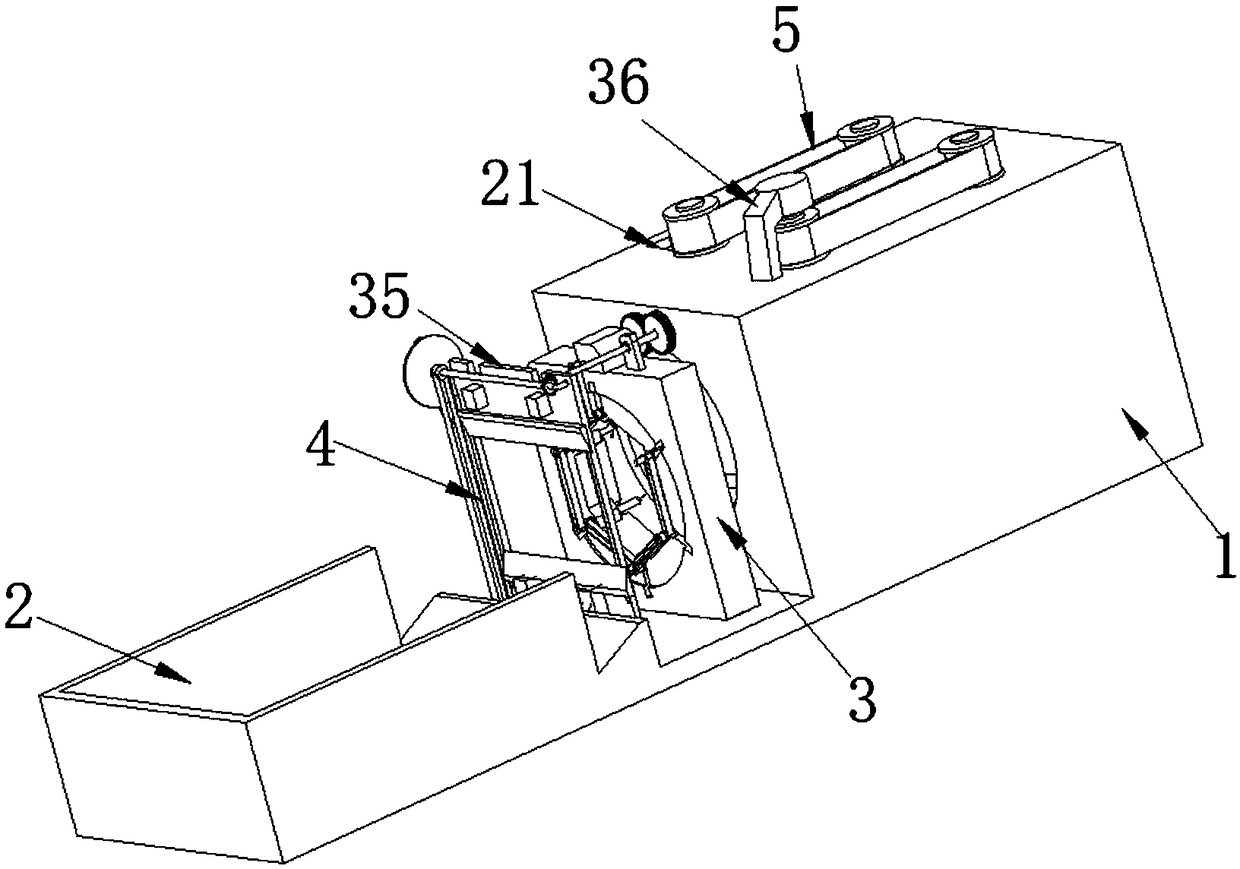

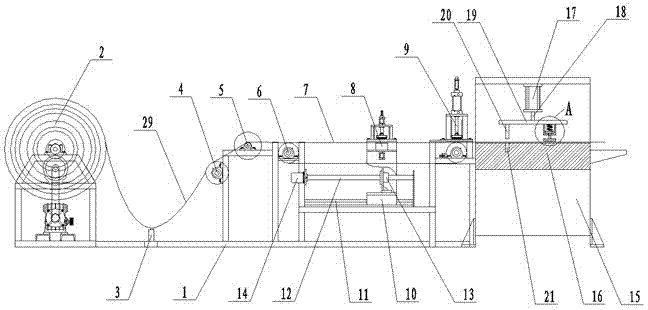

Automatic cutting machine of automobile inner decorative leather

PendingCN106884061AAvoid offsetHigh positioning accuracyLeather clicking/perforating/clickingSkins/hides/leather/fur manufacturing apparatusInfraredElectric machinery

The invention discloses an automatic cutting machine of automobile inner decorative leather. The automatic cutting machine comprises a rack, an unwinding device arranged at the most front end of the rack, an infrared-ray photoelectric switch arranged on the rack and at the position at the rear end of the unwinding device, a limiting device arranged on the rack and at the position at the rear end of the infrared-ray photoelectric switch, a guide wheel arranged on the rack and at the position at the rear end of the limiting device, a conveying device arranged on the rack and at the position at the rear end of the guide wheel; the conveying device comprises a conveying roller, a conveyer belt, a front laminating device and a rear laminating device; the front laminating device is arranged on a sliding rail in a sliding manner through a sliding block; a screw sleeve is fixedly arranged on the sliding block and matched with a lead screw; the lead screw is connected with a motor; a punching forming device is arranged on the rack and at the position at the rear end of the conveying device; the punching forming device structurally comprises a punching machine base; a punching platform is arranged at the middle of the punching machine base; a punching cylinder is arranged at the upper end of the punching machine base.

Owner:盐城市鑫富华机械有限公司

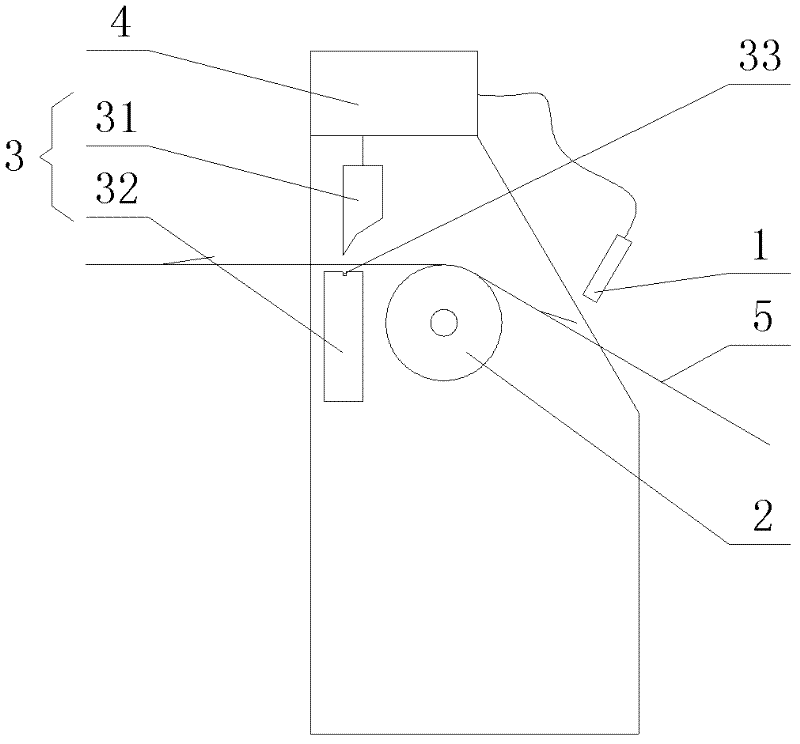

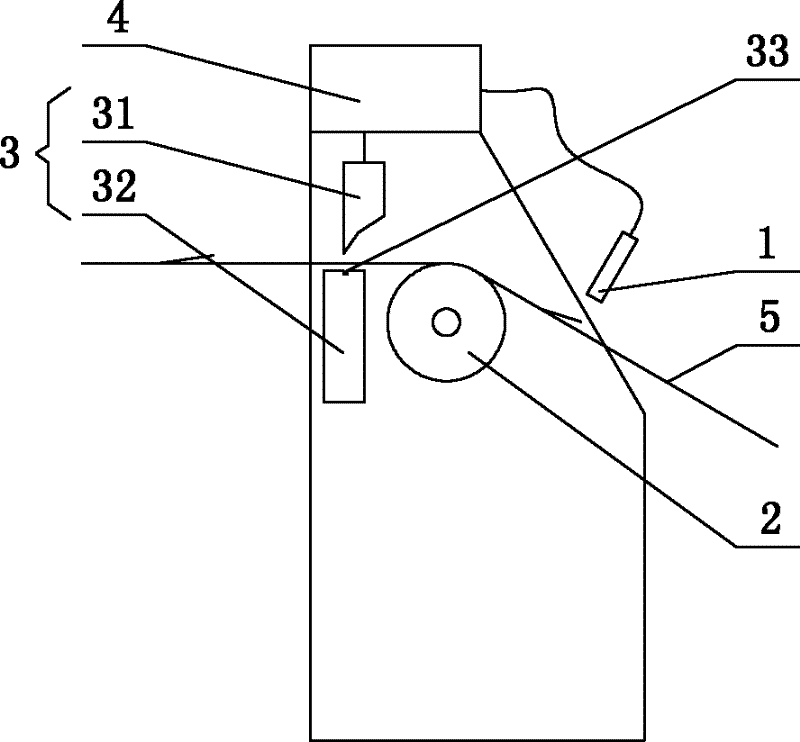

Automatic positioning cutoff machine of tongue depressor machine

InactiveCN102363306AGood truncation effectAchieve precise controlMetal working apparatusSignal onTime delays

The invention discloses an automatic positioning cutoff machine of a tongue depressor machine. The automatic positioning cutoff machine comprises a photoelectric detection head, a roller conveying mechanism and a cutoff mechanism, wherein the photoelectric detection head is connected with a control center and used for detecting signals on a conveyer belt; the cutoff mechanism comprises a cutoff platform at the lower part and a cutoff knife at the upper part, and the cutoff platform is provided with a sunken knife groove corresponding to the cutoff knife; the roller conveying mechanism is used for conveying the conveyer belt to the front end; and the control center controls the cutoff knife to downwards move to cut off the plastic packed product on the conveyer belt. The hot plastic packing mechanism of the tongue depressor machine has the advantages that: the plastic packed product on the conveyer belt is detected by adopting the photoelectric detection head, time delay is calculated by the control center, and cutoff of the cutoff knife is controlled, so that the effect of accurate control can be achieved, the cutoff effect is better compared with the conventional cutoff mechanism, cutoff deviation is prevented, and cutoff quality and work efficiency of a product are ensured.

Owner:WUXI JIANGSU WEIFENG PRINTING MACHINE

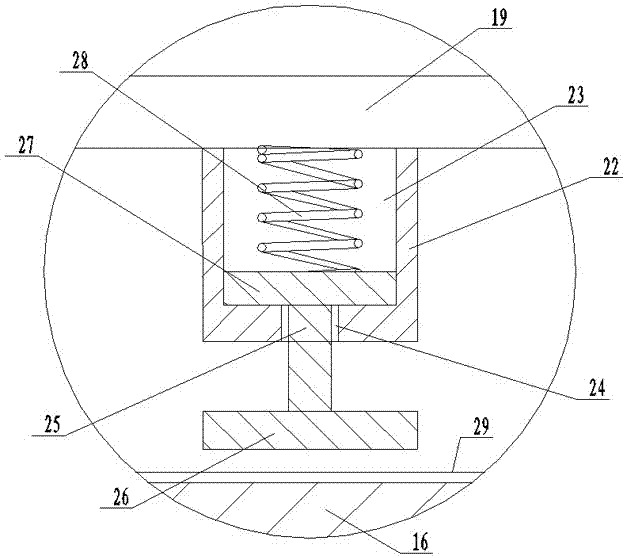

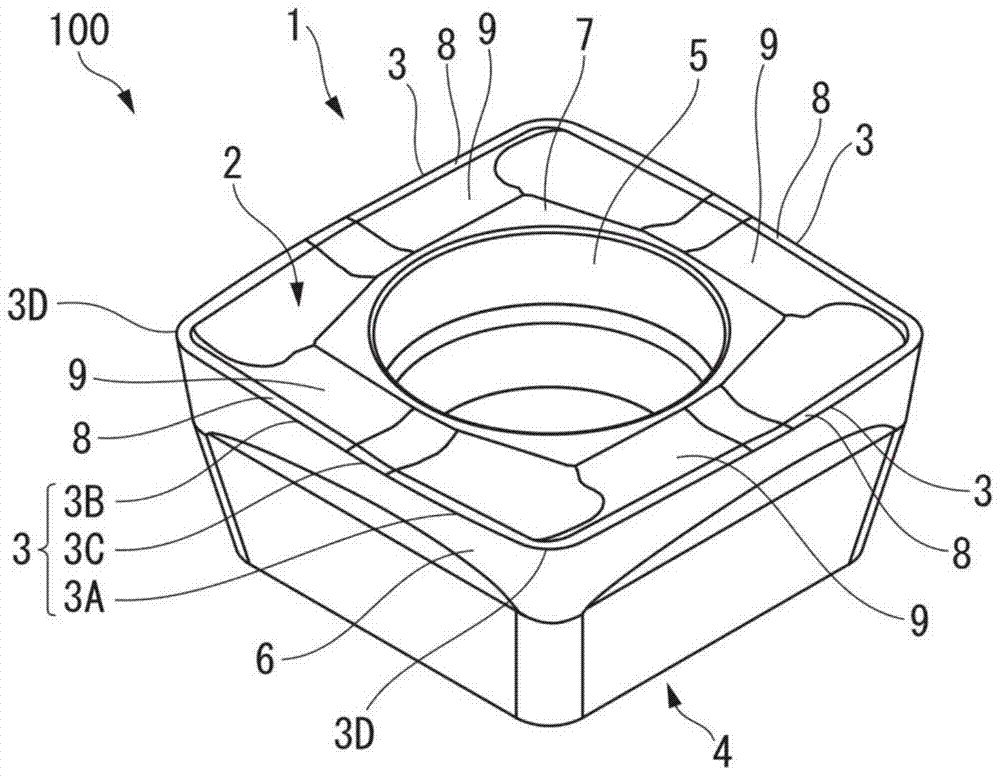

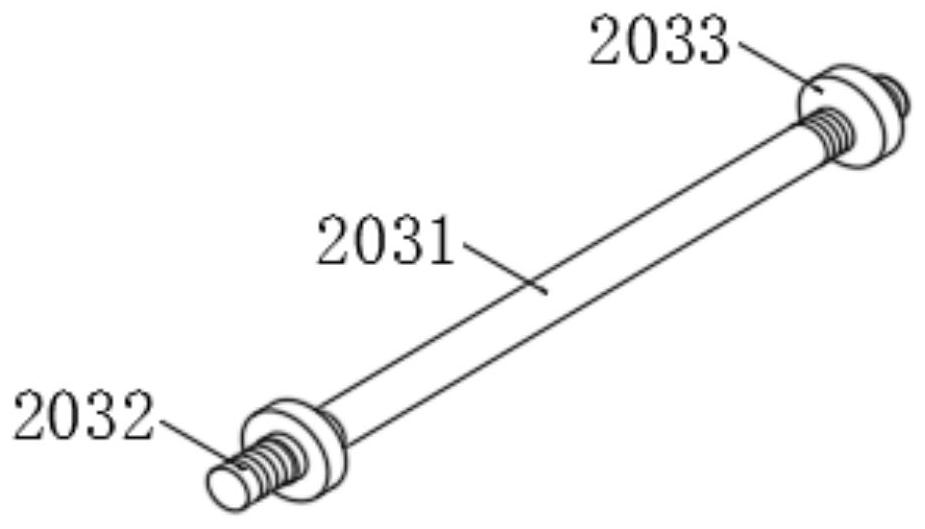

High-precision adjusting device for size of pipe section

ActiveCN112709838AUneven deformationUniform deformationDiaphragm valvesOperating means/releasing devices for valvesPinch valveStructural engineering

The invention discloses a high-precision adjusting device for the size of a pipe section. The high-precision adjusting device is characterized in that the high-precision adjusting device comprises a sliding sleeve, a pressing rod assembly and a bandage assembly, the sliding sleeve is arranged on a supporting pipe in a sleeving mode, the sliding sleeve has the freedom degree of linear sliding relative to the axis of the supporting pipe, eight open grooves are formed in the sliding sleeve, the sliding sleeve comprises a reducing section and a locking section which are sequentially arranged from front to back, the reducing section is in a circular truncated cone shape, the locking section comprises four cambered surface protruding positions and four cambered surface sunken positions, and the cambered surface protruding positions and the cambered surface sunken positions are sequentially arranged in the circumferential direction of the section. Due to the defects that the section of a conventional pinch valve is usually flattened into an approximately oval shape to reduce the sectional area, the deformation of a rubber pipe is uneven, the pipe wall is abraded by ore particles, the rubber pipe is prone to fatigue, in the process of reducing the section of a reducing valve, the section is approximately circular, and the deformation of the section of the rubber pipe is uniform, so that the fatigue defect can be relieved.

Owner:CENT SOUTH UNIV

Cable cutting-off device

The invention discloses a cable cutting-off device. The cable cutting-off device comprises a machine frame, a feeding port, a discharging port, a fixing seat and a cutting-off device, wherein the feeding port is formed in the left side wall of the machine frame, the discharging port is formed in the right side wall of the machine frame, the output end of a motor is connected with a threaded rod, the threaded rod penetrates through a frame body and a moving plate in sequence and is correspondingly in threaded rotation connection with the frame body and the moving plate, the frame body is located below the moving plate, the two sides of the moving plate are correspondingly provided with connecting rods, the bottom ends of the connecting rods penetrate through the top surface of the machine frame and are in sliding connection with the machine frame, the bottom ends of the connecting rods are connected with pressing plates, the connecting rods are sleeved with second springs, the two sidesof the frame body penetrate through the top surface of the machine frame, and is in sliding connection with the machine frame, a cutter is arranged at the bottom of the frame body, the fixing seat isarranged on the inner bottom surface of the machine frame, a wire penetrating groove is formed in the top of the fixing seat in the horizontal direction, and a cutting groove is formed in the middleof the top of the fixing seat. The cable cutting-off device has the advantages that the cutting stability is good, the functions of guiding and limiting a cable in an auxiliary mode are achieved, thenthe cable is cooled, and then the cutting-off surface of the cable is flat.

Owner:中合智腾建设有限公司

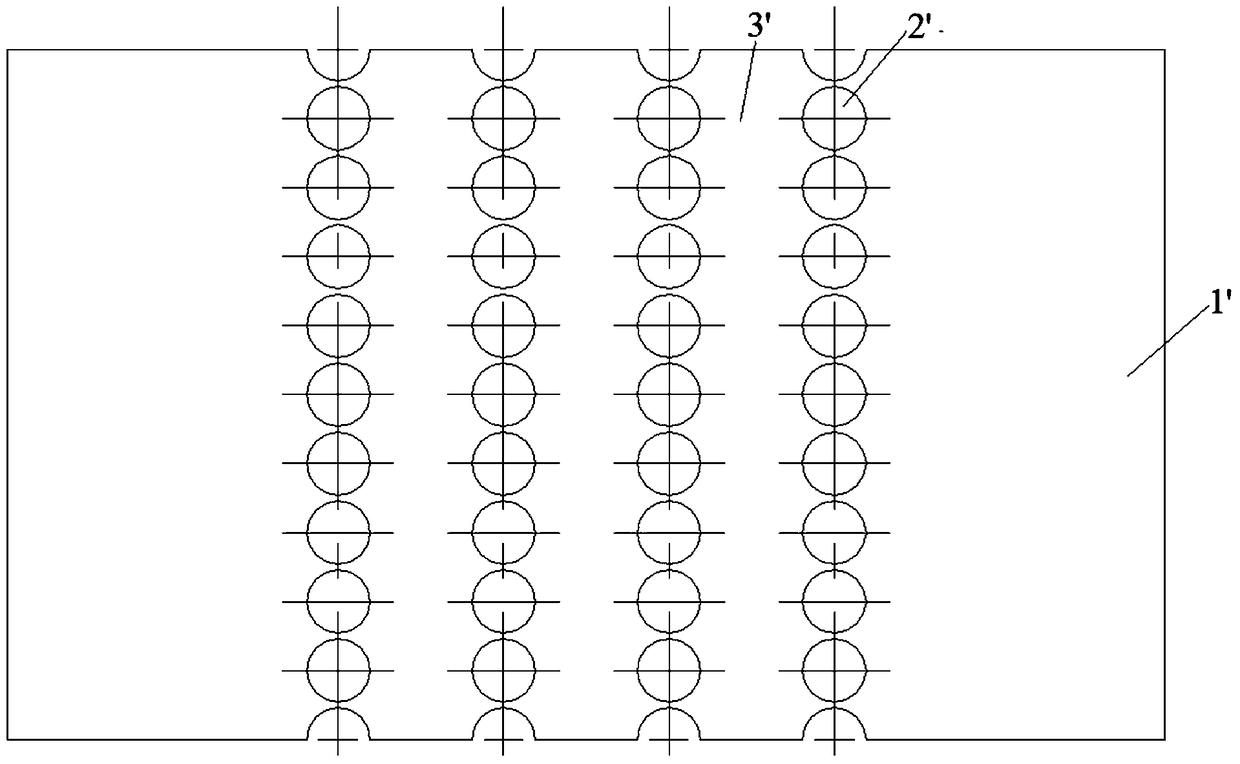

Soft foundation reinforcing construction method with good reinforcing effect

InactiveCN112227344AHigh strengthImprove bearing capacityBulkheads/pilesSoil preservationCrushed stoneStructural engineering

The invention relates to a soft foundation reinforcing construction method with a good reinforcing effect. The soft foundation reinforcing construction method comprises the following steps of S1, siltremoval, wherein floating silt on the upper layer of an area to be subjected to reinforcing construction is removed; S2, first-stage reinforcing pile burying, wherein multiple first-stage reinforcingpiles are buried in the area where the floating silt is removed in the step S1; S3, second-stage reinforcing pile burying, wherein second-stage reinforcing piles are buried in the periphery of the area where the first-stage reinforcing sand piles are buried; S4, gravel layer laying, wherein a graded gravel layer is laid at the tops of the first-stage reinforcing piles; and S5, overload pre-pressing, wherein an overload pre-pressing layer is arranged on the graded gravel layer, and overload pre-pressing reinforcing is conducted on the to-be-reinforced area through the overload pre-pressing layer. The method has the advantage that the soft foundation reinforcing effect is remarkably improved.

Owner:福建新华夏建工集团有限公司

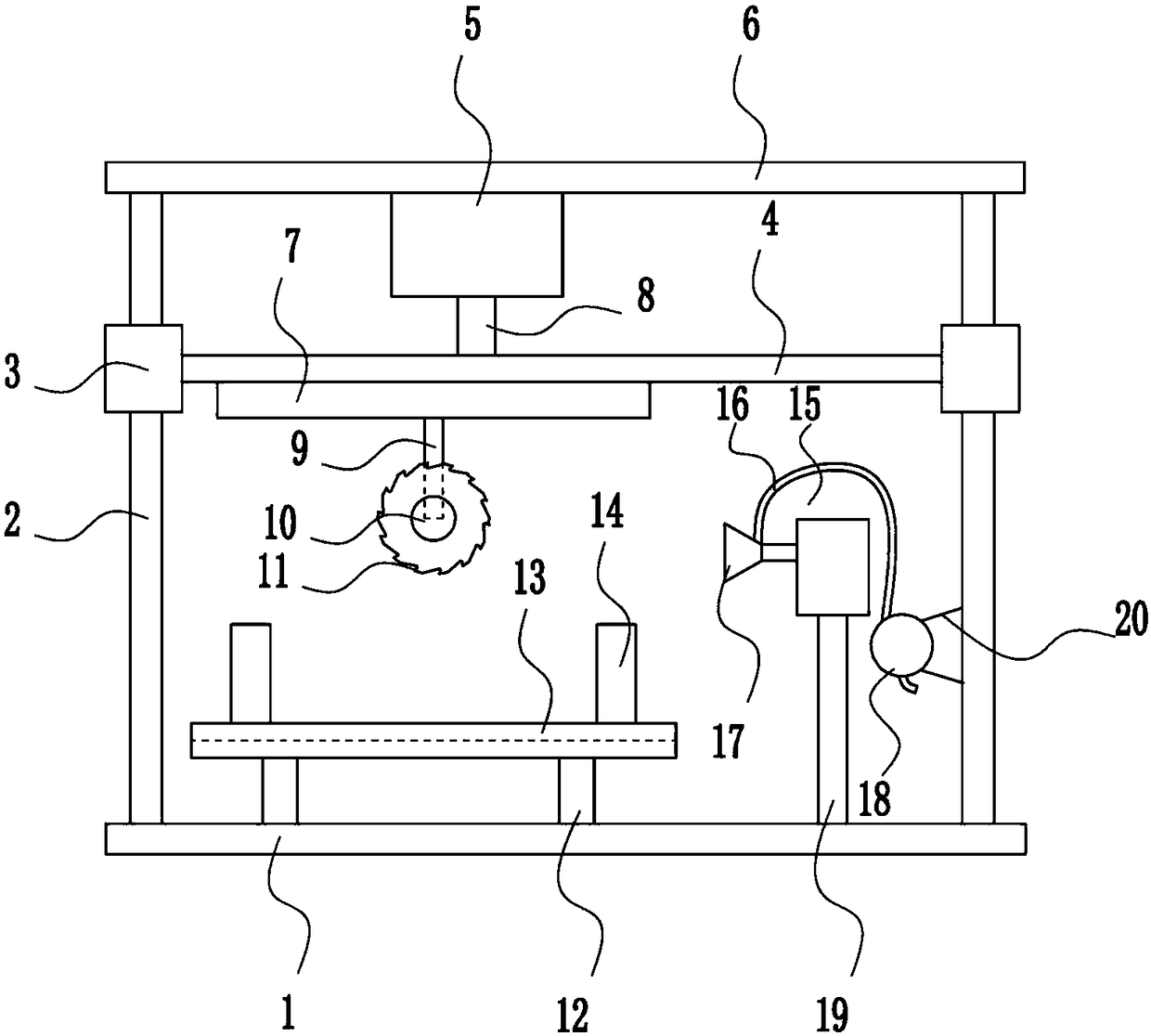

Automatic feeding and cutting device for traditional Chinese medicine decoction pieces

ActiveCN110450199AEasy to move horizontallyEasy for automatic loadingMetal working apparatusEngineeringChinese herbology

The invention discloses an automatic feeding and cutting device for traditional Chinese medicine decoction pieces. The automatic feeding and cutting device comprises a frame, wherein a first motor isinstalled at the top of one side of the frame, the end of an output shaft of the first motor is sleeved with a lead screw, and a connecting piece on the lead screw is connected with a lifting plate. According to the automatic feeding and cutting device for the traditional Chinese medicine decoction pieces, a third motor output shaft drives a first rotating rod to rotate; the first rotating rod drives a second gear on the outer peripheral surface to rotate; the second gear drives a third gear to rotate by meshing; the third gear drives a second rotating rod to rotate; the second rotating rod drives shaft sleeves at the two ends to rotate; the shaft sleeves are matched with a movable rod to rotate; the movable rod drives a lifting rod to periodically lift along a second sliding rod; the lifting rod drives a blade box at the bottom to lift; and the blade box drives a blade to cut off the traditional Chinese medicine decoction pieces on a tray. Through the arrangement, the blade can cut off the traditional Chinese medicine decoction pieces on the tray periodically, the structure is simple, and meanwhile, the cutting effect is good.

Owner:安徽新盛中药饮片有限公司

A hardware parts cutting device

ActiveCN107096962BAvoid stickingEasy accessMaintainance and safety accessoriesEngineeringMechanical engineering

The invention relates to a cutting off device, in particular to a fast cutting off device for hardware parts. The invention solves the technical problem of providing a cutting device for a covering steel plate for production of a circuit board, which is light and handy, fast in cutting off and good in cutting off effect. In order to solve the technical problem above, the invention provides such a fast cutting off device for hardware parts, which comprises a bottom plate, first guide rods, first guide covers, a moving rod, a lifting device, a top plate, a moving device, a lifting rod, a mounting rod, a second motor, a blade, first supports, and the like; the first guide rods are symmetrically welded on the left side and the right side of the top of the bottom plate, the top plate is welded on the top ends of the two first guide rods, the middle of the bottom of the top plate is provided with the lifting device, and the bottom of the lifting device is connected to the lifting rod. By controlling the lifting device to move up and down, the blade is controlled in an optimal position, such that the cutting off effect is better, and by driving the blade to move left and right through the moving device, the cutting off is more thorough.

Owner:NANTONG KAIDI AUTOMATIC MACHINERY

A melt for DC fuse link

ActiveCN105428178BFusing speed is fastGood truncation effectEmergency protective devicesDc circuitComputer science

The invention discloses a melt for a DC fuse link, which comprises two melt bodies. Each melt body is provided with multiple columns of first holes and multiple columns of second holes, and the size of each first hole is smaller than that of the second hole; the multiple columns of first holes and the multiple columns of second holes, at intervals from left to right, are distributed on the corresponding melt bodies; the two melt bodies are connected in a partial overlapping mode, the overlapped place of the two melt bodies is provided with two columns of first holes and a column of third holes from left to right, and each third hole is formed by partially overlapping two second holes. The melt for the DC fuse link of the invention can provide reliable protection for a related DC circuit and elements.

Owner:上海电器陶瓷厂有限公司

A high-precision adjustment device for pipe cross-section size

ActiveCN112709838BUneven deformationUniform deformationDiaphragm valvesOperating means/releasing devices for valvesPinch valveStructural engineering

The invention discloses a high-precision adjusting device for the cross-section size of a pipeline, which is characterized in that it includes a sliding sleeve, a pressing rod assembly and a strap assembly, the sliding sleeve is sleeved on a support tube, and the sliding sleeve has a linear sliding feature relative to the axis of the support tube. Degree of freedom, there are eight slots on the sliding sleeve, the sliding sleeve includes a diameter-reducing section and a locking section arranged in sequence from front to back, the diameter-reducing section is in the shape of a truncated cone, and the locking section includes four arcuate protrusions and four arcuate depressions, arcuate protrusions and arcuate depressions are arranged in sequence along the circumference of the cross section. Since the cross section of conventional pinch valves is usually flattened into an approximately elliptical shape to reduce the cross-sectional area, the rubber hose Due to the uneven deformation and the wear of the ore particles on the pipe wall, the rubber hose is prone to fatigue defects. In the process of reducing the cross section of the variable diameter valve of the present invention, the cross section is approximately circular, and the deformation of the rubber hose cross section is relatively uniform, so fatigue defects can be alleviated.

Owner:CENT SOUTH UNIV

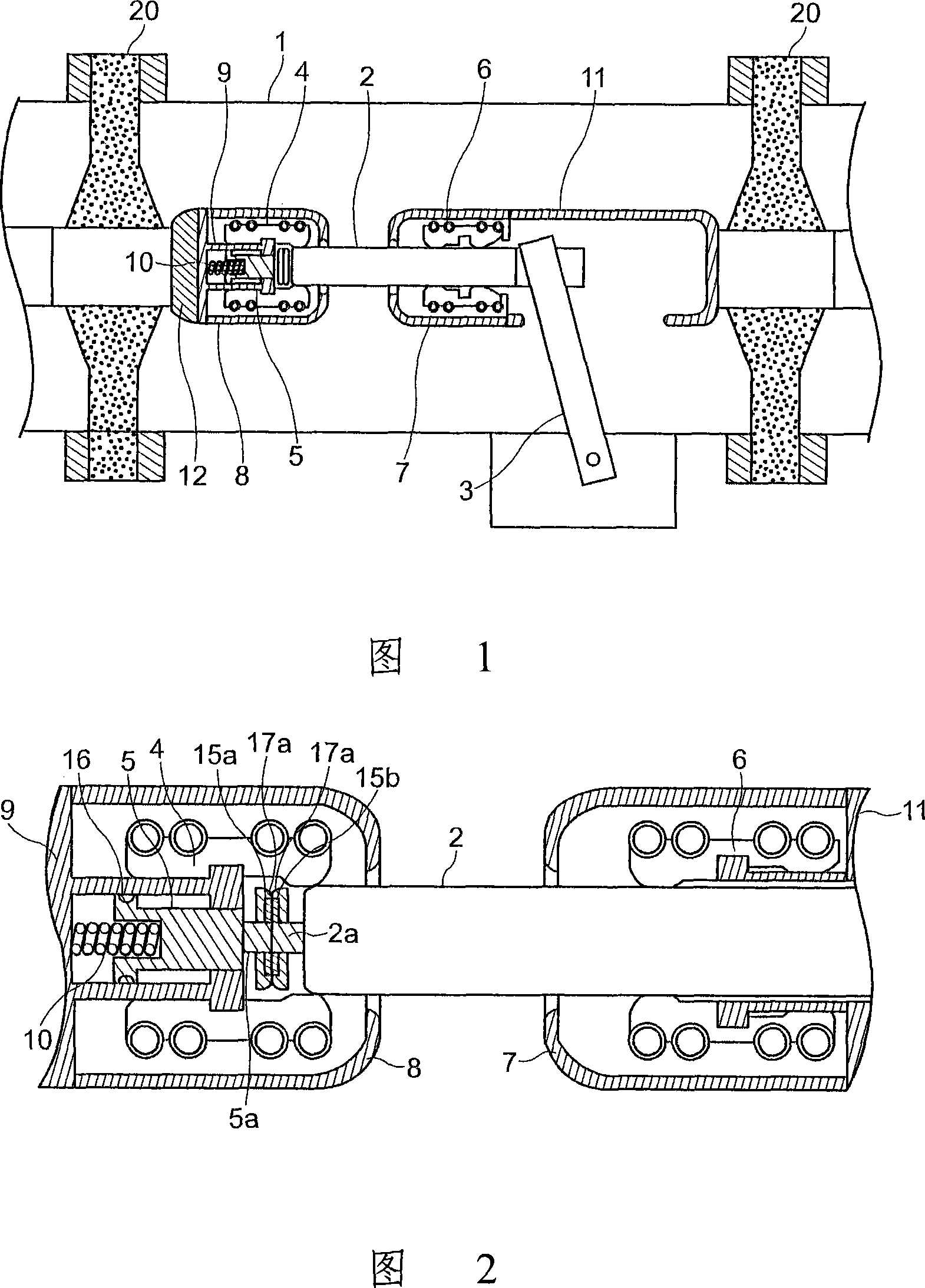

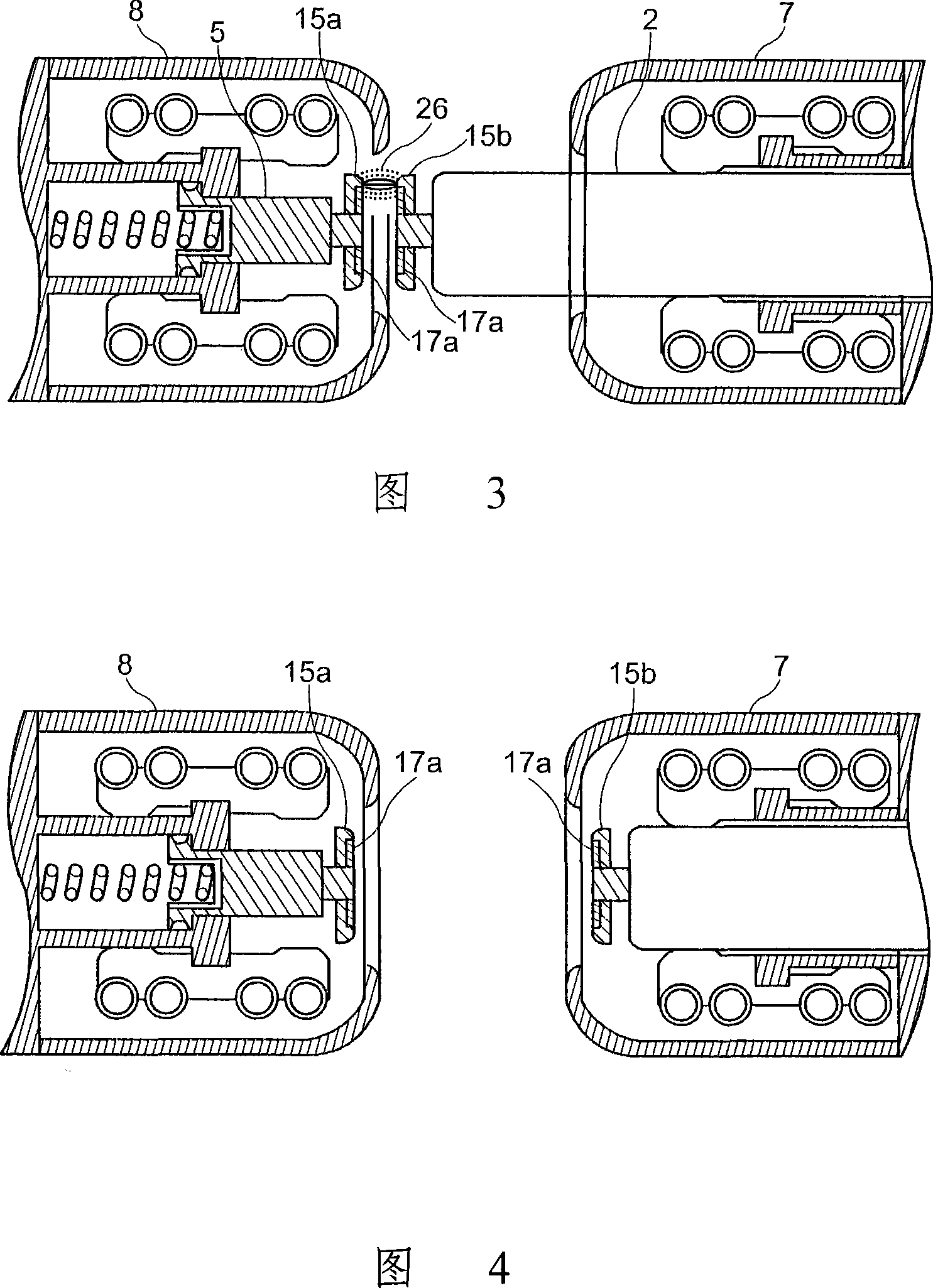

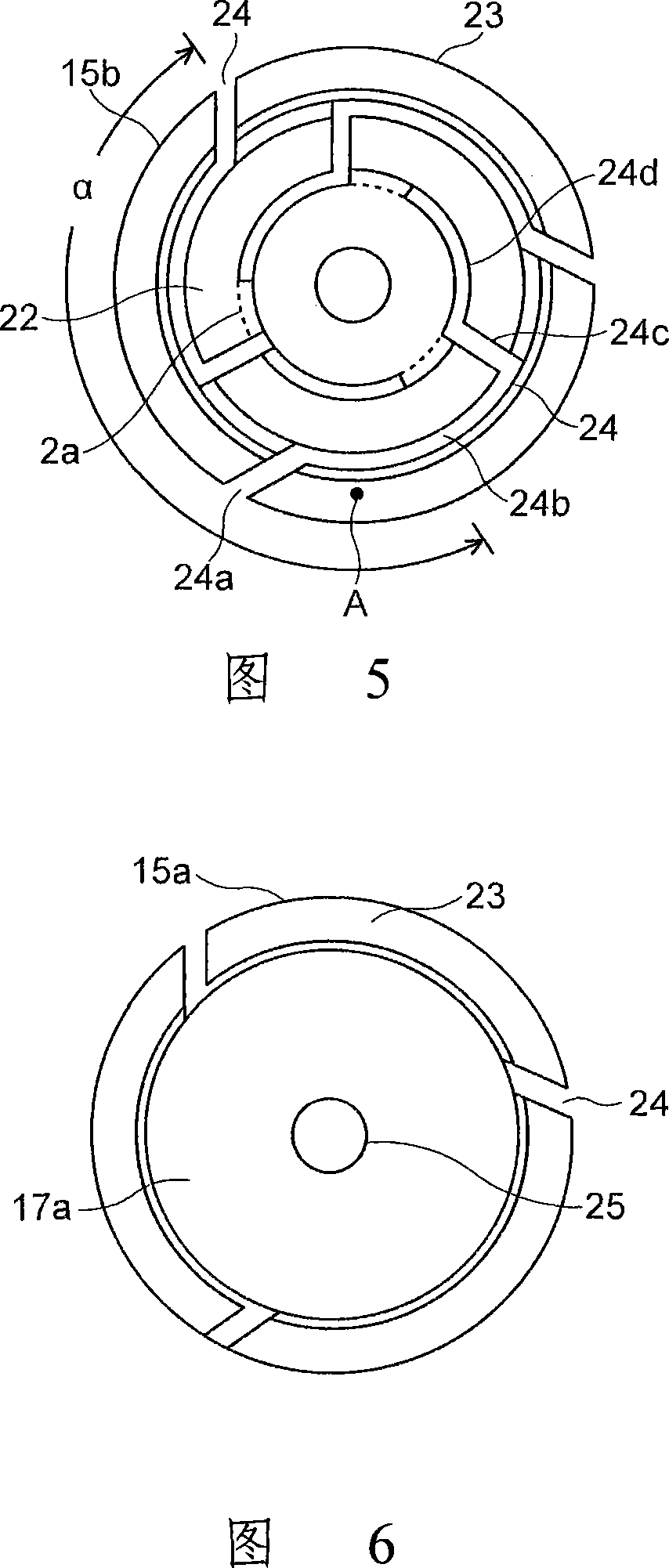

Gas-insulated switch

ActiveCN101226846BReduce weightPrevent from crossingHigh-tension/heavy-dress switchesAir-break switchesSwitchgearBiomedical engineering

The invention provides a gas insulated switchgear, capable of preventing the diameter from enlarging in simple structure and rotating the arc with good efficiency and realizing the downsizing and light-weighting in low operating physical force. The opposite side insulating parts (17a) are set at the opposite surface of the non-contact depressed part (22) in the spiral electrodes (15a,15b), in addition a rear-face side insulator (17b) having an equivalent or greater diameter is arranged at a rear face side of the spiral electrodes (15a, 15b). Thus even thought part of the periphery of the arc (26) leaves the arc moving part (23) and protrudes from the non-contact depressed part (22) side or the arc moving part (23), the insulating parts (17a,17b) can still prevent part of the current flowing through the arc (26) from spanning the groove (26b) and flowing through the non-contact depressed part (22) or flowing through the rear-face side of the spiral electrodes (15a,15b), therefore the action to the arc (26) can be stably performed for a long time, depending on the total shape of the groove and the electromagnetic force of the current.

Owner:JAPAN AE POWER SYST

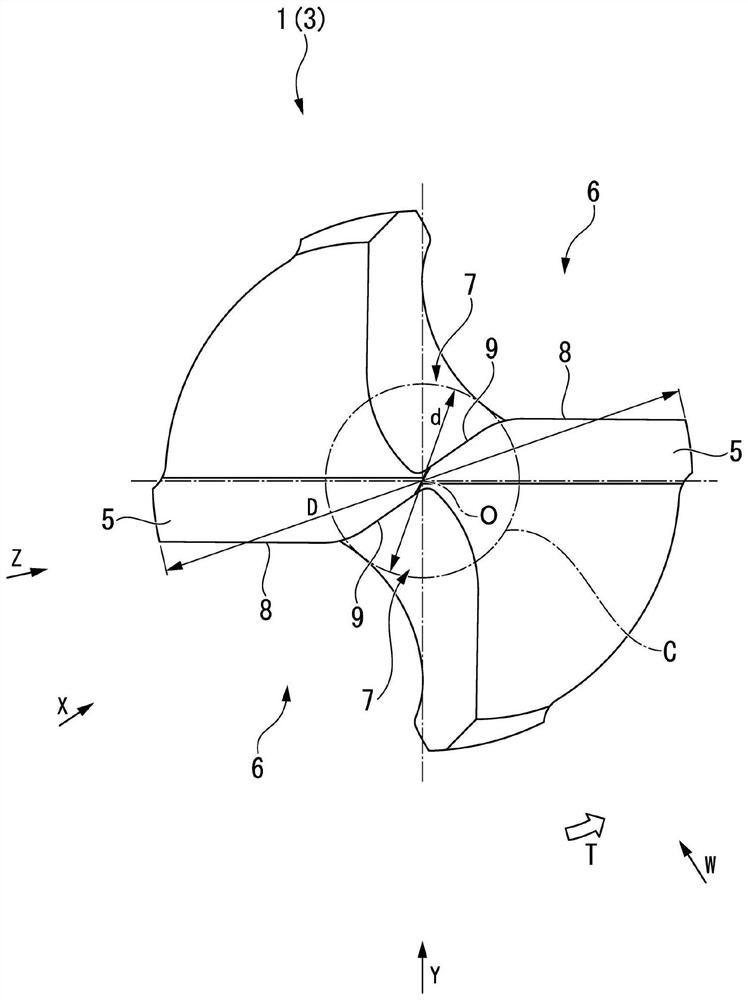

Drill

In this drill: a main cutting blade (8) is formed on a tip side ridge section of a chip discharge groove (6) formed on the tip outer periphery of a drill body (1); a thinning blade (9) is formed on a tip side ridge section of a thinning section (7) having recessed a groove shape formed in the tip inner periphery of the chip discharge groove (6); when viewed from the twist direction of the chip discharge groove, the radius of the inscribing circle of the chip discharge groove falls within the range of 0.3xD2 to 0.7xD2 with respect to the diameter D2 of a second circle; in the thinning section (7), the radius (R2) of a thinning inscribing circle (C6) falls within the range of 0.3xd to 0.7xd with respect to the core thickness (d) when viewed in the thinning direction; and the ratio A / B between the ratio A=R1 / D2 of a radius R1 to the diameter D2 and the ratio B=R2 / d of the radius (R2) to the core thickness (d) fall within the range of 0.8 to 1.25.

Owner:MITSUBISHI MATERIALS CORP

Cast-in-place pile head concrete stripping and chiseling device

ActiveCN113513022AFast and accurate dockingSolve the quick positioningBulkheads/pilesMechanicsWire rope

The invention discloses a cast-in-place pile head concrete stripping and chiseling device. The cast-in-place pile head concrete stripping and chiseling device comprises a lifting appliance (1), a lifting hook (2), a steel wire rope (3) and a hanging ring (4), and is characterized in that the lower end of the hanging ring (4) is fixed to the small opening end of a positioning conical barrel (6), a fixing ring (7) is fixed to the lower portion of the large opening end of the positioning conical barrel (6), a connecting piece (5) is fixed in a ring body of the hanging ring (4), a vertical supporting rod (8) is fixed to the position, located on the axis of the positioning conical barrel (6), of the lower end of the connecting piece (5), the bottom of the fixing ring (7) is fixed to the upper end of a vertical fixing arm (12), a lifting mechanism is installed at the lower end of the vertical fixing arm (12), and the lifting connecting end of the lifting mechanism is fixedly connected with an annular outer frame (17). The device is reasonable in structure, mechanical automatic construction is adopted, the construction efficiency is greatly improved, the position of a broken cut-off plane can be accurately controlled, the overall stripping and chiseling quality is good, and the cut-off plane is regular.

Owner:湖北远大建设集团有限公司

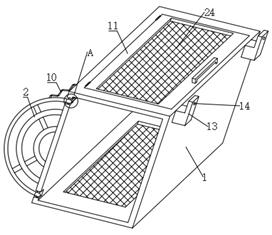

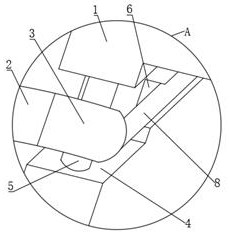

A salvage device for river cleaning

ActiveCN112359798BAvoid cloggingImprove fishing efficiencyWater cleaningGeneral water supply conservationRiver routingWater flow

The invention belongs to the technical field of river course garbage cleaning, in particular to a salvage device for river course cleaning. Aiming at the problem that the overall salvage efficiency of the existing salvage device is not high, the following scheme is proposed, including a box body, one side of the front end of the box body There are two first grooves, a positioning rod is fixed in the first groove, a connecting block is set on the positioning rod, a network frame is fixed between the two connecting blocks, and a first spring is fixed at the rear end of the network frame. The inner wall of one side of the body is provided with a first chute, and a first sliding block is slidably connected in the first chute, a strut is fixed at the front end of the first sliding block, and a floating plate is fixed inside the first sliding block. In the present invention, external tools such as rakes are used to pull the garbage to the opening position, and the garbage enters the box along the water flow, and the floating plate drives the grid to rotate under the action of the non-uniform water flow. The net frame rotates back and forth, which can push the garbage such as branches and enter the box, thereby improving the fishing efficiency.

Owner:安徽禾美环保集团有限公司

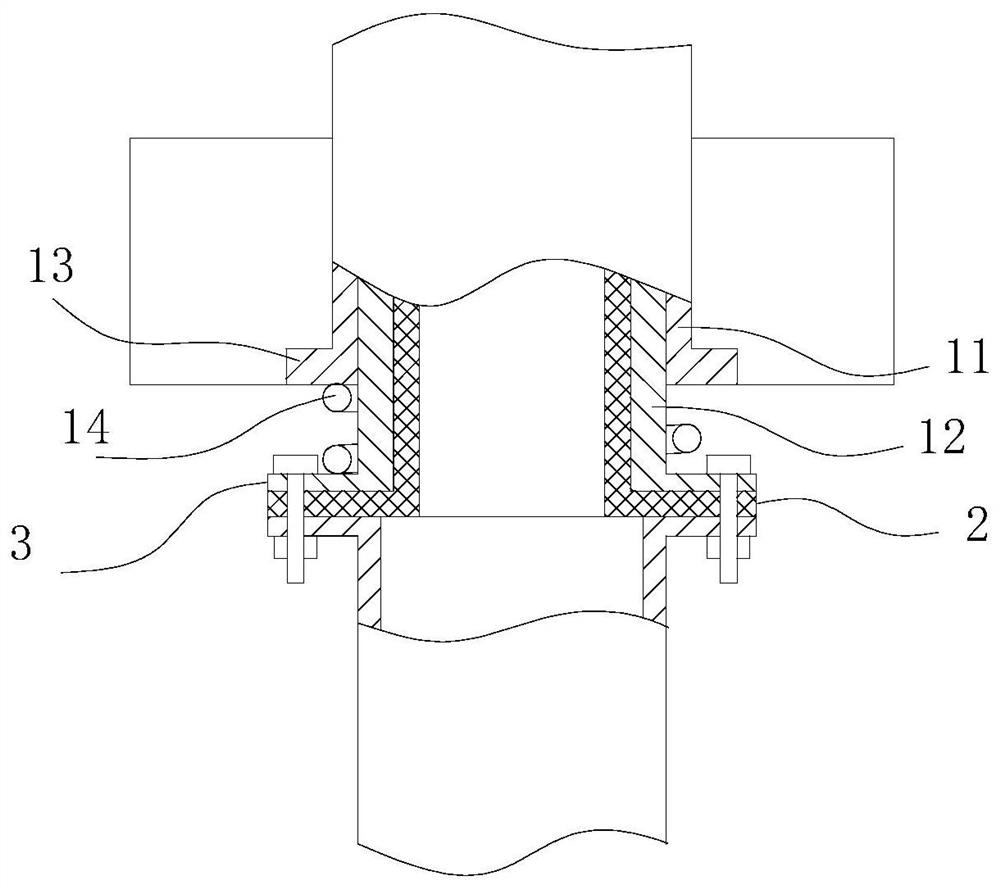

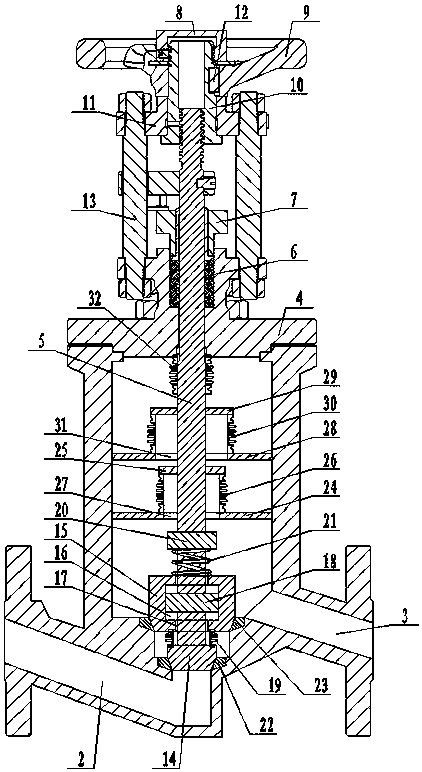

Chlorine cast steel stop valve

PendingCN110056660AReduce shockGood truncation effectValve members for absorbing fluid energyLift valveInlet channelScrew thread

The invention discloses a chlorine cast steel stop valve. The chlorine cast steel stop valve comprises a cast steel valve body, an inlet channel and an outlet channel are formed in the lower end of the cast steel valve body, a cast steel valve cover is arranged at the upper end of the cast steel valve body, a valve rod is arranged in the valve body, the upper end of the valve rod is connected witha hand wheel assembly, the lower end of the valve rod is connected with a valve clack assembly, wherein a sealing filling and a pressing plate are arranged between the valve rod and the cast steel valve cover; the hand wheel assembly comprises a dust cap, a hand wheel, a valve rod nut, a support flange and a flat key, the hand wheel is connected with the valve rod nut through the flat key, the dust cap is arranged above the hand wheel and is connected with the valve rod nut through threads, the support flange is in axial rotation fit with the valve rod nut, and the support flange is connectedwith the cast steel valve cover through stand columns; the valve clack assembly comprises a small valve clack and a large valve clack, the diameter of the small valve clack is smaller than that of the large valve clack, and a limiting sliding cavity is formed in the large valve clack.

Owner:JIANGSU DINGSHENG VALVE

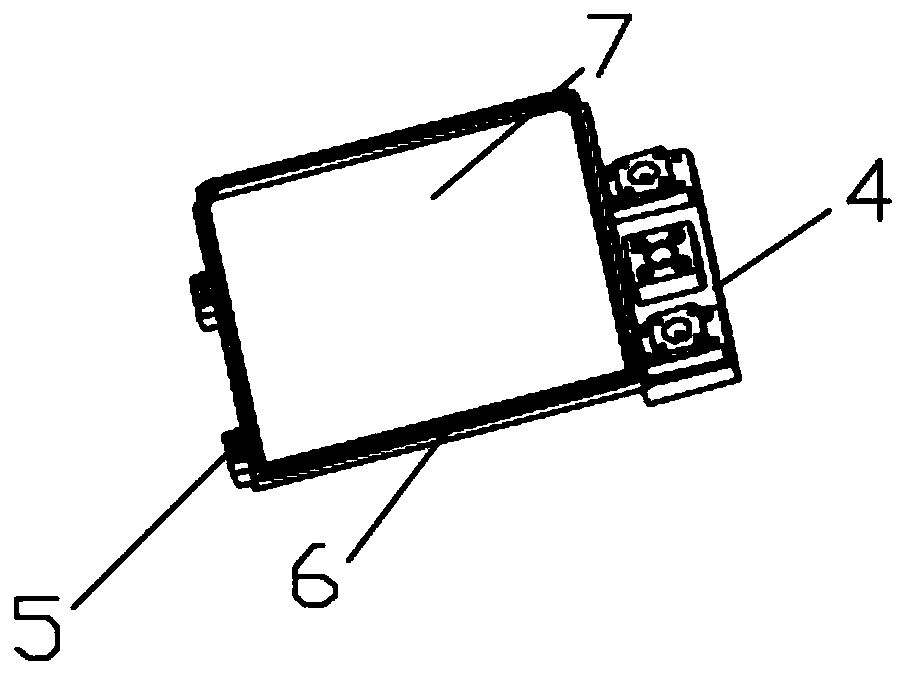

Heat-insulation polyphenyl board forming device

ActiveCN109015848AGood truncation effectRemove burrsMetal working apparatusPress ramCircular discFuel tank

The invention discloses a heat-insulation polyphenyl board forming device. The heat-insulation polyphenyl board forming device comprises a metal shell. An oil tank is mounted on the upper end face ofthe metal shell. A control panel is mounted on one side of the metal shell. Supporting legs are mounted at the four corners of the bottom surface of the metal shell. Rubber suction cups are mounted atthe bottom ends of the supporting legs. A feeding port is formed in the front end face of the metal shell. A supporting plate is mounted on the front end face of the feeding port. Supporting columnsare mounted on the bottom surface of the front end of the supporting plate. A fixing plate is mounted on the upper end face of the front end of the supporting plate. A disc handle is mounted on the front side of the fixing plate. A sliding plate is mounted on the rear side of the fixing plate. A groove is mounted above the feeding port. A connecting rod is mounted on the front end face of the groove. A handle is mounted on the front end face of the connecting rod. According to the heat-insulation polyphenyl board forming device, punch-formed boards can be cut through a high-temperature cuttingknife, so that the cutting effect is good; and the edges of the boards can be pressed.

Owner:湛江市欧美嘉建筑工程有限公司

An automatic feeding and cutting device for decoction pieces of traditional Chinese medicine

ActiveCN110450199BEasy for automatic loadingEasy to placeMetal working apparatusGear driveGear wheel

The invention discloses an automatic feeding and cutting device for traditional Chinese medicine decoction pieces. The automatic feeding and cutting device comprises a frame, wherein a first motor isinstalled at the top of one side of the frame, the end of an output shaft of the first motor is sleeved with a lead screw, and a connecting piece on the lead screw is connected with a lifting plate. According to the automatic feeding and cutting device for the traditional Chinese medicine decoction pieces, a third motor output shaft drives a first rotating rod to rotate; the first rotating rod drives a second gear on the outer peripheral surface to rotate; the second gear drives a third gear to rotate by meshing; the third gear drives a second rotating rod to rotate; the second rotating rod drives shaft sleeves at the two ends to rotate; the shaft sleeves are matched with a movable rod to rotate; the movable rod drives a lifting rod to periodically lift along a second sliding rod; the lifting rod drives a blade box at the bottom to lift; and the blade box drives a blade to cut off the traditional Chinese medicine decoction pieces on a tray. Through the arrangement, the blade can cut off the traditional Chinese medicine decoction pieces on the tray periodically, the structure is simple, and meanwhile, the cutting effect is good.

Owner:安徽新盛中药饮片有限公司

A high-precision variable-diameter valve with resistance-increasing and pressure-regulating control

ActiveCN112610720BUneven deformationUniform deformationDiaphragm valvesOperating means/releasing devices for valvesHydrologyMechanics

The invention discloses a variable-diameter valve for high-precision resistance-increasing and pressure-regulating control, which includes a support tube and a rubber tube built in the support tube. An adjustment device for adjusting the cross-sectional size of the rubber tube is installed on the support tube. The end of the support tube is fixed There is a flange plate, and the driving device for driving the adjustment device is fixed on the support tube. The driving device pushes the sliding sleeve to slide along the axial direction of the support tube. The transformation of the pipeline in the structure of the present invention should be adapted to the original mining system as much as possible. And it retains the convenient reducibility and improves the test efficiency. The present invention is a nestable flange structure, and all structures can be nested in the original pipeline system, with high convenience, low difficulty in disassembly and installation, and no need for on-site welding , a production system suitable for sea trials. This device can be installed in low water and deep sea test to adjust the pressure, and this device can be removed in high water depth production.

Owner:CENT SOUTH UNIV

Welding Chopping Knife

ActiveCN107710394BGood truncation effectEasy to slideSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

The invention provides a welding capillary, comprising a main body, having a through hole through which a filament passes through; a first pressing surface, configured to press the filament, provided around the through hole and extending relative to the through hole; The first inclined surface inclined in the direction in which it exists; and the second pressing surface, which presses the filament, has a tapered tapered surface provided between the first inclined surface and the through hole, and is provided on the The second inclined surface between the tapered surface and the first inclined surface is characterized in that the square mean square root slope of the roughness curve elements of the second inclined surface is smaller than the roughness curve of the first inclined surface The square mean square root slope of the features.

Owner:TOTO LTD

Internally pre-tightened valve

ActiveCN112923069APrevent outflowGood truncation effectOperating means/releasing devices for valvesLift valveStructural engineeringMechanics

The invention discloses an internally pre-tightened valve. The internally pre-tightened valve comprises a valve body and further comprises a valve cover arranged on the valve body, a switch part pivoted on the valve cover, a handle arranged at the upper end of the switch part, a flow adjusting part and a filtering part which are arranged at the water inlet end of the valve body, wherein the switch part comprises an operating rod and further comprises an adjusting cylinder screwed on the operating rod, a first sliding groove concavely formed in the inner wall of the adjusting cylinder, an adjusting plate arranged on the operating rod and capable of sliding in the first sliding groove, a first spring and a second spring which are sleeved on the operating rod, a guide cylinder arranged at the lower end of the adjusting cylinder, a sealing plate arranged at the lower end of the operating rod, a first sealing frame arranged at the edge of one side of the sealing plate, a first screw screwed on the first sealing frame, a third spring sleeved on the first screw and pressed in the first sealing frame, a valve clack arranged on the lower side of the sealing plate, and a sealing strip arranged at the edge of the other side of the sealing plate. The internally pre-tightened valve is good in sealing performance.

Owner:池州市日升阀门管件制造有限公司

Drill bits with replaceable inserts and bits

InactiveCN105073316BInhibit deflectionAvoid breakageTransportation and packagingCutting insertsTool bitDrill bit

The insert for a drill according to the present invention is detachably installed on the axis (O) side and the outer peripheral side of the tip of the drill body (11) rotating around the axis (O). The edge portion of the polygonal surface in the direction of drill rotation is formed with cutting edges (3) facing toward the tip side of the drill body (11) and trajectories of rotation around the axis (O) when viewed from the direction of the axis (O). The cutting edge (3) is provided with a margin (8), and the margin angle of the margin (8) changes with the cutting edge (3) located on the outer peripheral side of the drill body (11) when it is installed on the drill body (11). One end (3A) of the cutting edge (3) gradually increases toward the negative angle side toward the other end (3B), and the land width of the land (8) increases from one end (3A) of the cutting edge (3) to the other end The (3B) side gradually increases.

Owner:MITSUBISHI MATERIALS CORP

Cut-off device for rice noodle production and processing and use method of cut-off device

ActiveCN113733184AAdjust laying widthEase of meeting truncation requirementsLighting and heating apparatusClimate change adaptationAgricultural engineeringIndustrial engineering

The invention relates to a cut-off device for rice noodle production and processing and a use method of the cut-off device. The cut-off device for rice noodle production and processing comprises a first conveying table and a second conveying table, wherein a first conveying groove and a second conveying groove are formed in the top of the first conveying table and the top of the second conveying table respectively; a plurality of adjusting assemblies which are evenly distributed and used for adjusting the laying width of rice noodles are arranged between the inner walls of the two sides of the second conveying groove; a cooling mechanism used for cooling extruded rice noodles is arranged at the top of the first conveying table; a flattening mechanism used for flattening the rice noodles is arranged at the top of the second conveying table; and a cut-off mechanism used for cutting off the rice noodles is arranged at the end, away from the first conveying table, of the second conveying table. The problems that an existing cut-off device is poor in cut-off effect when in use, is only limited to rice noodles with one size requirement, is low in applicability, is not high in cut-off continuity, cannot meet the requirement for large-batch production, is low in cut-off efficiency and the like are solved.

Owner:安徽悠之优味食品有限公司

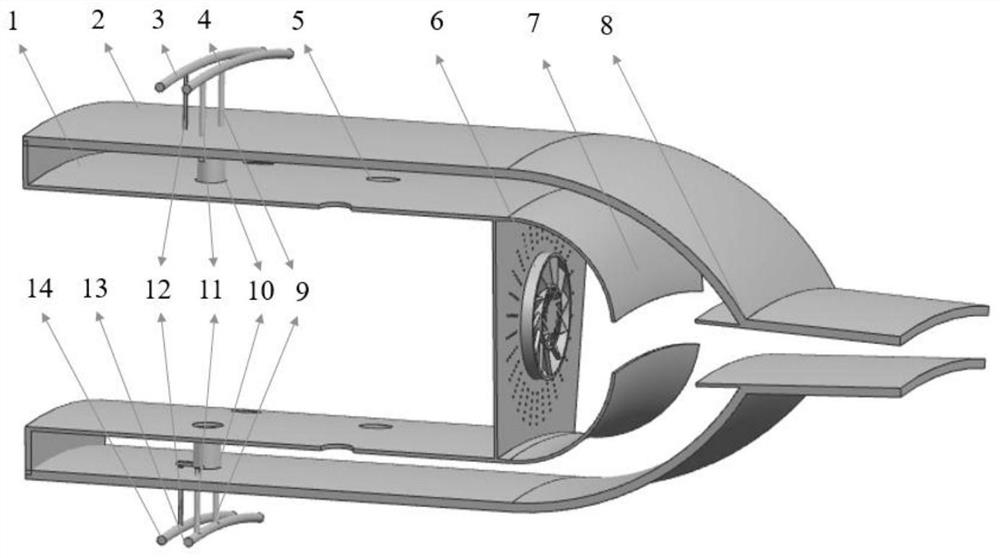

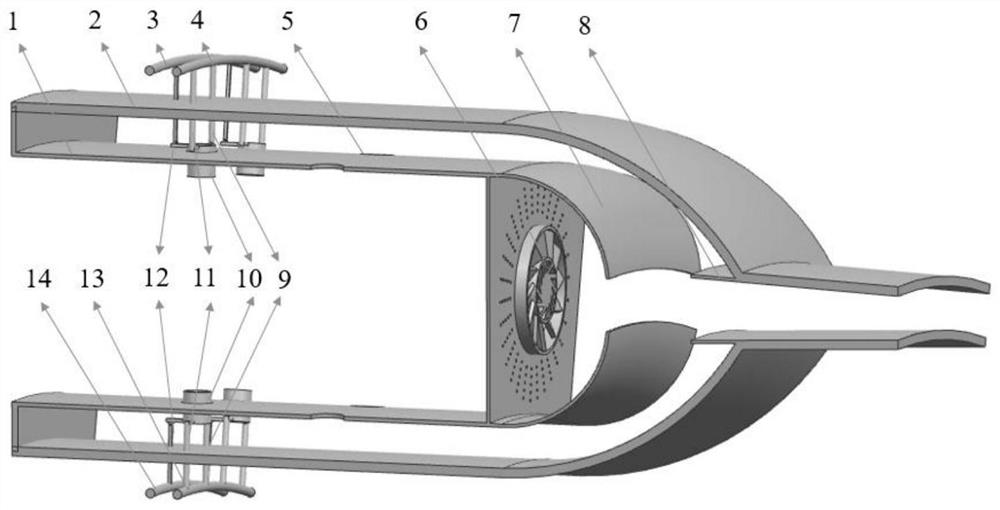

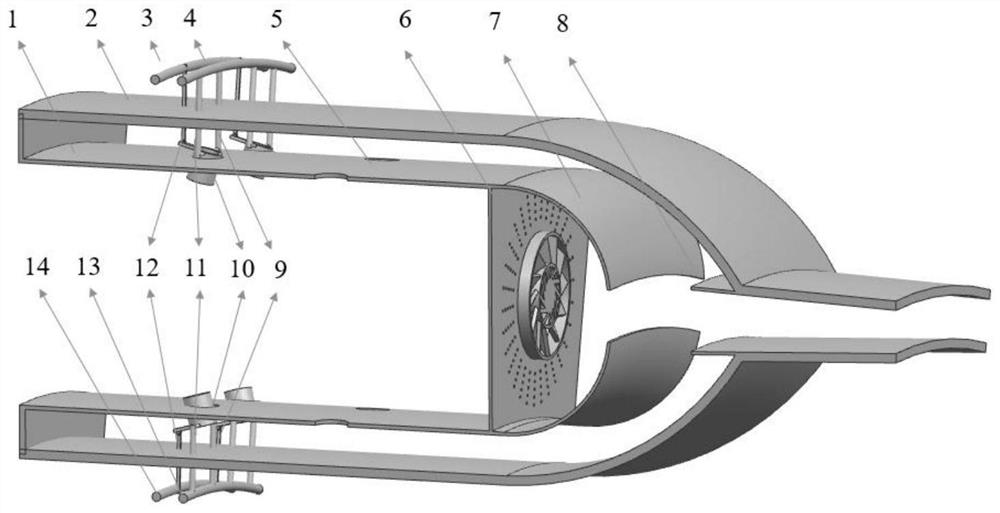

Blending hole adjustment system and method for adjusting combustion chamber outlet temperature distribution

ActiveCN111486477BImprove controllabilityIncreased Jet Penetration DepthContinuous combustion chamberCombustion chamberJet flow

The invention discloses a mixing hole adjustment system and method for adjusting the outlet temperature distribution of a combustion chamber, belonging to the field of gas turbine combustion; when the thrust is high, because the inlet temperature of the turbine guide is relatively high, the control terminal is based on the previously calibrated combustion chamber The corresponding relationship between the total pressure of the inlet air and the spatial attitude angle of the telescopic mixing hole is used to calculate the required spatial position of the telescopic mixing hole under the current working condition, and convert it into a hydraulic adjustment signal and transmit it to the mechanical structure. Rod and rotating rod, the insertion depth of the telescopic mixing hole is controlled by the extension of the telescopic rod, and the rotation angle of the mixing hole is controlled by the expansion and contraction of the rotating rod. The mutual cooperation of the two can change the jet penetration of the mixing hole The depth and jet inclination angle can achieve the purpose of adjusting the outlet temperature distribution of the combustion chamber, greatly increasing the service life of the turbine guide and reducing the design requirements of the turbine guide.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Chlorine forged steel stop valve

PendingCN110056659AImprove sealingGood truncation effectSpindle sealingsLift valveInlet channelMaterials science

The invention discloses a chlorine forged steel stop valve. The chlorine forged steel stop valve comprises a forged steel valve body. An inlet channel and an outlet channel are formed in the lower endof the forged steel valve body. A forged steel valve deck is arranged at the upper end of the forged steel valve body. A valve rod is arranged inside the valve body. The upper end of the valve rod isconnected with a hand wheel assembly, and the lower end of the valve rod is connected with a valve clack assembly. Sealing filler and a pressing plate are arranged between the valve rod and the forged steel valve deck. The hand wheel assembly comprises a dustproof cap, a hand wheel, a valve rod nut, a support flange and a flat key. The hand wheel is connected with the valve rod nut through the flat key. The dustproof cap is arranged above the hand wheel and further connected with the valve rod nut through a thread. The support flange and the valve rod nut are in axial rotating fit. The support flange is connected with the forged steel valve deck through a stand column. The valve clack assembly comprises a small valve clack and a large valve clack, and the diameter of the small valve clackis smaller than that of the large valve clack. A limiting slip cavity is formed in the large valve clack.

Owner:JIANGSU DINGSHENG VALVE

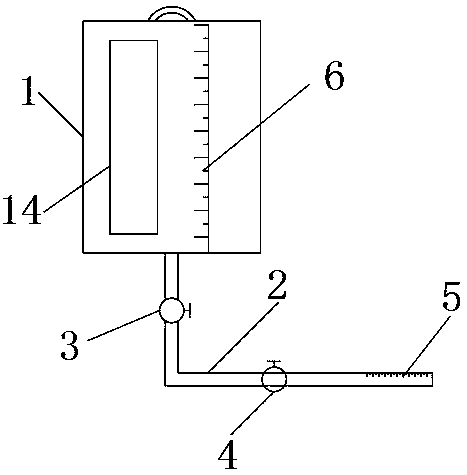

Thermosensitive accurate enema bag

PendingCN111467600AGood truncation effectEasy to observeCannulasEnemata/irrigatorsUrologyBiomedical engineering

The invention relates to the technical field of enema bags, in particular to a thermosensitive accurate enema bag. The thermosensitive accurate enema bag comprises an enema bag body, wherein an enemapipe is communicated with the enema bag body, a valve I and a valve II are mounted on the enema pipe, and a thermosensitive patch is attached to the enema bag body. When the thermosensitive accurate enema bag is used, the truncation effect of the enema pipe is improved through the two valves, the incomplete truncation condition is avoided, truncation operation with a pair of haemostatic forceps isavoided, and a thermosensitive patch made of a thermosensitive material is added to the enema bag body and can change the color with change of temperatures, so that a medical worker conveniently observes.

Owner:朱爱林

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com