Wind turbine blade structure, machining method and applications thereof

A technology of wind turbine blades and blades, which is applied in the field of wind turbine blade structure, and can solve problems such as scrapped blades, hidden dangers of blade strength, and increased blade costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0101] A 38m long blade, the main beam design is composed of unidirectional glass fiber cloth reinforced epoxy resin composite material, the main beam width is 310mm, the single layer cloth thickness is 0.9mm, and the density is 1950kg / m 3 , the thickest layer is 50 layers. I 1 =2354062.5mm 4 , the moment of inertia generated in the shimmy direction (perpendicular to the blade axis) is I 2 =111716250mm 4 .

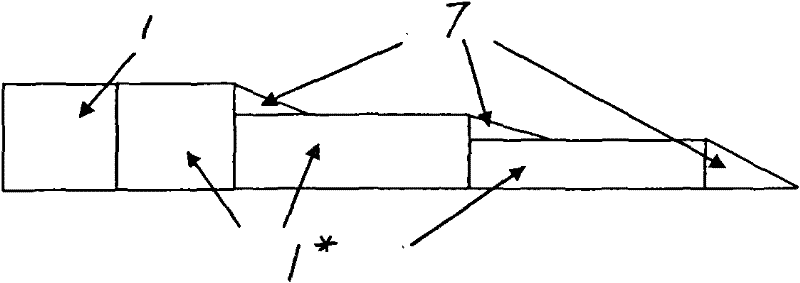

[0102] Now, the specific gravity is 60kg / m 3 The PVC foam material is pre-processed into Figure 9 The trapezoidal column shown, the upper bottom width of the trapezoidal column (wedge column 1') b=105mm, the included angle θ=60°, and the column height h=50mm. Based on this, the lower bottom width of the trapezoidal column is calculated to be 162.7mm. Column 1' is combined with unidirectional fabric wrapping identical to the current design Figure 10 The section shown, wherein, the bottom layer 2' (bottom fiber cloth), inner cladding layer 3' (inner fiber cloth) and...

Embodiment 2

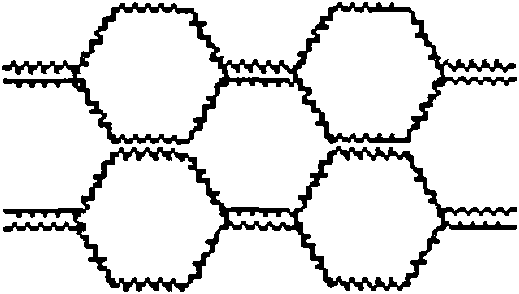

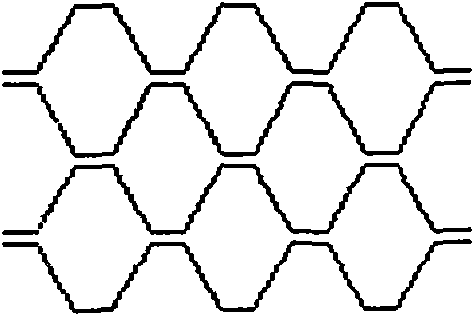

[0105] For the main beam structure of the blade in the above-mentioned embodiment 1, a 3mm thick axial bamboo sliced slat is adopted, the slat width is 160mm, and the slat axial modulus of elasticity E 1 =12GPa, its specific gravity ρ=800kg / m 3 ,according to Figure 6h Bonding shown, the interior angle of the triangular wedge 1" is 60°, resulting in Figure 16 The honeycomb cell cross-section beam shown has the same beam length as the main beam of the thickest section of the blade, and is closed at both ends. According to the geometric dimensions of the given section, it is not difficult to calculate the moment of inertia in the waving direction of the section as I′ 1 =15672897.3mm 4 , The moment of inertia in the shimmy direction is I′ 2 =100882233.3mm 4 . When used as the main beam of the blade, lay two layers of unidirectional cloth on the bottom skin layer foundation, that is, the bottom layer is 2” (bottom fiber tape), and the thickness of the single layer is 0.9m...

Embodiment 3

[0108] The outer diameter of the root circle of a 38m-long blade is D=1890mm, the root circle is 1m long, including the embedded bolt sleeve at the root, and the weight of the 1m-long blade section at the root is 888kg. The bending stiffness distribution along the two orthogonal axes is shown in Figure 11 (marked as the current structure in the figure).

[0109] The design of the blade root section of the present invention is described as follows.

[0110] 1. Raw materials (0° direction along the blade axis)

[0111] (1) Triaxial cloth [+45° / 0° / -45°], single-layer thickness 0.87mm, after RIM dipping, the modulus of elasticity along the axial direction of the blade is E=25.5GPa, density=1950kg / m 3 , code A;

[0112] (2) Unidirectional fabric [0°], single layer thickness 0.9mm, elastic modulus E along blade axial direction after RIM dipping 1 =39.5GPa, transverse elastic modulus E 2 =14GPa, shear modulus G 12 =14GPa, Poisson's ratio μ 12 = 0.21, density = 1950kg / m 3 , co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| elasticity | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com