Belt conveyor automatically detecting and adjusting tension

A belt conveyor, automatic detection technology, applied in the direction of conveyors, conveyor objects, conveyor control devices, etc., can solve problems that affect production efficiency, belt elongation, and unfavorable real-time grasp of belt conveyor production conditions, etc. , to achieve the effect of ensuring production process parameters and simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

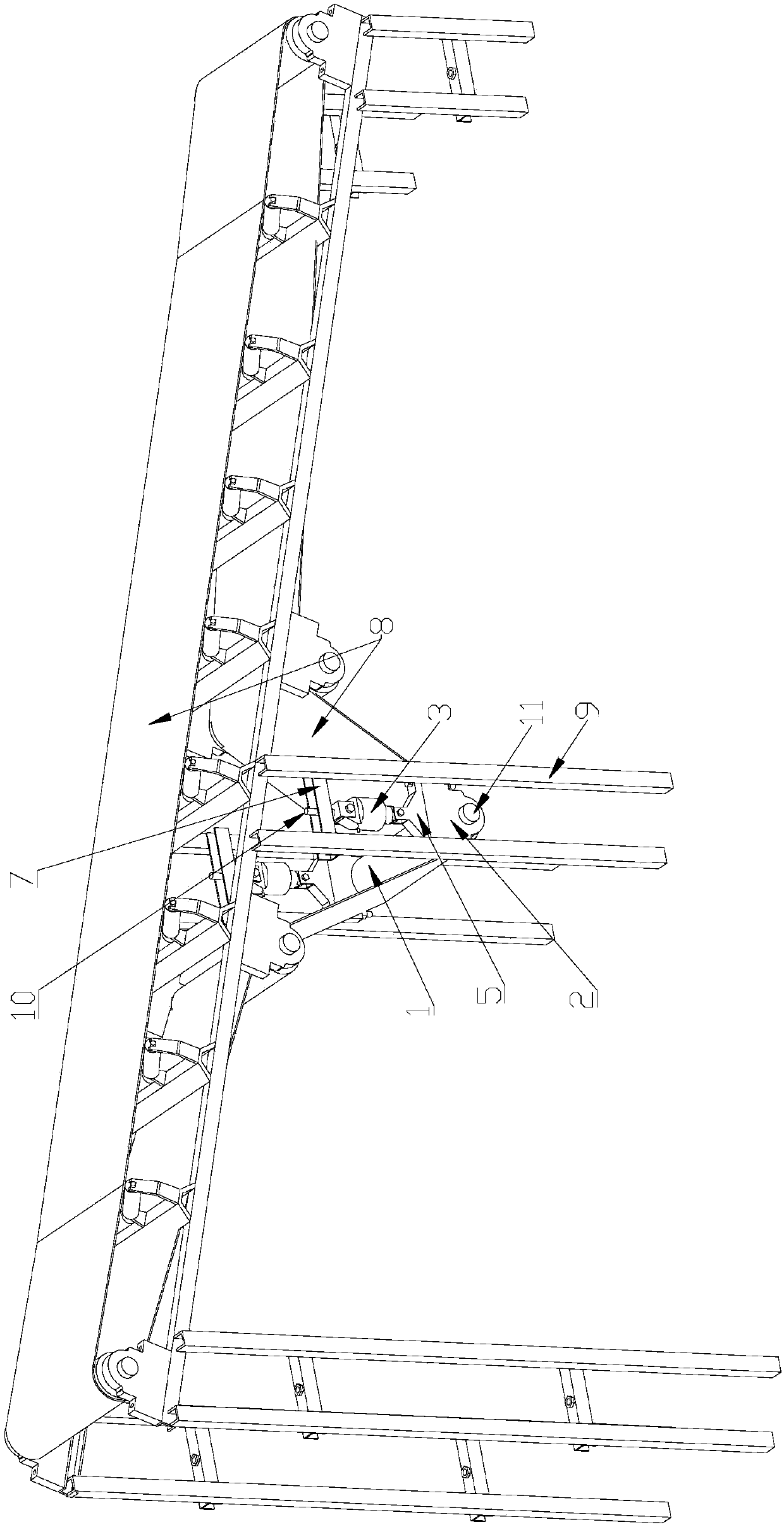

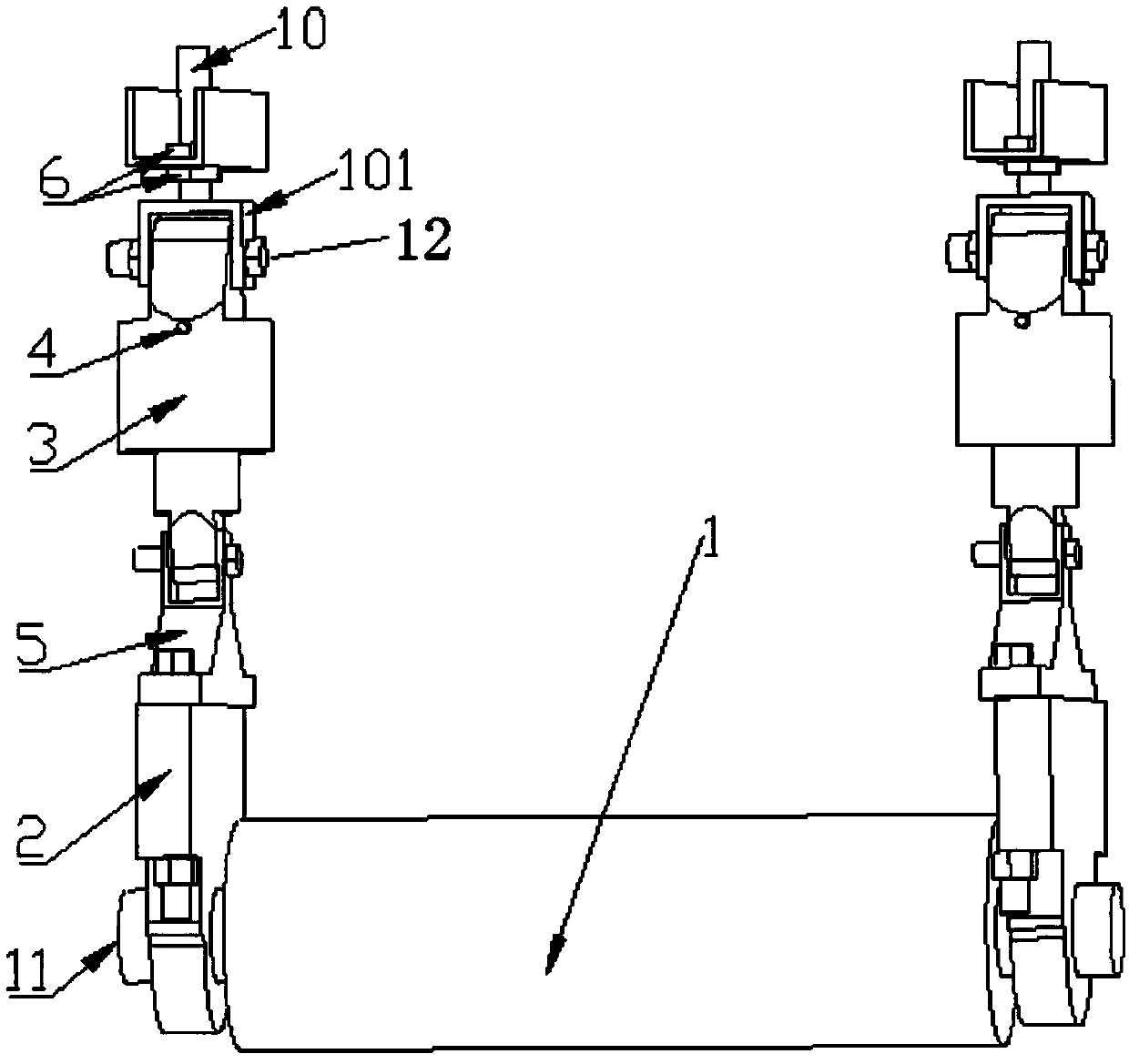

[0030] like Figure 1 to Figure 4 , a belt conveyor that automatically detects and adjusts tension, including a frame 9, a belt 8, a tensioning pulley 1, and a shaft lug 2 connected to the frame 9, and the bottom of the shaft lug 2 is provided with a shaft hole, so The shaft parts 11 at both ends of the tensioning wheel 1 are respectively rotatably connected in the shaft holes of the shaft lugs 2 on both sides, which are characterized in that:

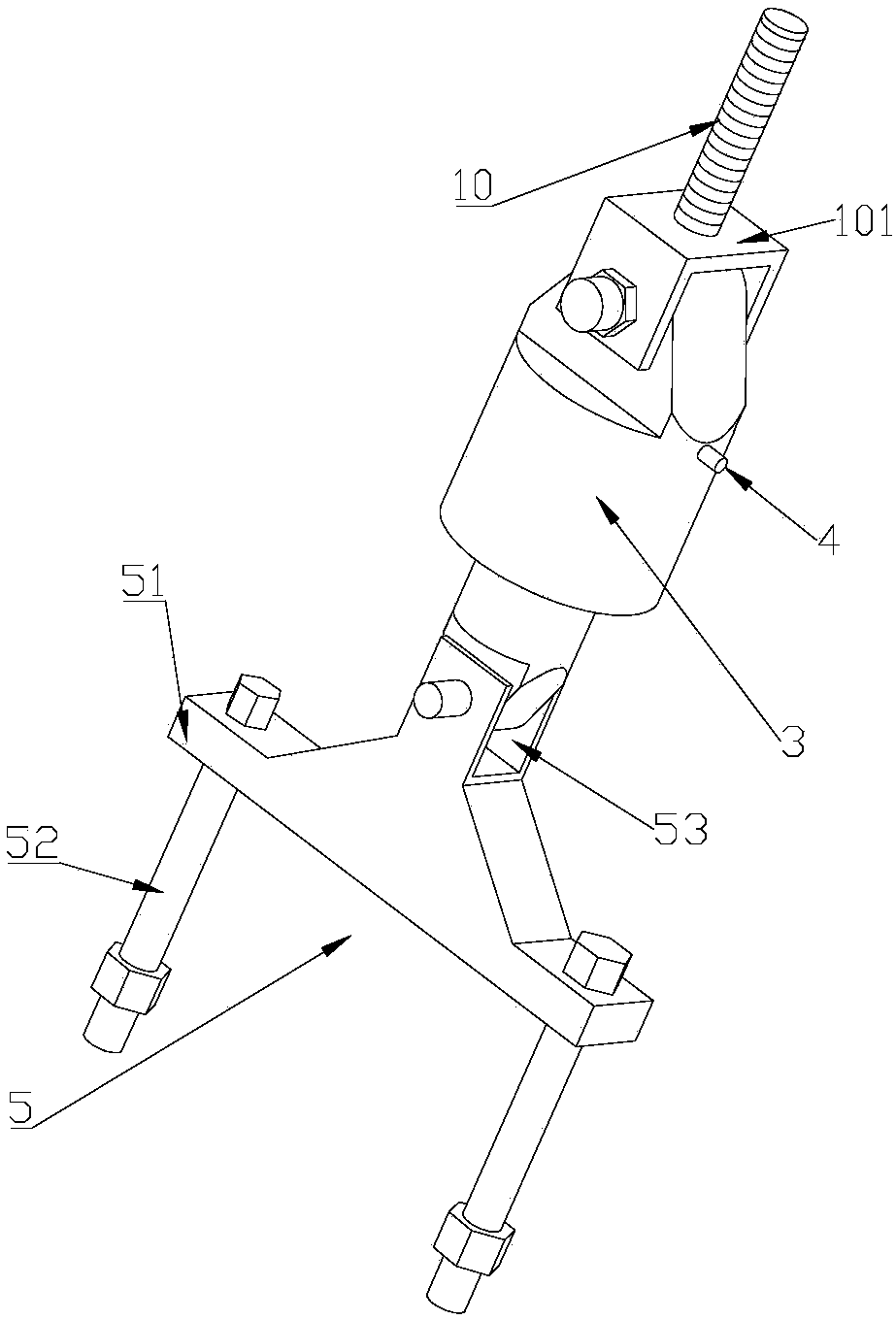

[0031] It also includes a tension detection and adjustment device. The tension detection and adjustment device includes a control system, a servo hydraulic cylinder 3 with a hydraulic pressure sensor 4, a screw device 10 including at least a screw part, a connecting flange 5, and a frame fixed on the frame 9. A fixing device 7, and the fixing device 7 is located above the tensioning wheel 1;

[0032] The top end of the shaft lug 2 is fixedly connected to the bottom end of the flange 5, the top end of the connecting flange 5 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com