Screen plate aluminum frame capable of adjusting and enhancing fixing effect

A technology of screen plate and aluminum frame, which is applied in the field of specific devices and can solve problems such as failure of aluminum frame, shrinkage deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

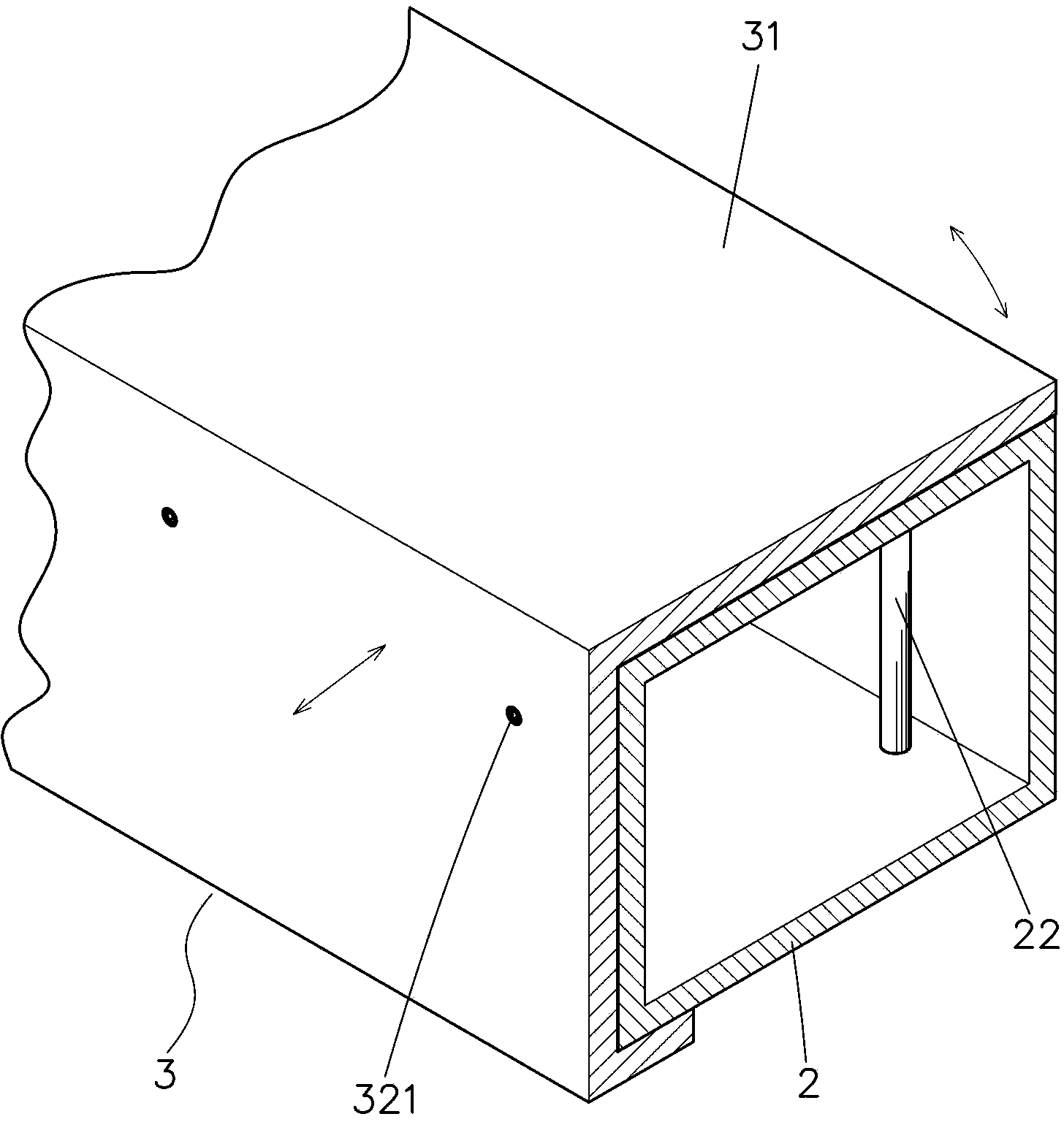

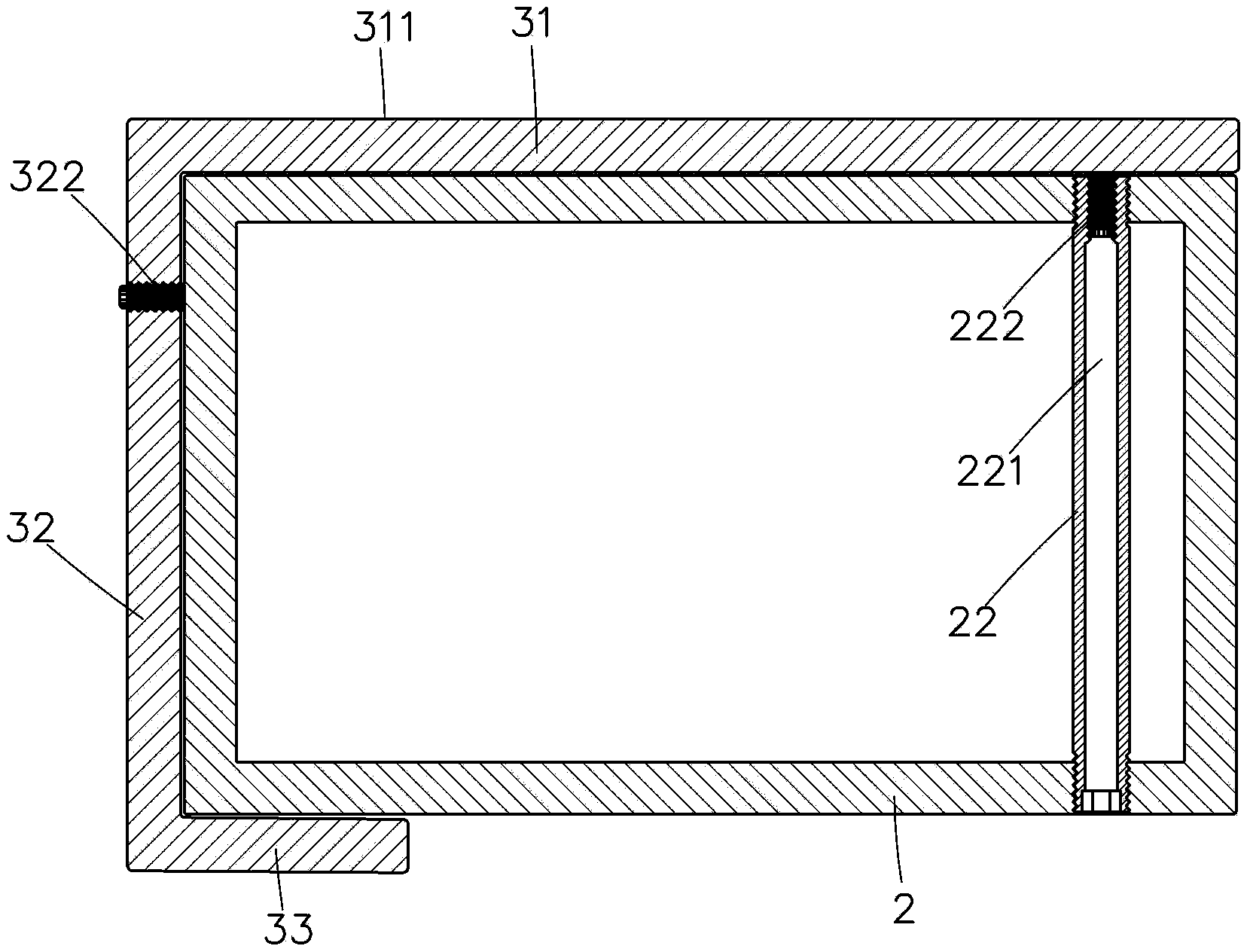

[0060] The present invention has a screen aluminum frame that adjusts and improves the holding effect, and the applicable printing screen aluminum frame includes: such as figure 2 and Figure 20 Shown is a rectangular hollow screen aluminum frame 1 formed by four aluminum extruded hollow aluminum pipe sections 2 articulated by argon welding; and as shown Figure 5 and Figure 21 The shown solid metal screen frame 1A is integrally formed by a compression mold and has solid sections 2A on each side in a rectangular shape.

[0061] ginseng Figure 1 to Figure 5 As shown, the main technical principle of the adjustable printing screen aluminum frame of the present invention is that a hollow aluminum tube section 2 or a solid section 2A on each side of the hollow screen aluminum frame 1 or the solid metal screen frame 1A is sleeved with a left, Move right, up and down to adjust the horizontal tension of the screen plate and the L-shaped stretching adjustment bar 3 of the vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com