Battery production equipment

A technology for producing equipment and batteries, applied in the field of battery production equipment, can solve problems such as the increase of defective battery cells and the reduction of production efficiency of battery cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

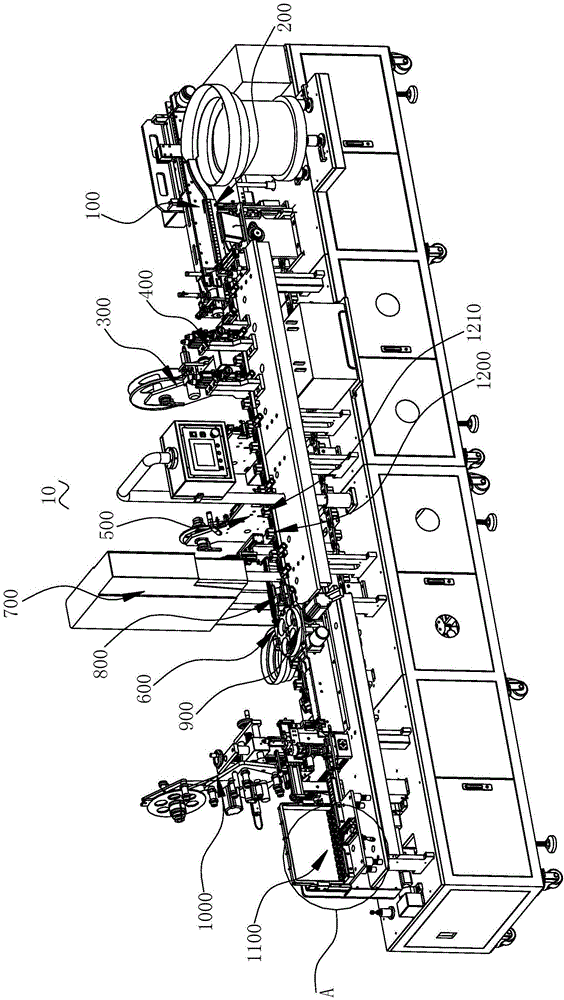

[0040] Such as figure 1 As shown, it is a structural diagram of a battery production device 10 according to an embodiment of the present invention.

[0041] The battery production equipment 10 first assembles the battery cells 20 on the tray 22 into the plastic shell 30 in pairs, then welds the resistors 42 on the resistance strip 40 to the battery cells 20, and then pastes buffer glue on the battery cells 20 50, then cover the cover plate 60 on the plastic shell 30 and carry out welding and packaging, after that, the good and bad products are screened through the inspection program, and then the trademark (not shown) is pasted on the surface of the plastic shell 30, and finally the finished product is packed.

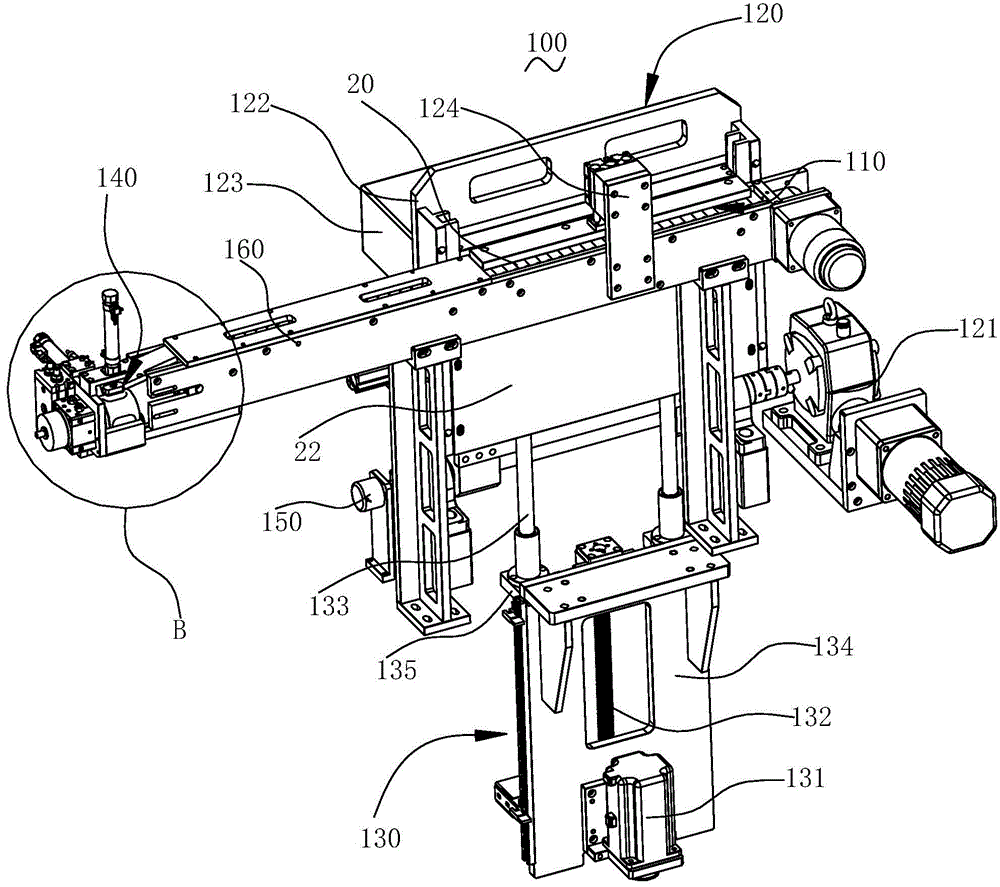

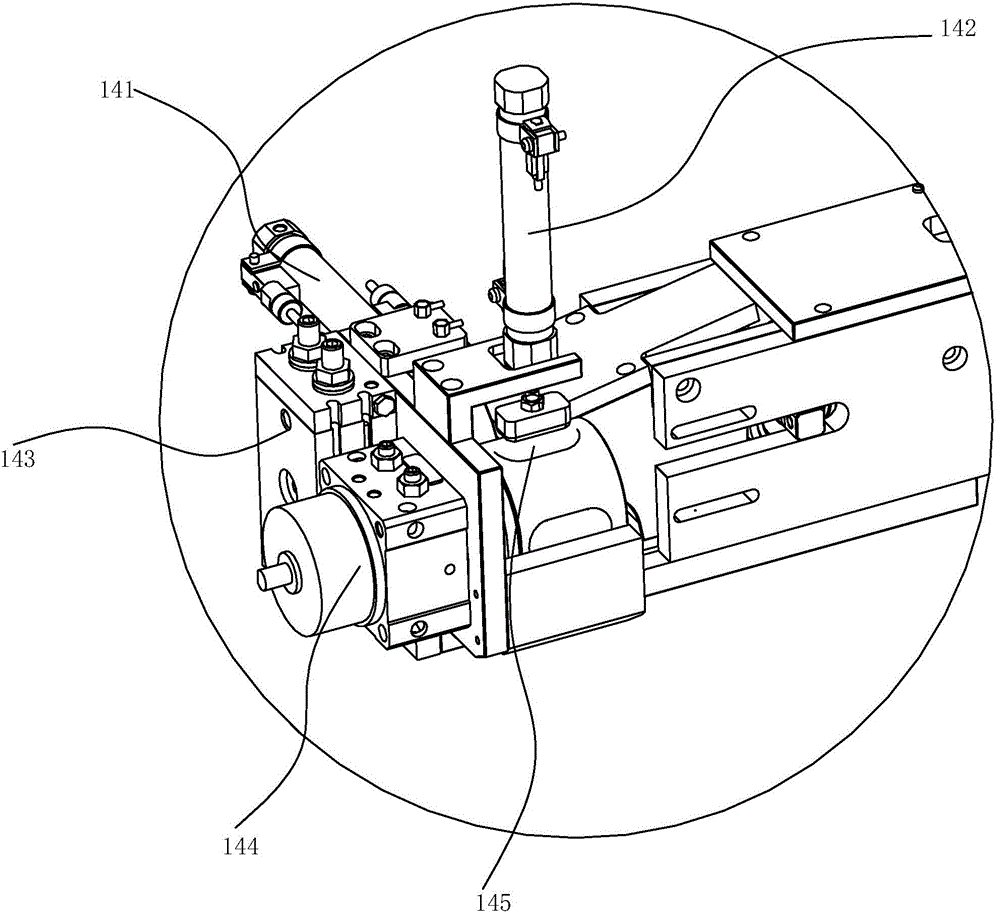

[0042] The battery production equipment 10 includes: a cel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com