Turnover fixture, power battery assembling method and equipment

A technology of power battery and assembly method, which is applied in battery pack parts, lead-acid battery construction, secondary battery and other directions, can solve problems such as affecting the geometric accuracy of the battery cell, hidden dangers of the reliability of the battery cell manufacturing, and reducing the performance of the battery cell, etc. Achieve the effect of avoiding direct contact with the cell, avoiding repeated transfers, and improving positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

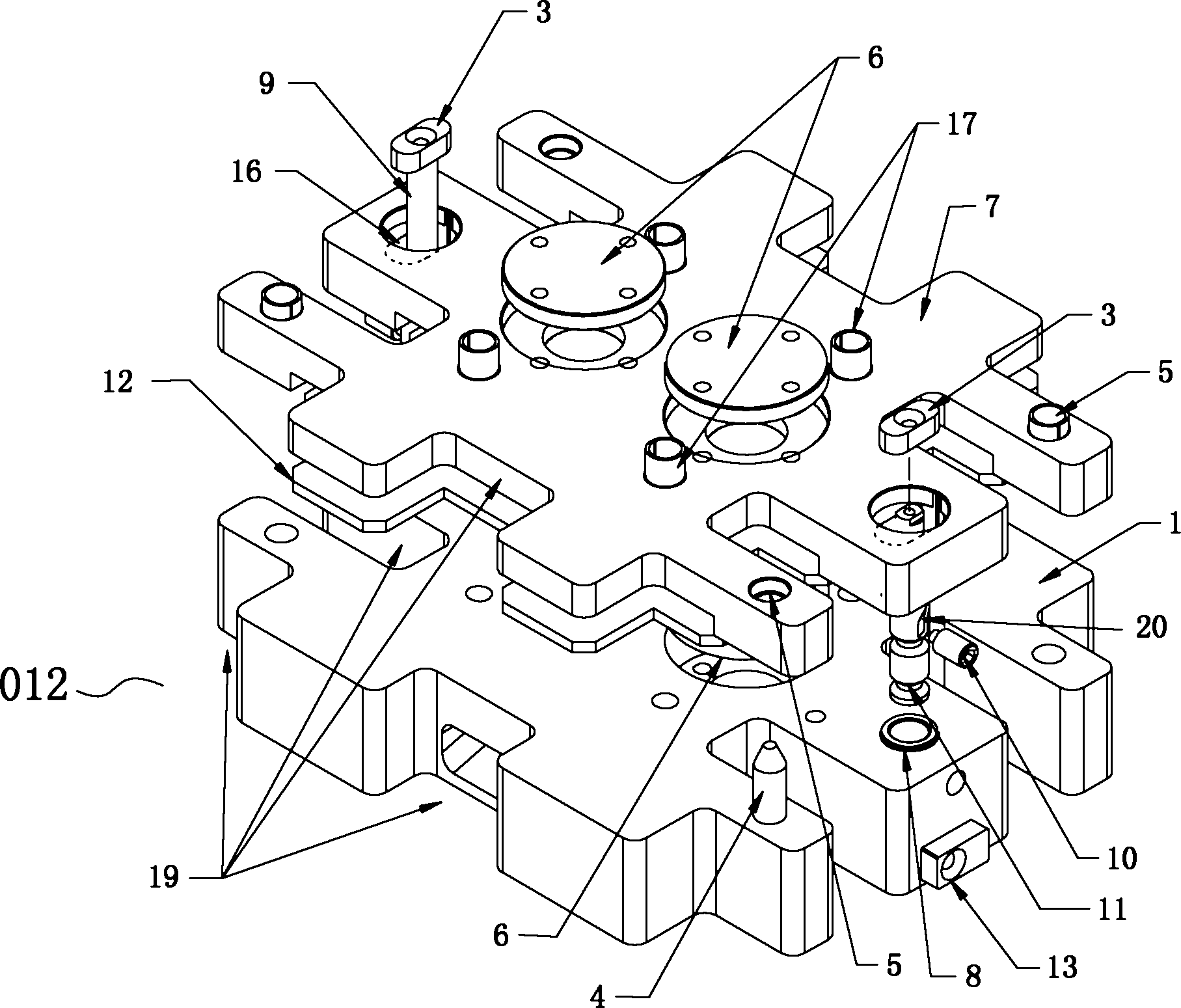

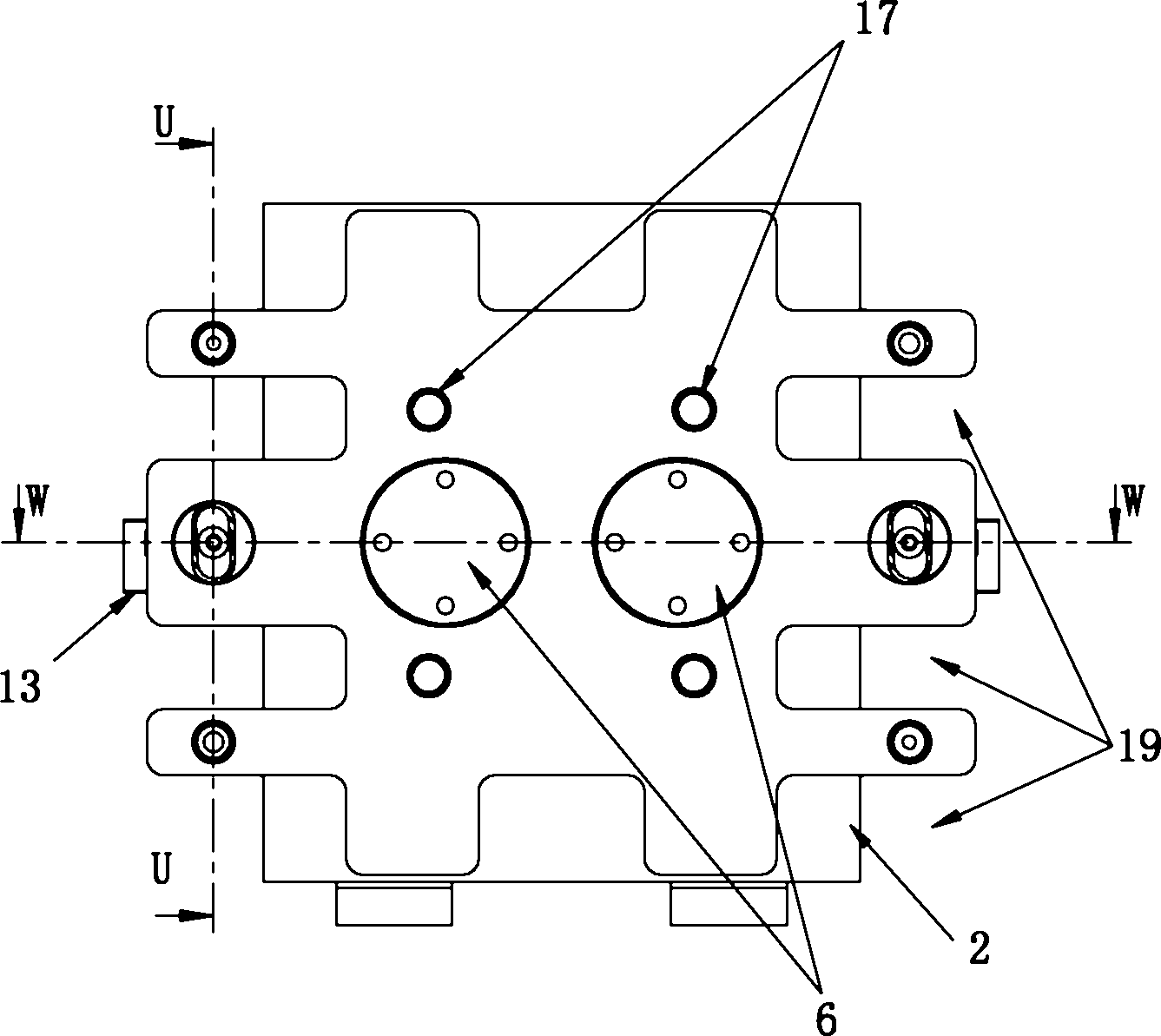

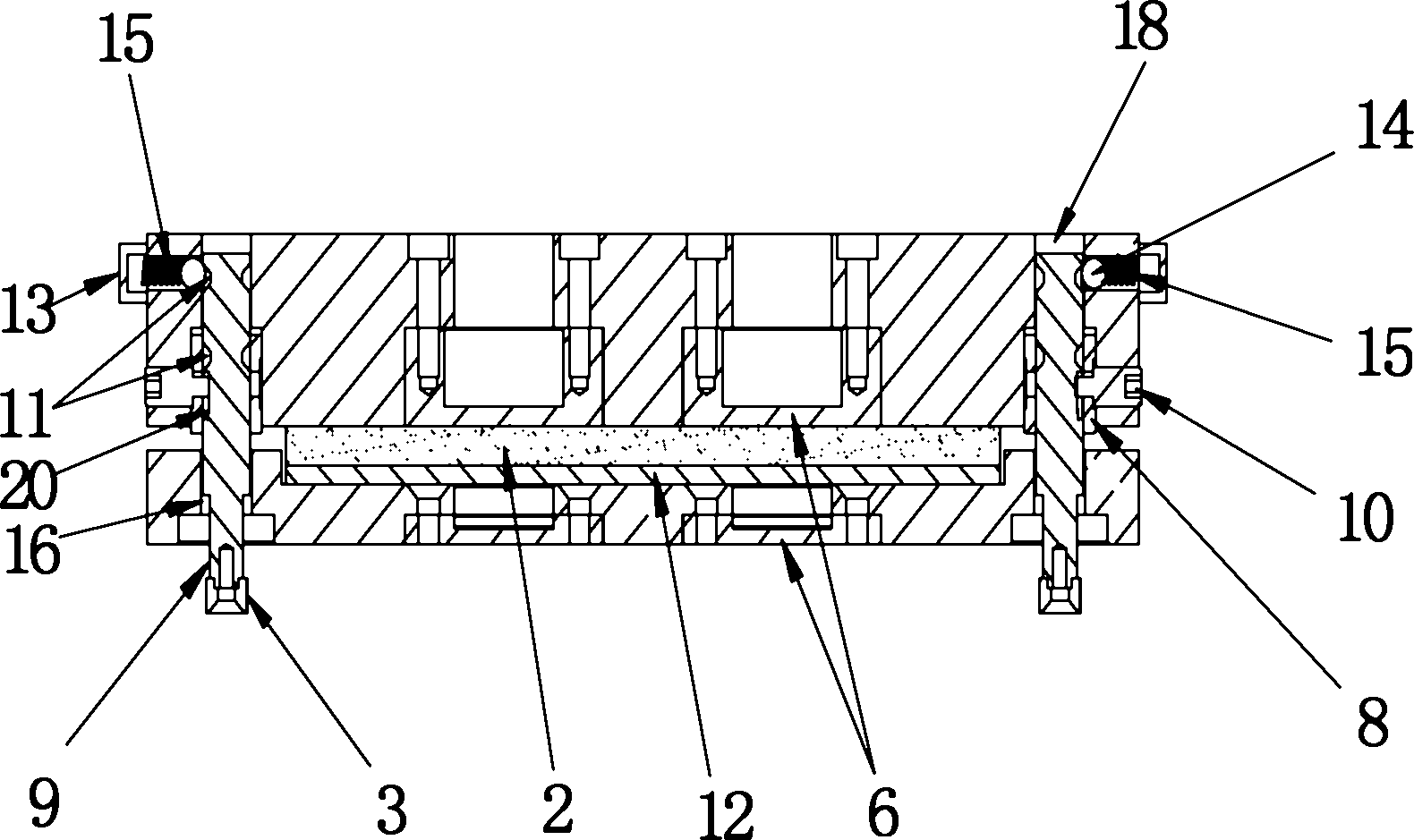

[0040] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

[0041] Please refer to Figure 1 to Figure 5 , a turnover fixture, which cooperates with the electric core 2, includes a clamp bottom plate 1 and an upper cover 7 matched by a connecting mechanism, and a buffer for positioning and protecting the electric core 2 is also provided between the clamp bottom plate 1 and the upper cover 7 mechanism. The buffer mechanism has a telescopic property, which prevents the battery cell 2 from being pinched by the rigid connection of the turnover fixture. At the same time, the elastic force generated during its expansion and contraction can press and position the battery cell 2; the buffer mechanism can be set in the turnover clamp. The backing plate of flexible material, or the mechanism that hard plate cooperates with spring, can also be the spring that makes the two connection gaps variable i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com