Reeling machine

A technology of a winding machine and a winding mechanism, which is applied in the field of battery cell manufacturing equipment, can solve the problems such as insufficient tension control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

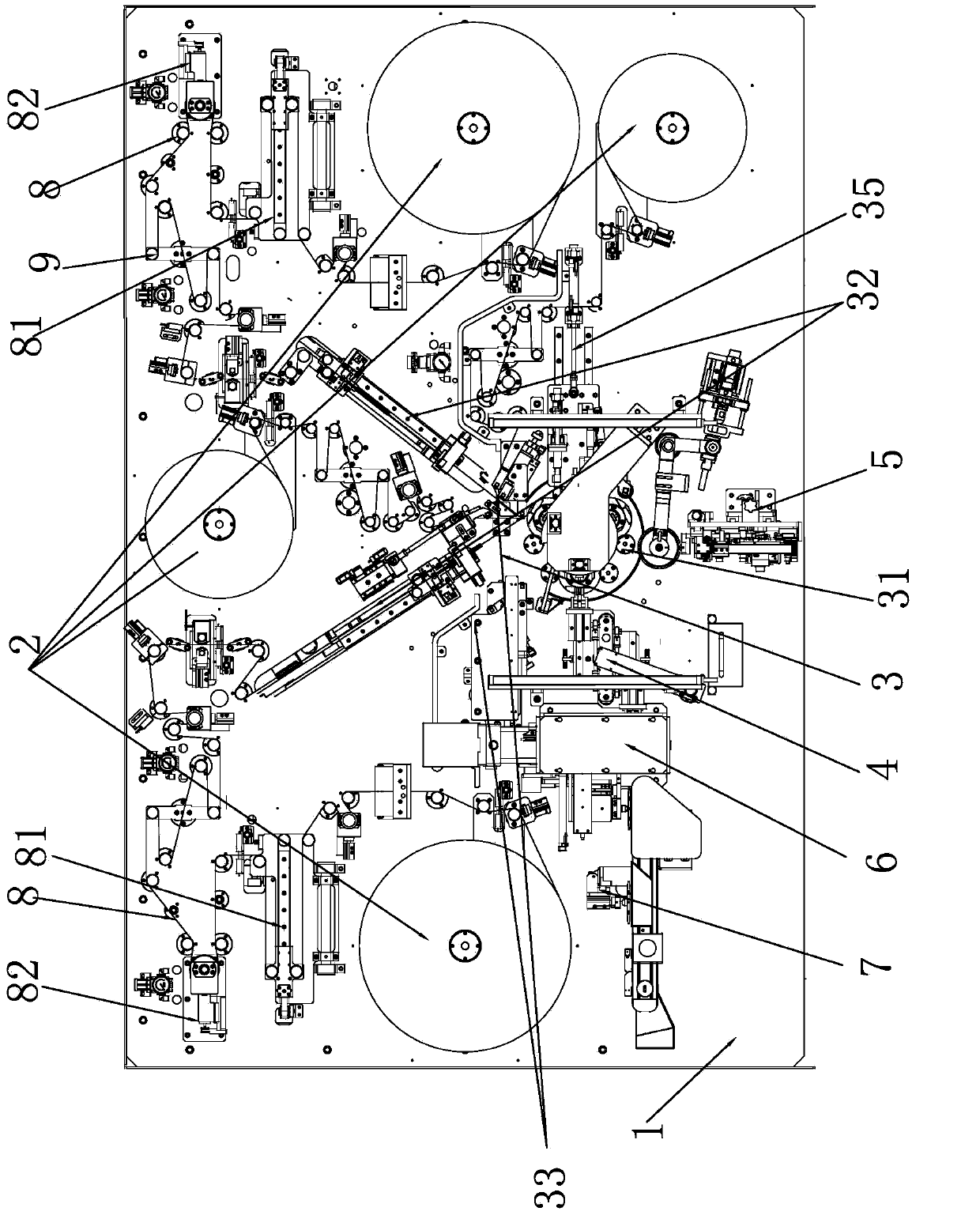

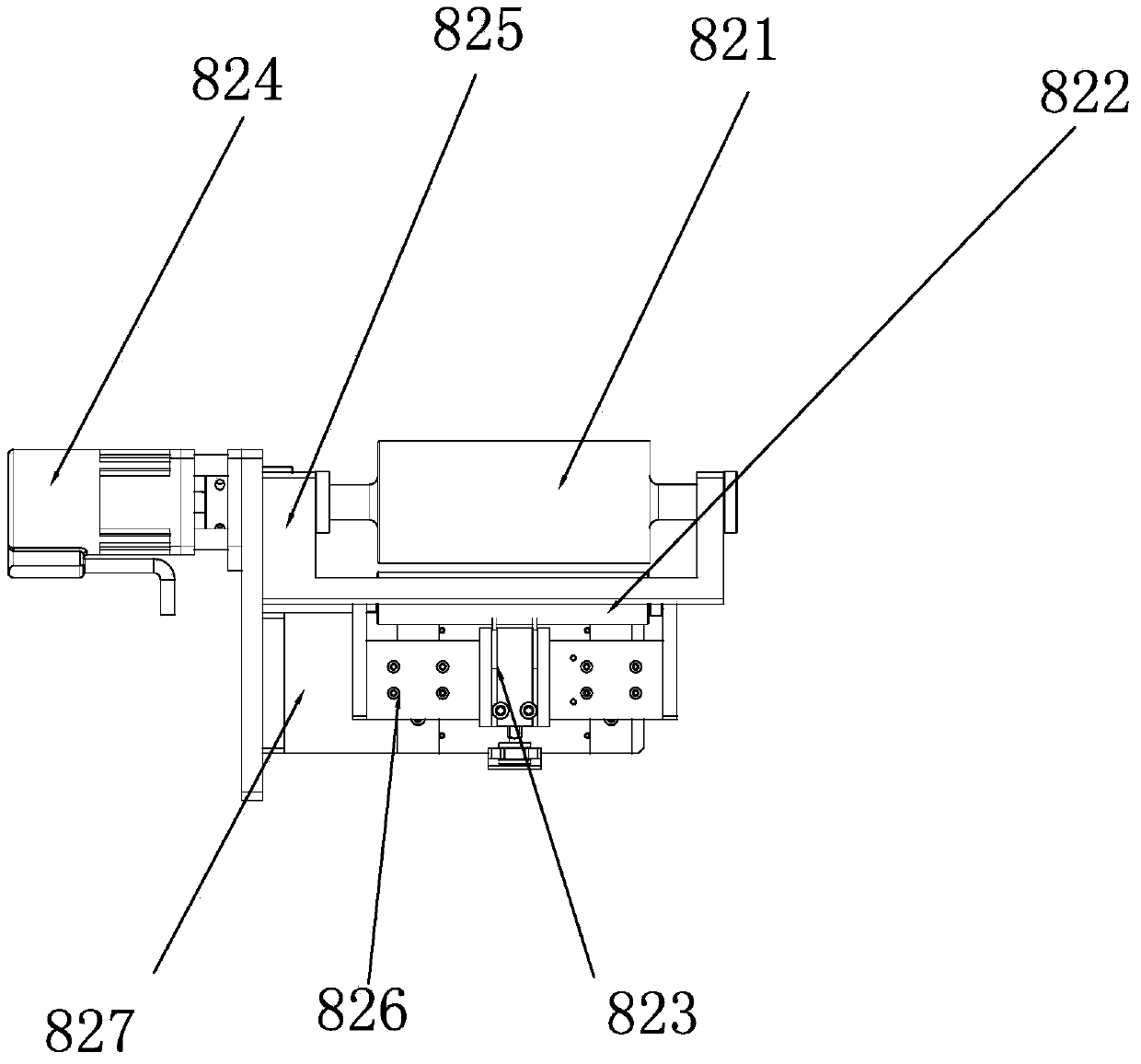

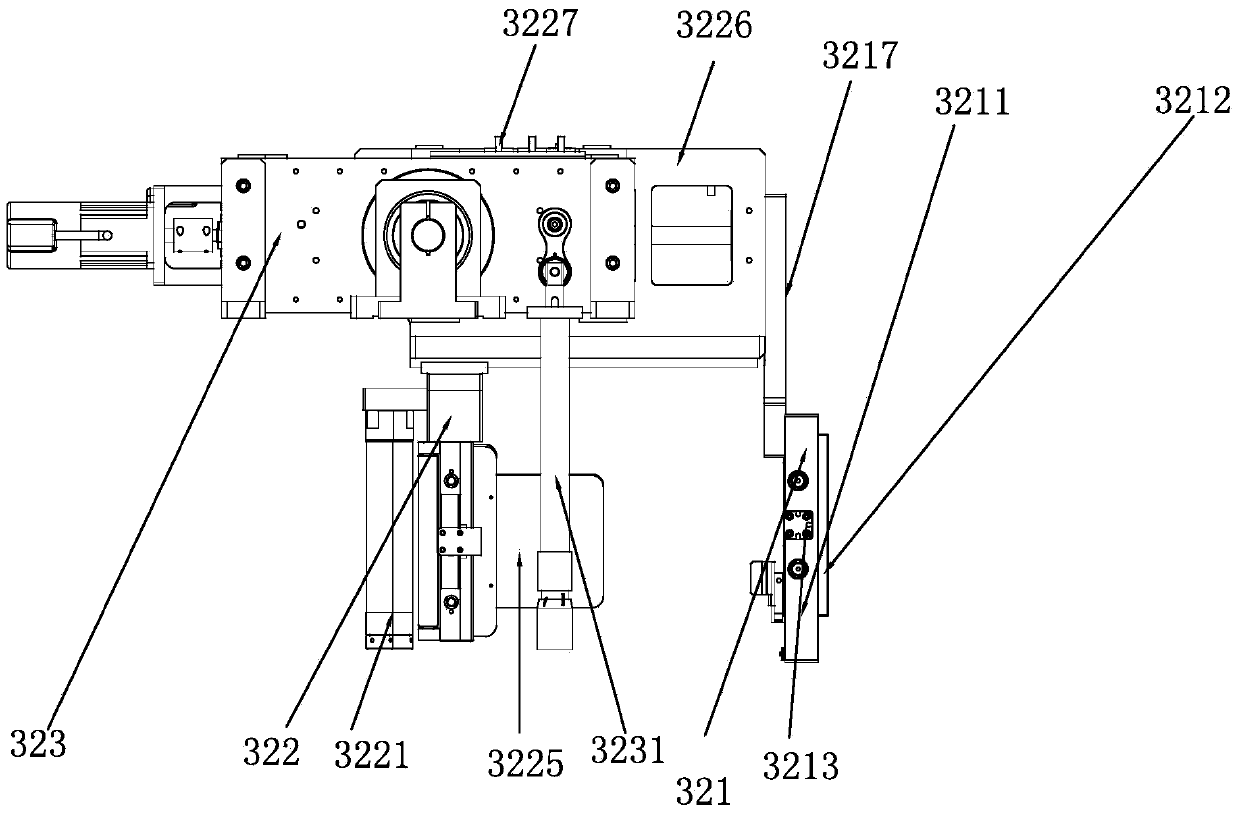

[0026] refer to figure 1 According to a preferred embodiment of the present invention, the winding machine includes a frame assembly 1, an unwinding mechanism 2, a winding mechanism 3, a blanking mechanism 4, a glue application device 5, a short circuit detection device 6, a defective product removal device 7 and a tension Control mechanism 8, the unwinding mechanism carries out the unwinding of positive and negative electrode sheets and the diaphragm unwinding, and a control unit is set at the unwinding mechanism to control the unwinding speed by calculating the diameter of the roll; the winding mechanism includes a winding head 31, an input Sheet device 32, pre-rolling assembly 33, diaphragm cutting and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com