Automatic battery end cover assembling machine

An automatic assembly machine and end cap technology, which is applied in the direction of assembling battery machines, battery pack components, small-sized batteries/batteries, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

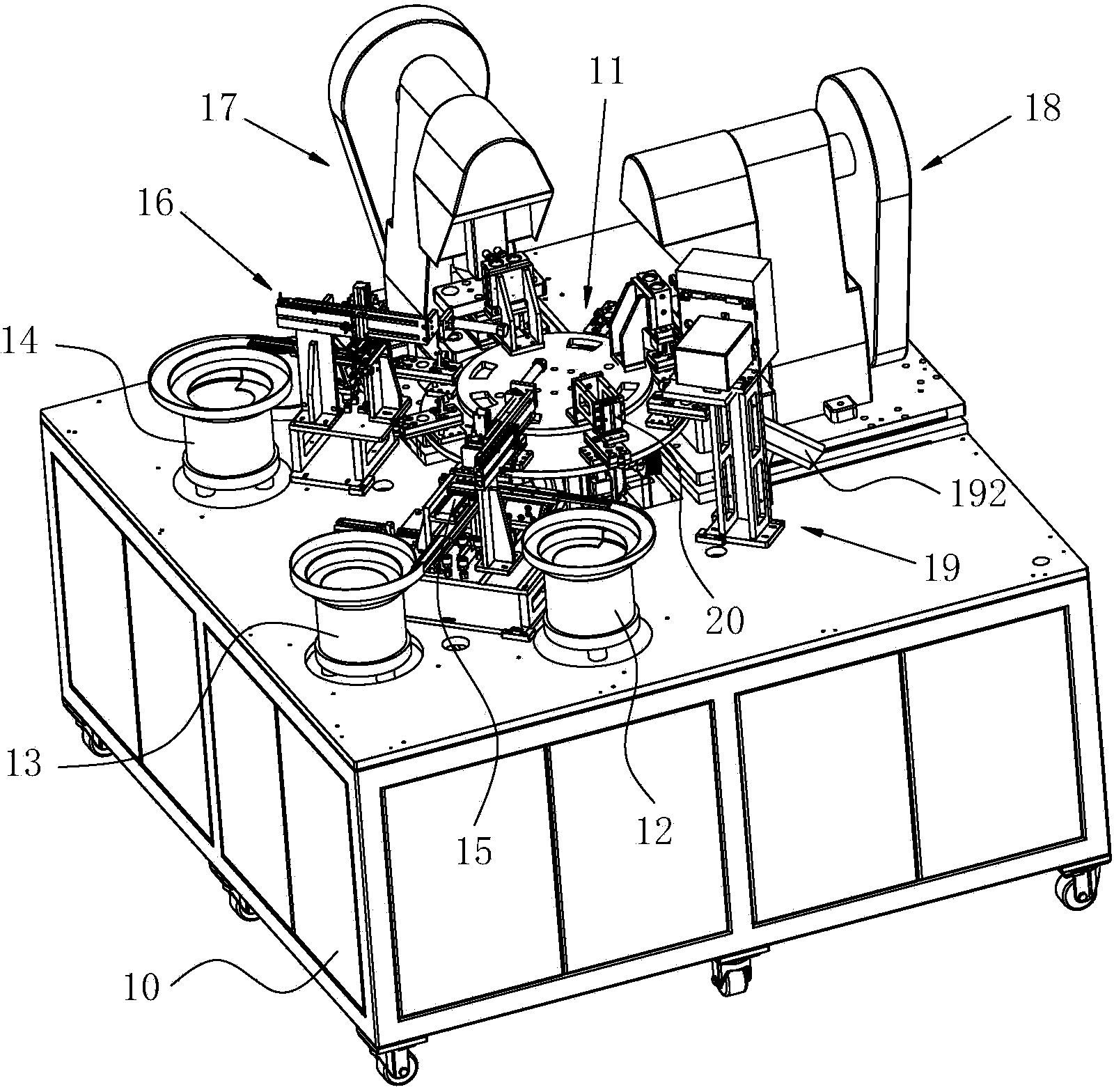

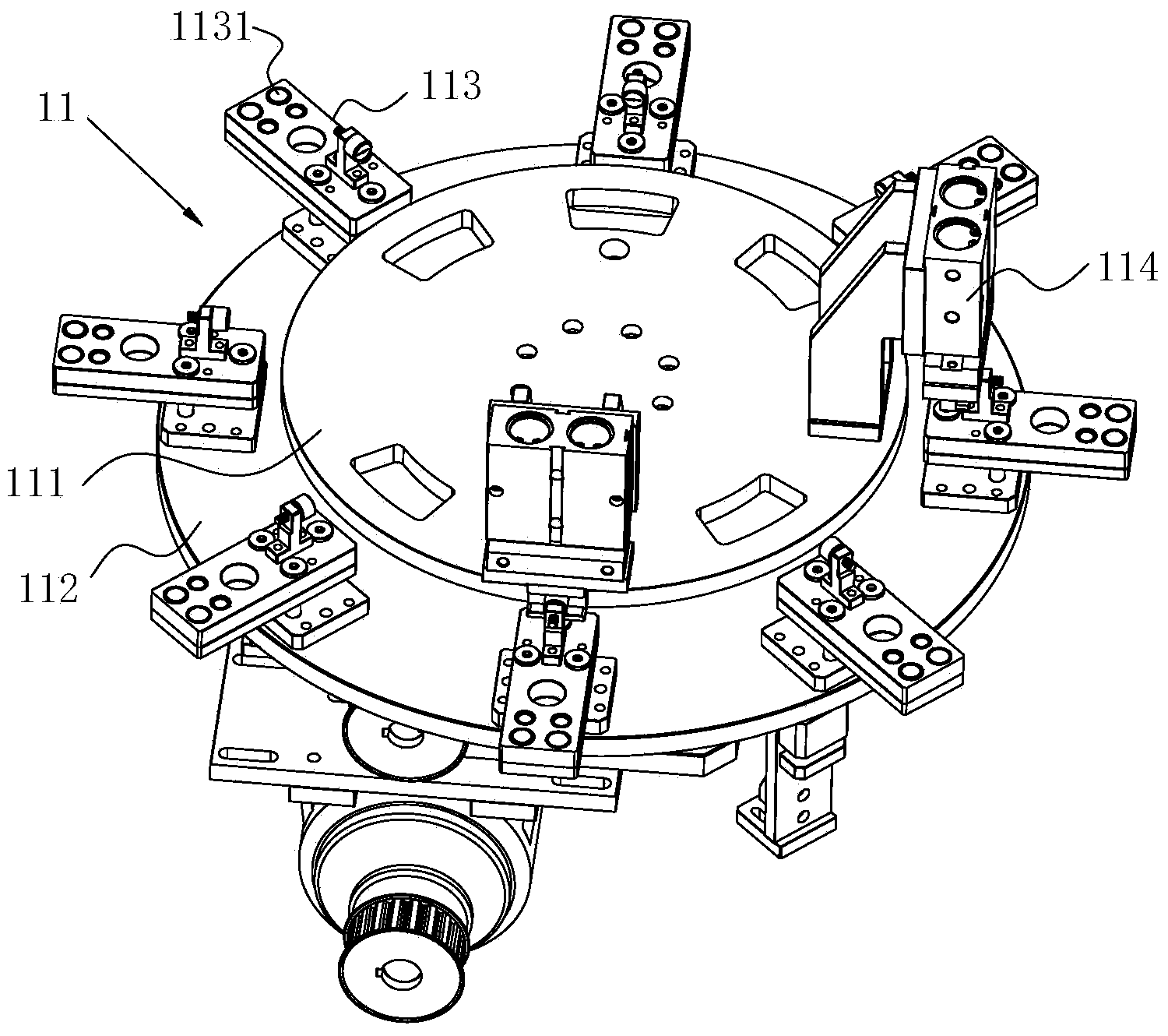

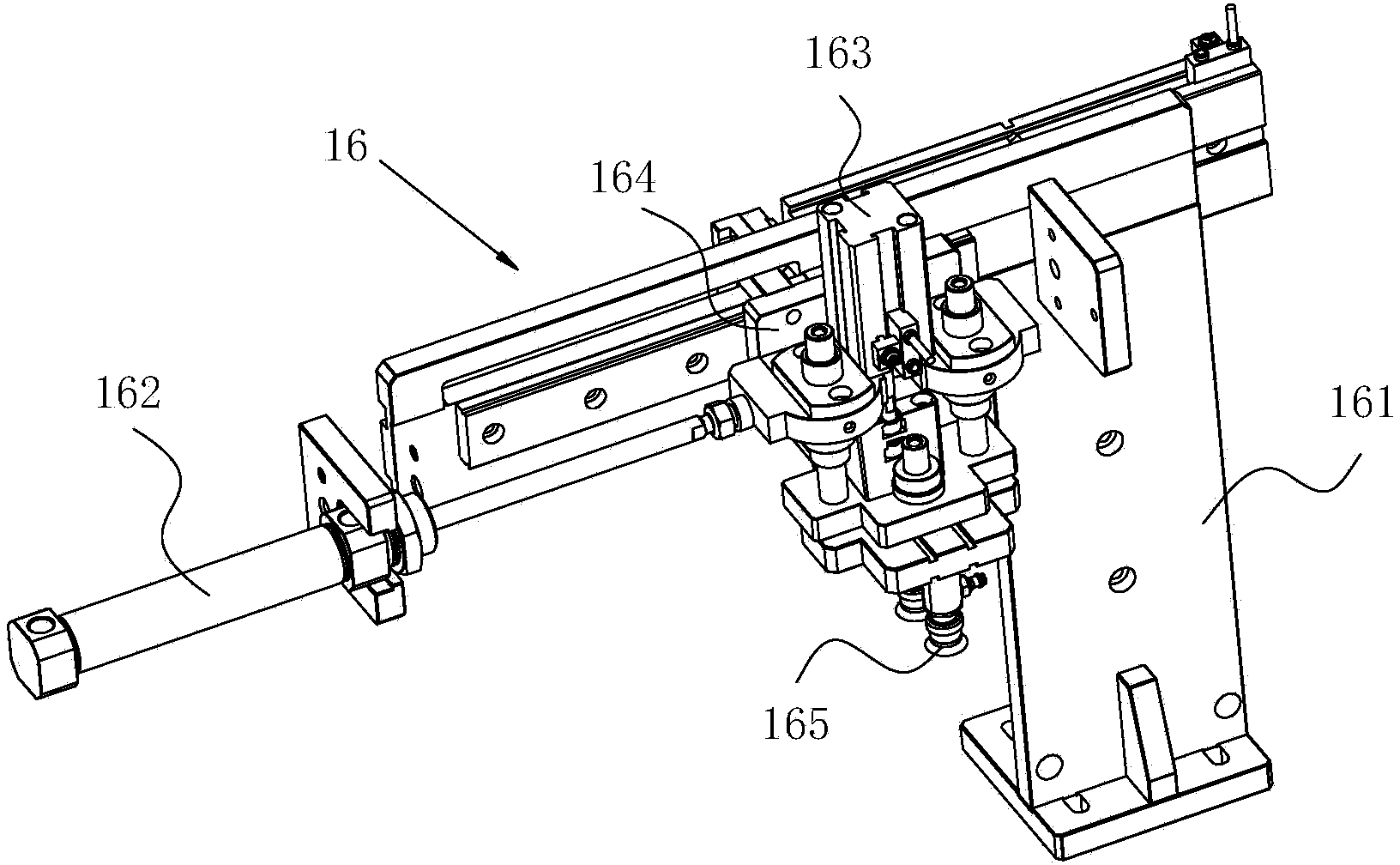

[0052] Such as Figure 1-7 As shown, in this embodiment, an automatic battery end cover assembly machine includes a frame 10 and a central turntable 11 that is arranged in the middle of the frame 10 and can rotate intermittently. The angle that the center turntable 11 rotates each time is 45 degrees, the circumference of the central turntable 11 is provided with eight evenly distributed positioning molds 113, each positioning mold 113 is provided with two sets of placement grooves 1131 on the side away from the rotation axis of the central turntable 11, and the placement grooves 1131 are round holes The hole diameter of one set of placement grooves 1131 on the side of the positioning mold 113 away from the rotation axis of the central turntable 11 is larger than the aperture diameter of the other se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com