Method for producing cutter teeth of spiral bevel gear with spherical involute profile of tooth tapered tooth

A technology of spherical involute and spiral bevel gears, which is applied to gear tooth manufacturing tools, gear tooth manufacturing devices, gear cutting machines, etc., and can solve problems such as inability to obtain spherical involute tooth profiles, increased noise, and manufacturing difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

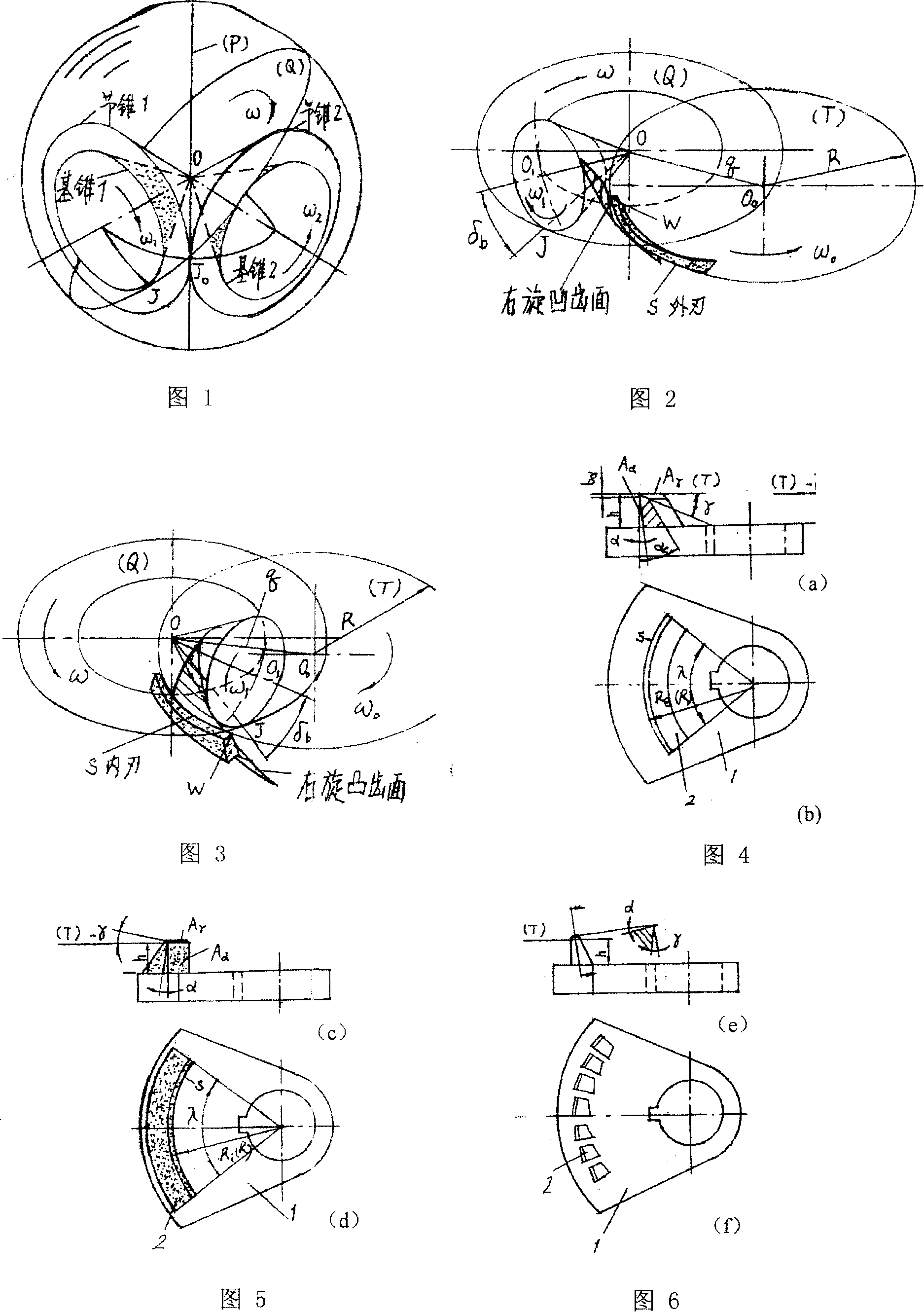

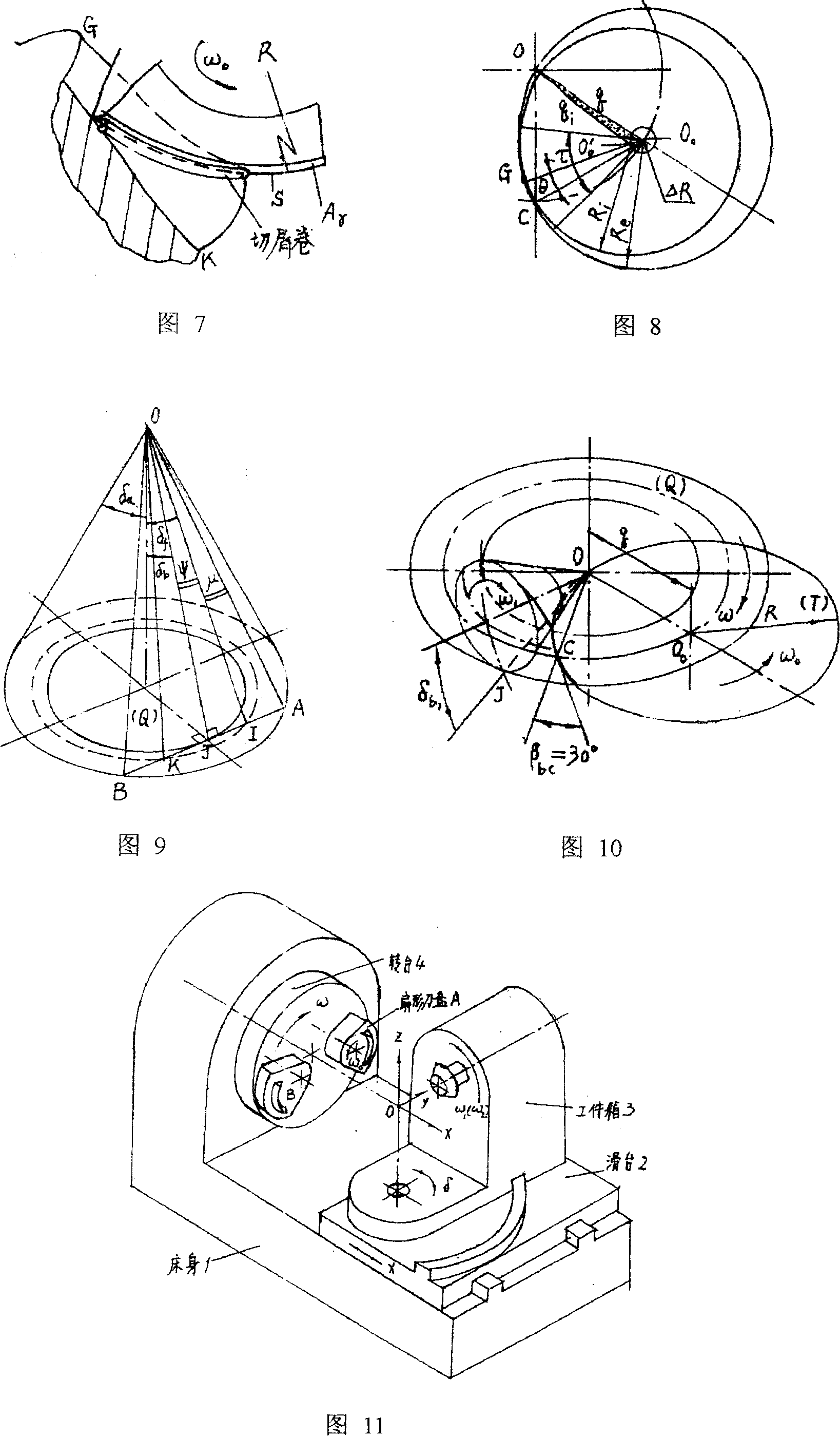

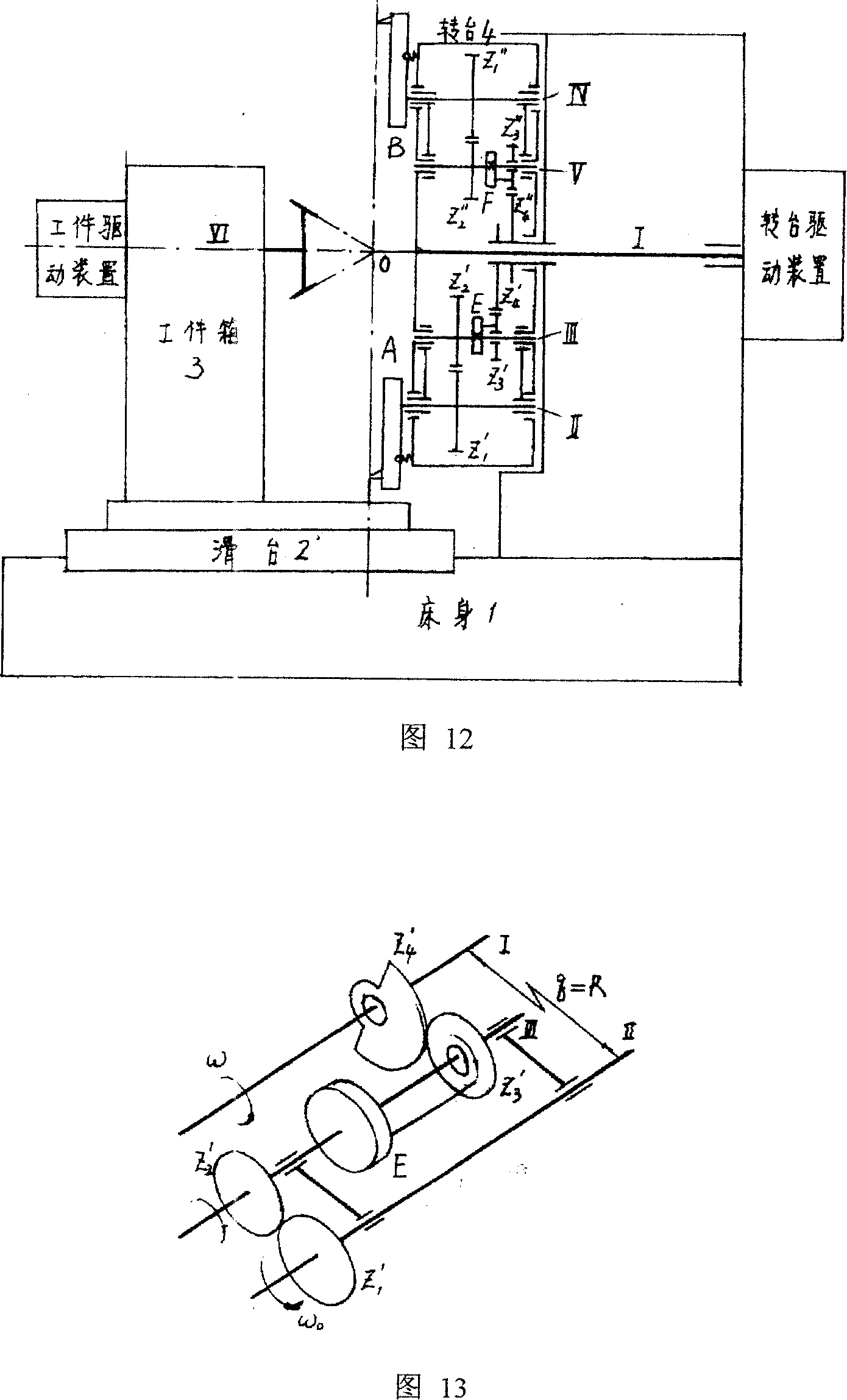

[0057] Press R=q and Z Q * Definite principle implements the machine tool of gear cutting method of the present invention to show in accompanying drawing 11,12,13, and lathe layout is the same as traditional layout, by bed 1, slide table 2, workpiece box 3, turntable 4, fan-shaped outer edge cutterhead A, fan-shaped interior The blade cutter disc B and other components, the workpiece box 3 rotates around Z, satisfying δ b The adjustment; the sliding table 2 is adjusted along the X axis to meet the tangent between the base cone and the (Q, T) plane; when the rough milling cutter is used to mill the tooth groove, the full tooth height can be gradually milled according to the X axis direction feed In order to reduce the load of the milling cutter teeth; the gear blank axis VI is given ω by the workpiece driving device 1 , ω 2 The movement of the turntable is composed of a planetary gear train, where Z' 4 ,Z" 4 It is a sun gear (fixed when cutting teeth, loosen to adjust the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com