Battery winder

A battery roll and winding device technology, applied in the field of battery winding machines, can solve the problems of not meeting high efficiency, high quality production, affecting the quality of battery cores, and prone to deflection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

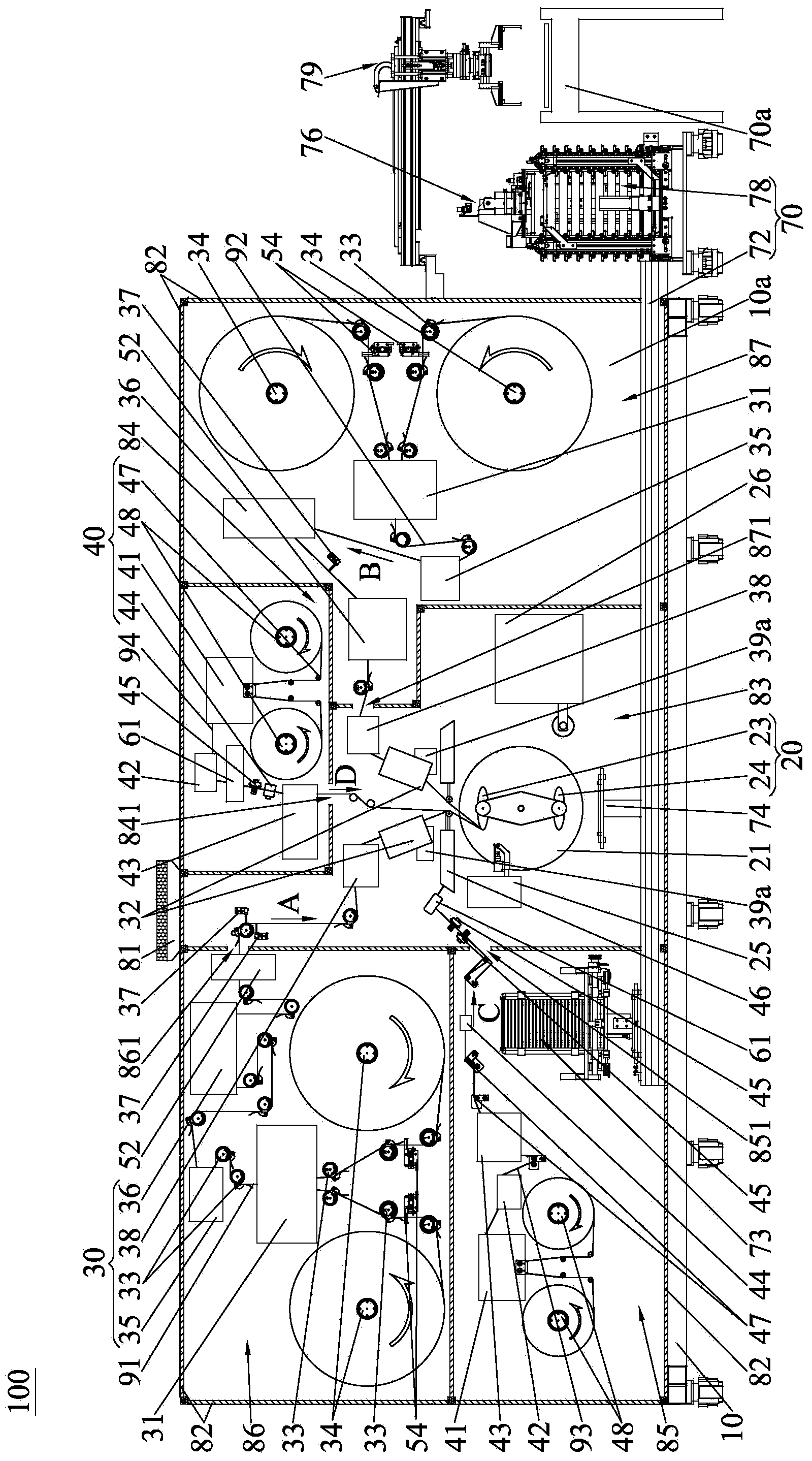

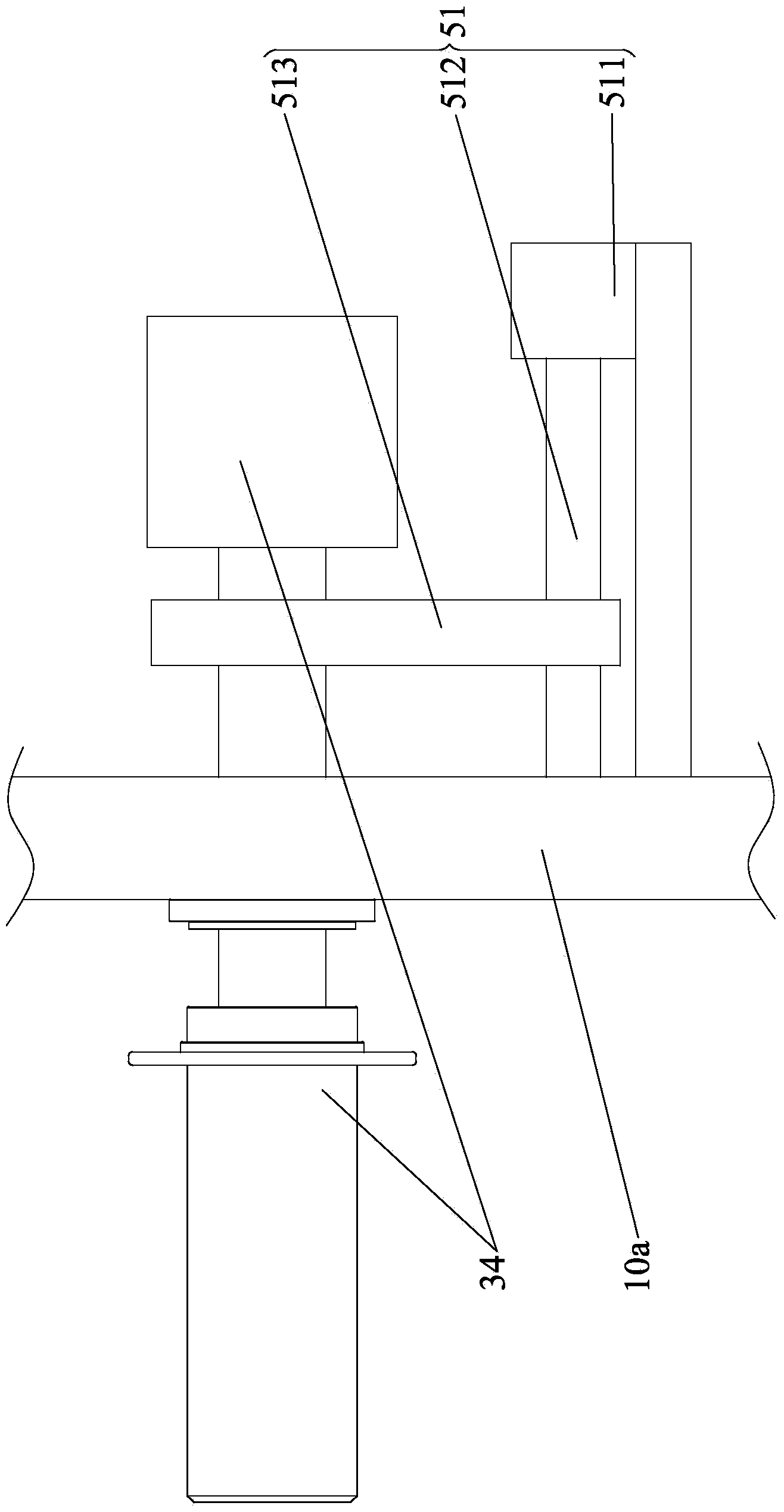

[0027] see figure 1 , the battery winding machine 100 of the present invention is suitable for winding the strip-shaped anode pole piece 91, cathode pole piece 92, left diaphragm 93 and right diaphragm 94 to form a battery core (not shown in the figure), wherein, the present invention The battery winding machine 100 includes: a frame 10, a mounting substrate 10a, a winding device 20, a two-pole sheet conveying device 30 and two diaphragm conveying devices 40, the mounting substrate 10a is vertically arranged on the frame 10, the winding device 20, The two-pole sheet conveying device 30 and the two diaphragm conveying devices 40 are all arranged on the mounting substrate 10a. The mounting substrate 10a is preferably a whole plate with a non-splicing structure. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com