Engine crankcase bearing block splitting working method and apparatus

A crankcase and processing device technology, which is applied to crankshaft bearings, engine components, machines/engines, etc., can solve the problems affecting the machining accuracy of cracking grooves and is not suitable for the production of multiple varieties, so as to save broaching process and small deformation , to reduce the effect of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The method and device of the present invention will be further described in detail in the following embodiments given in conjunction with the accompanying drawings.

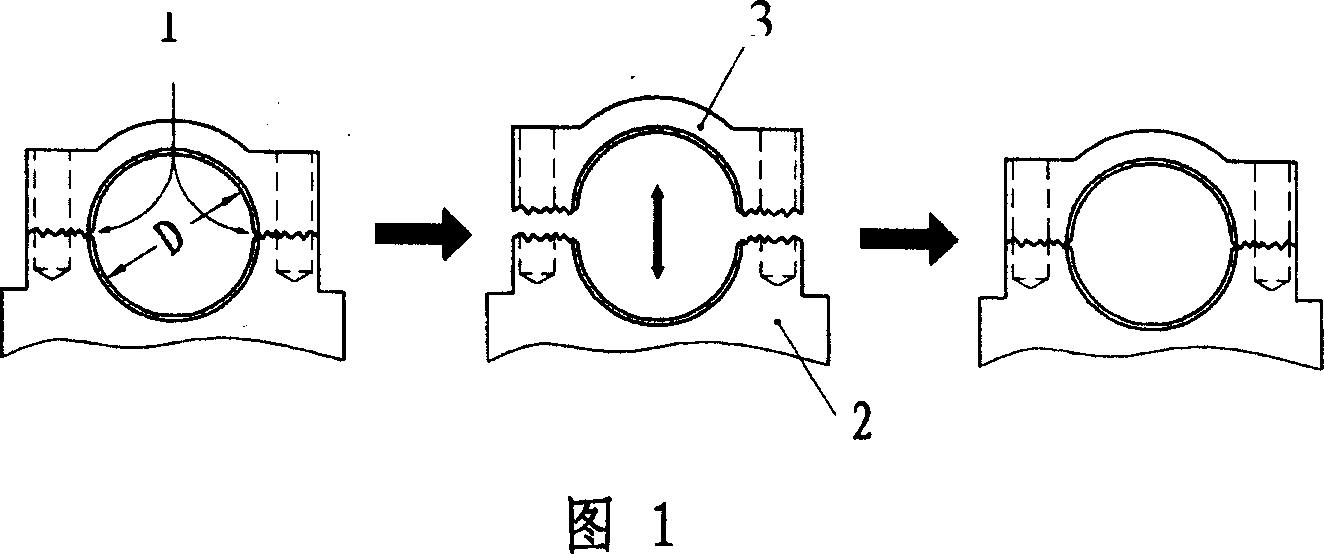

[0023] The engine crankcase bearing block cracking processing method of the present invention, carry out according to the following steps:

[0024] The back pressure mechanism composed of the compression block 8, the back pressure support 13, etc. goes down, and the compression block 7 exerts back pressure on the bearing cover 3 through the back pressure spring 9.

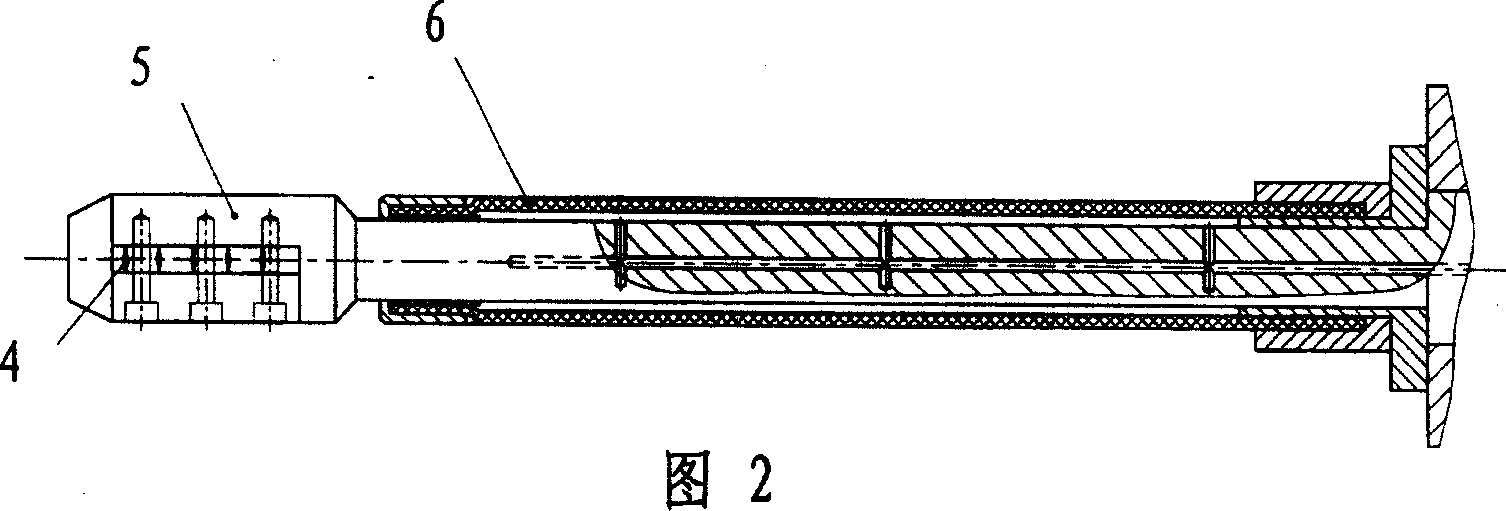

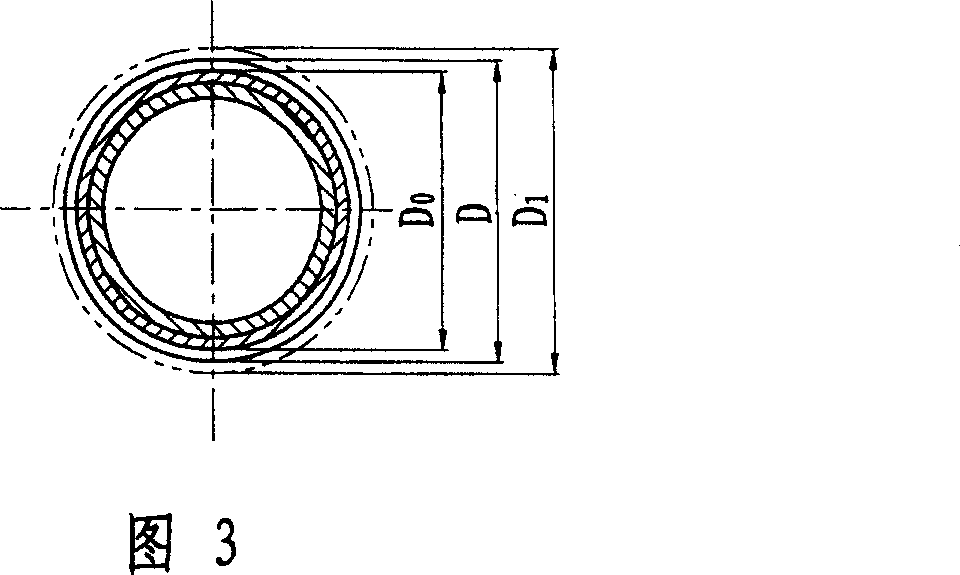

[0025] Under the action of the horizontal hydraulic cylinder 17, the slider body 15 and the broach bar 5, the outer diameter is D 0 The high-pressure hose 6 is inserted into the bearing hole with a diameter D from the initial position, and the broach 4 completes the processing of the initial cracking groove 1.

[0026] The high-pressure oil pressurized by the booster cylinder 16 enters the high-pressure hose 6, and the inner high pressure caus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com