Welding Chopping Knife

A technology of chopper and inclined surface, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of reducing the bondability of filaments and wires, poor peeling of joints, and poor peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

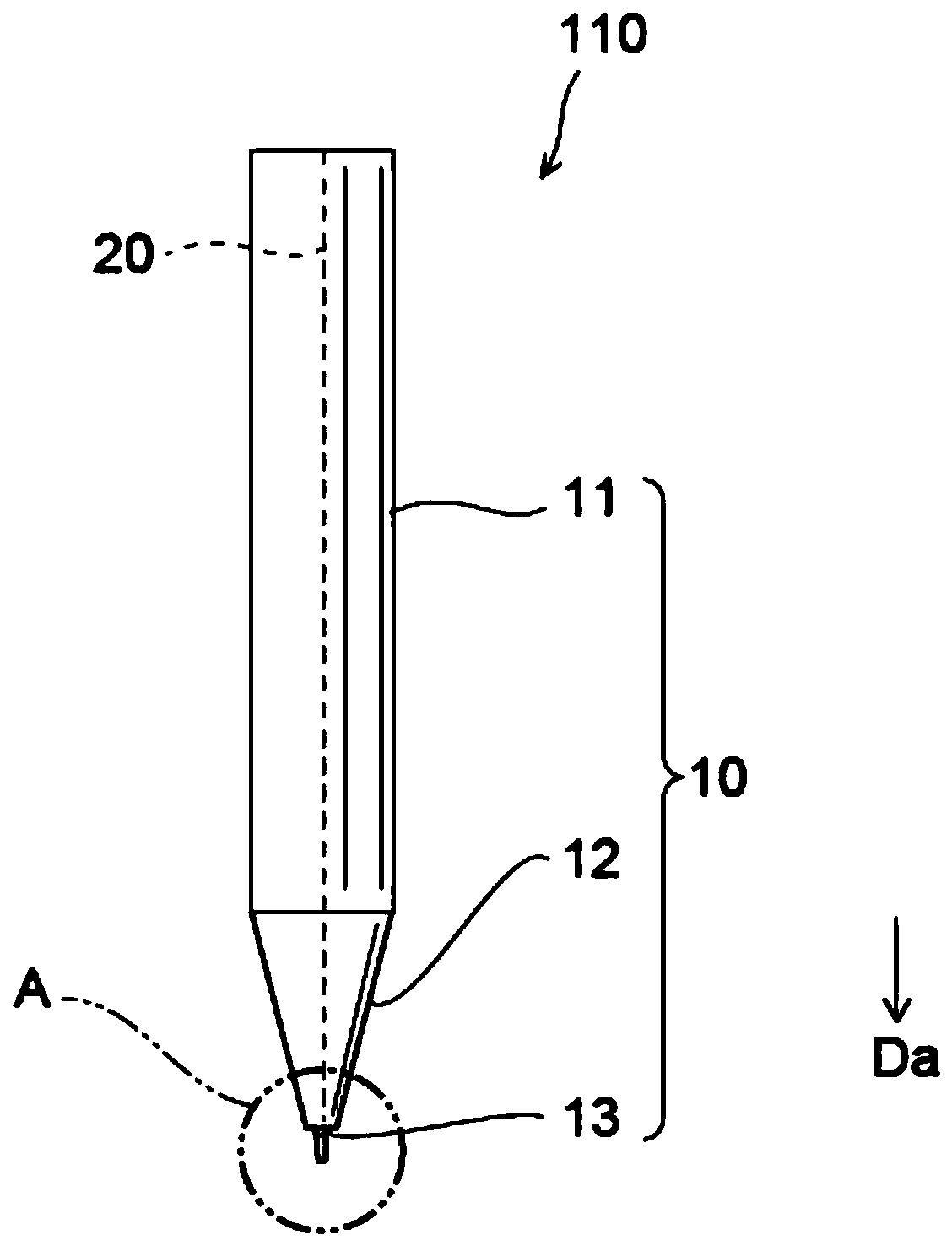

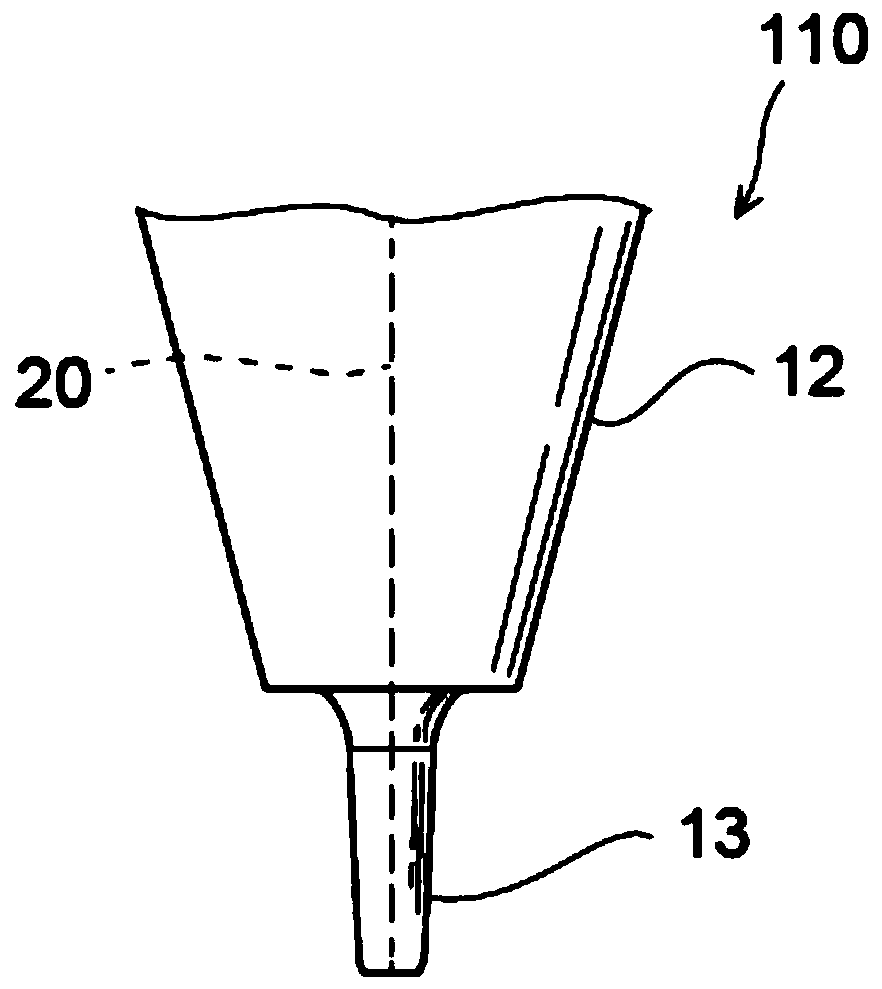

[0055] figure 1 It is a schematic diagram illustrating the welding capillary according to this embodiment.

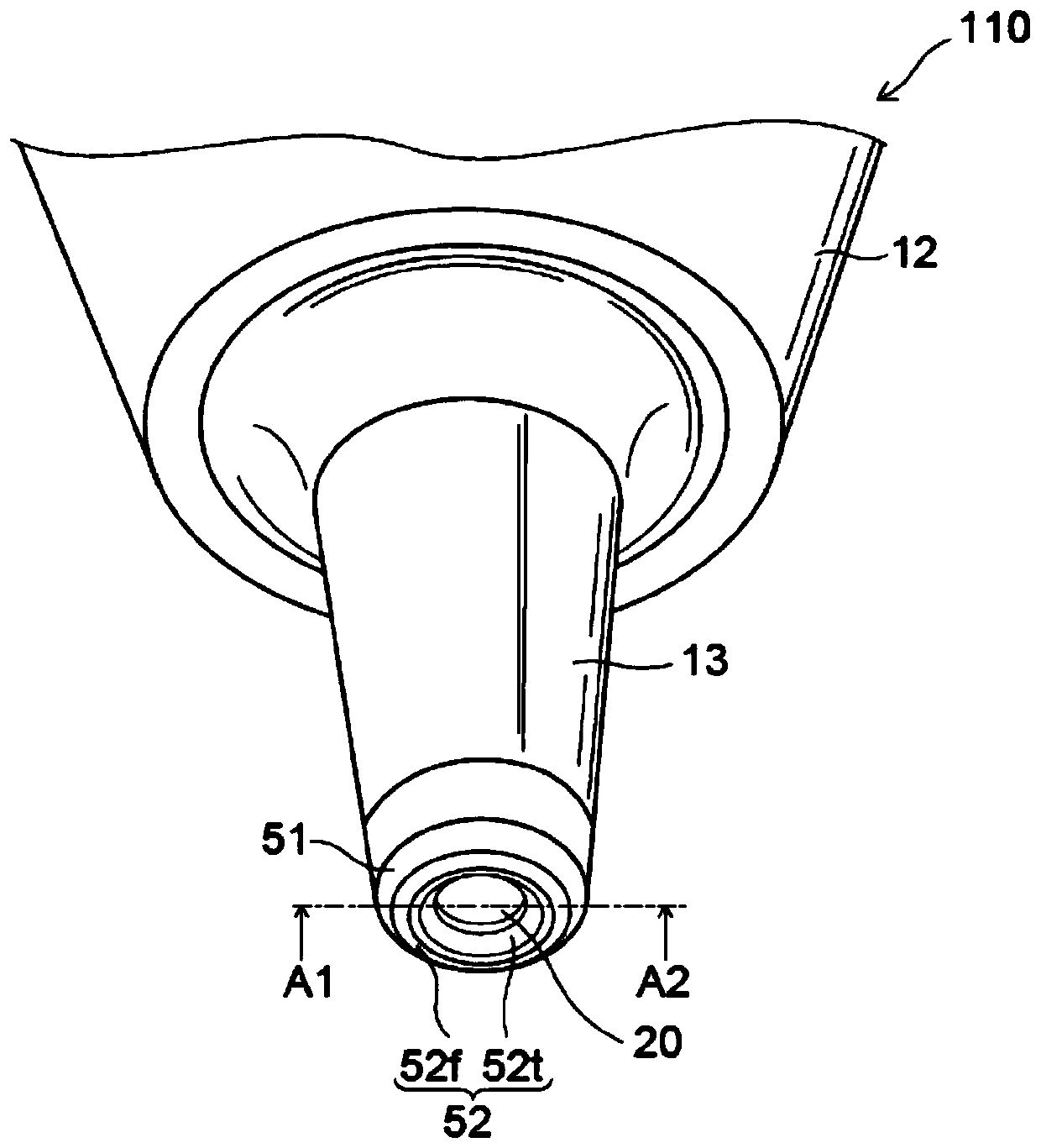

[0056] figure 2 It is a schematic enlarged view illustrating the tip shape of the welding capillary according to this embodiment.

[0057] figure 1 The welding capillary 110 as a whole is shown in . figure 2 is shown in the magnified figure 1 A diagram of area A is shown.

[0058] Such as figure 1 As shown, a welding capillary (hereinafter, sometimes referred to as “capillary”) 110 has a main body portion 10 . The main body portion 10 is a cylindrical member and has a through hole 20 . The through hole 20 is a through hole extending in the axial direction Da of the main body portion 10 . When using a riving knife, the thread passes through the through hole 20 .

[0059] The body part 10 is provided with: a cylindrical part 11 ; a conical part 12 provided on the front end side of the cylindrical part 11 ; and a bottle neck 13 provided on the front end side of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com