Automatic butt-joint positioning and cutting-off structure for concrete pile head

An automatic docking and concrete technology, which is applied in the direction of foundation structure engineering, sheet pile walls, stone processing tools, etc., can solve the problems that affect the construction progress and construction quality, prone to deviation, irregular sectional surfaces, etc., and achieve the overall stripping chisel removal Good quality, good crushing, peeling and truncation, avoiding the effect of excessive truncated length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

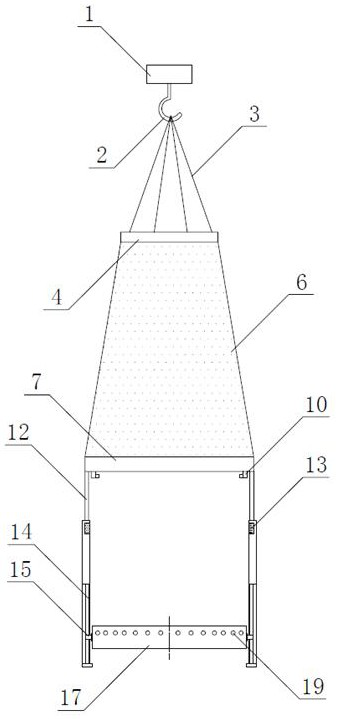

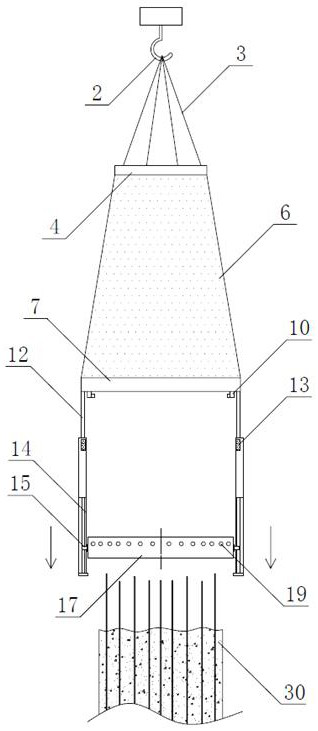

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0028] see Figure 1 to Figure 8 , a concrete pile head automatic docking positioning and truncation structure of the present invention, comprising a hanger 1, a hanger 2, a wire rope 3 and a hanger ring 4, the lower end of the hanger 1 is equipped with a hanger 2, and the hanger 2 passes through the wire rope 3 It is connected with the hanging ring 4 located below, and it is characterized in that: the lower end of the hanging ring 4 is fixed to the small mouth end of the positioning cone 6, and the lower part of the large mouth end of the positioning cone 6 is fixed with a fixed ring 7, and the hanging A connector 5 is fixed in the ring of the ring 4, the lower end of the connector 5 is located on the axis of the positioning cone 6 and is connected to the top of the vertical support rod 8 through a ball joint hinge shaft, and the mid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com