Gas-insulated switch

A gas-insulated switch, gas technology, applied in electrical switches, high-voltage/high-current switches, electrical components, etc., can solve problems such as spending a lot of labor and time on permanent magnets, not suitable for effectively rotating and driving arcs, and hindering the miniaturization of devices. , to achieve the effect of improving truncation performance, low operating force and stable truncation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

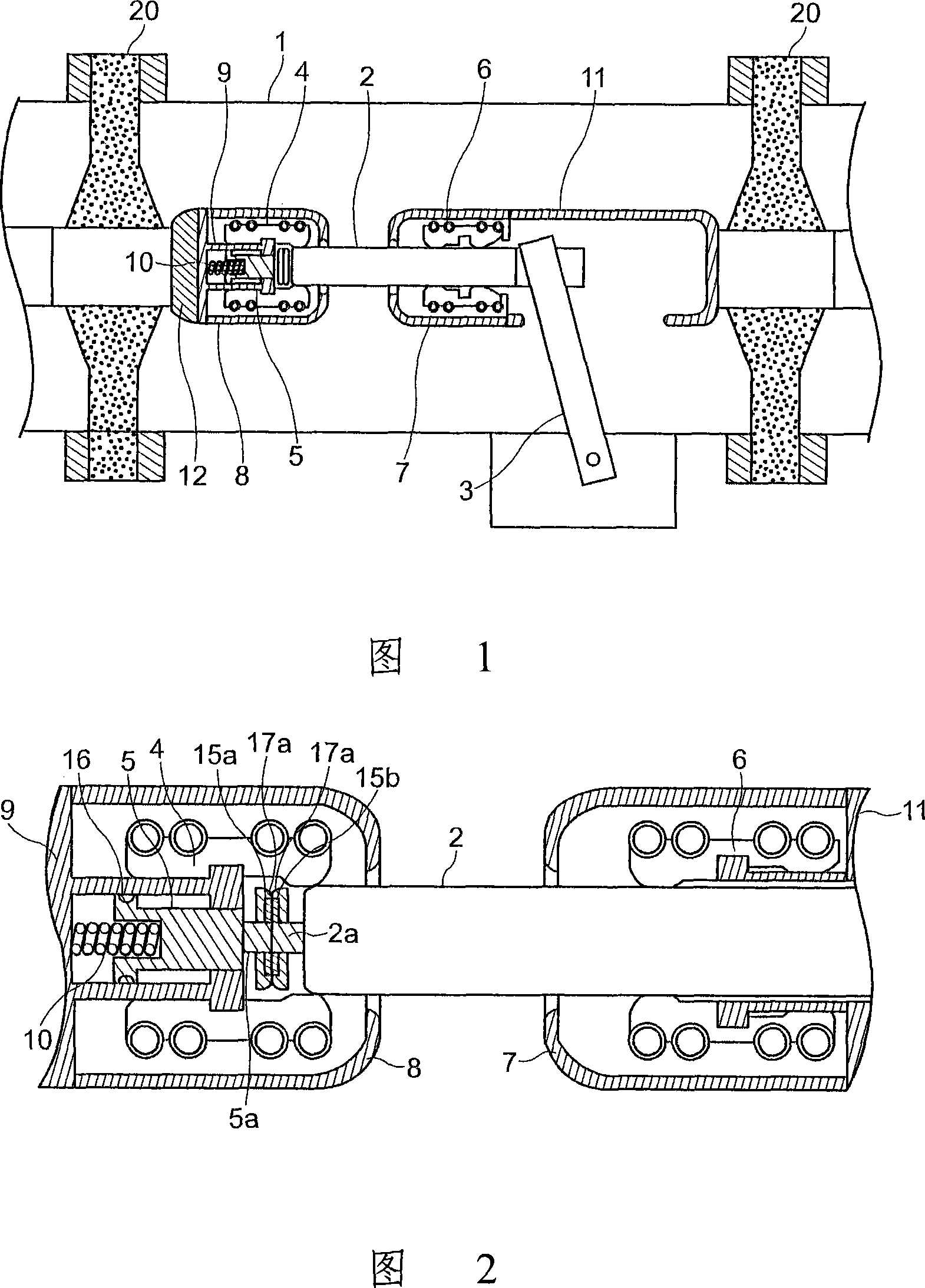

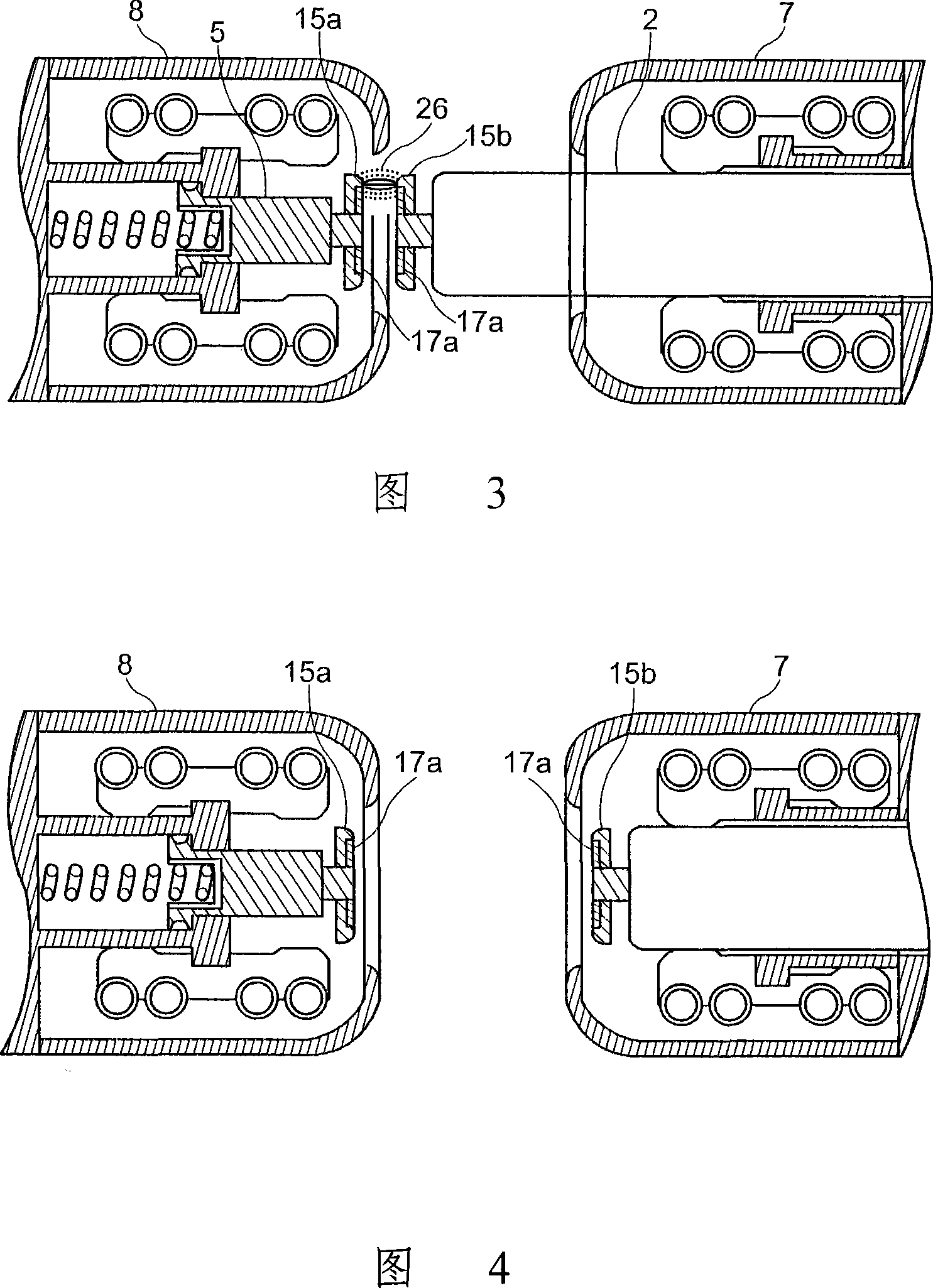

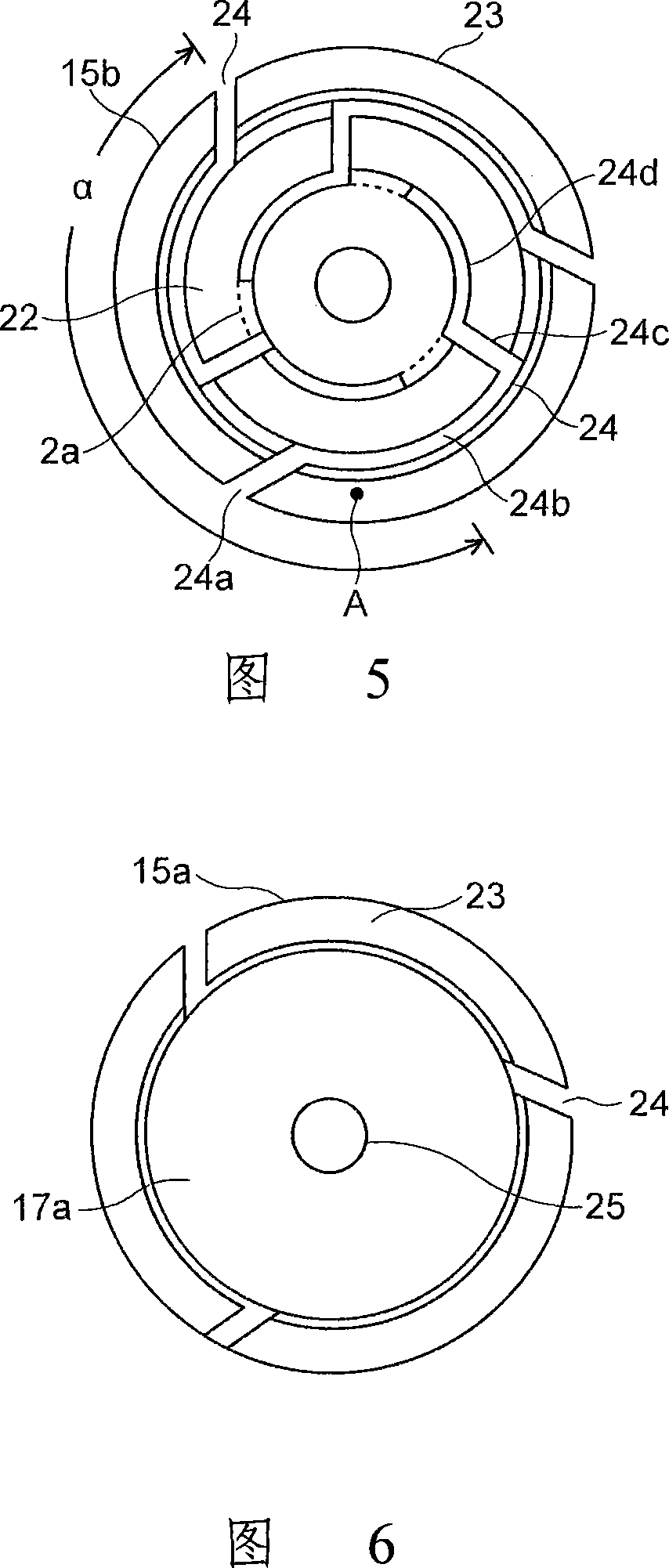

[0029] Next, first, a gas insulated switch as an example of the present invention will be described with reference to FIGS. 1 , 2 and 5 .

[0030] The electrode closed state of the gas insulated switch of the present invention is shown in the sectional view of FIG. 1 . In the airtight container 1, a gas region is formed by an insulating gasket 20. In this gas region, as an insulating gas, SF 6 Negative gas such as gas, dry air, nitrogen, carbon dioxide, SF containing negative gas 6 / N 2 Mixed gas, N without negative gas 2 / O 2 mixed gas etc.

[0031] Among the conductors embedded in the central part of the insulating gasket 20, the movable side and the fixed side high voltage conductors 11, 12 are respectively supported and fixed in a state of being electrically insulated from the airtight container 1, and are separated from each other by a predetermined insulation distance. On the opposing parts of the high voltage conductors 11, 12, seals 7, 8 for electric field relaxat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com