Vertical guide rail automatic cloth conveying device for transfer printing machine

A transfer printing, vertical technology, applied in the direction of rotary printing machine, printing machine, transfer printing, etc., can solve the problems of pattern deformation, uneven coloring, etc. compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The following is an embodiment according to the present invention and described in conjunction with the accompanying drawings, which is a vertical guide rail automatic cloth conveying device used on a cold transfer printing machine. However, the present invention is not limited to the described embodiments, and various modifications can be made by those skilled in the art within the scope of the inventive concept and the protection defined by the claims.

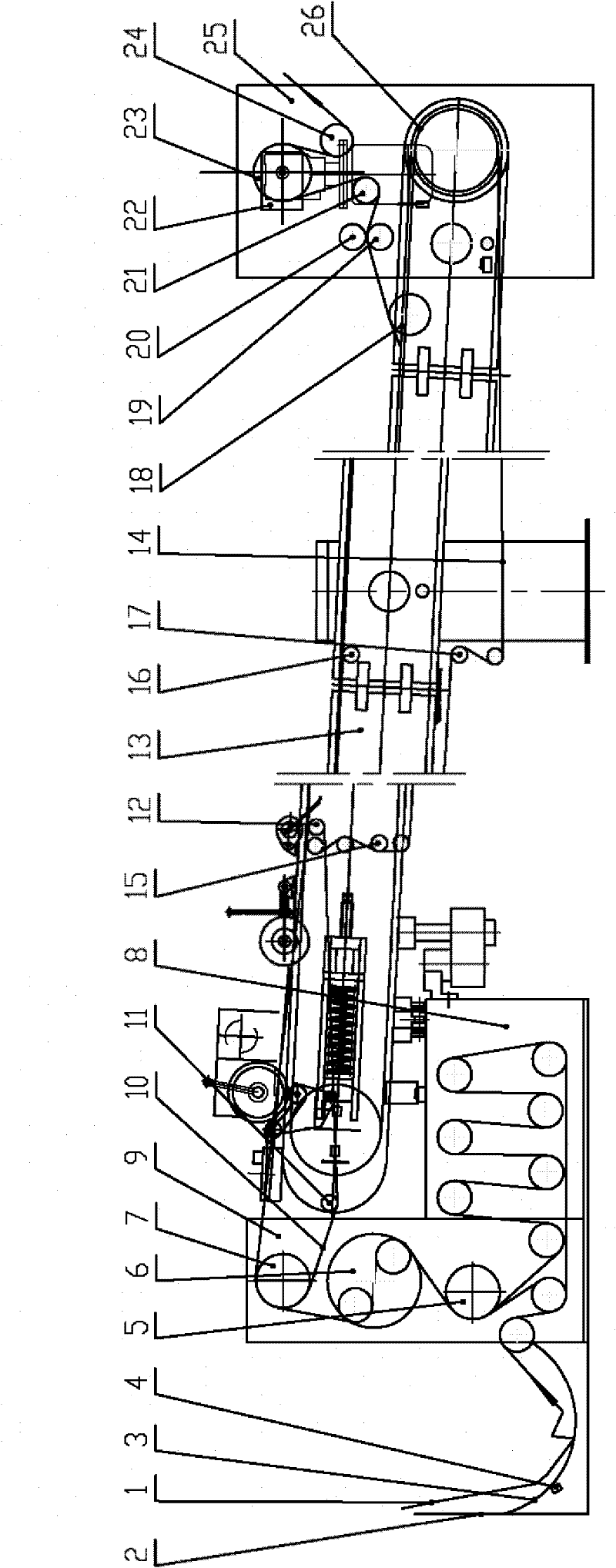

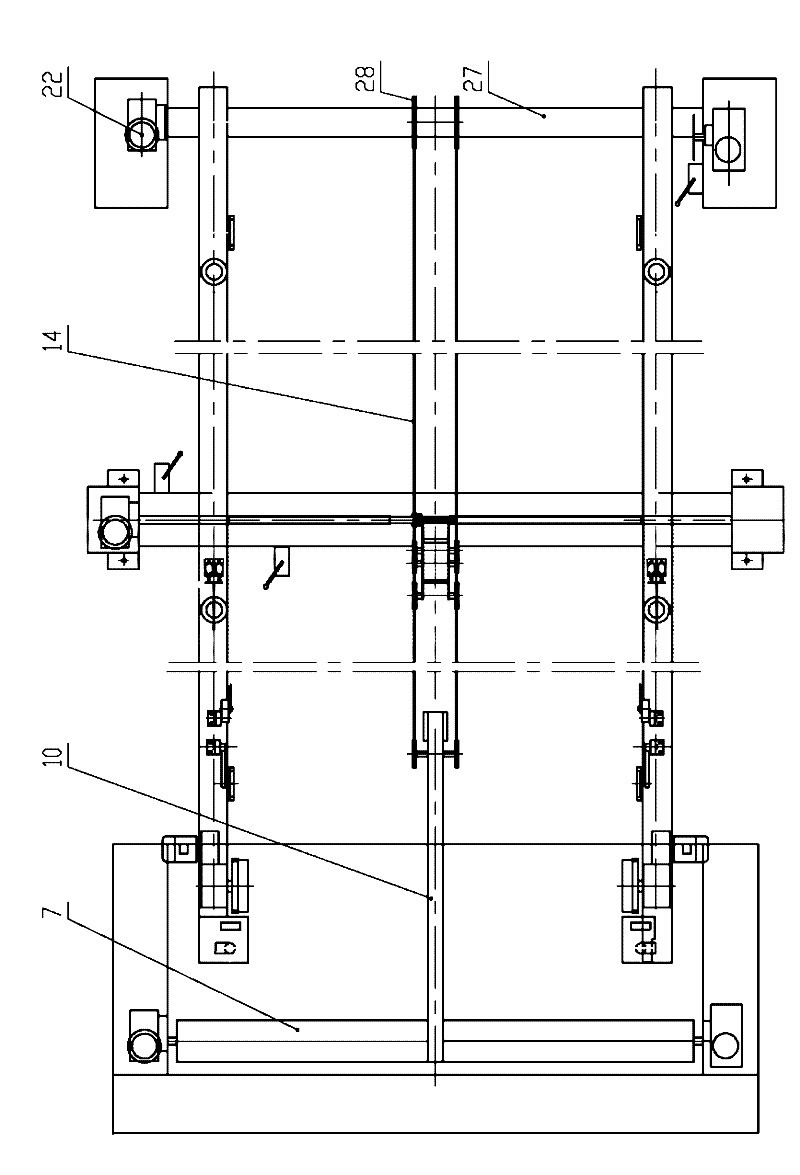

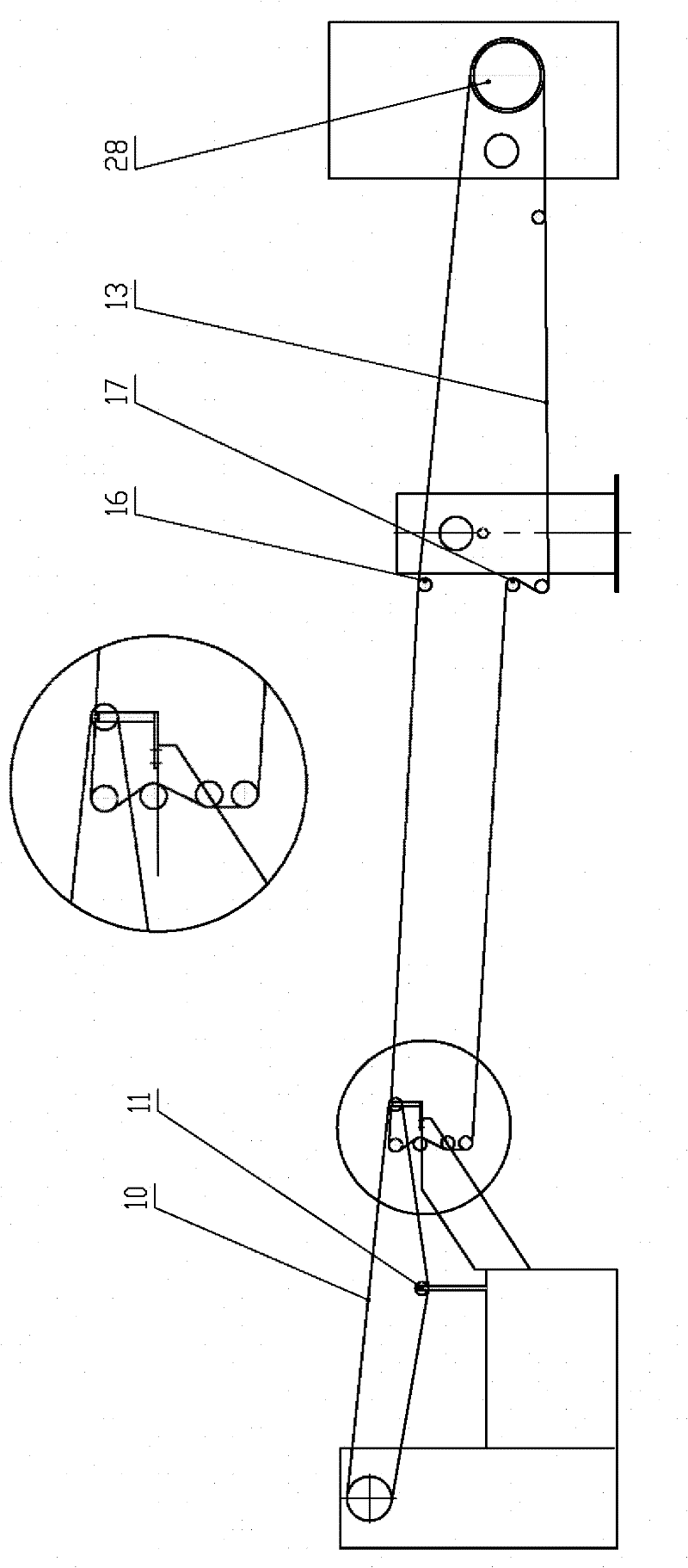

[0050] Such as figure 1 , figure 2 with image 3 As shown, the vertical guide rail automatic cloth feeding device of the transfer printing machine includes a cloth storage device 2, a head box 9, a cloth feeding device 13 and a tail box 25 connected in sequence, and is fixedly connected to the left and right sides before the transfer printing device of the transfer printing machine. on the rack and connected to the automatic control system. The head box 9 is composed of a weft adjusting device 8 and an overfeeding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com