Room-temperature self-repairing type thermoplastic polymer material and preparation method thereof

A thermoplastic polymer and self-repairing technology, which is applied in the field of room temperature self-repairing thermoplastic polymer materials and its preparation, can solve the problems of weak interfacial adhesion, lack of chemical interaction, low strength, etc., and achieve increased bonding capacity and high Repair efficiency and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

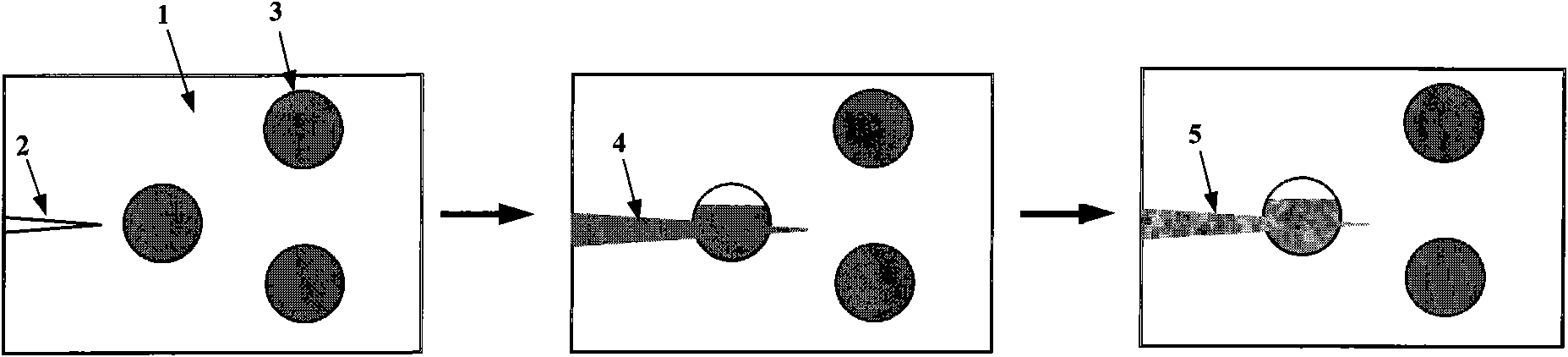

Image

Examples

Embodiment 1

[0028] Preparation of microcapsules containing liquid vinyl monomer: 6.0g melamine, 10.0g 37% (weight ratio) formaldehyde solution and 20ml distilled water were added to a three-necked reaction flask, and reacted at 70-75°C and pH 8-9 for about After 30 minutes, a transparent melamine-formaldehyde prepolymer solution was obtained. After the product is naturally cooled, add 180g of 0.3% (by weight) styrene-maleic anhydride copolymer sodium salt solution, 1.0g of sodium dodecylbenzenesulfonate and 0.5g of polyvinyl alcohol, and add 30g of core material A after mixing. Glycidyl acrylate, emulsified at 25°C and 300rpm for 20-30 minutes, then slowly adjusted the pH value of the reaction system to about 4.0-4.5 with 10% (weight ratio) citric acid solution, at a heating rate of 0.5°C / min The temperature of the reaction system was raised to 50-60° C., and the reaction temperature was maintained for 1.5-2.5 hours. The reaction solution was cooled to room temperature, filtered, and the...

Embodiment 2

[0030] Add 24.0g of methyl methacrylate and 1.031g of tetrabutylammonium bromide into a three-necked flask with argon gas to fully dissolve them, then add 0.057g of cuprous bromide, 0.069g of N , N, N', N', N"-pentamethyldiethyltriamine and 0.078g ethyl 2-bromoisobutyrate, and stirred evenly, reacted at 25°C for 5 hours, weighed 1.3g The microcapsules loaded with glycidyl methacrylate prepared in Example 1 were uniformly dispersed in the above-mentioned polymethyl methacrylate prepolymer at room temperature, mixed and degassed, and then poured into a silica gel mold for curing at room temperature for 48 hours. All operations were carried out in an airtight isolation protective cover with argon gas.

[0031]Use the cantilever beam impact sample to conduct fracture test and evaluate the repair efficiency of the material: before the impact, the sample is placed in a constant temperature oven at 25°C for 2 hours, and then it is completely destroyed by the impact instrument, and th...

Embodiment 3

[0033] Add 24.0g of methyl methacrylate and 1.031g of tetrabutylammonium bromide into a three-necked flask with argon gas to fully dissolve them, then add 0.057g of cuprous bromide, 0.069g of N , N, N', N', N"-pentamethyldiethyltriamine and 0.078g ethyl 2-bromoisobutyrate, and stirred evenly, reacted at 25°C for 5 hours, weighed 2.7g The microcapsules loaded with glycidyl methacrylate prepared in Example 1 were uniformly dispersed in the above-mentioned polymethyl methacrylate prepolymer at room temperature, mixed and degassed, and then poured into a silica gel mold for curing at room temperature for 48 hours. All operations were carried out in an airtight isolation protective cover with argon gas.

[0034] The evaluation method is the same as in Example 2. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com